Device and method for comprehensive recycling of heat energy in plate and strip processing line

A technology for processing lines and strips, applied in the field of heat energy recovery and utilization of strip processing lines, can solve the problems of increasing the load of the exhaust fan, losing the heat of the flue gas, and complex equipment structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings. It should be understood that the preferred embodiments are only for illustrating the present invention, not for limiting the protection scope of the present invention.

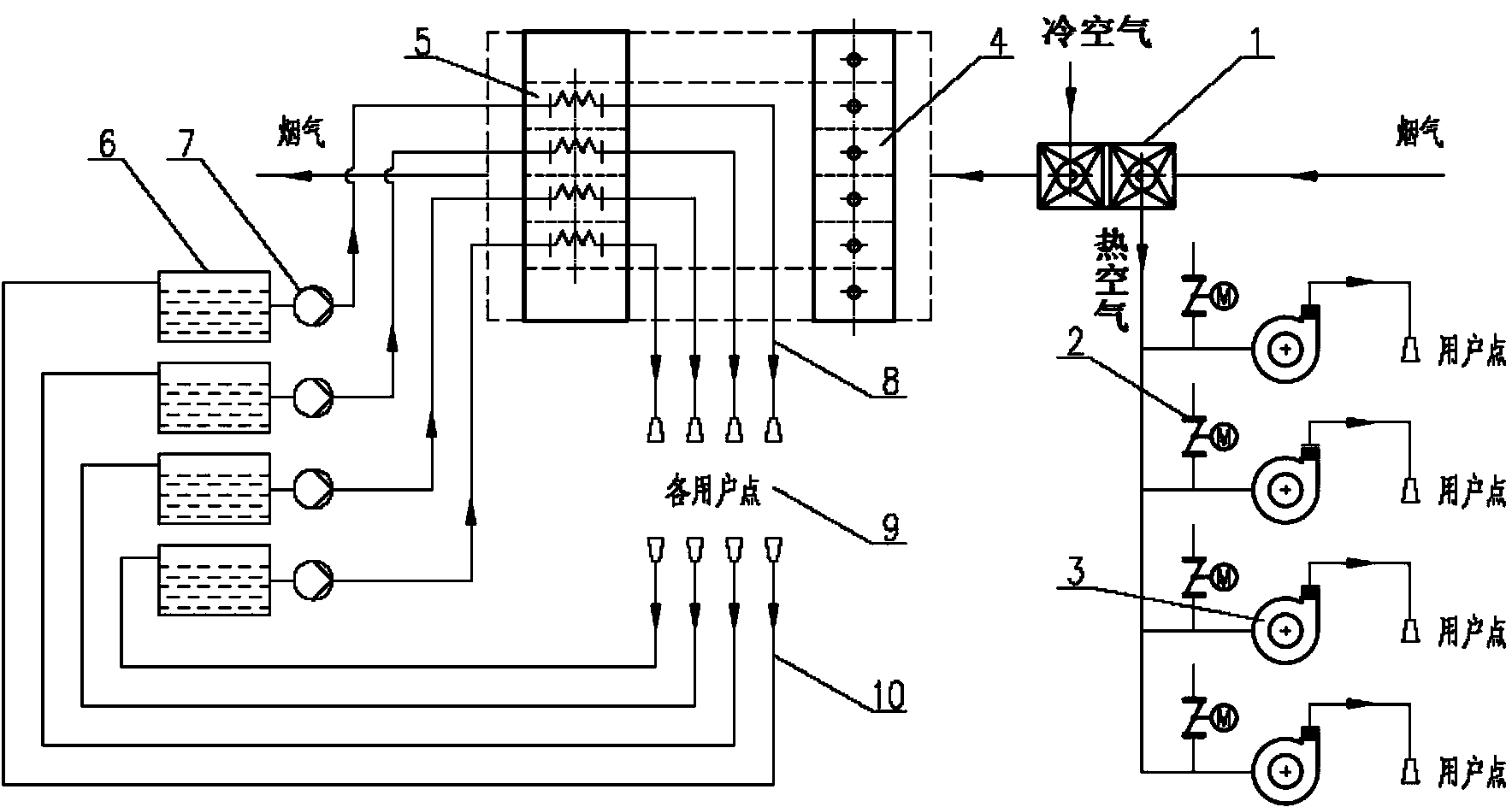

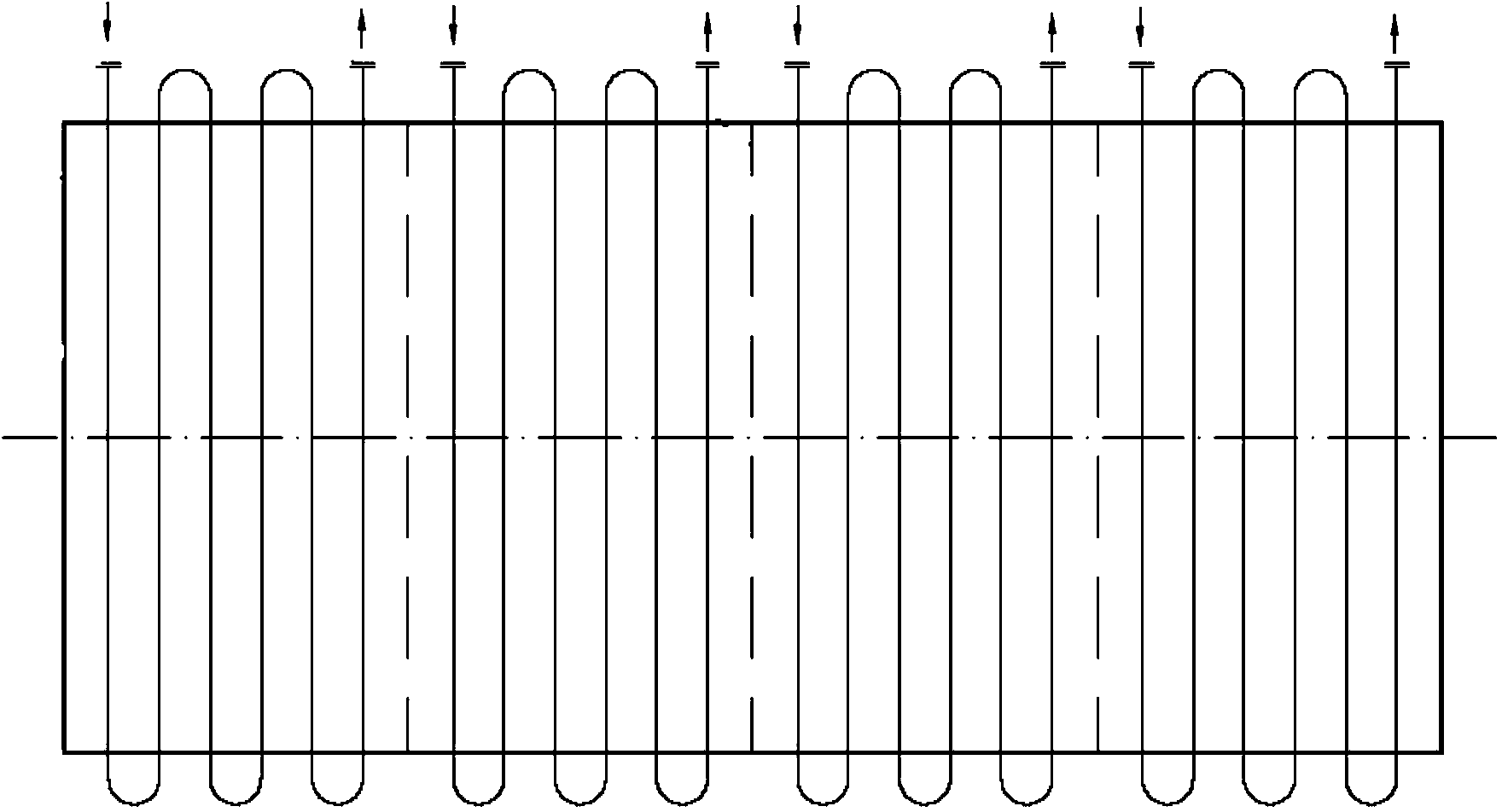

[0023] As shown in the figure, a heat energy comprehensive recovery and utilization device for a strip processing line includes a flue gas-air heat exchanger 1 and a flue gas-fluid heat exchanger. The flue gas outlet of the flue gas-air heat exchanger and the flue gas The flue gas inlet of the gas-fluid heat exchanger is connected, the hot air outlet of the flue gas-air heat exchanger and the hot air demand point are provided with a drying fan 3, and the flue gas-fluid heat exchanger is provided with at least There is a circulating heat exchange fluid pipeline for supplying heat sources to the user point, and each circulating heat exchange fluid pipeline is provided with a circu...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap