Patents

Literature

98results about How to "Heating directly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

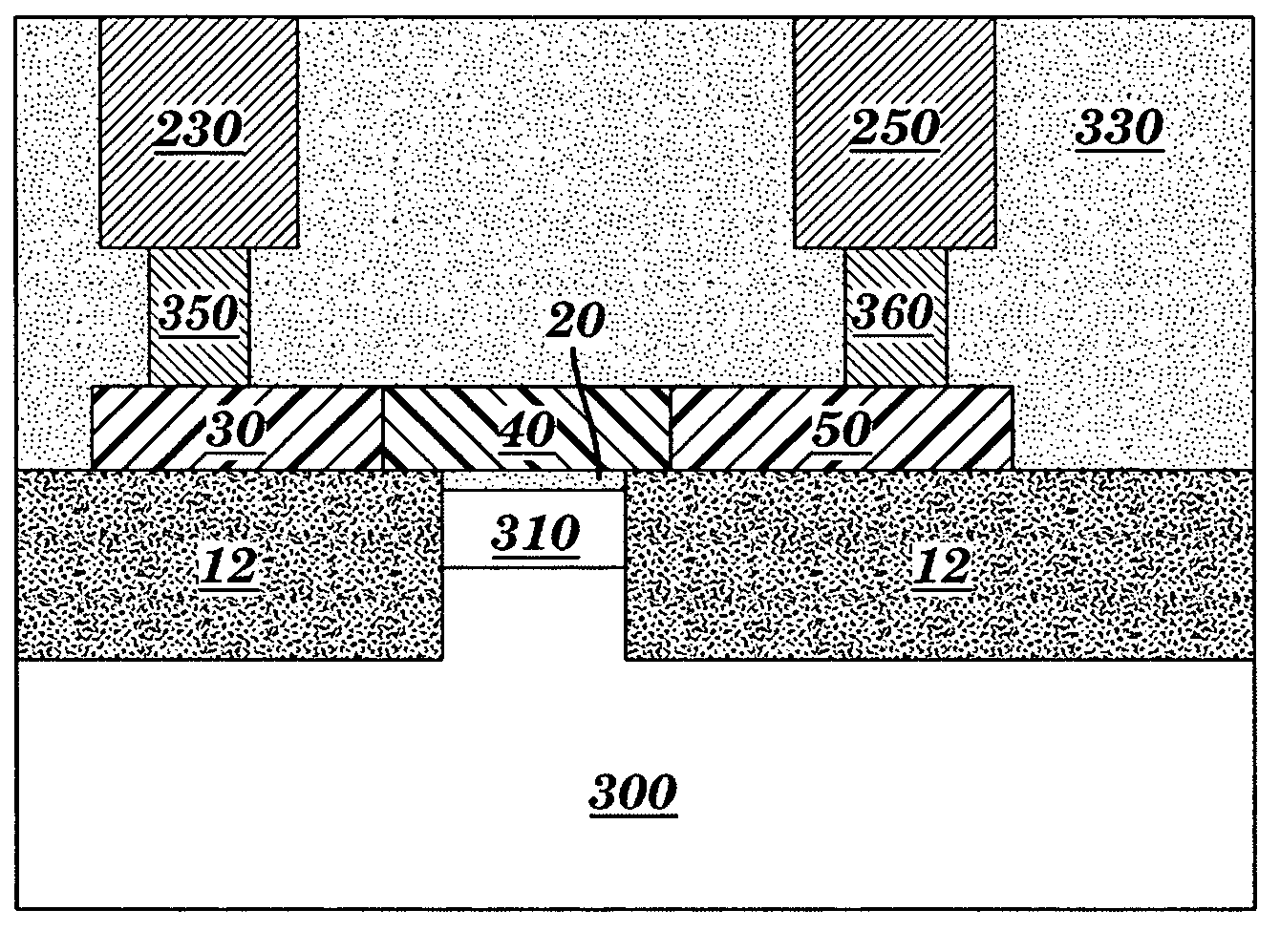

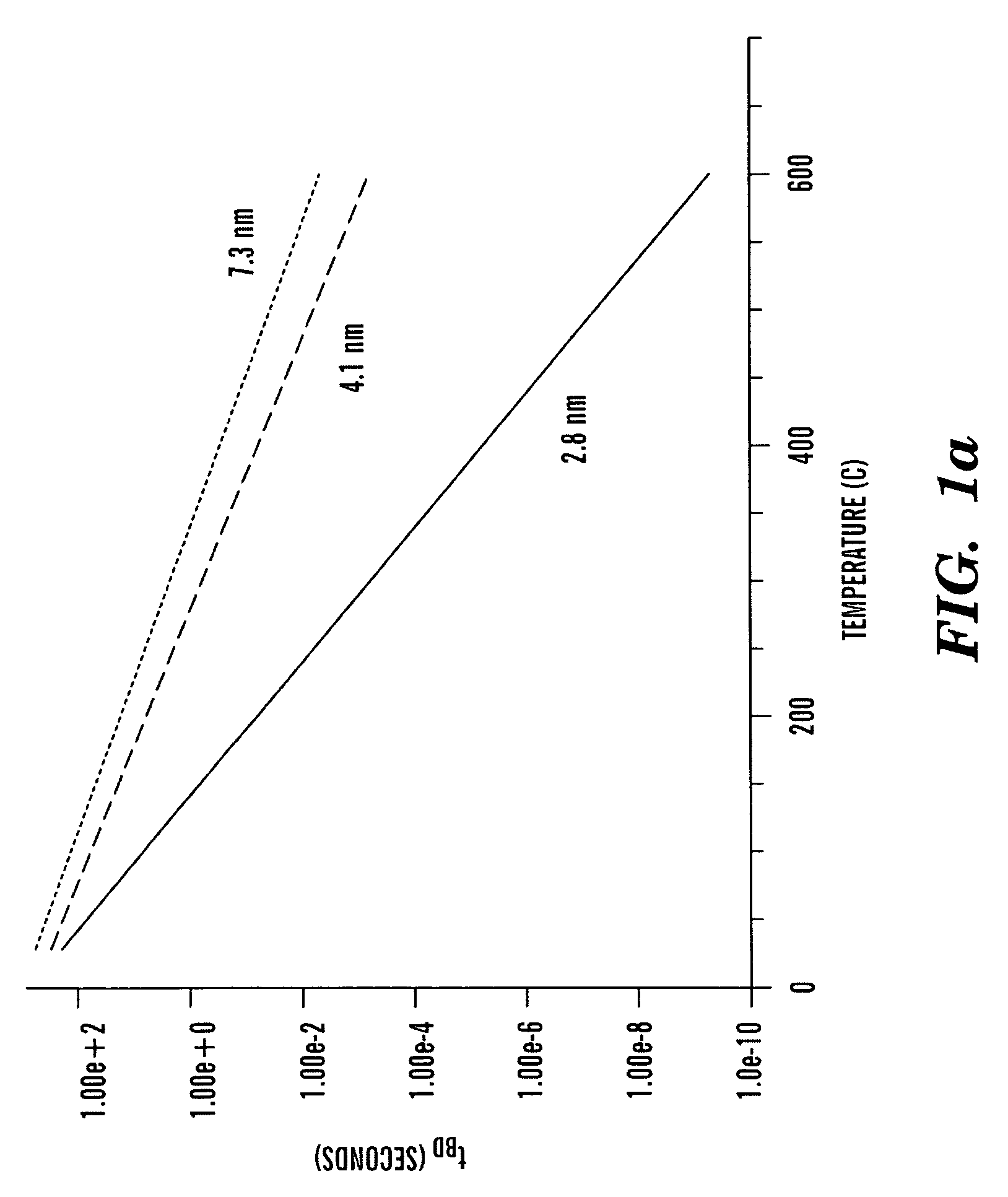

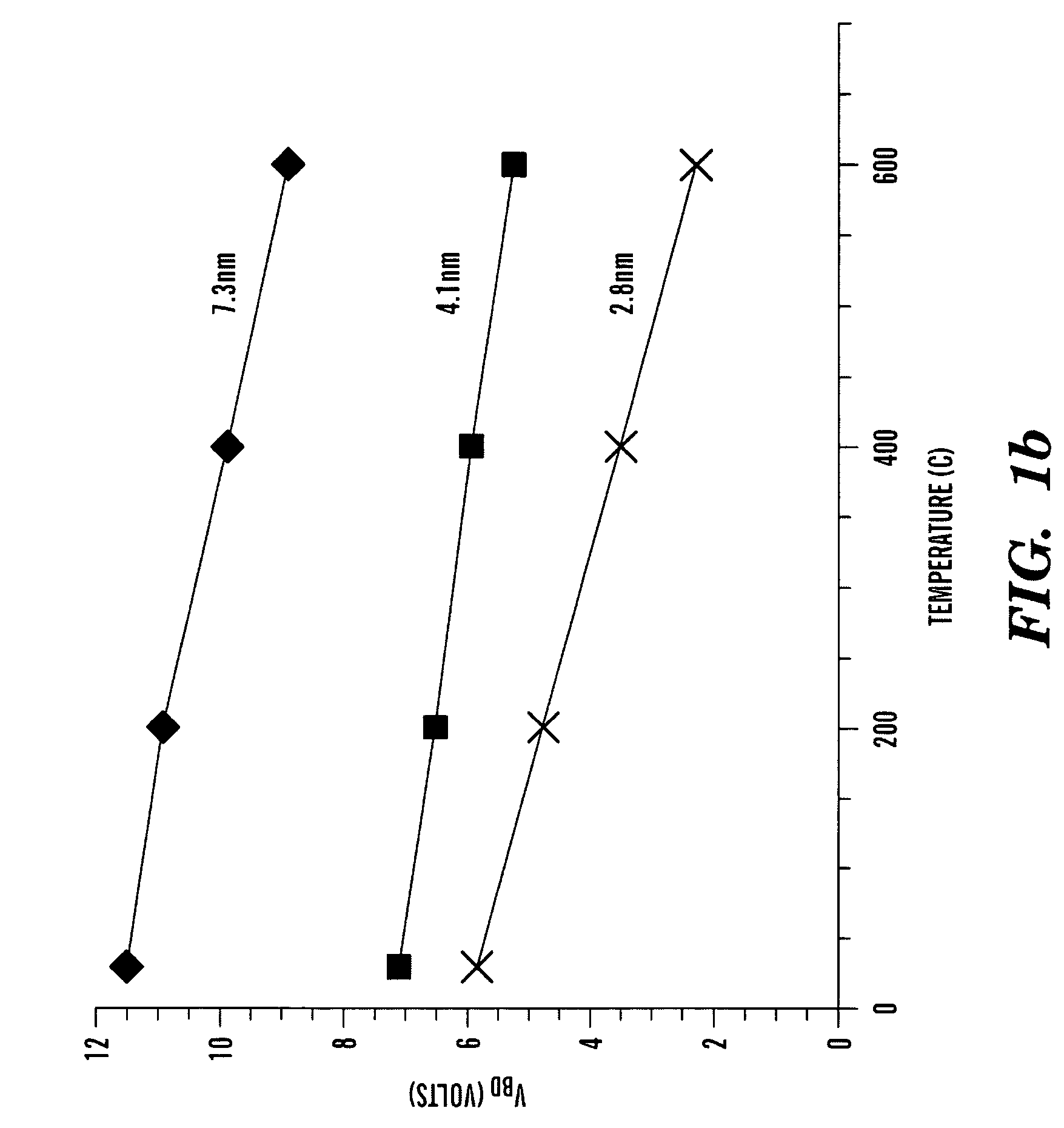

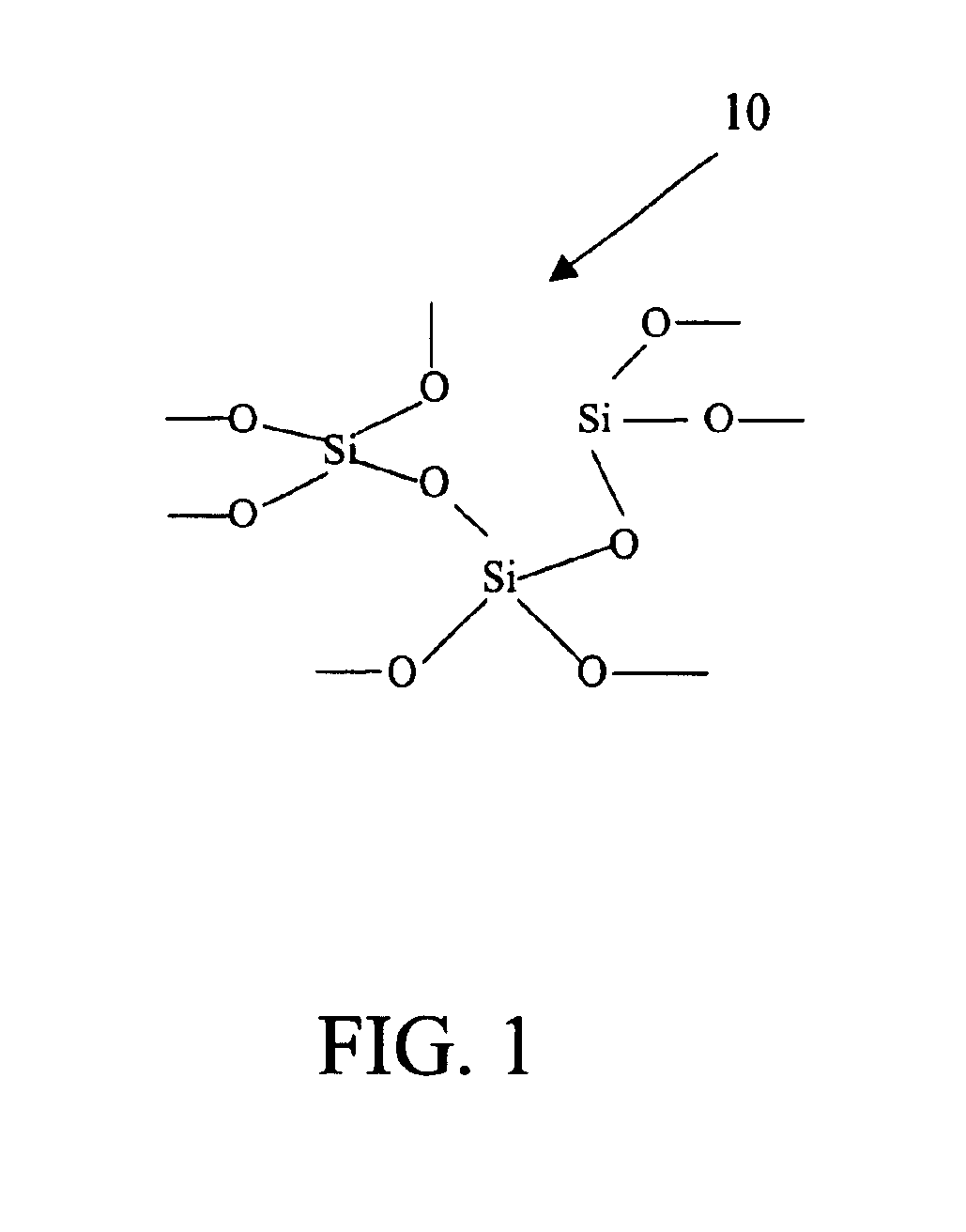

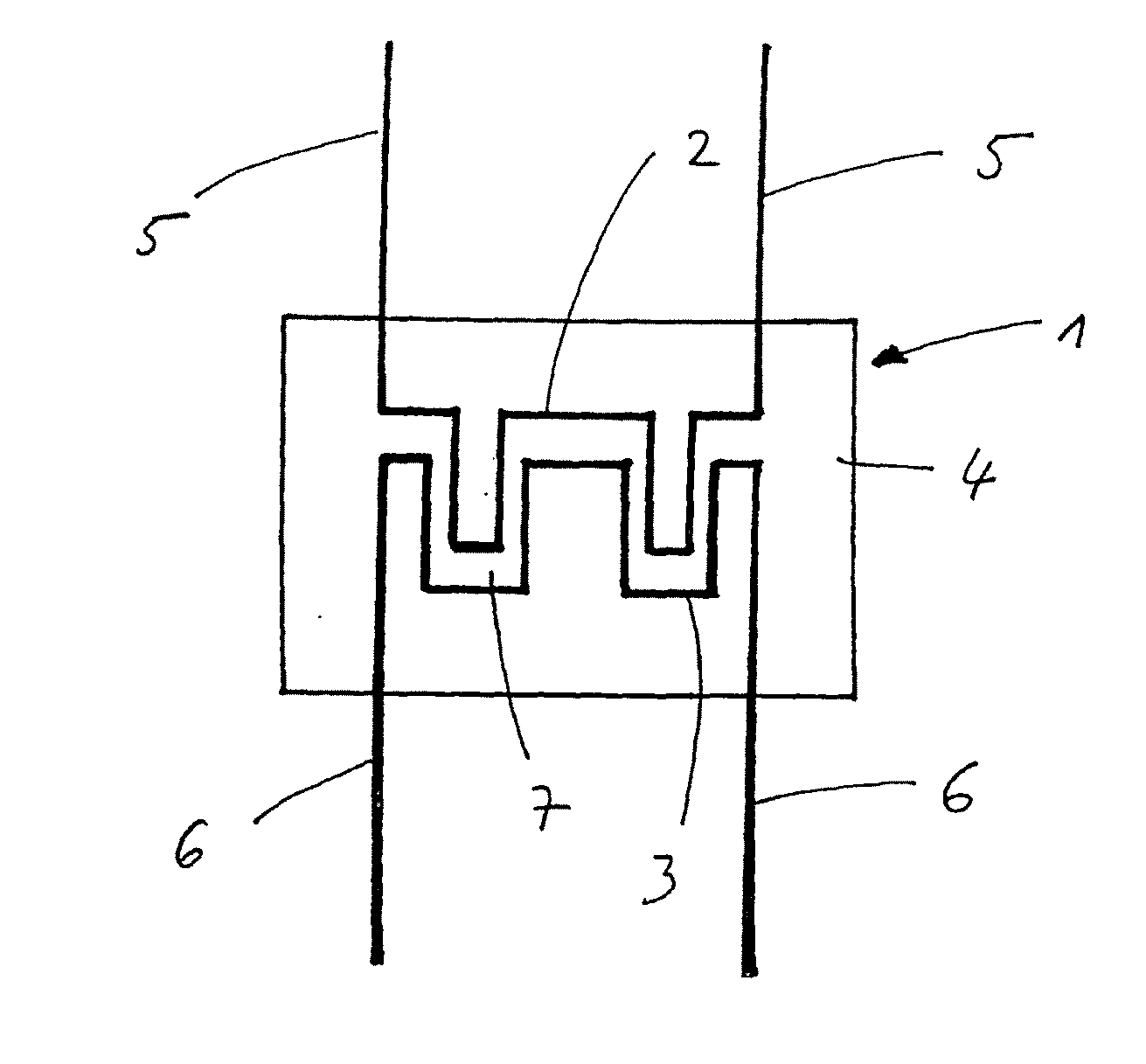

Antifuse structure having an integrated heating element

InactiveUS20060102982A1Improve the heating effectHeating directlySemiconductor/solid-state device detailsSolid-state devicesElectrical conductorEngineering

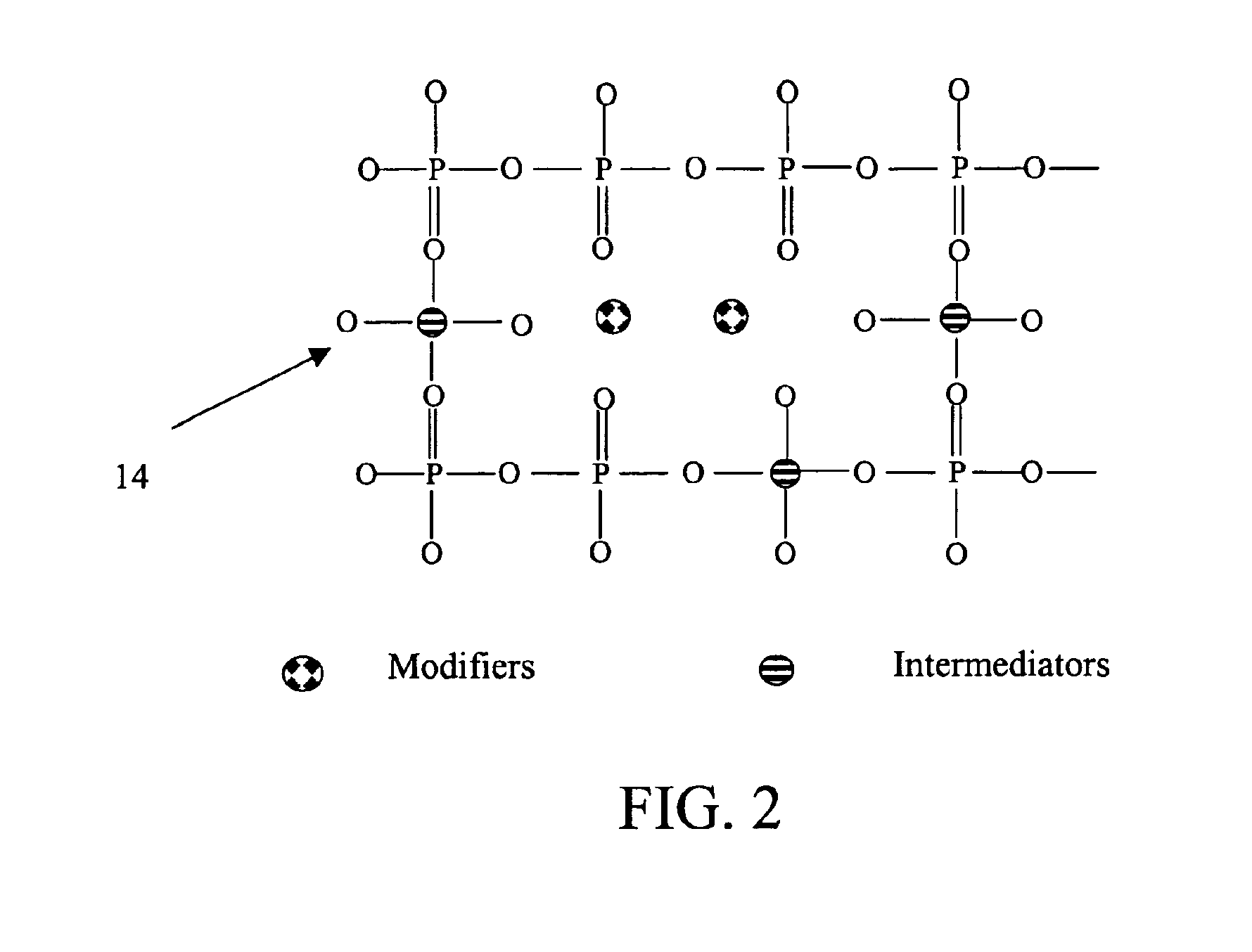

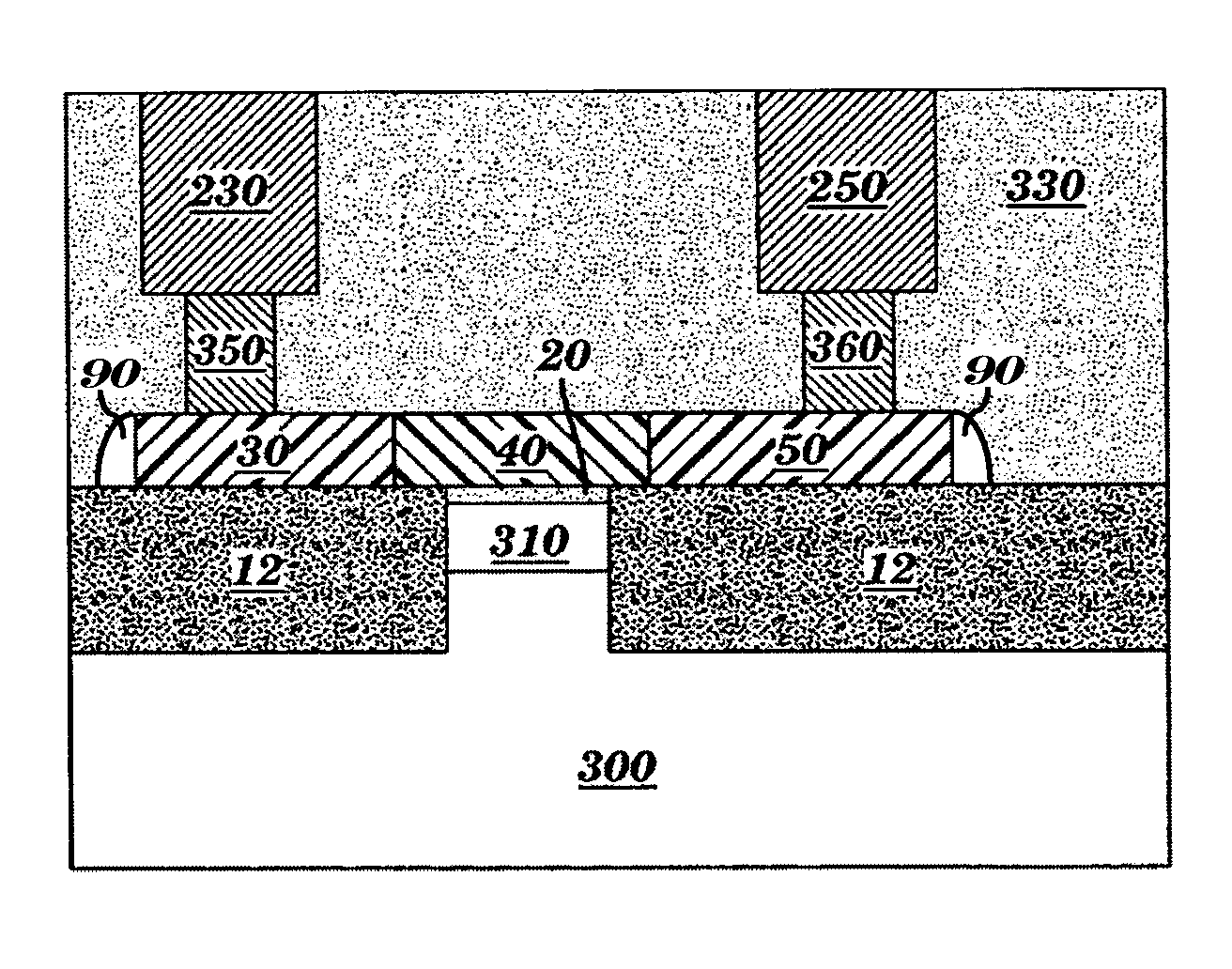

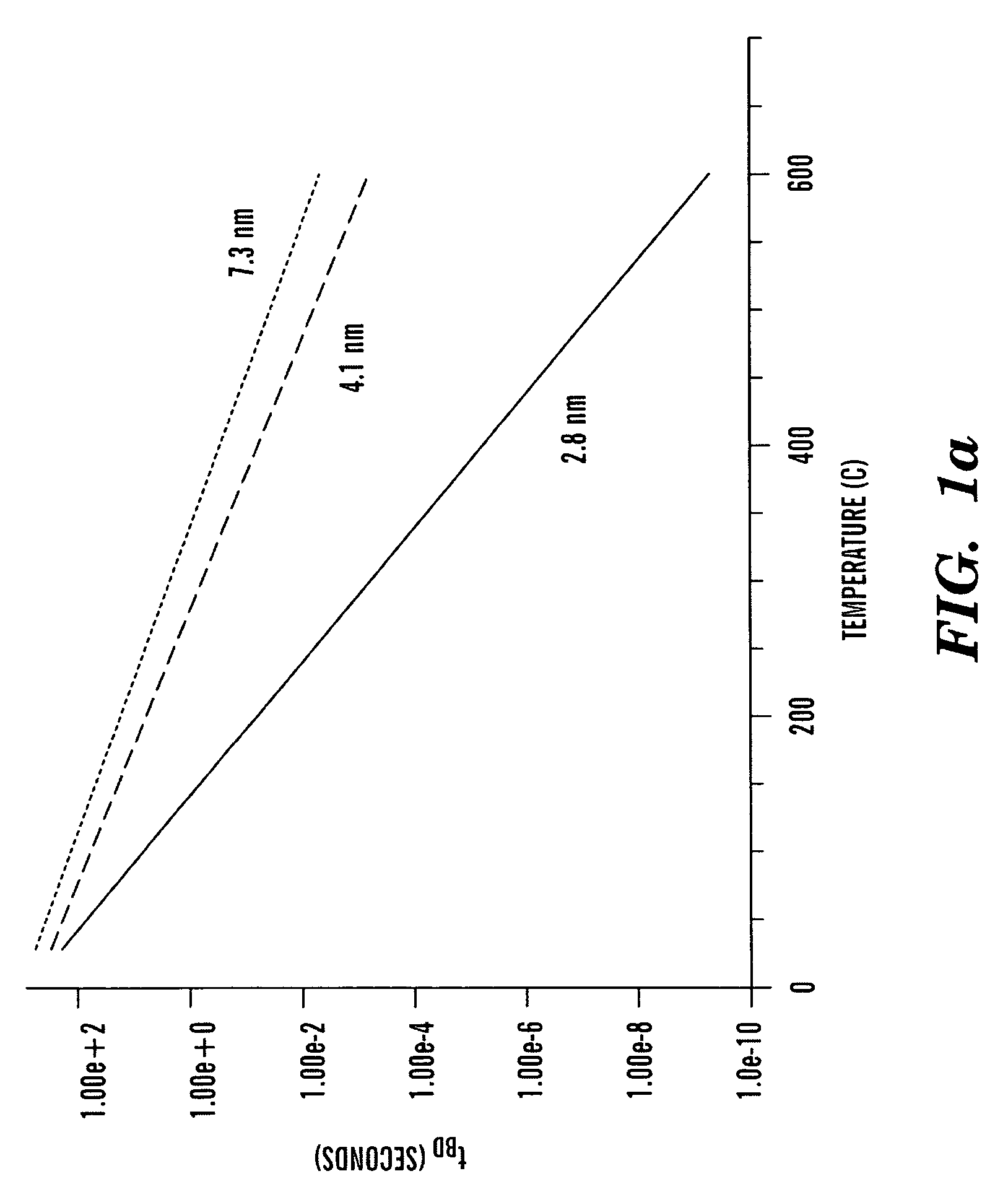

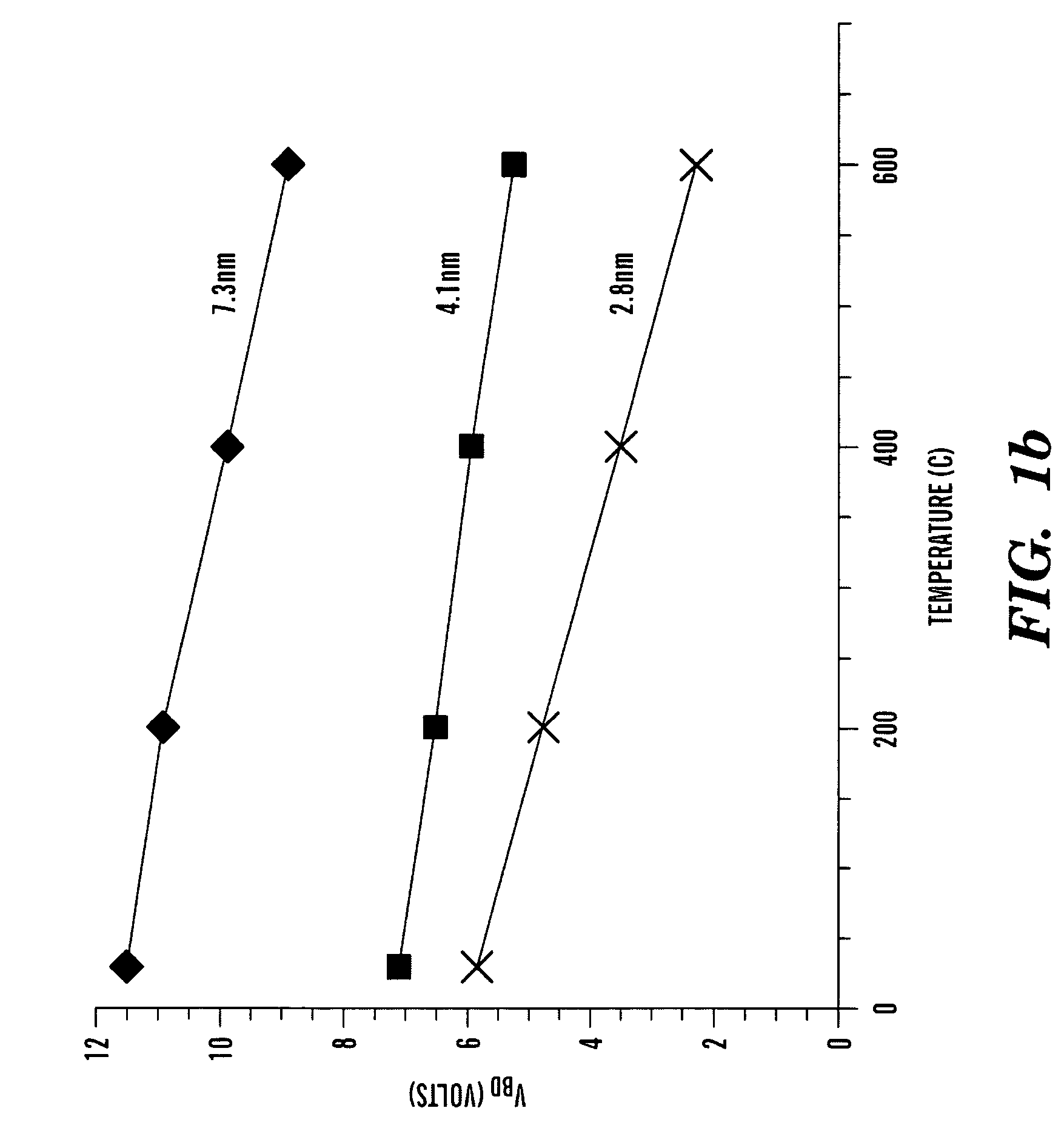

The present invention provides antifuse structures having an integrated heating element and methods of programming the same, the antifuse structures comprising first and second conductors and a dielectric layer formed between the conductors, where one or both of the conductors functions as both a conventional antifuse conductor and as a heating element for directly heating the antifuse dielectric layer during programming.

Owner:GLOBALFOUNDRIES INC

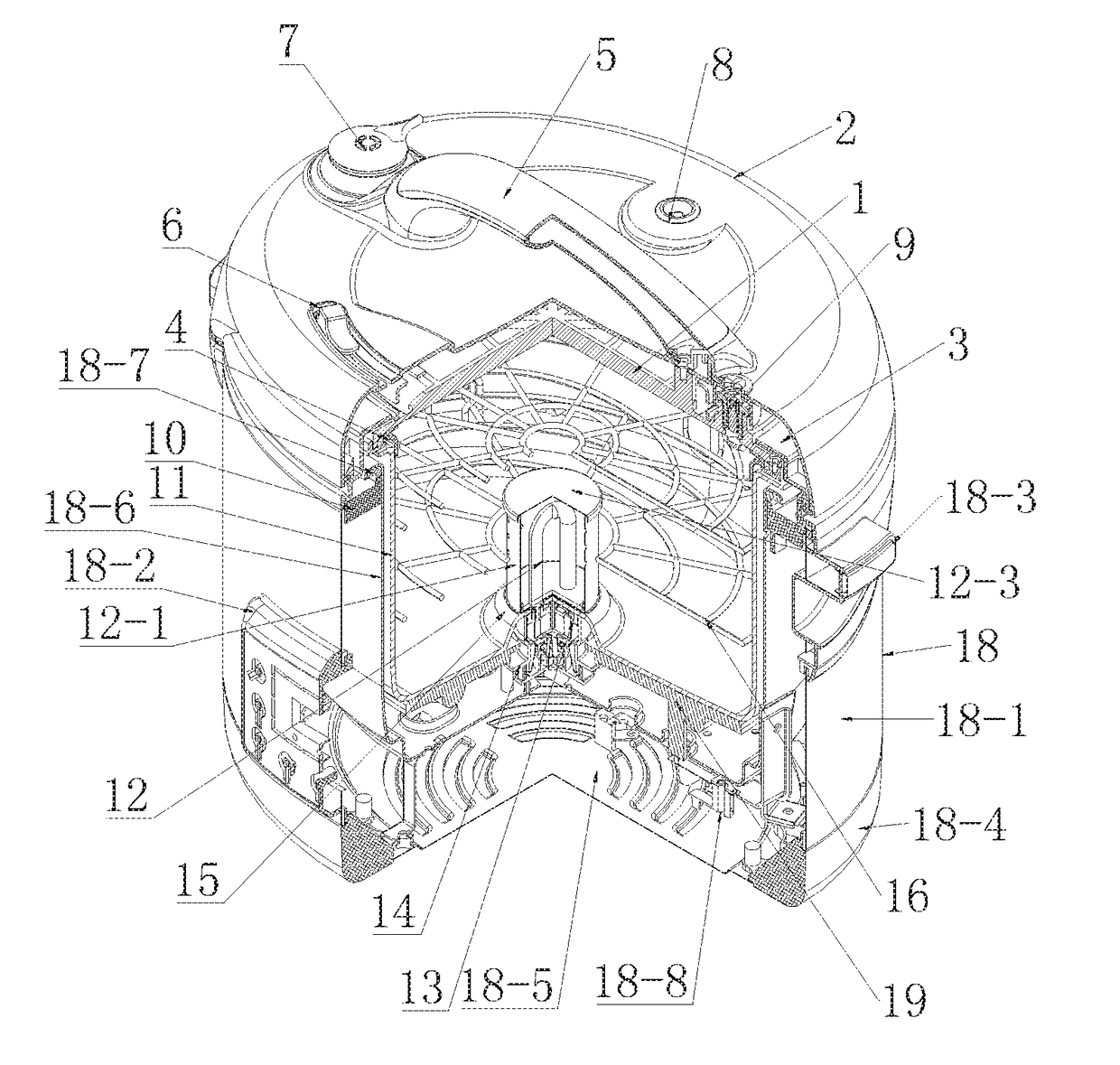

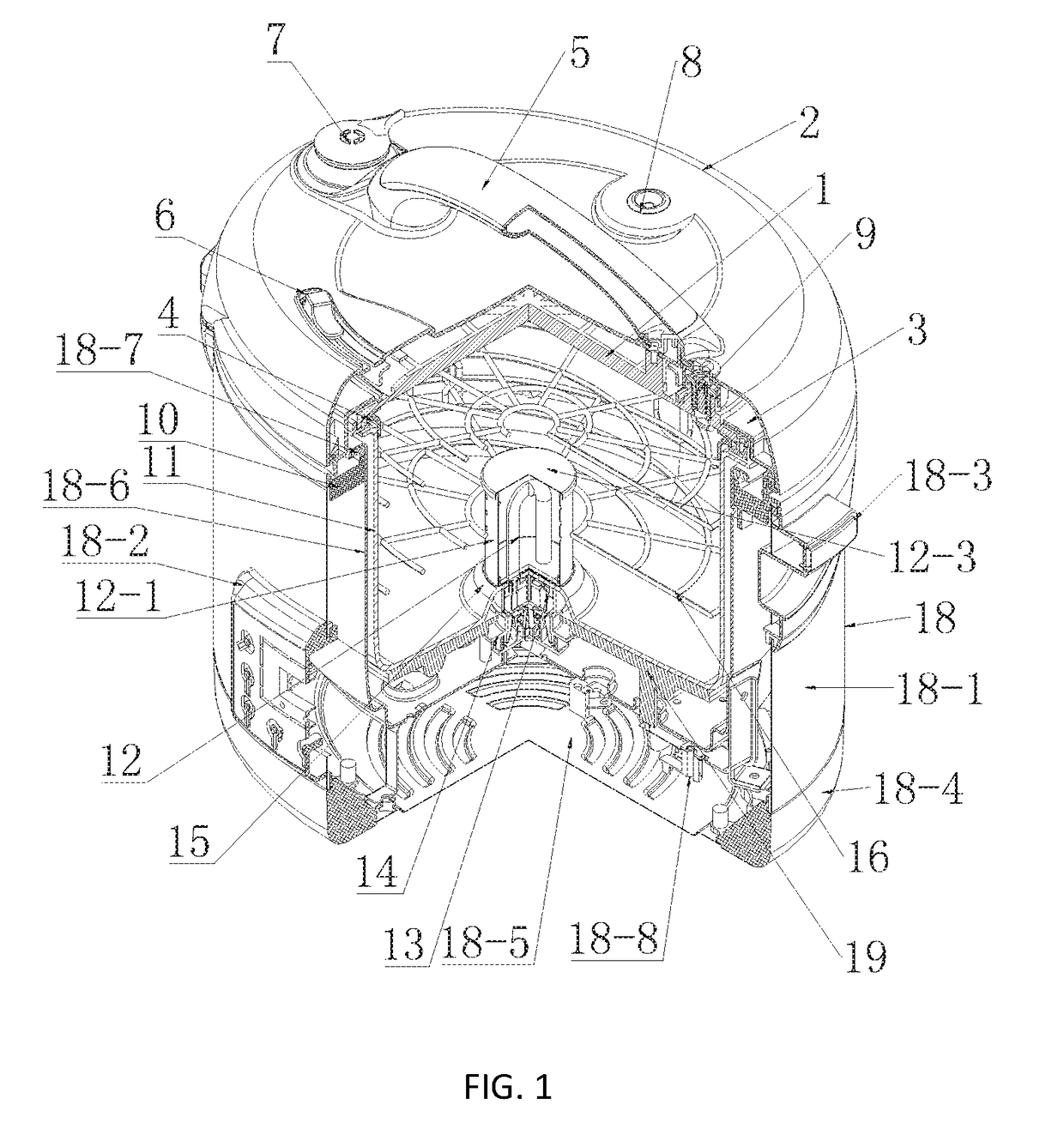

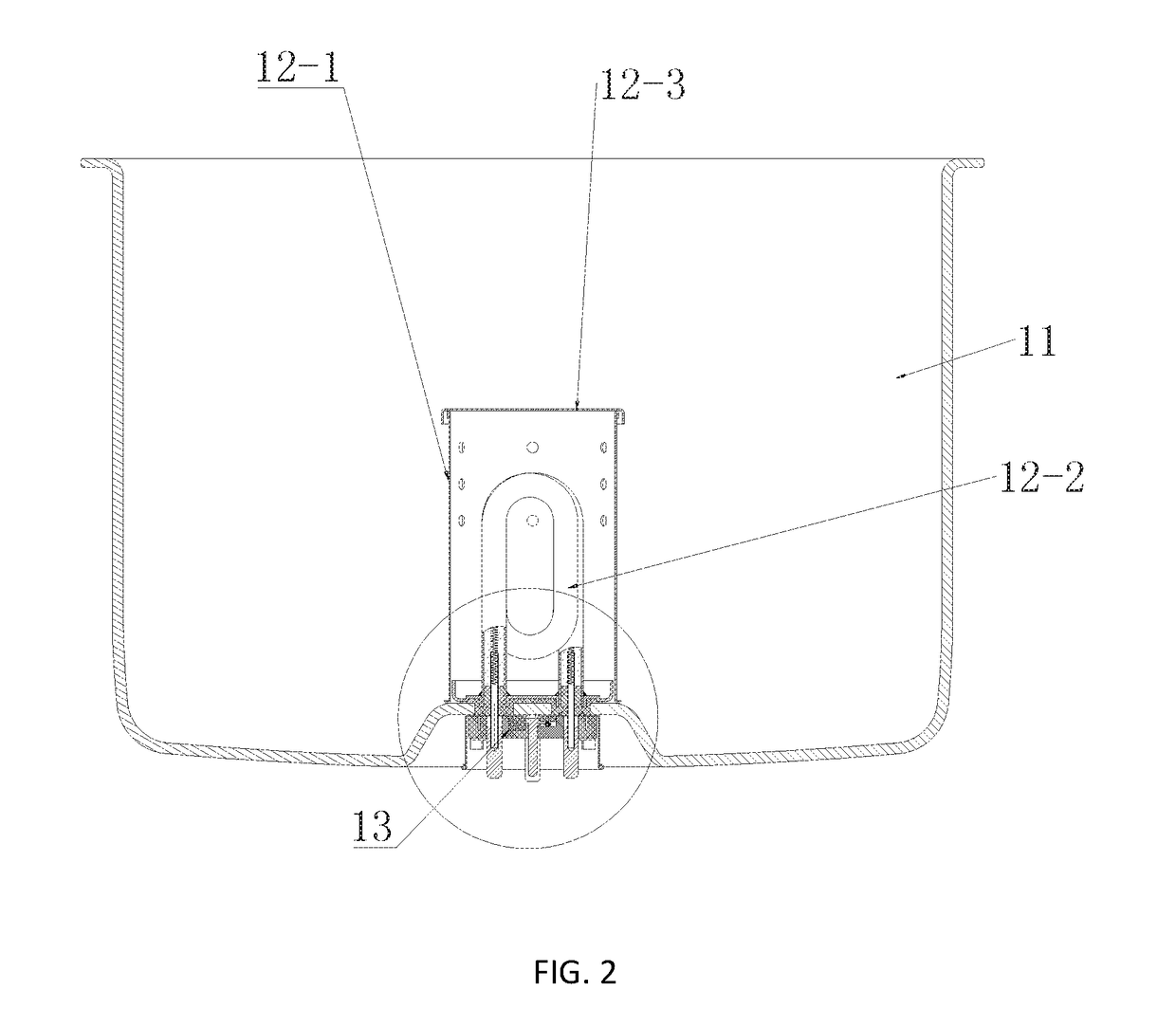

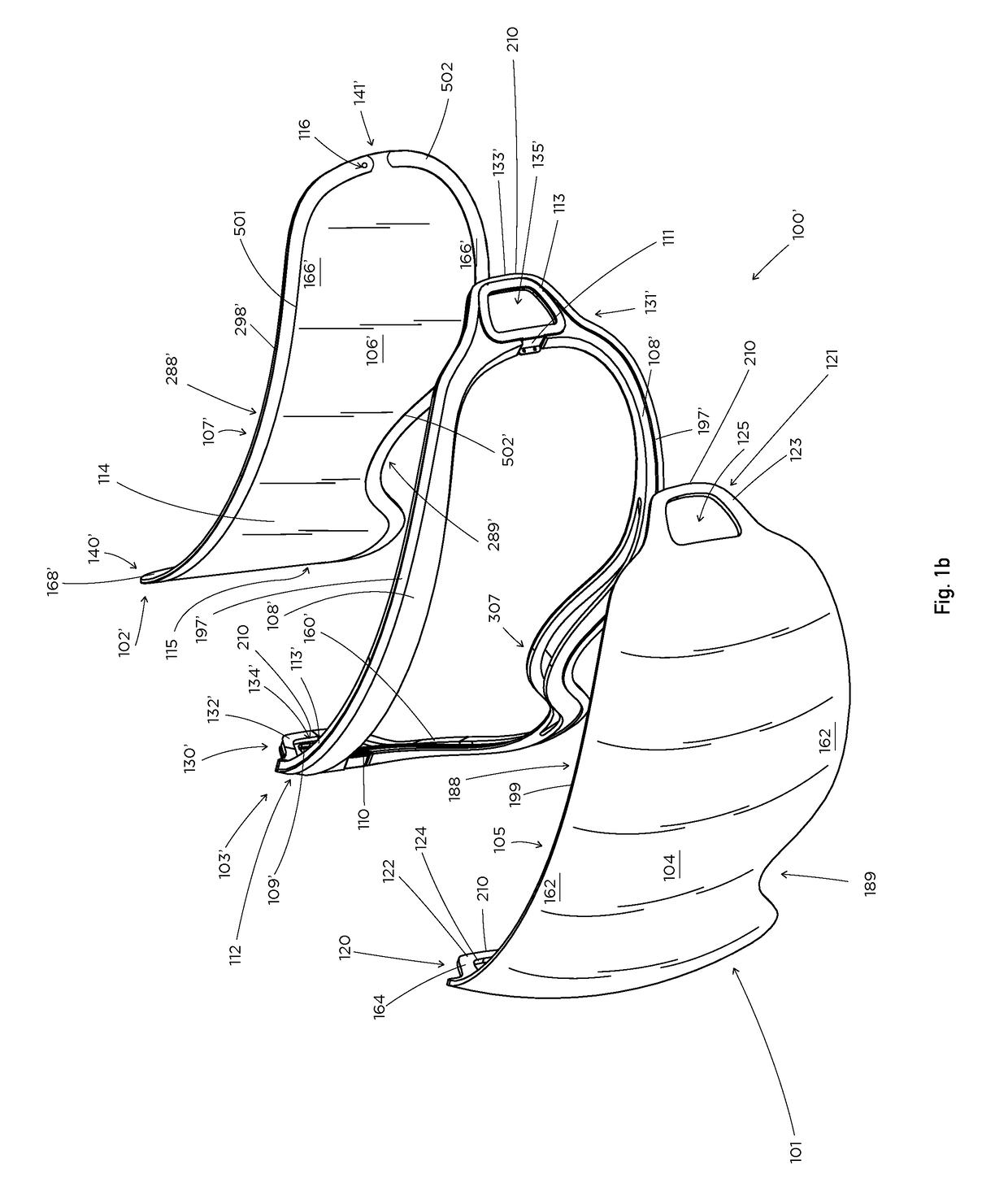

Electric pressure cooker with auxiliary heater

ActiveUS20180116438A1Boost cooking temperatureSimple structureCooking-vessel lids/coversPressure-cookersCookerEngineering

It discloses an electric pressure cooker with auxiliary heater, comprising pot cover subassembly, pot body subassembly, built-in heating plate subassembly and inner pot subassembly, characterized in that the said inner pot subassembly comprises inner pot, auxiliary heater and connector plug corresponding to auxiliary heater, the pot body is provided with connector socket corresponding to connector plug.

