Wave wheel washing machine and its position limiting method

A pulsator washing machine and limit technology, which is applied to other washing machines, washing machines with containers, washing devices, etc., can solve the problems of increased noise, increased friction of the washing machine, serious vibration of the whole machine, etc., to reduce vibration, reduce Mechanical contact, the effect of reducing friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

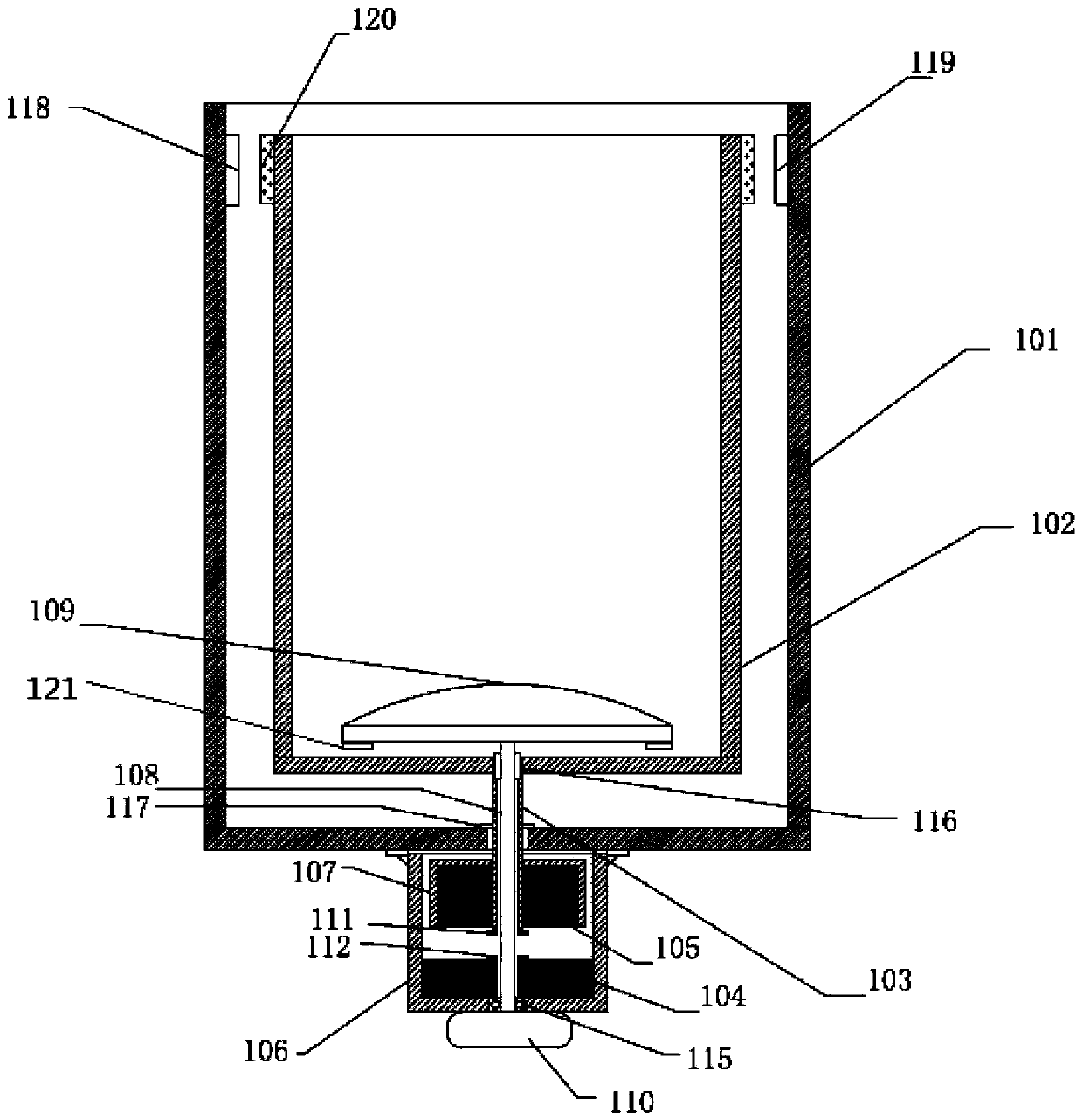

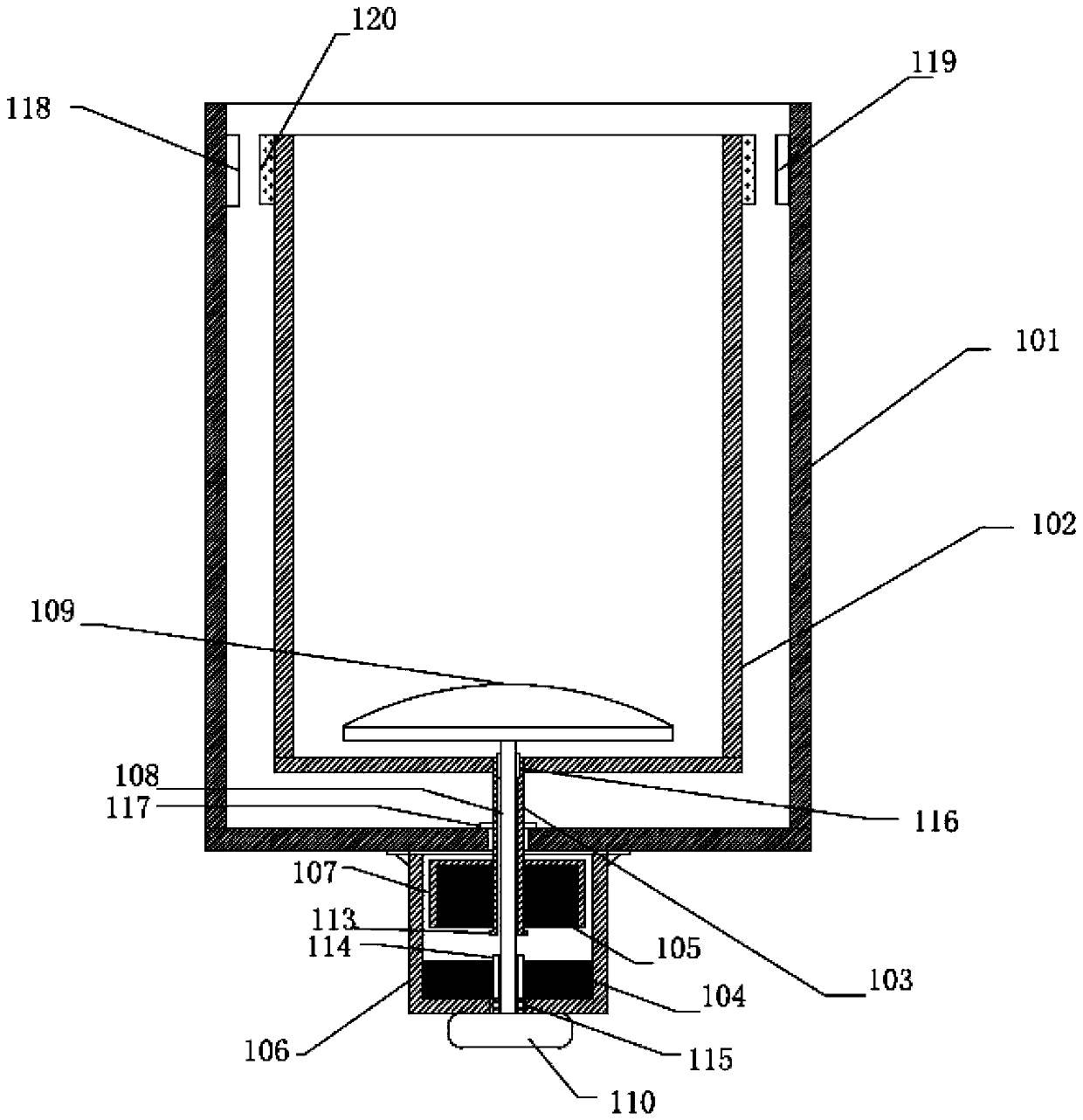

[0011] Such as figure 1 As shown, a washing machine includes an outer cylinder 101 and an inner cylinder 102, and also includes two magnets cooperating with the inner cylinder 102 and the outer cylinder 101 to repel each other, and the inner cylinder 102 is suspended in the outer cylinder 101 by the repulsive force between the magnets , There is a limiting part between the two magnets to prevent them from contacting.

[0012] The inner cylinder 102 is suspended in the outer cylinder 101 by the repulsive force between the two magnets, so that the inner cylinder 102 has almost no mechanical contact with the outer cylinder 101 during rotation, thereby effectively reducing friction and reducing noise.

[0013] In addition, clothes and water are housed in the inner cylinder 102 during the washing process, and the inner cylinder 102 sinks under the action of gravity, and the magnets arranged in cooperation with the inner cylinder 102 will also sink. If there are too many clothes loa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com