Grass feeding mechanism of combine harvester

A combine harvester and grass feeding technology, which is applied to harvesters, agricultural machinery and implements, cutters, etc., can solve problems such as looseness or wear at the joint between the header and the conveying trough, and grain leakage, so as to prevent secondary material leakage Problems, prevention of grain leakage, and the effect of preventing wear and tear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

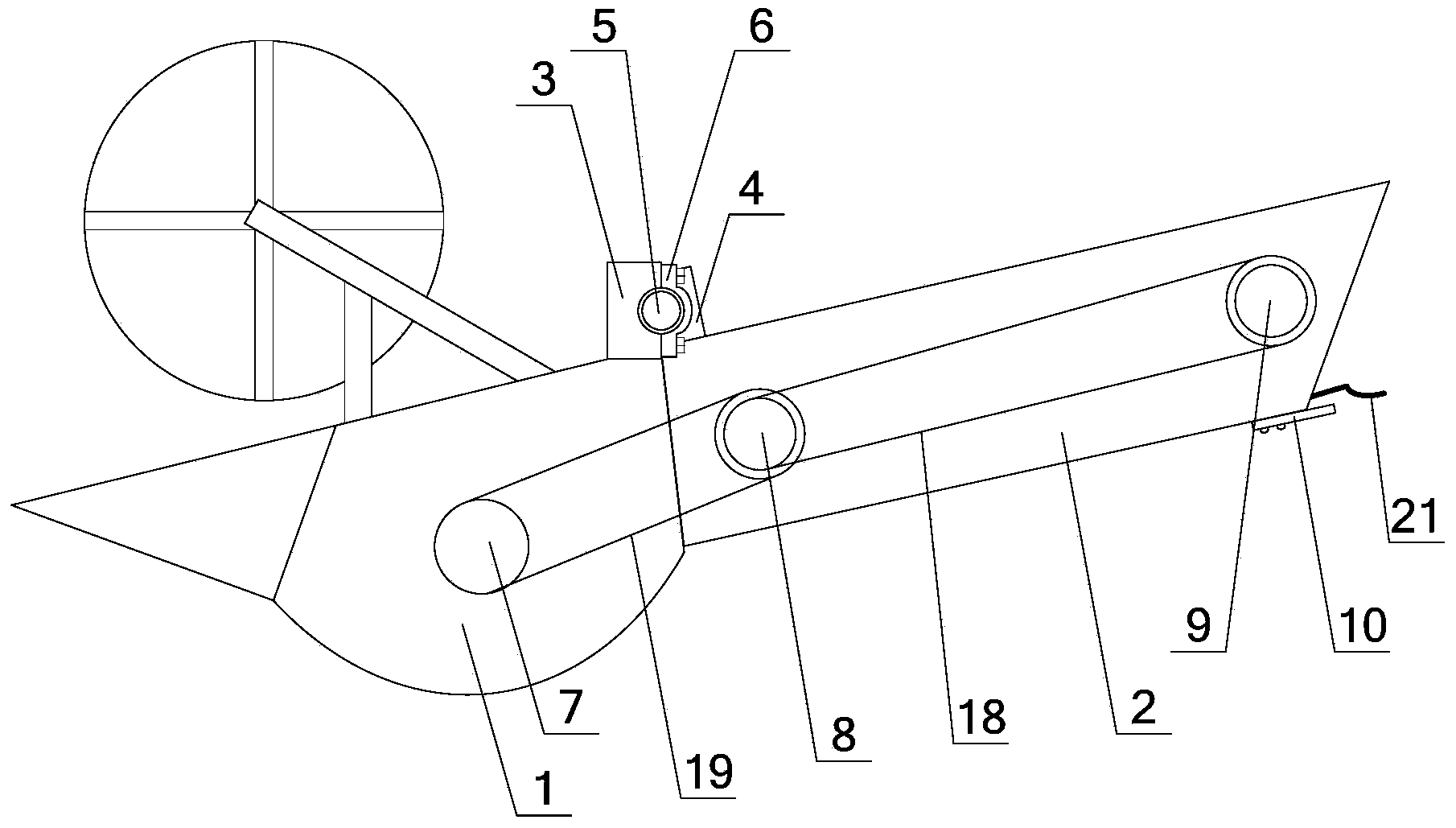

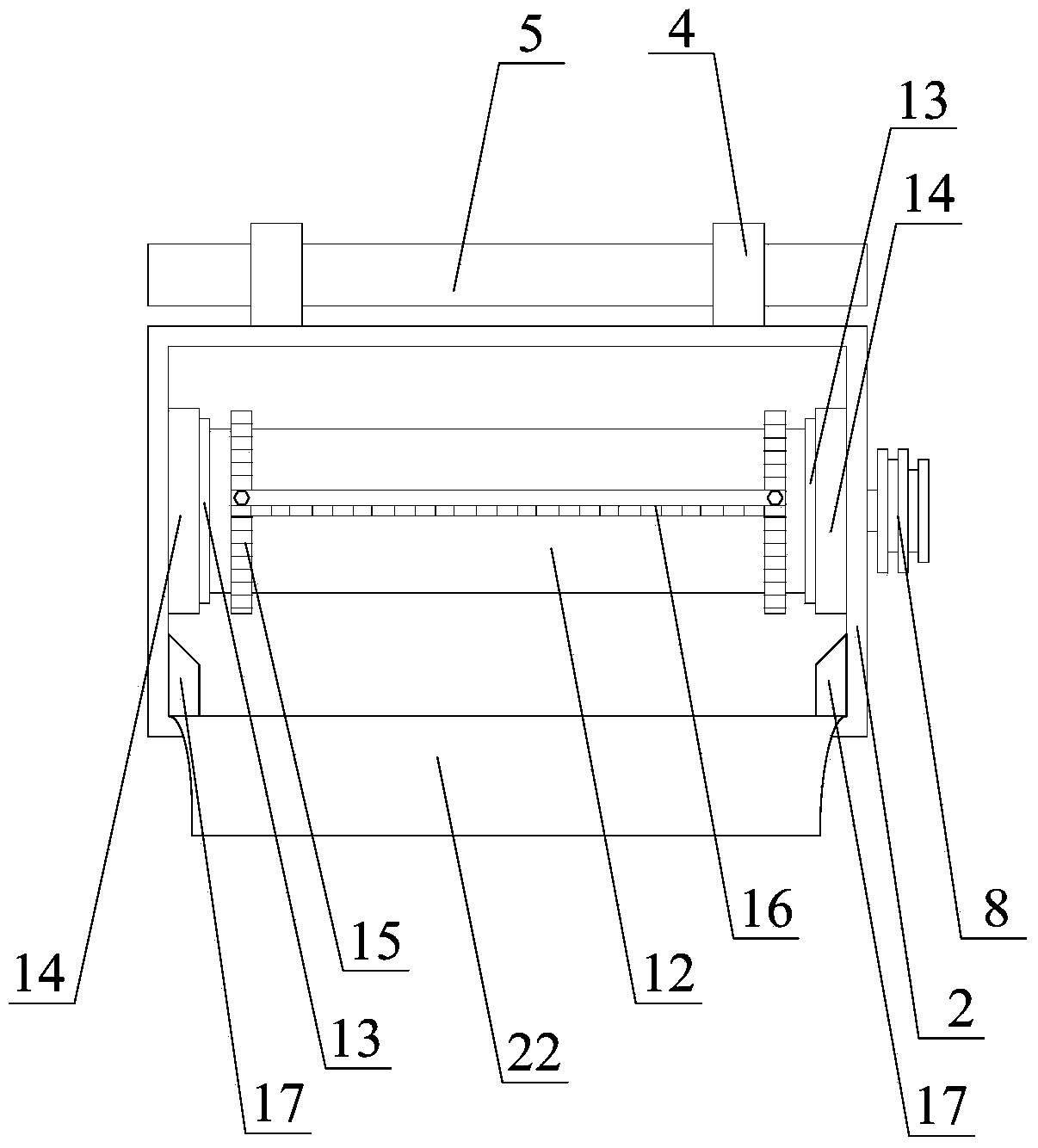