Owner:FOSHAN SHUNDE AIDE IND

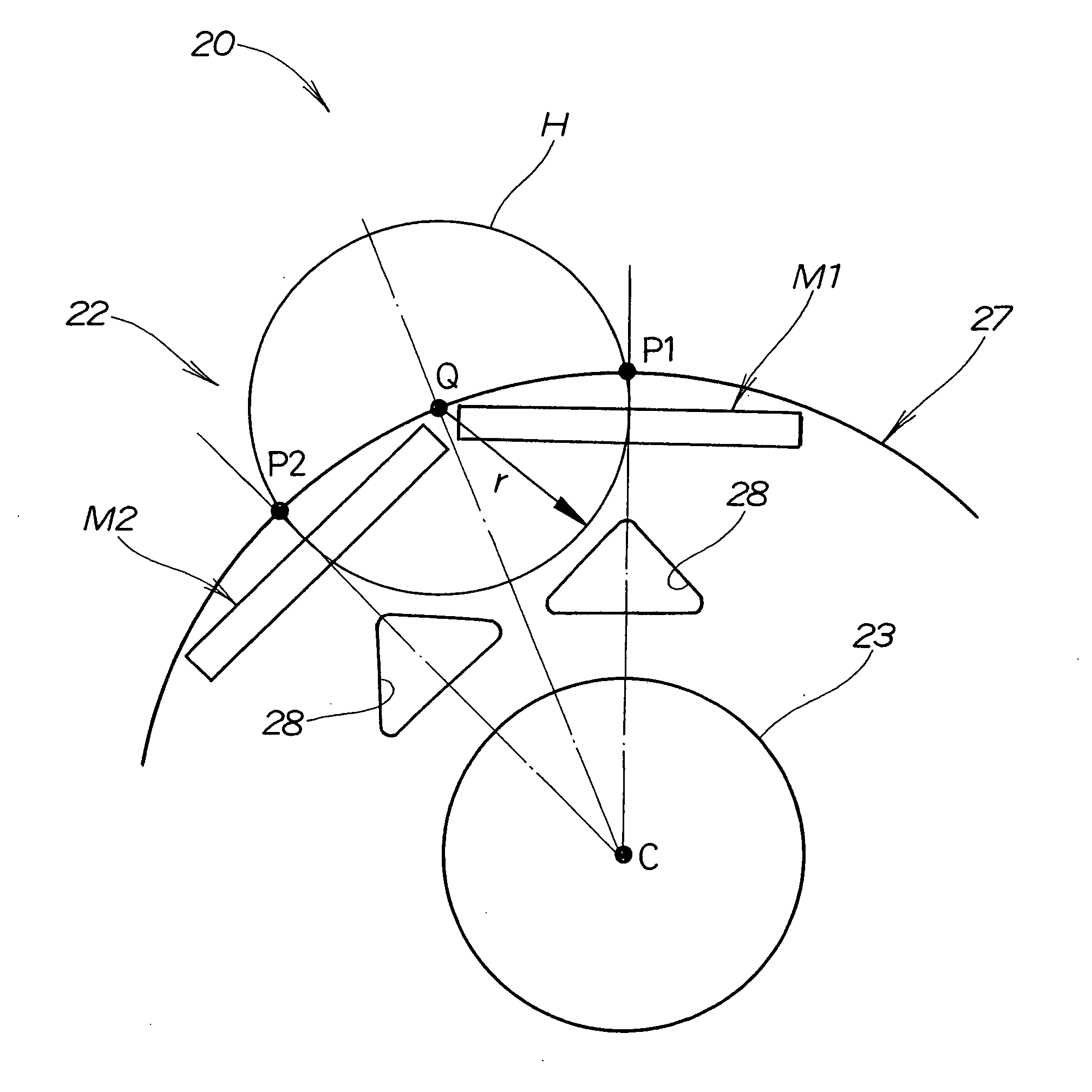

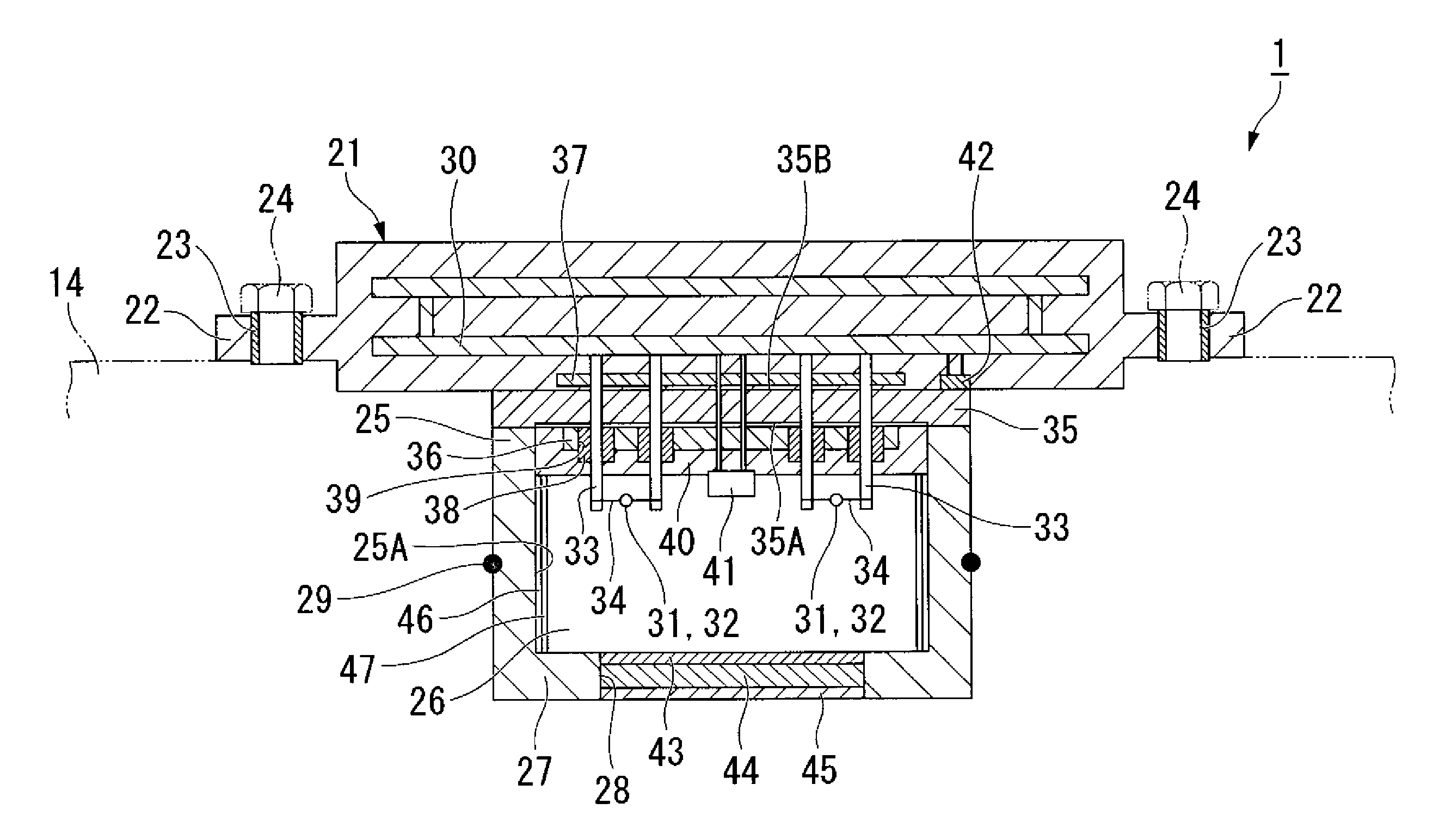

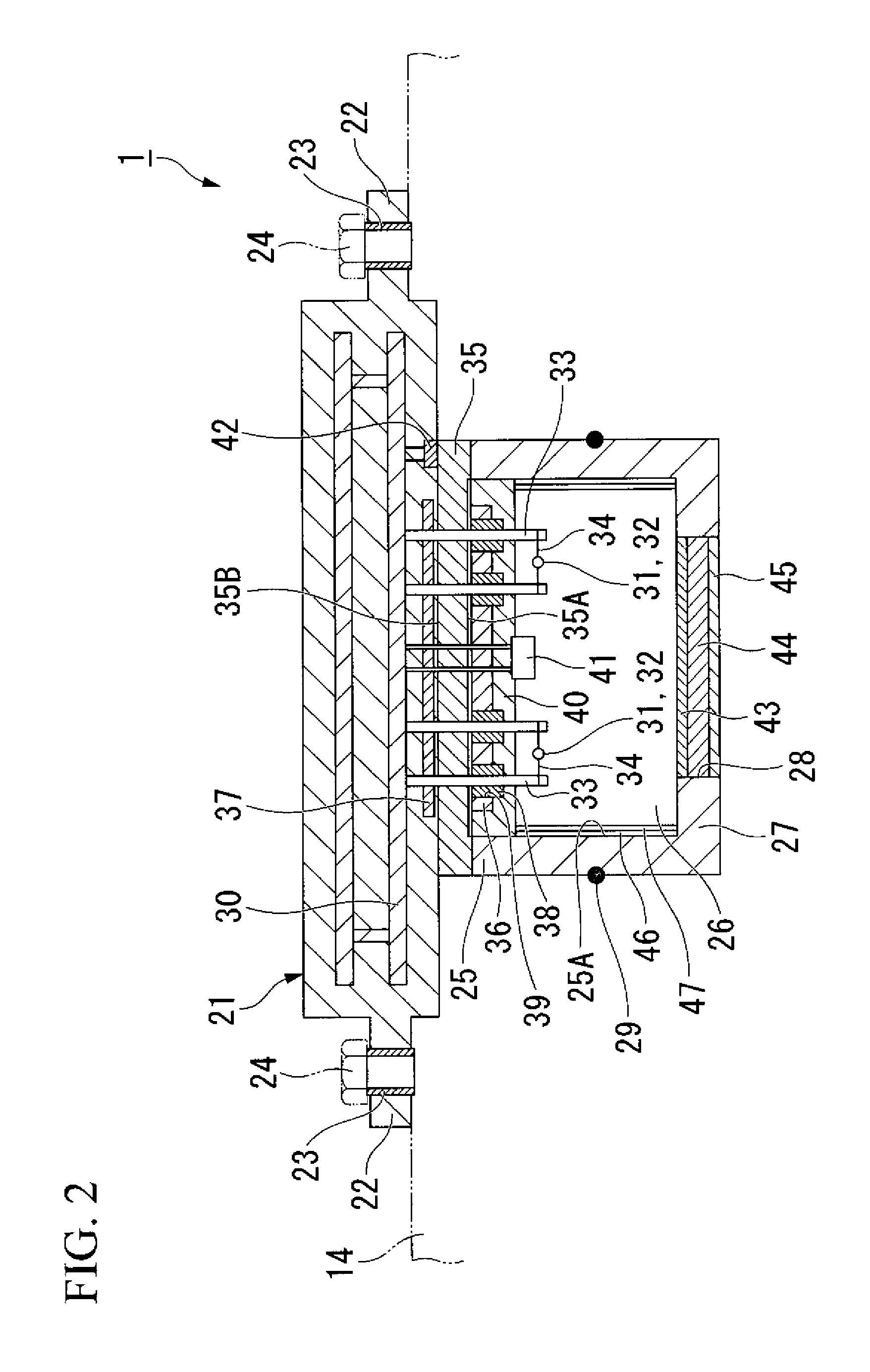

Electric motor

ActiveUS20050140235A1High magnetic flux densityReduce weightHybrid vehiclesSynchronous generatorsEngineeringMagnet

An electric motor including a stator with a plurality of coils wound around a ring-shaped iron core, and a rotor rotatably disposed inside the stator is provided. The rotor includes a rotor shaft and a yoke. The yoke is provided near its periphery with a plurality of plate-like permanent magnets arranged at equal pitches. Heat generated from the rotor is released through a plurality of air holes formed in the yoke between the rotor shaft and the permanent magnets.

Owner:HONDA MOTOR CO LTD

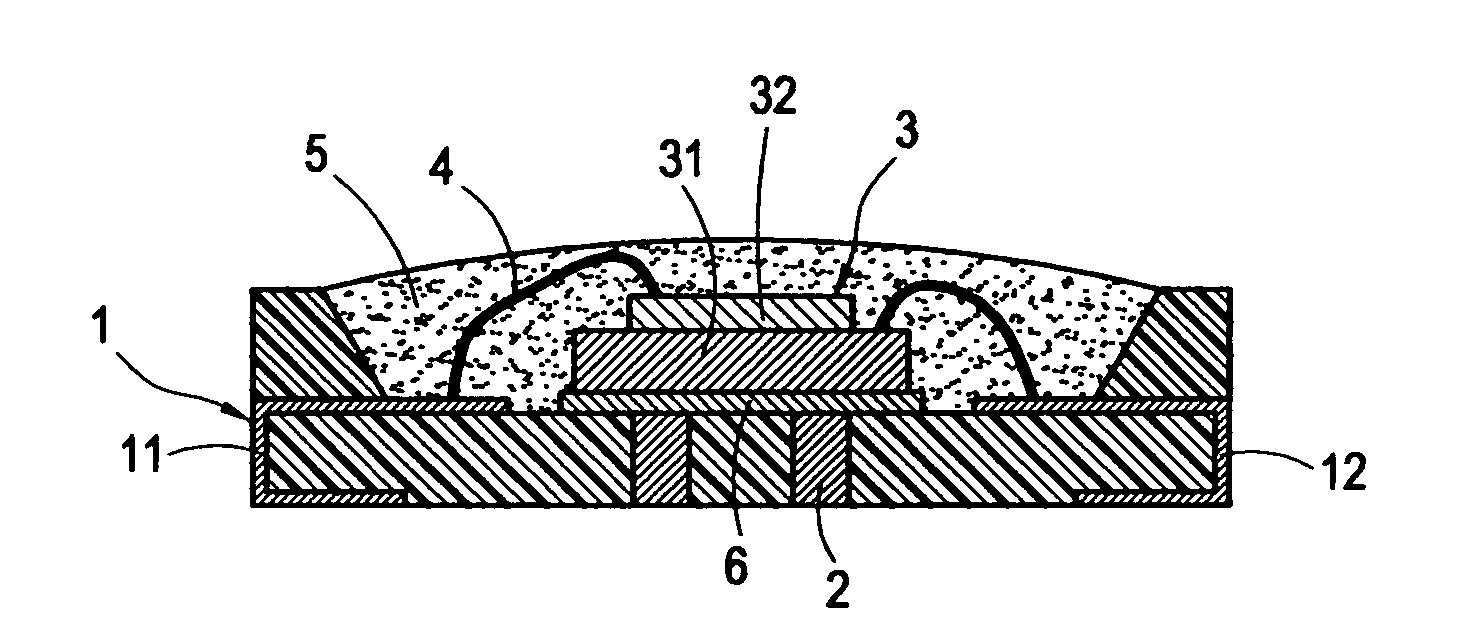

Structure of heat dissipation of implant type light emitting diode package and method for manufacturing the same

InactiveUS20070235739A1Rapid productionAccurately establishedSolid-state devicesCircuit thermal arrangementsHeat conductingEngineering

A structure of heat dissipation of implant type light emitting diode package having a heat column and a method of manufacturing the same include a substrate, a heat column, and a light emitting diode chip, and the heat column is implanted directly onto a predetermined position of the light emitting diode chip of the substrate and penetrated through both surfaces of a circuit board, and a distal surface of the heat column is coupled with the light emitting diode chip to form a heat conducting end, so that the operating heat produced by a light emitting diode can be dispersed from the package structure through the heat column, so as to achieve an optimal heat dissipating effect.

Owner:EDISON-OPTO

Electric motor

ActiveUS7122930B2Reduce weightMoment of inertia of the rotor is reducedHybrid vehiclesMagnetic circuit rotating partsEngineeringMagnet

An electric motor including a stator with a plurality of coils wound around a ring-shaped iron core, and a rotor rotatably disposed inside the stator is provided. The rotor includes a rotor shaft and a yoke. The yoke is provided near its periphery with a plurality of plate-like permanent magnets arranged at equal pitches. Heat generated from the rotor is released through a plurality of air holes formed in the yoke between the rotor shaft and the permanent magnets.

Owner:HONDA MOTOR CO LTD

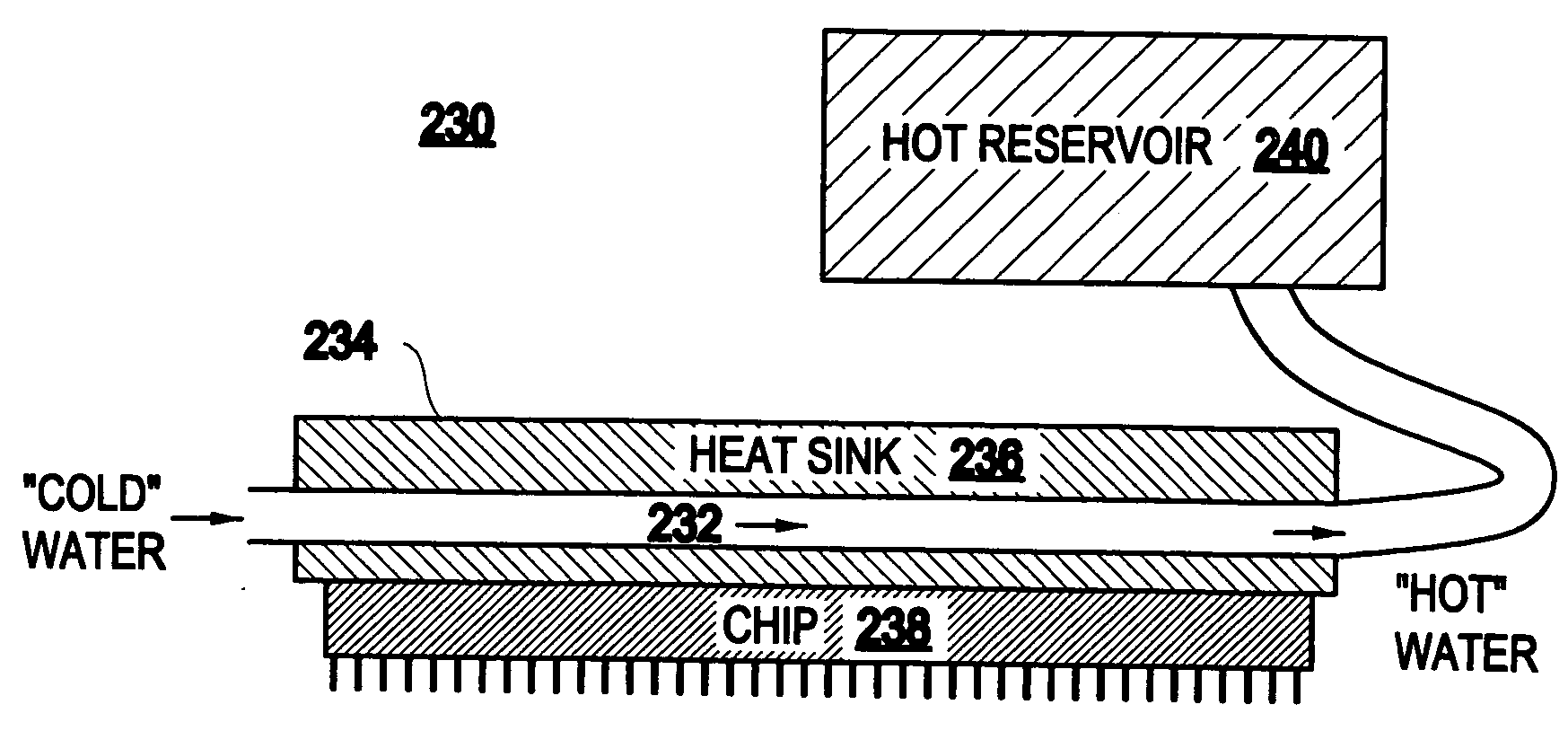

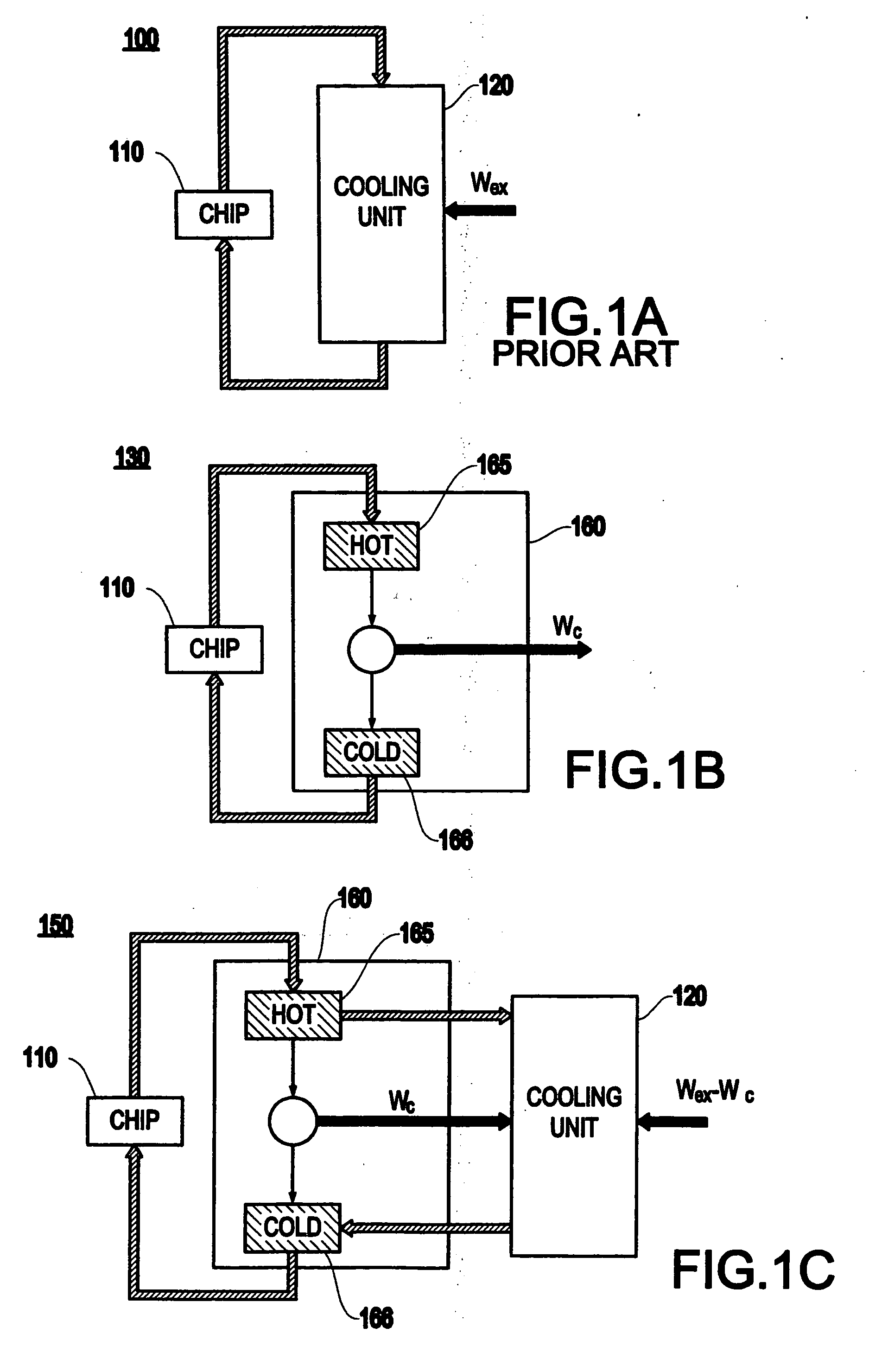

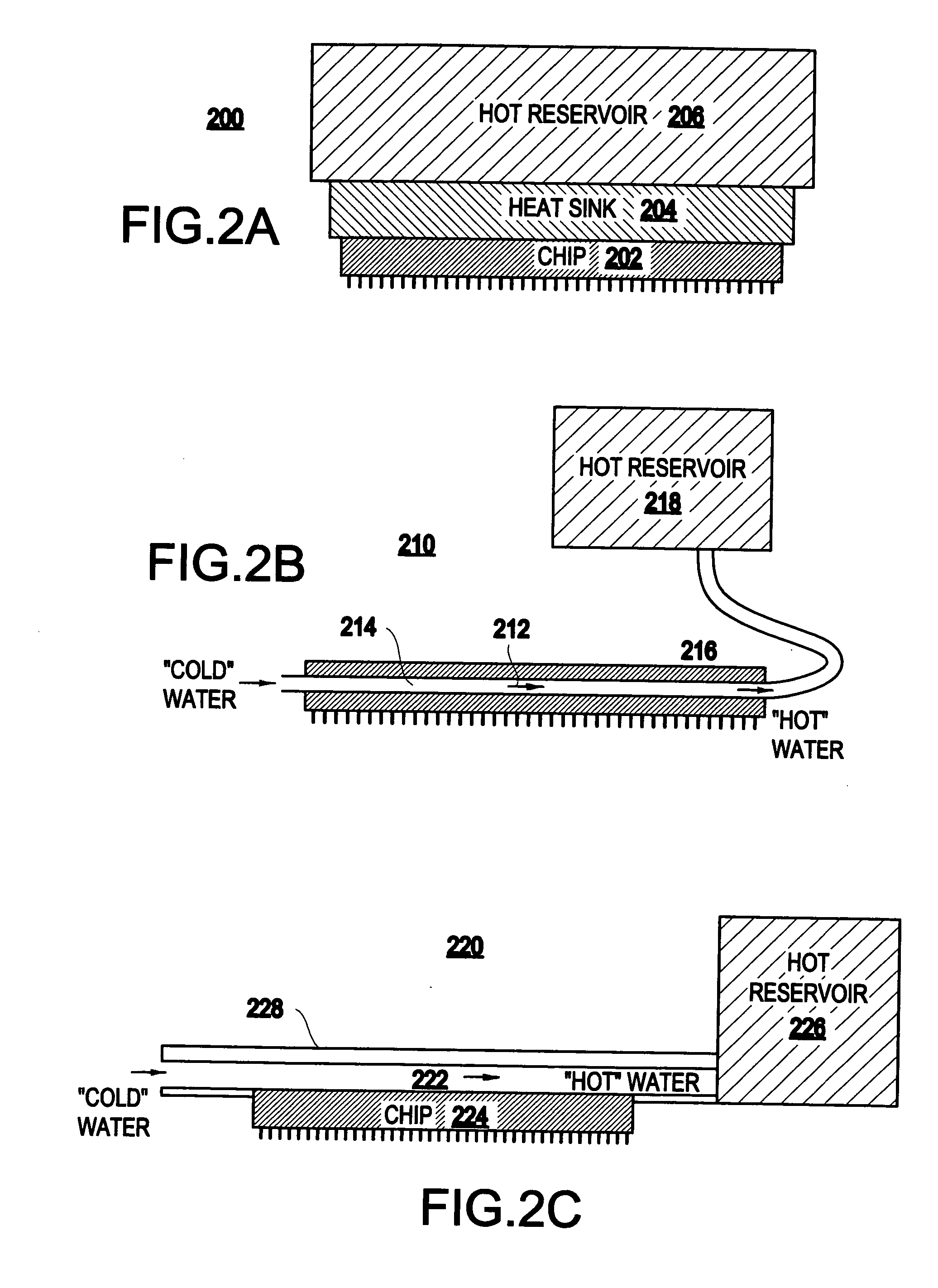

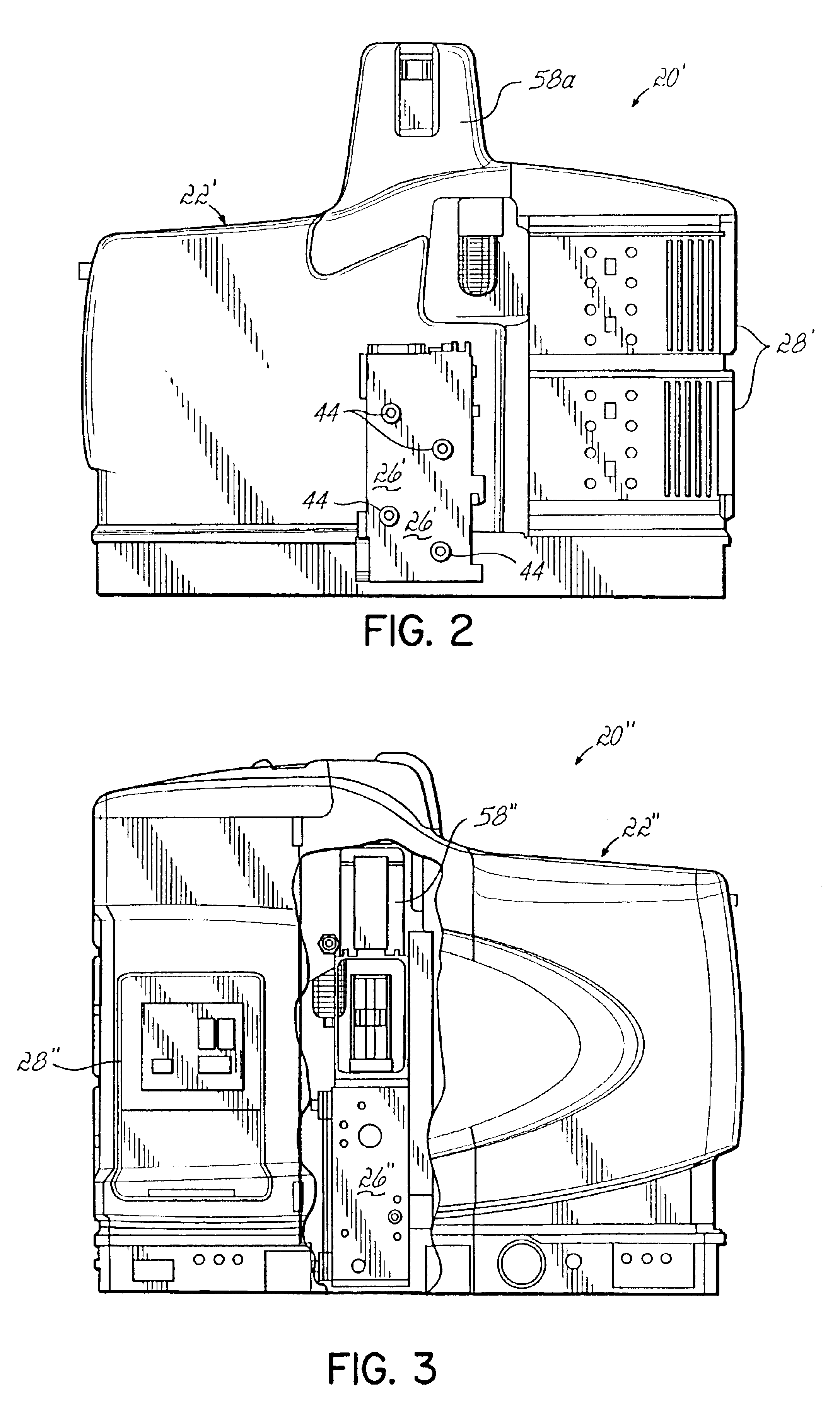

Method and apparatus for improving power efficiencies of computer systems

InactiveUS20050078447A1Improve power efficiencyImprove power densitySemiconductor/solid-state device detailsSolid-state devicesPower gridProcess engineering

An assembly (and method) including at least one microprocessor, includes a mechanism for recycling heat generated by at least one microprocessor to energy, and a mechanism for directing the heat from the at least one microprocessor to the mechanism for recycling heat. The energy generated by the mechanism for recycling the heat can be used to cool the at least one microprocessor or to supply an electric power grid.

