Camera module

A technology for camera modules and packaging substrates, which is applied to TVs, color TV parts, electrical components, etc., and can solve the problem of tilting the optical axis of the lens, shortening the distance between the lens and the image sensor, and affecting the image quality of the camera module and other issues to achieve the effect of ensuring the image quality and avoiding changes in relative positions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

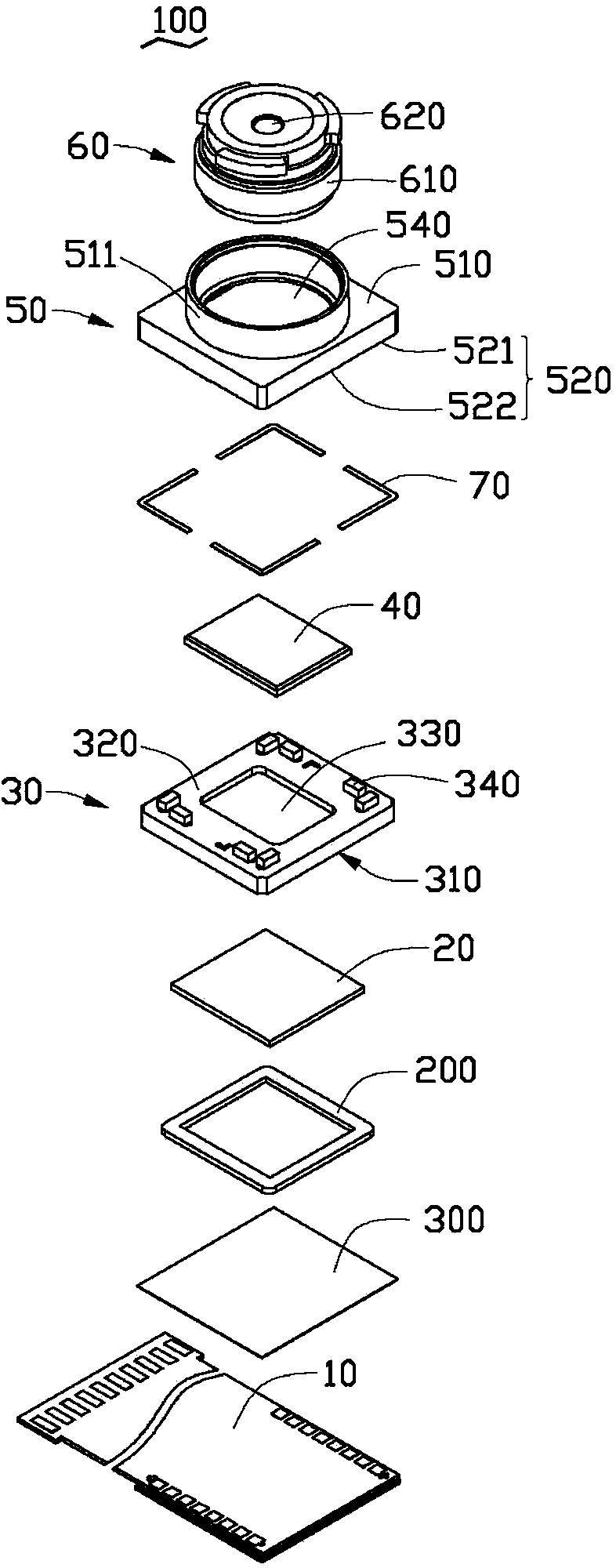

