A unit curtain wall system with a cantilever structure

A unit curtain wall and cantilever technology, applied in the direction of walls, building components, building structures, etc., can solve the problems of weakening the scale benefit of the unit curtain wall, reducing the construction efficiency, interrupting the continuity of the unit curtain wall, and improving the drainage system. , The effect of improving the performance of the curtain wall and the firm cantilever structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

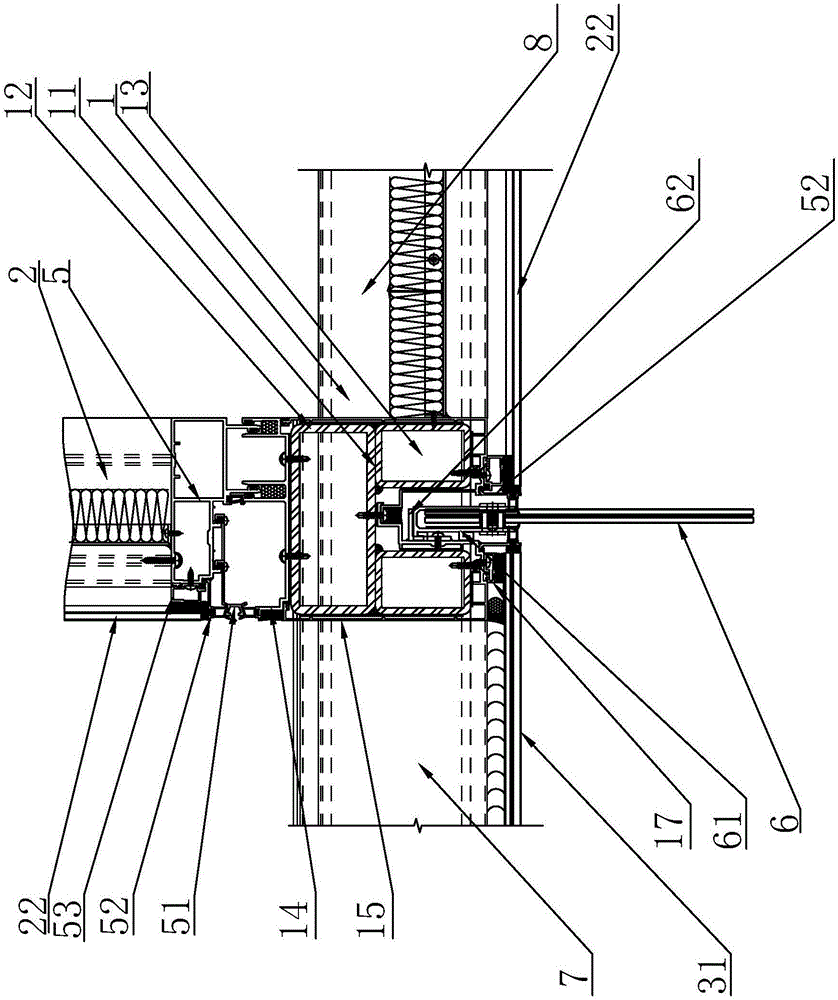

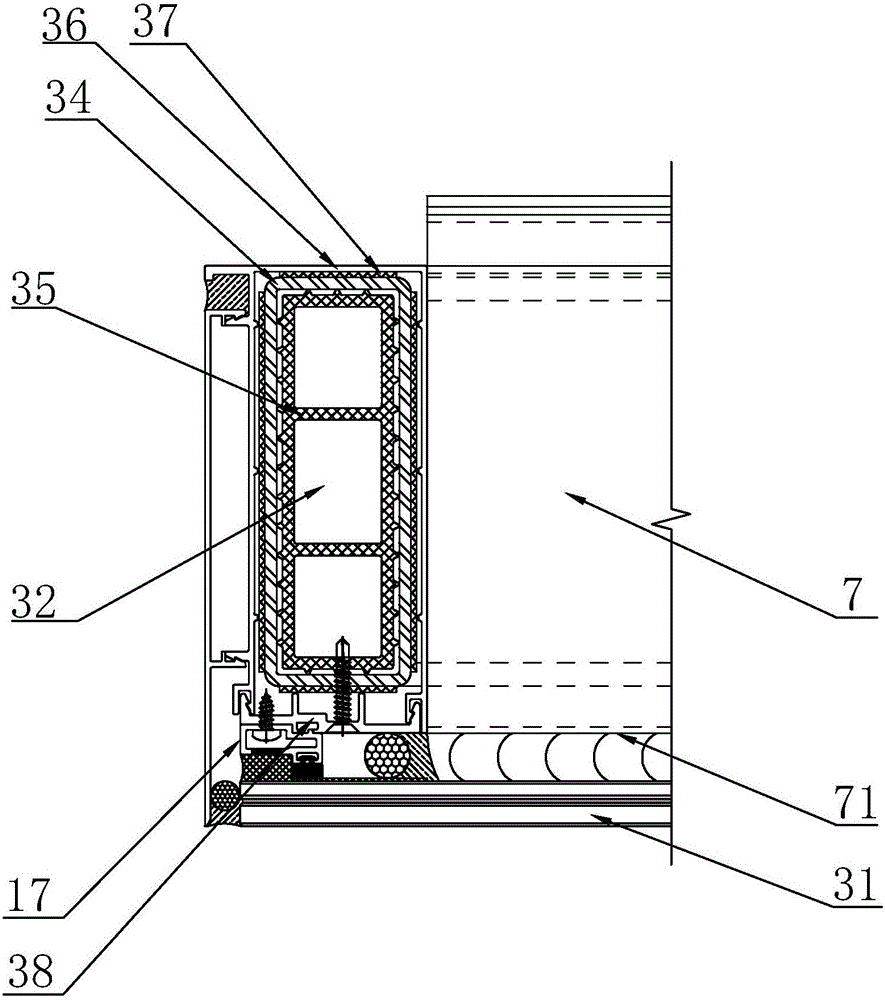

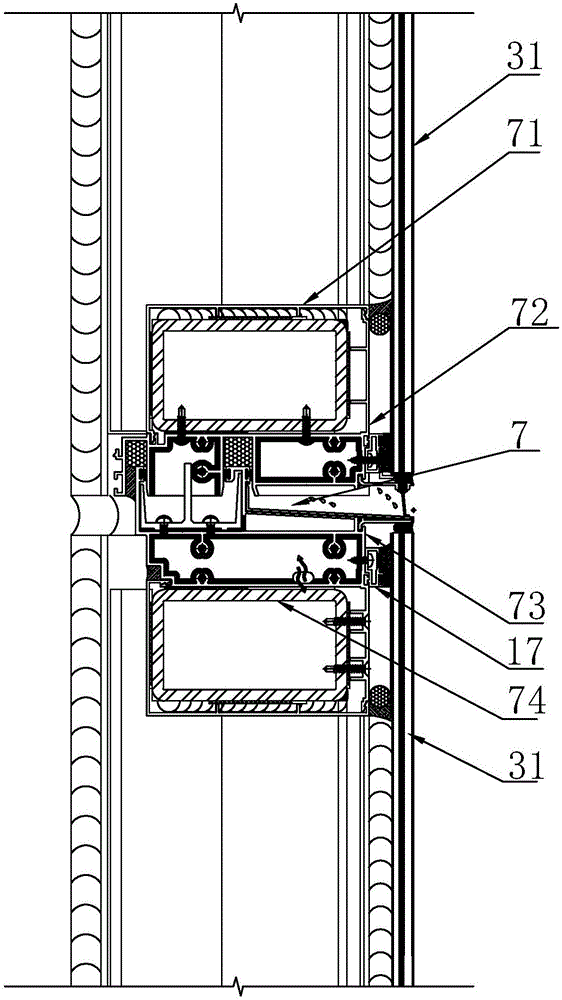

[0021] refer to Figure 1 to Figure 5 , the present invention is a unit curtain wall system with a cantilevered structure, comprising a cantilevered unit panel 1 constituting the curtain wall and a corner unit panel 2 perpendicular to the cantilevered unit panel 1, the cantilevered unit panel 1 includes a cantilevered panel part 3 and the main plate part 4, the cantilevered unit plate 1 contains the main column 11 inside, and the main column 11 is composed of steel square tube members inside, and the cantilevered plate part 3 protruding from the curtain wall panel includes a The cantilevered structural beam 7 fixedly connected to the main column 11 is a steel square tube member inside the cantilevered structural beam 7. The main body plate part 4 includes a main body beam 8 perpendicular to the main column 11 and fixedly connected to the main column 11. The main beam 8 The interior is a steel square tube member.

[0022] This unit curtain wall system with cantilever structure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com