Owner:IBM CORP

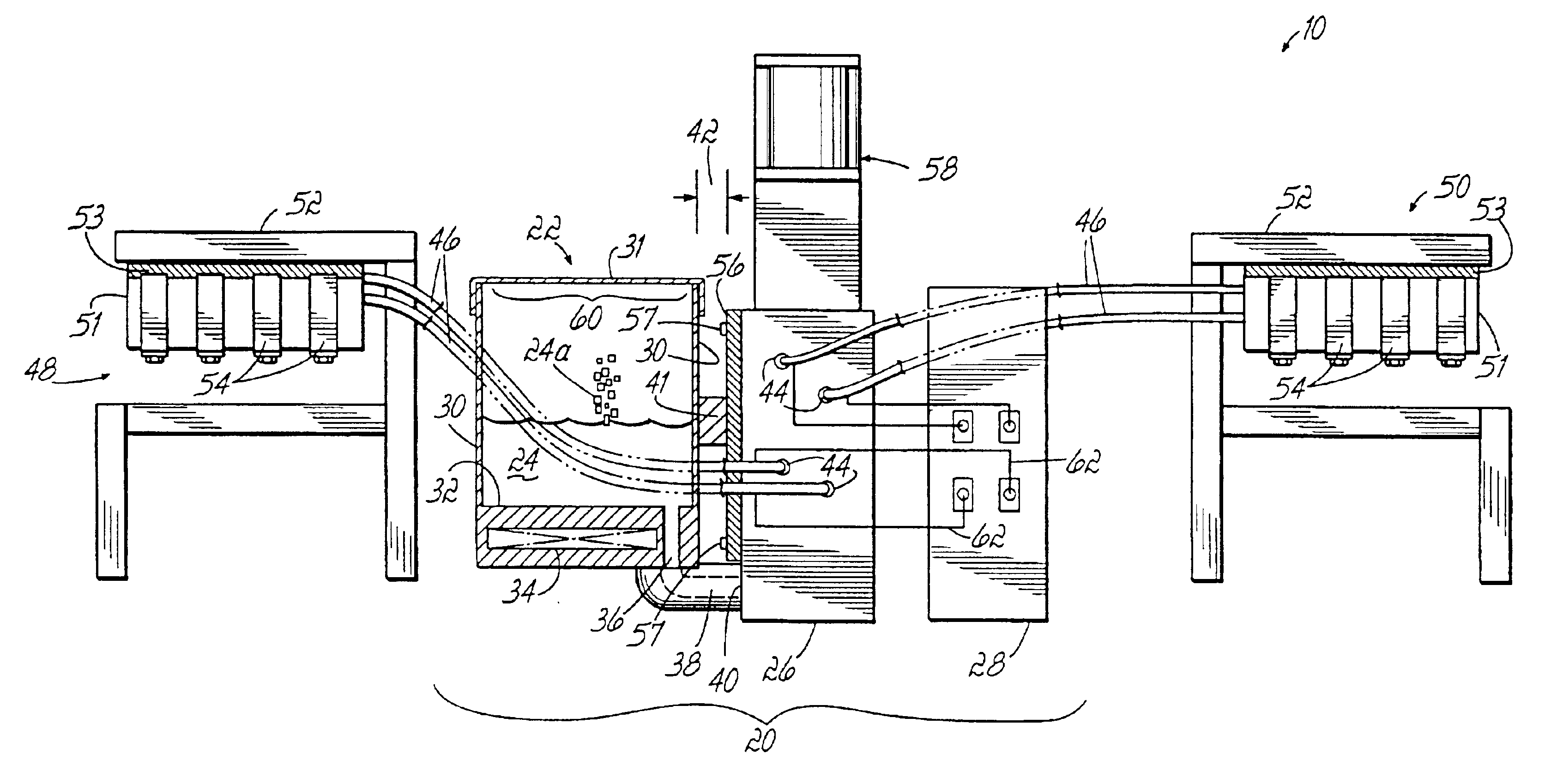

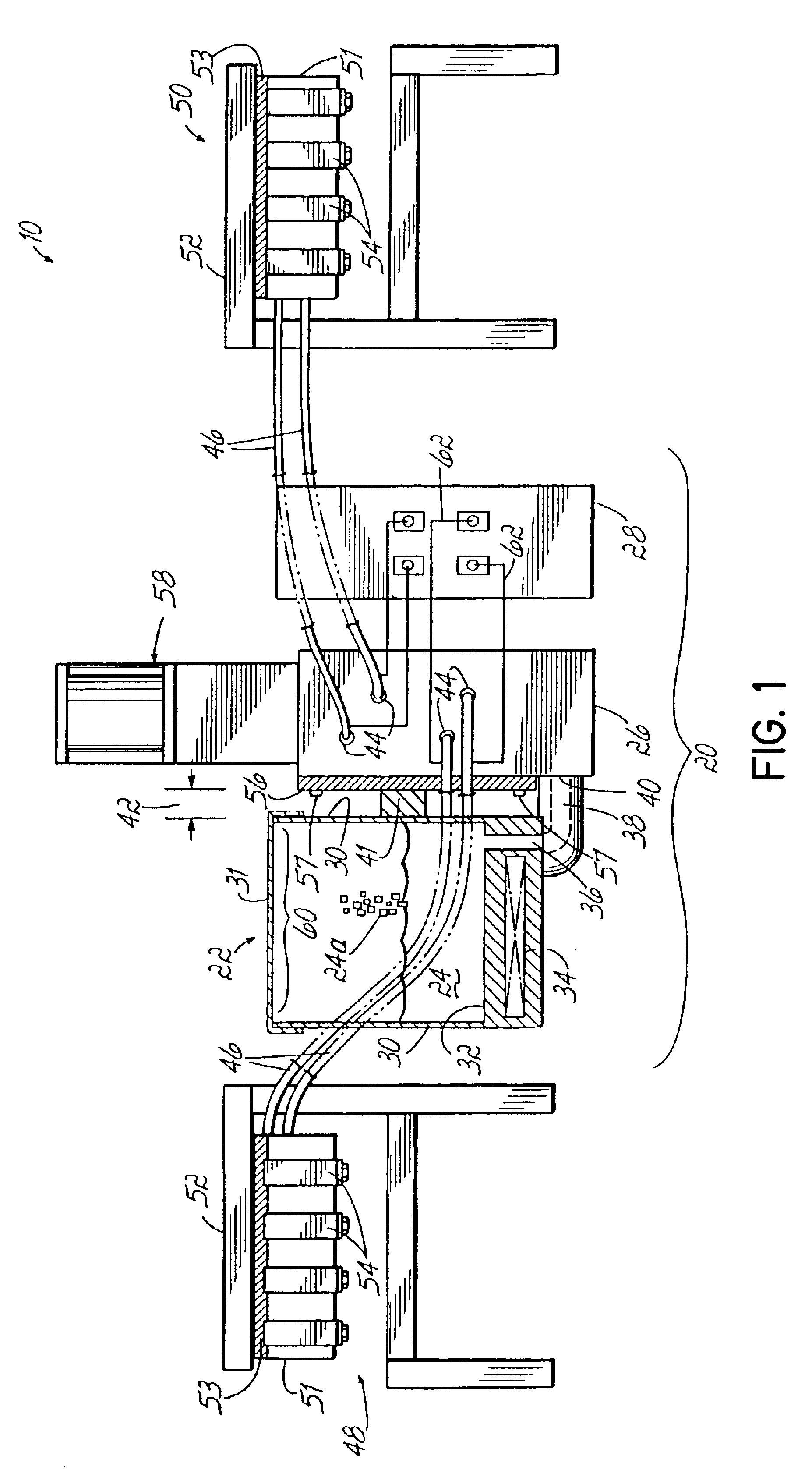

Hot melt adhesive system having centralized manifold and zone heating capability

InactiveUS6883684B2Improve accessibilityReduce space occupyLiquid surface applicatorsLarge containersEngineeringHot-melt adhesive

A dispensing unit for a hot melt adhesive system has a manifold centrally located within the dispensing unit to permit commonality between heated hoses of substantially the same length used to supply adhesive guns at either side of the dispensing unit. The dispensing unit also includes a manifold that is thermally isolated from the adhesive tank. The manifold has a heater that is independent of the tank heater for more precise temperature control of adhesive flowing through the manifold. A pump coupled to the manifold is located external to the tank and is heated by the manifold heater.

