On-line Estimation Method of Oxygen-enriched Bottom-blowing Copper Smelting Process Parameters Based on Mixed Model

A technology of process parameters and mixed models, applied to furnace types, drum furnaces, crucible furnaces, etc., can solve problems such as bottom blowing furnaces cannot be determined quantitatively, key parameters cannot be measured in real time, product quality fluctuations, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0089] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

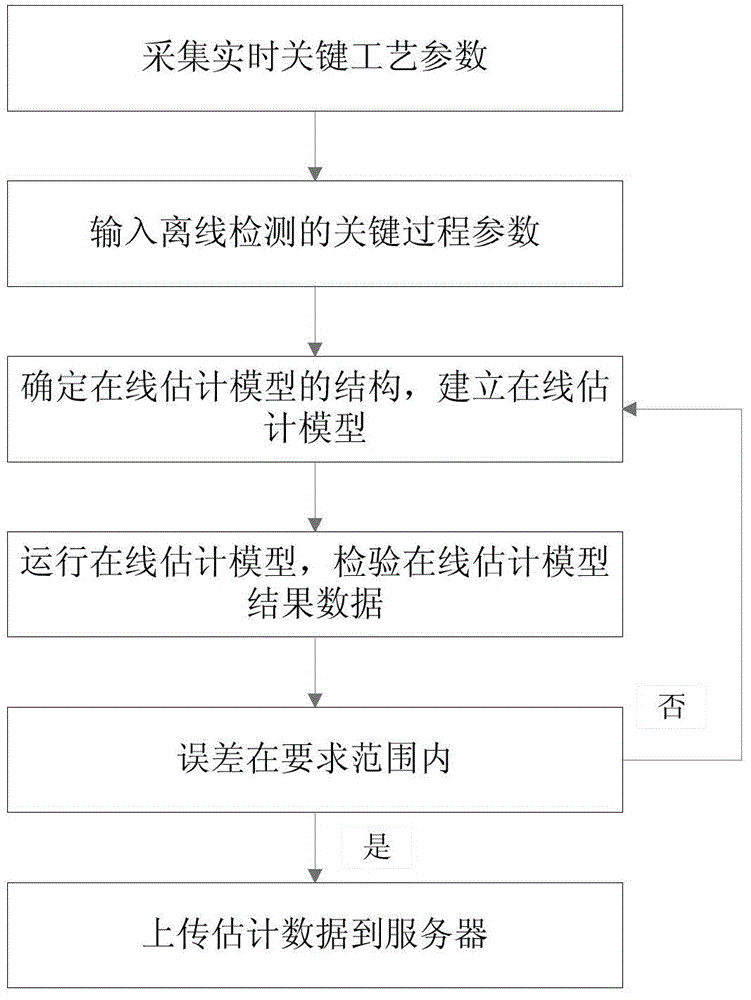

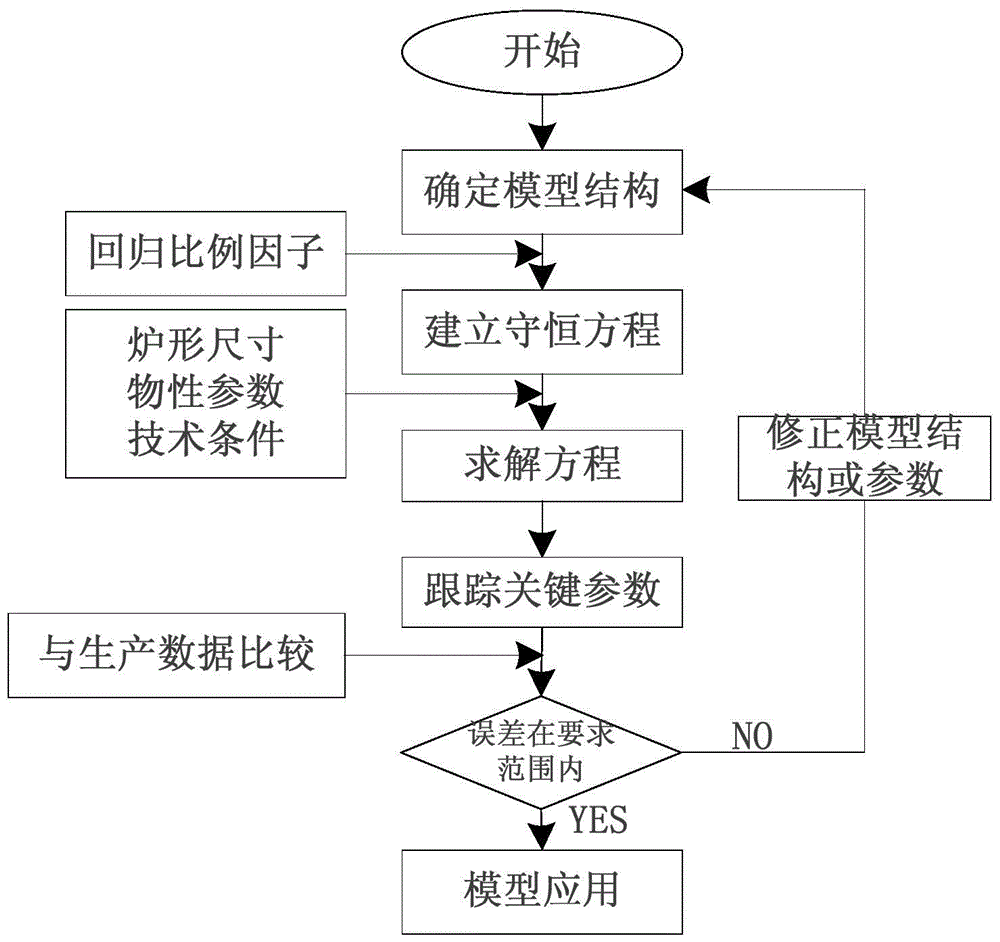

[0090] On-line estimation method for process parameters of oxygen-enriched bottom-blowing copper smelting based on mixed model, the flow chart of the method is as follows figure 