Waste alcohol sediment separation device for sausage casing residues

A separation device and alcohol precipitation tank technology, applied in the field of heparin precipitation and its waste alcohol separation device, can solve the problems of affecting yield, easy loss of heparin, high power of centrifugal equipment, etc., achieving simple and ingenious design, reducing production costs, and improving production efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

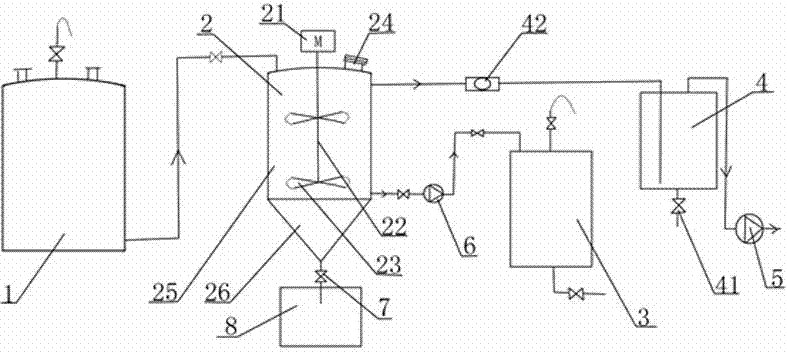

[0010] In order to further illustrate the present invention, introduce below in conjunction with accompanying drawing of description:

[0011] Refer to attached figure 1 , heparin precipitation and its waste alcohol separation device, which includes desorption tank 1, alcohol precipitation tank 2, waste alcohol storage tank 3, gas storage tank 4 and vacuum pump 5, the lower end of desorption tank 1 is connected to the upper end of alcohol precipitation tank 2 through pipelines , the upper end of the alcohol precipitation tank 2 is equipped with a vacuum tube, the other end of the vacuum tube is connected to the upper end of the gas storage tank 4, the upper end of the gas storage tank 4 is connected to the vacuum pump 5 through a pipeline, and the side of the alcohol precipitation tank 2 is close to the lower end of the waste alcohol recovery tube , the waste alcohol recovery pipe leads to the upper end of the waste alcohol storage tank 3, and the waste alcohol recover...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com