Owner:NORDSON CORP

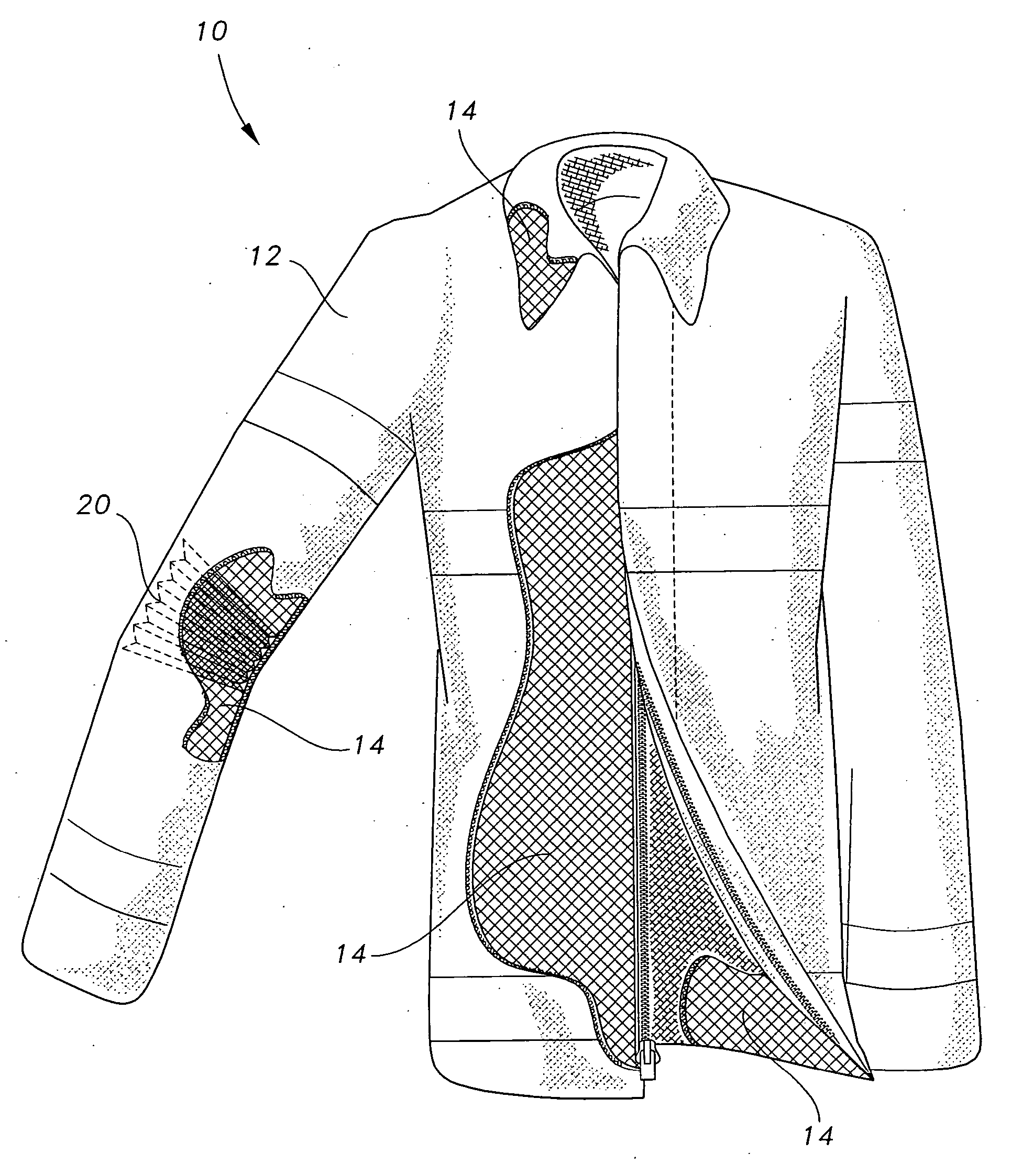

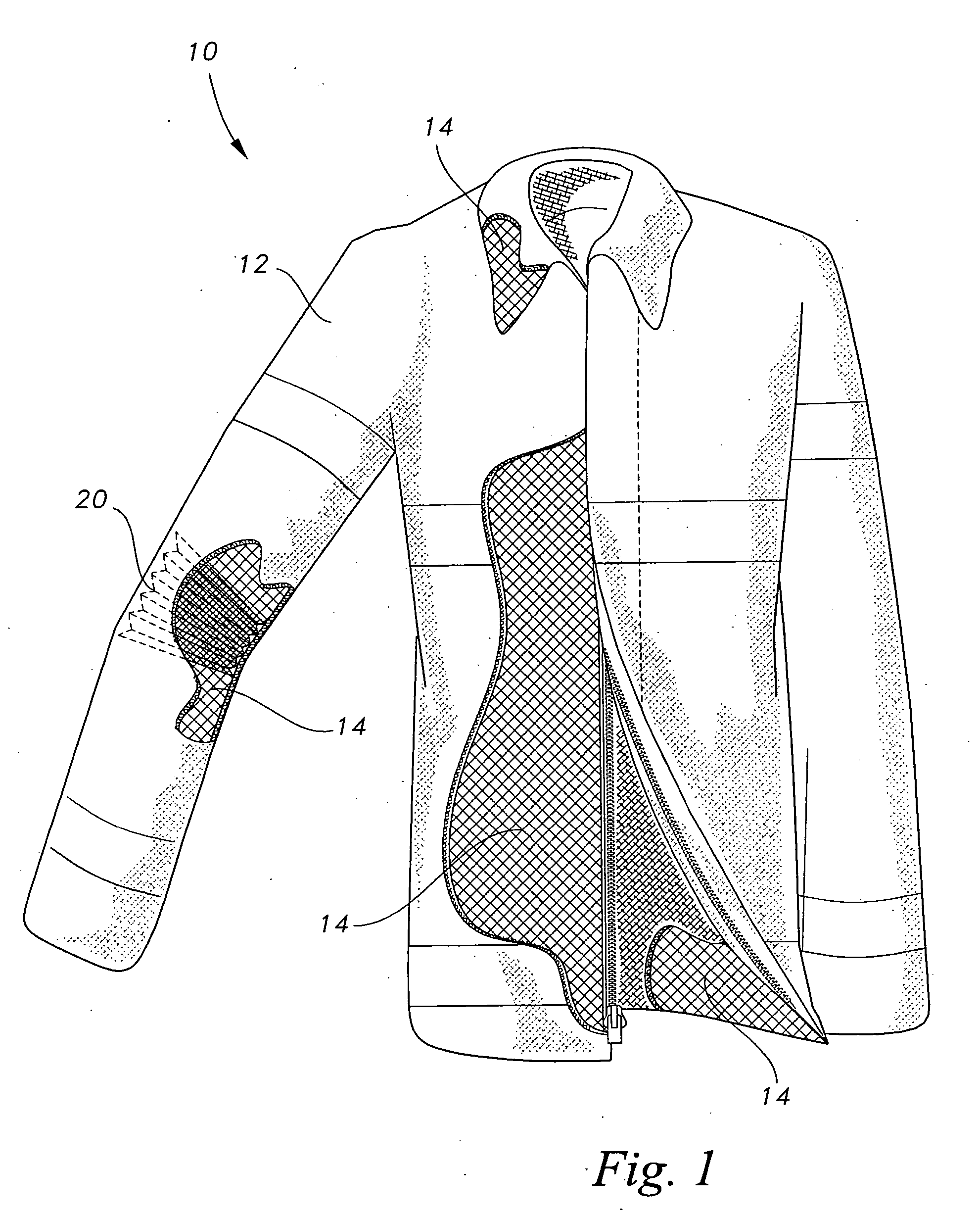

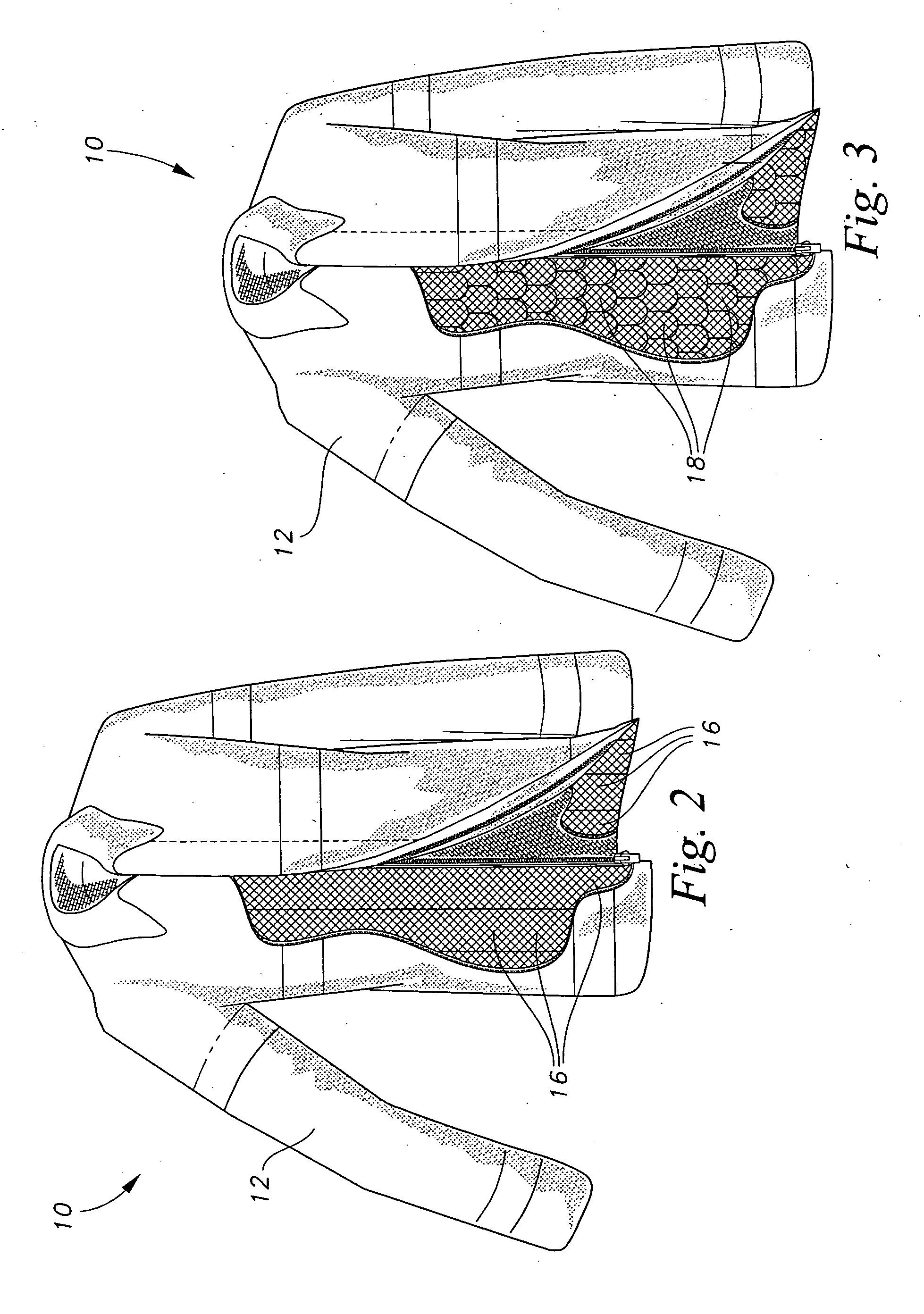

Hazardous duty garments

InactiveUS20050251900A1Permit free movementEasy to checkChemical protectionHeat protectionHeat resistanceThermal insulation

An improved hazardous duty garment system includes an abrasion-resistant, flame-resistant and heat-resistant outer shell, a moisture barrier attached inside the outer shell, and a thermal liner attached to the outer shell and the moisture barrier. The thermal