1 As shown, it includes: basic automation part, data informatization part, model algorithm part and operation interface part.

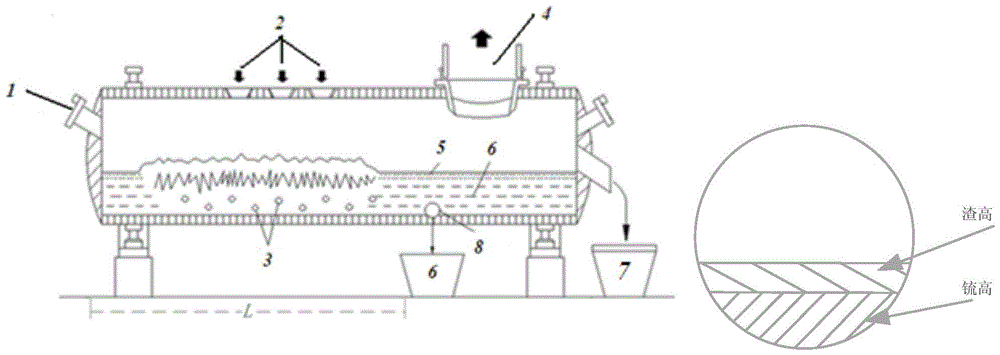

[0091] The basic automation part is to measure the actual physical quantities such as the copper concentrate feed rate and oxygen-enriched flow rate at the bottom blowing operation site by detecting sensors such as weighing sensors and flow sensors, and then upload the physical quantity signals to the control system (PLC or DCS) through the data transmission network ), execute regulators such as weighing belts, electric regulating valves, etc. to receive control instructions from the control system to change the feed amount of copper concentra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com