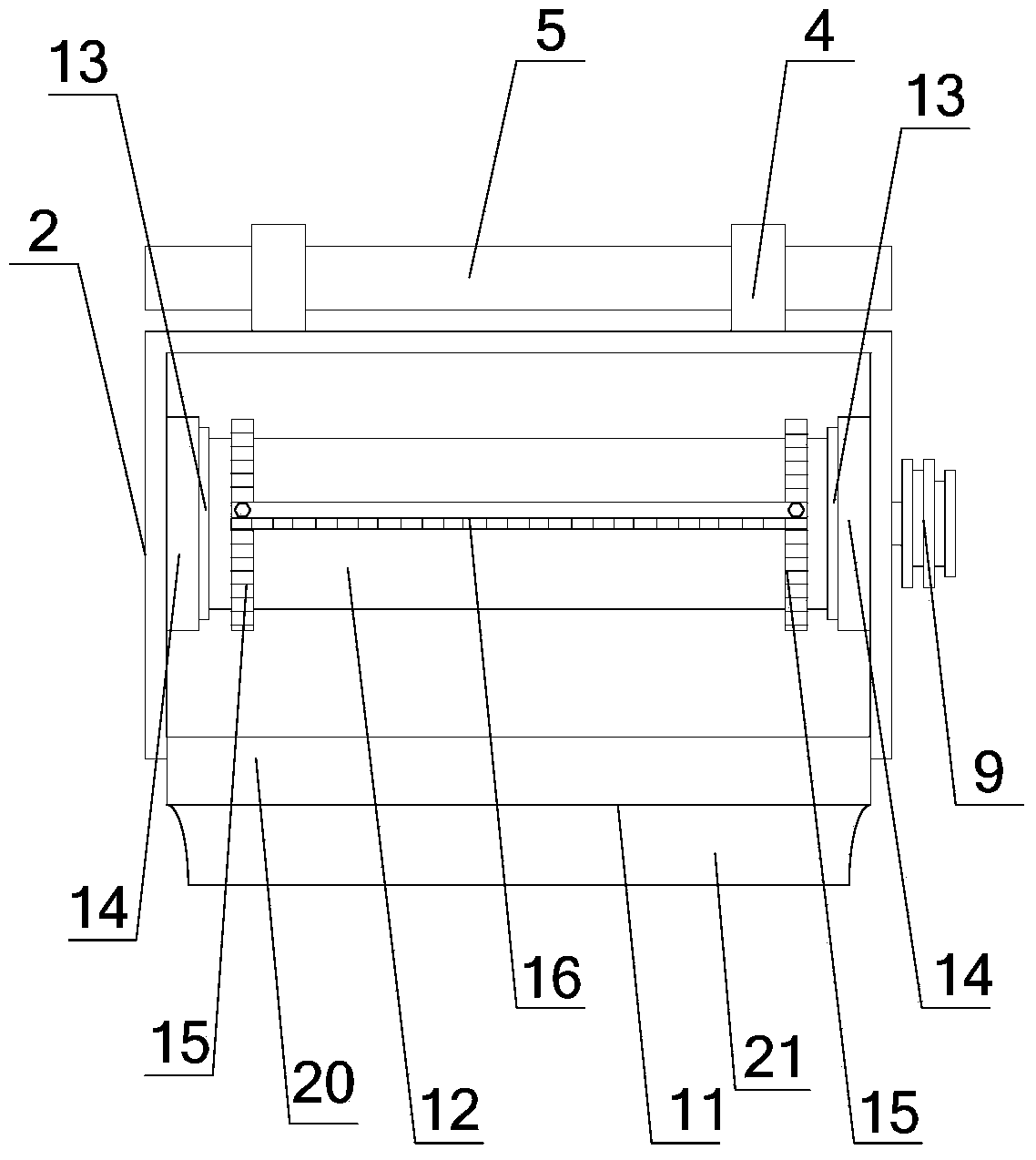

[0017] Such as Figure 1-3 As shown, the grass feeding mechanism of the combine harvester of the present invention comprises a header 1 and a conveying trough 2, a rotating shaft support 4 is provided above the grass inlet of the conveying trough 2, and a rotating shaft 5 is horizontally provided on the rotating shaft support 4 , the axial direction of the rotating shaft 5 is parallel to the upper edge of the grass inlet of the conveying trough 2; two fixing seats 3 are arranged above the grass outlet of the mowing platform 1, and the fixing seats 3 are provided with a semicircular notch, and the rotating shaft 5 The shaft heads at both ends are rotatably embedded in the semicircular notches of the two fixed seats 3, and locked by the arc lock 6; Arc-shaped plate 22; the outside of the lower edge of the grass outlet of the conveying trough 2 is provided with a rubber pad 10, and the inboard of the lower edge of the grass outlet of the conveying trough 2 is provided with a leak...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com