Hammer pulling device

A hammer body and sliding rod technology, applied in the direction of hand-held tools, manufacturing tools, etc., can solve the problems of reduced service life, difficult to pull out bearings, time-consuming and labor-intensive problems, and achieve the effect of simple structure and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

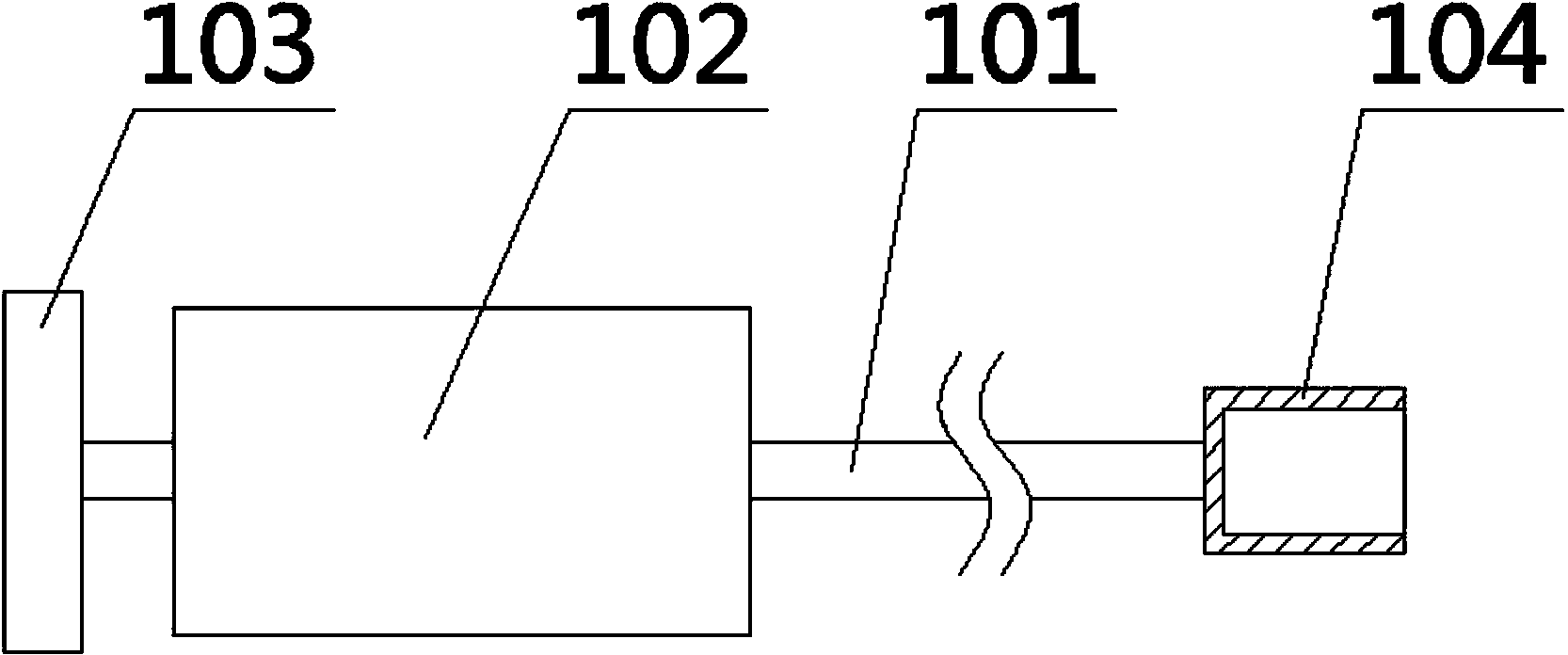

[0038] figure 1 shows the structure of the hammer device provided by Embodiment 1 of the present invention; please refer to figure 1 , Embodiment 1 of the present invention provides a pull hammer device, the pull hammer device is mainly used for the removal of coal shearer bearings. The pulling hammer device includes a sliding rod 101 and a hammer body 102 slidably connected with the sliding rod 101 . One end of the sliding rod 101 is provided with a baffle 103 , and the other end is provided with a sleeve 104 . The sleeve 104 is provided with a fastening structure for fastening the bearing.

[0039] When using the pull hammer device, the bearing is fastened by the fastening structure on the sleeve 104, and then the hammer body 102 is pulled quickly and forcefully, so that the hammer body 102 slides along the slide bar 101 until it hits the baffle plate 103, and the hammer body 102 is applied to The large instantaneous force of the baffle plate 103 makes the baffle plate 10...