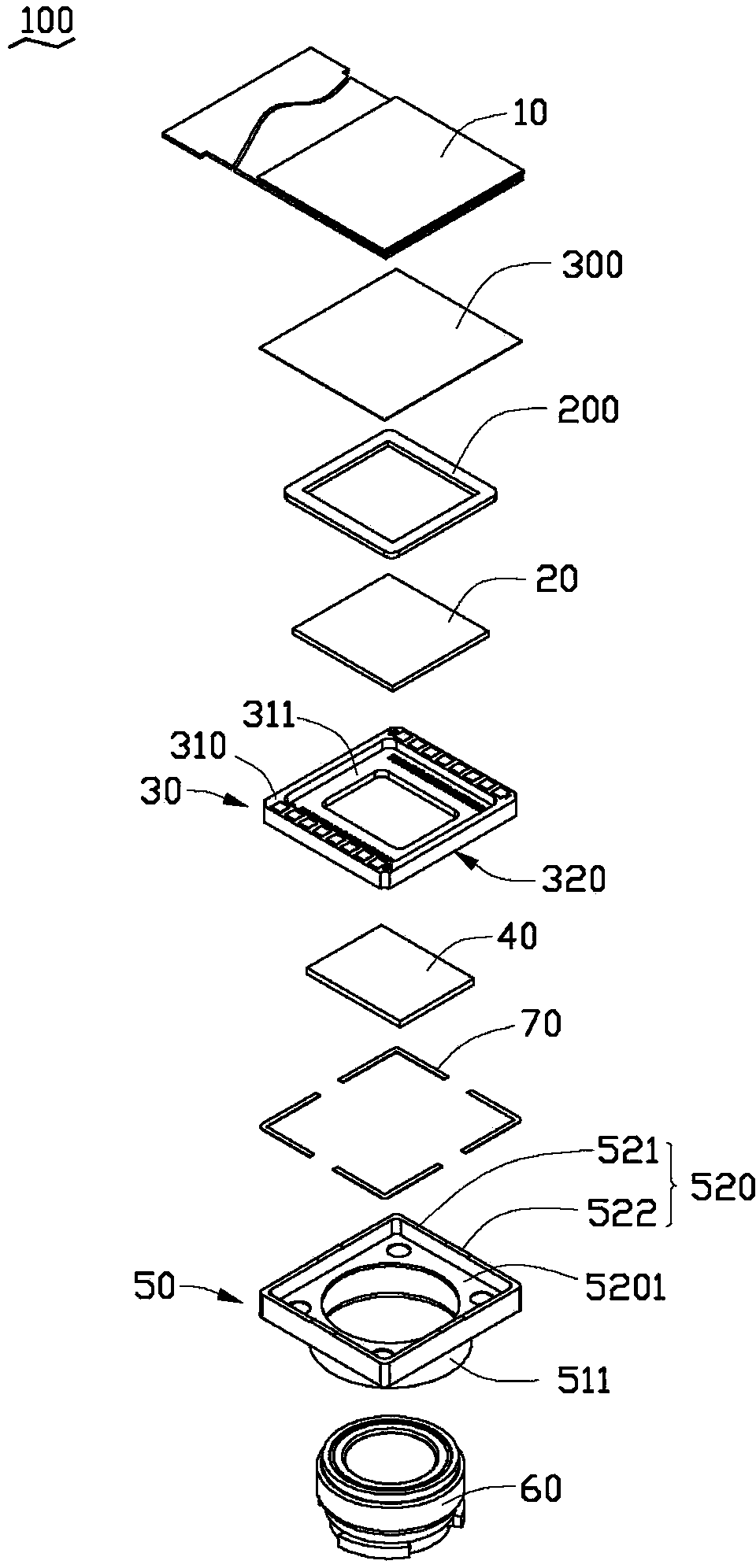

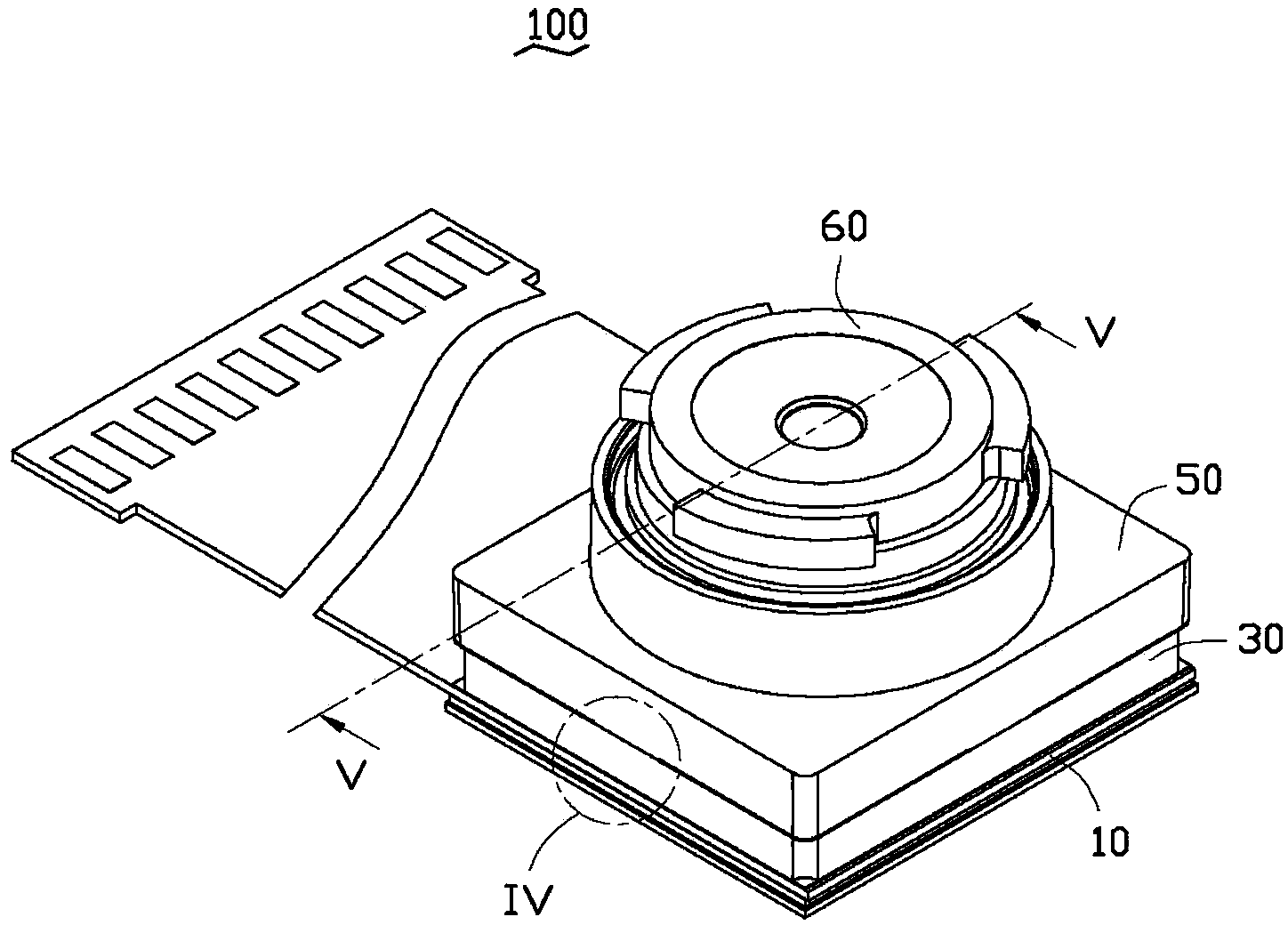

[0014] The embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings. see figure 1 and figure 2 , The camera module 100 provided by the embodiment of the present invention includes a circuit board 10 , an image sensor 20 , a package substrate 30 , a filter 40 , a mirror holder 50 and a lens 60 . In this embodiment, the circuit board 10 is a flexible circuit board.

[0015] The packaging substrate 30 is in the shape of a square frame, and is electrically connected to the circuit board 10 for packaging the image sensor 20 on the circuit board 10 . Specifically, the packaging substrate 30 includes a first surface 310 facing the image sensor 20 and a second surface 320 facing away from the first surface 310 . The first surface 310 defines a receiving groove 311 for receiving the image sensor 20 . An opening 330 penetrating through the first surface 310 and the second surface 320 is opened in the center of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com