Novel carriage hinge and mold and method for manufacturing novel carriage hinge

A technology for forming molds and hinges, which is applied in the field of hinges, can solve the problems of discounting the scope of application, affecting the efficiency of loading and unloading goods, etc., and achieve the effect of firm structure, simple and firm structure, and fewer processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The technical solutions of the present invention will be described in further detail below through specific implementation methods.

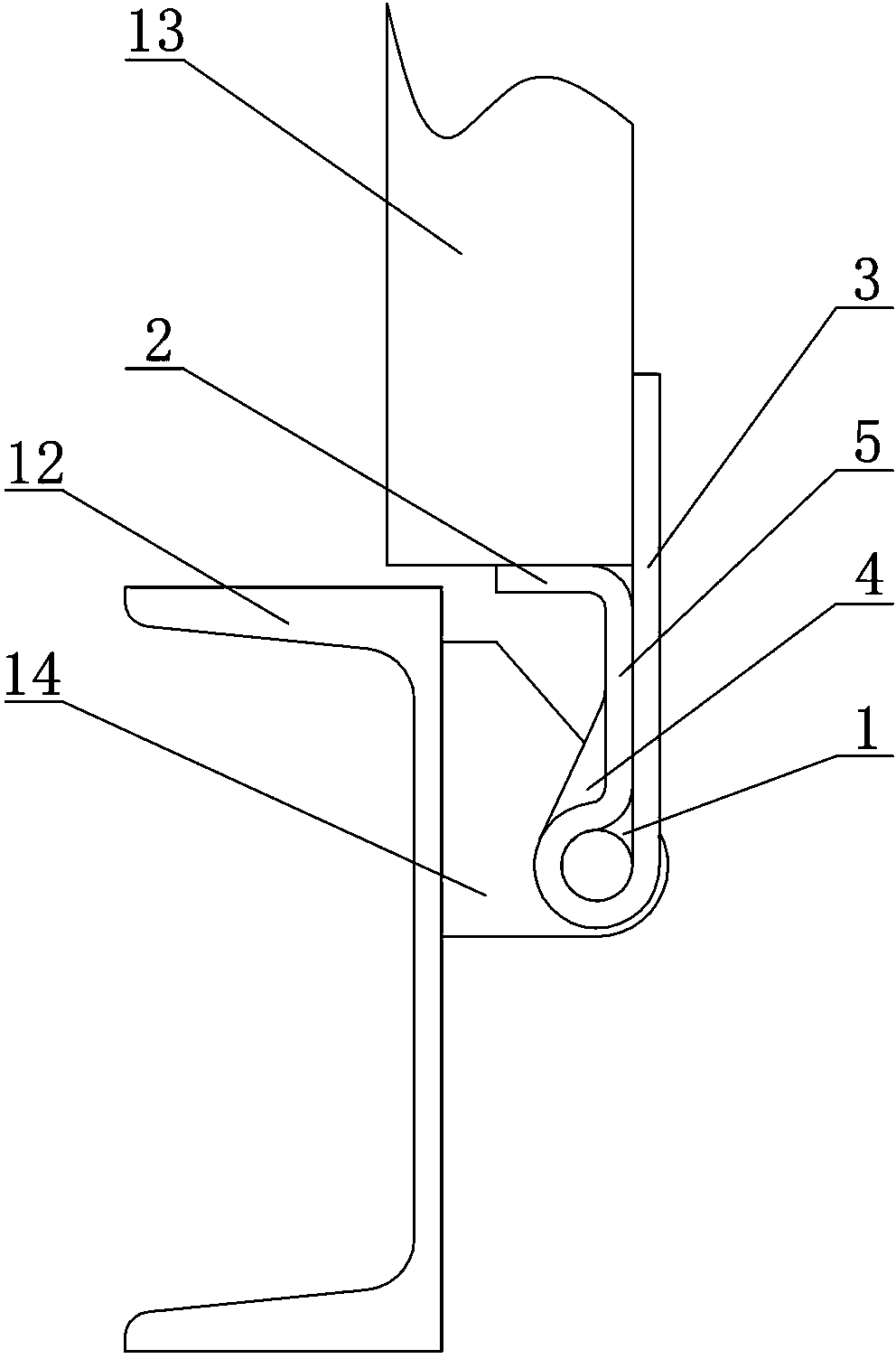

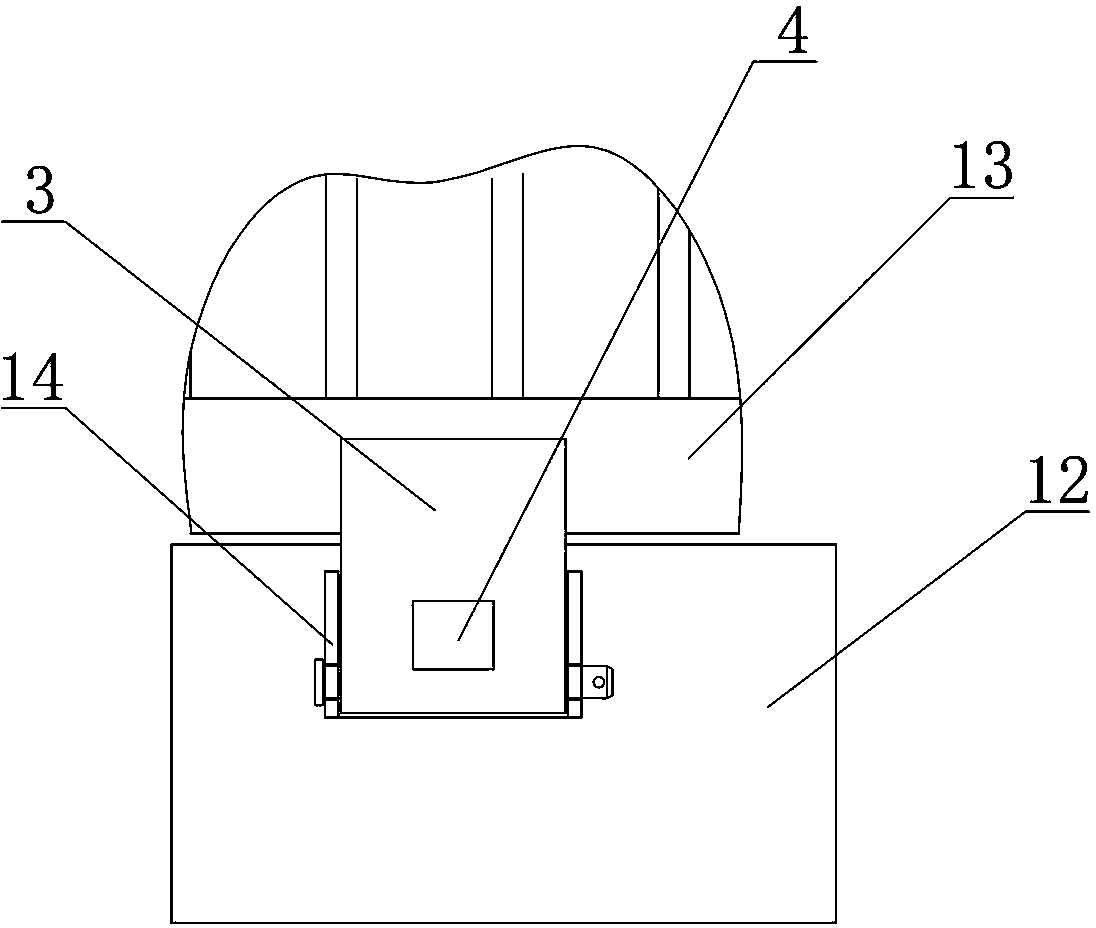

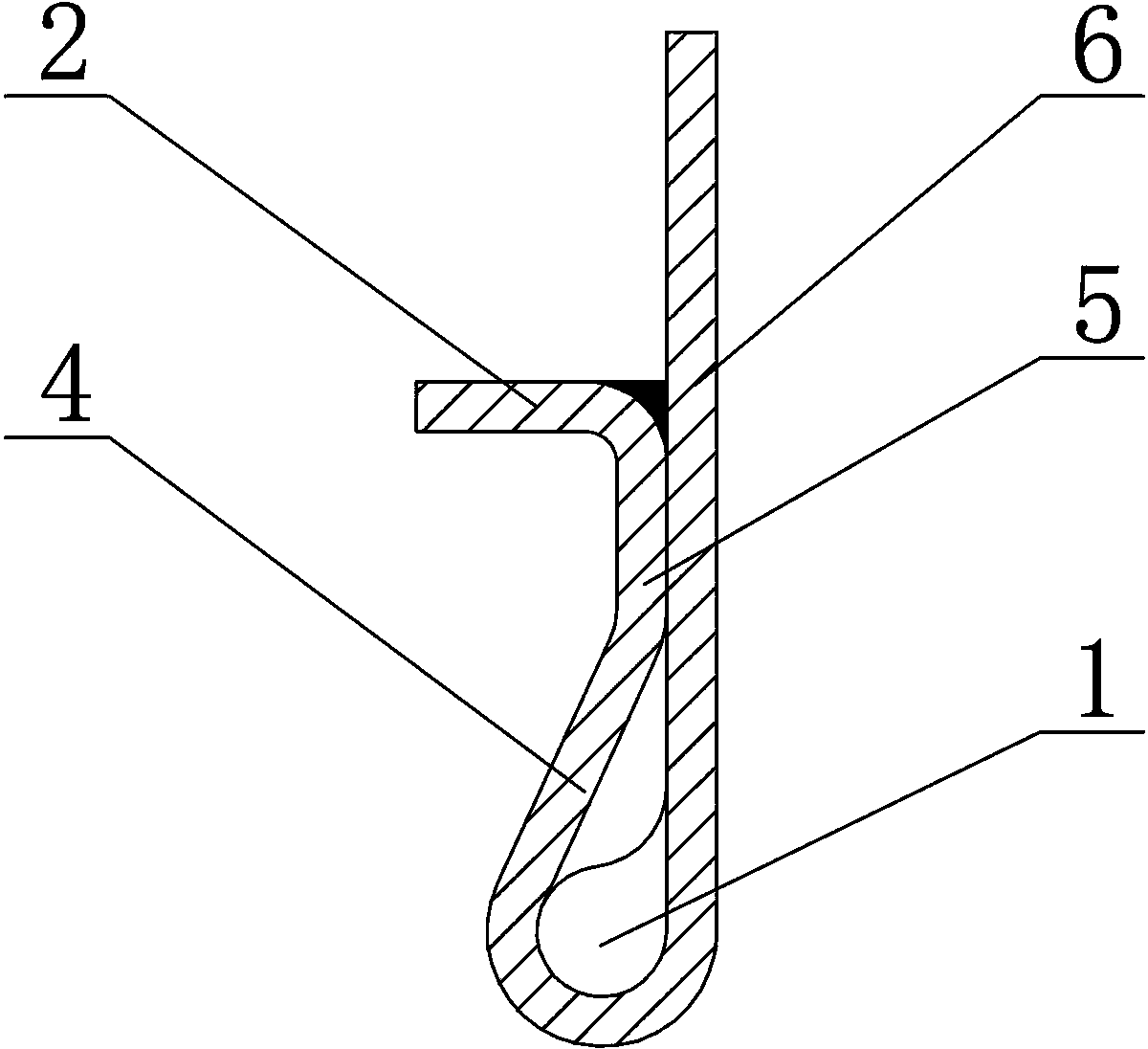

[0038] Such as Figure 1-Figure 3 As shown, a new type of carriage hinge includes an upper hinge and a lower hinge 14, the upper hinge is fixed to the lower part of the side panel of the carriage, the lower hinge 14 is fixed to the side beam side, and the upper hinge and the lower hinge 14 are fixed by pins. Shaft connection, so as to connect the side panel of the carriage with the side beam, the lower hinge 14 is a U-shaped steel plate, the through hole is correspondingly set on the two side plates of the U-shaped steel plate, and the middle outer end of the U-shaped steel plate It is welded and fixed to the side of the side beam. The upper hinge is an inner rolling ear structure formed by cold rolling of steel plates, including the inner plate 6, the outer plate 3, the ear hole 1 and the supporting plate 2, the supporting plate 2 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com