Embodiment 2

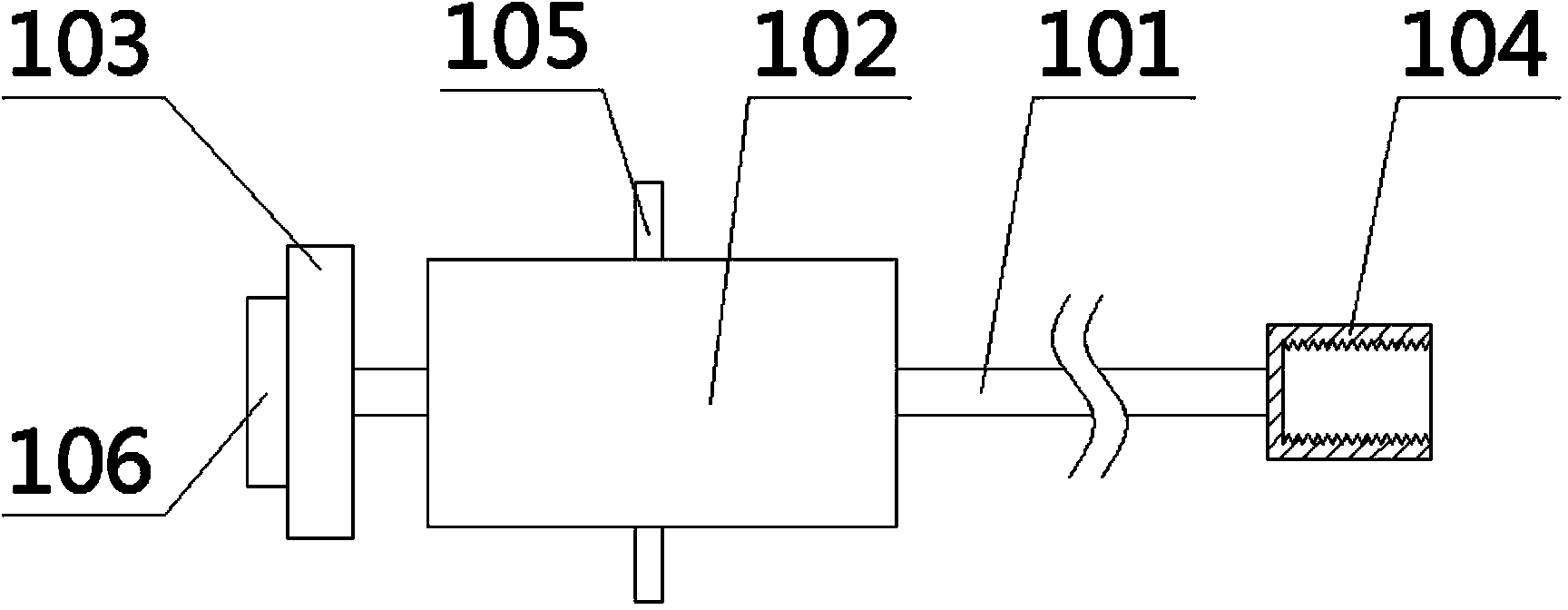

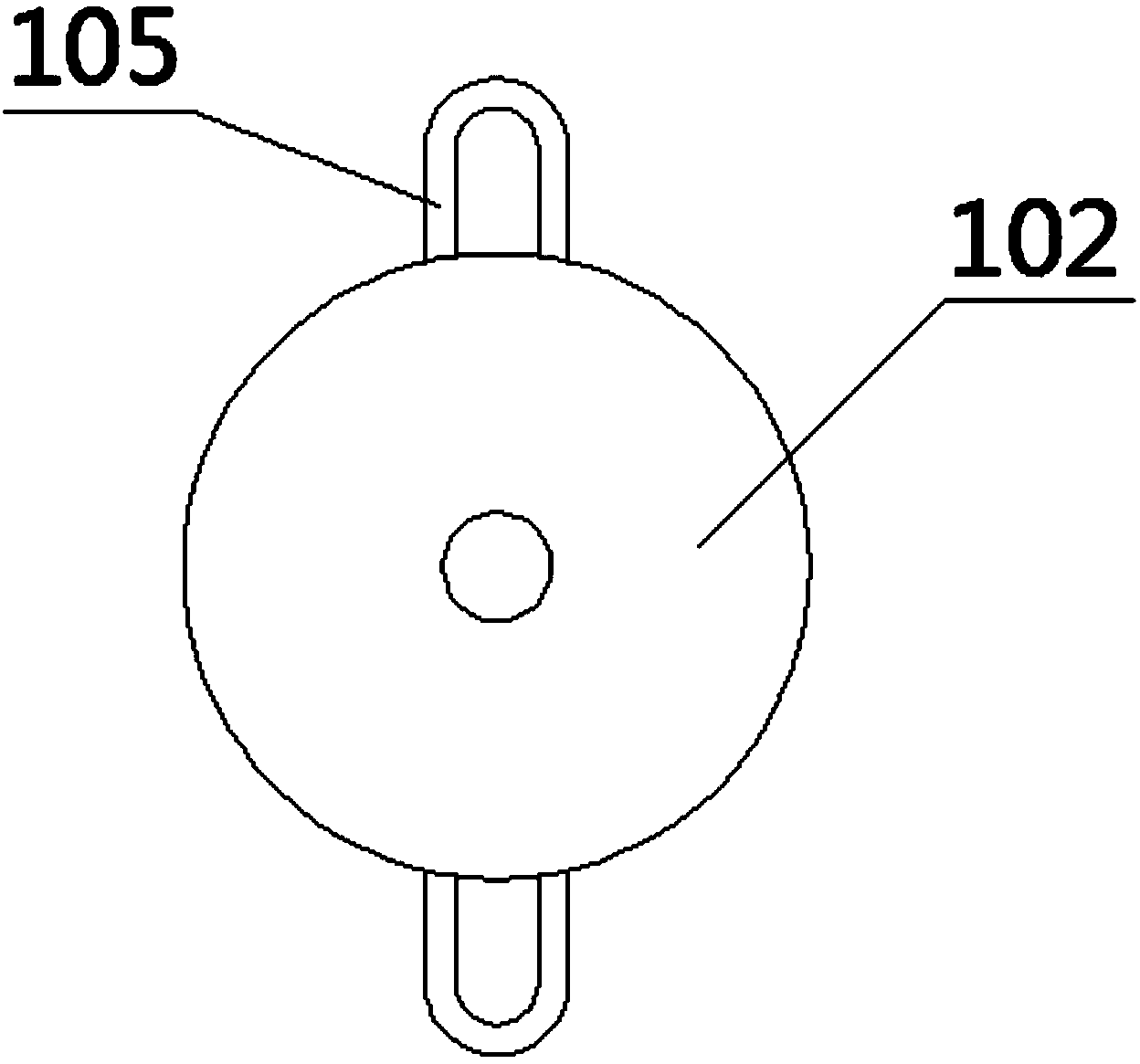

[0042] figure 2 Shows the structure of the pull hammer device provided by Embodiment 2 of the present invention; image 3 Shows the top view structure of the hammer body 102 of the hammer device provided in Embodiment 2 of the present invention; please refer to figure 2 with image 3 , Embodiment 2 of the present invention provides a pull hammer device, which includes all the technical features of the pull hammer device provided in Embodiment 1, and the pull hammer device also includes the following technical features:

[0043] The inner wall of the sleeve 104 is provided with an inner wire. By setting the inner wire on the inner wall of the sleeve 104, the inner wire can cooperate with the bearing, so that the sleeve 104 and the bearing are screwed together to achieve the purpose of fastening the bearing so as to pull out the bearing.

[0044] The sleeve 104 and the baffle 103 are integrally welded with the sliding rod 101 respectively. Sleeve 104, baffle plate 103, sli...

Embodiment 3

[0055] Embodiment 3 of the present invention provides a pull-hammer device, which differs from the pull-hammer device provided in Embodiment 2 only in the structure of the sleeve 104 .

[0056] Figure 4 shows the structure of the pull hammer device provided by Embodiment 3 of the present invention; please refer to Figure 4 , The side wall of the sleeve 104 of the pull hammer device provided in Embodiment 3 of the present invention is provided with at least two threaded holes 107 that cooperate with fastening screws. By setting at least two threaded holes 107 on the side wall of the sleeve 104, when fastening the bearing, first put the sleeve 104 on the bearing, and then screw the screw through the threaded hole 107 until the screw clamps the bearing, thereby achieving The purpose of fastening the bearings is to pull out the bearings.

[0057] There are four threaded holes 107 and they are evenly distributed symmetrically to the center. By setting the threaded holes 107 to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com