liner includes at least one layer of thermal insulation attached to a layer of a metal screen thermal barrier. The metal screen layer may be made from a plurality of panels and fitted closely together, or a plurality of shingles. The metal screen panels are individually removable and replaceable. The metal screen provides superior heat dissipation properties and superior tolerance of direct heat.

Owner:HARLACKER JOHN A

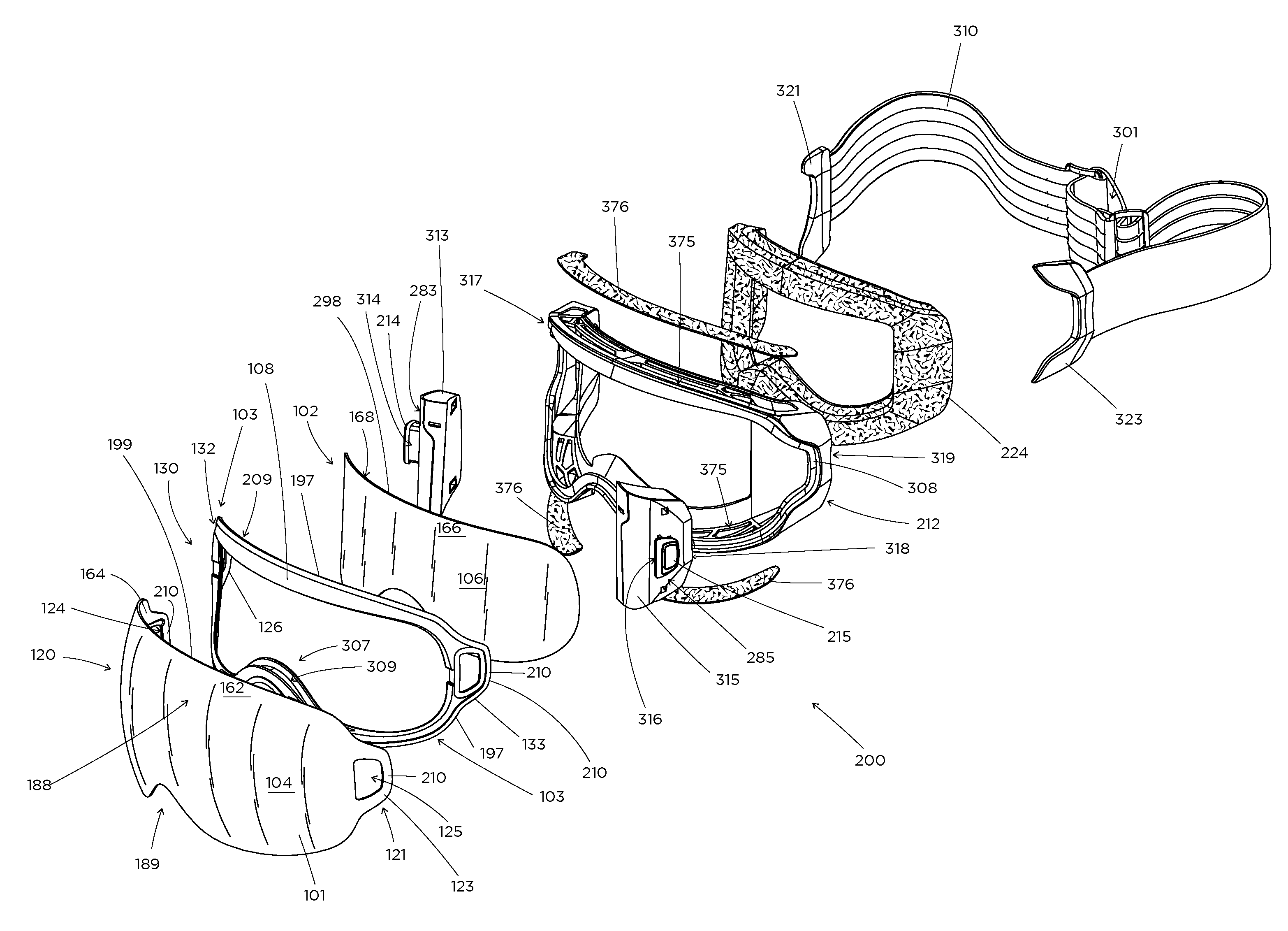

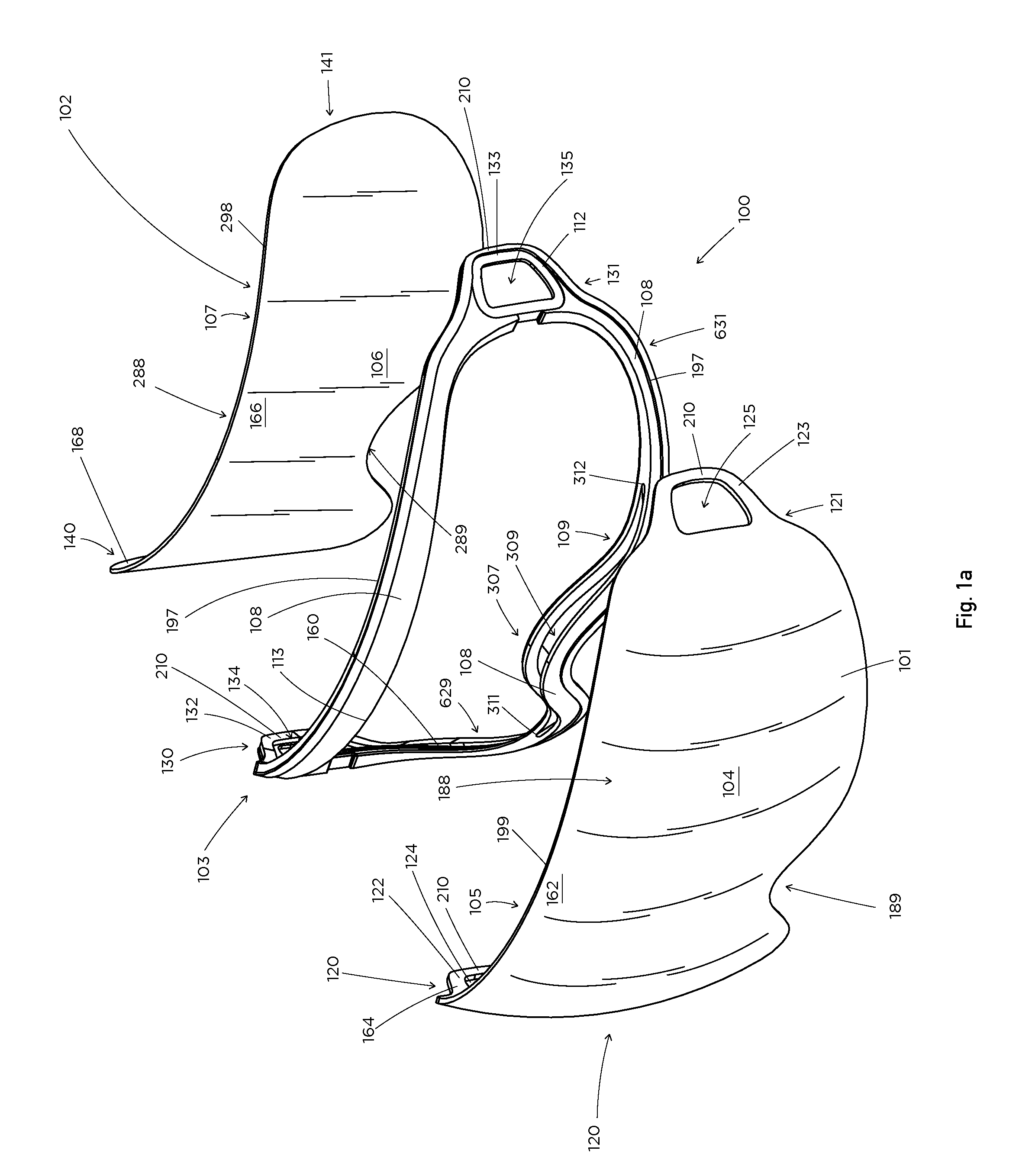

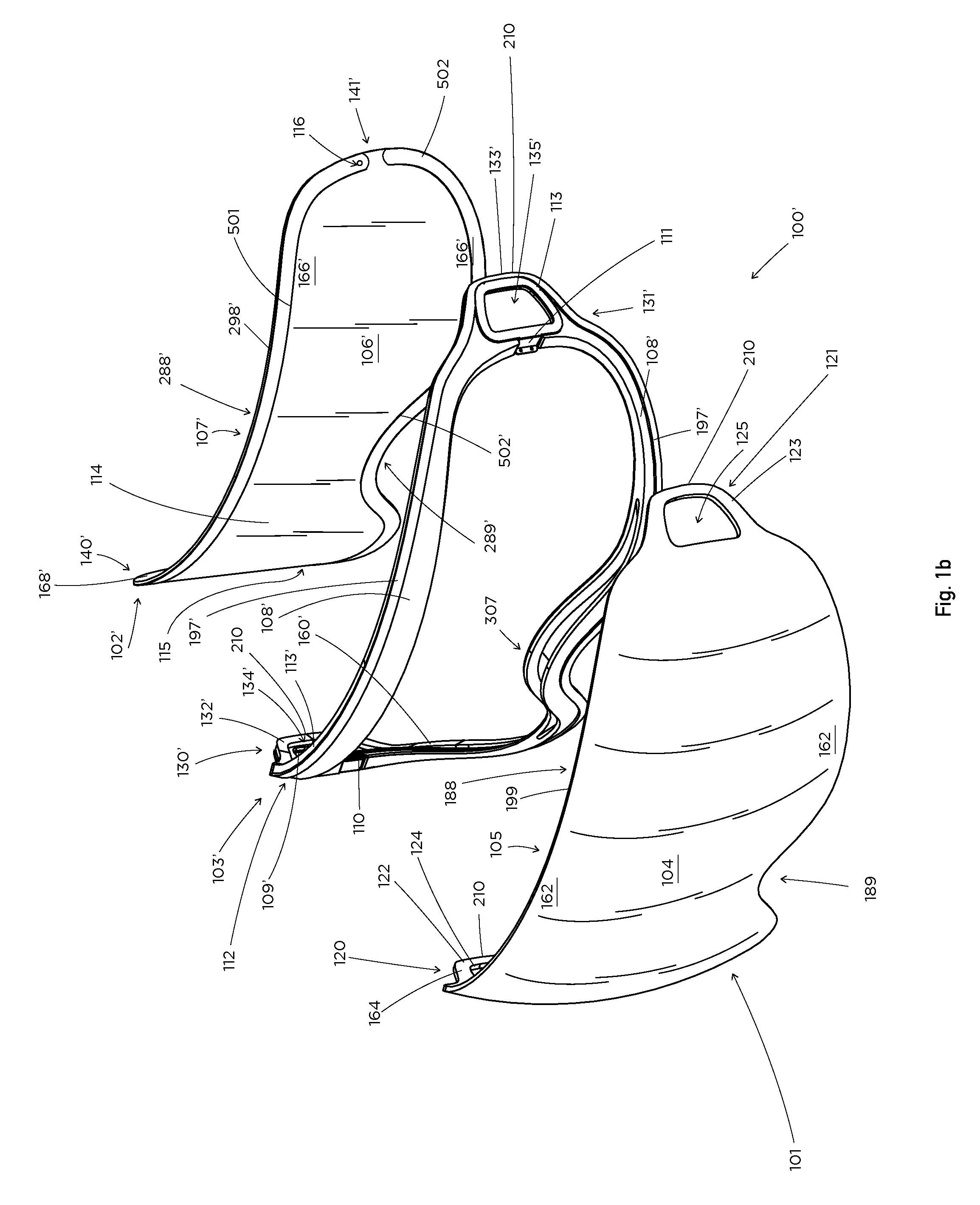

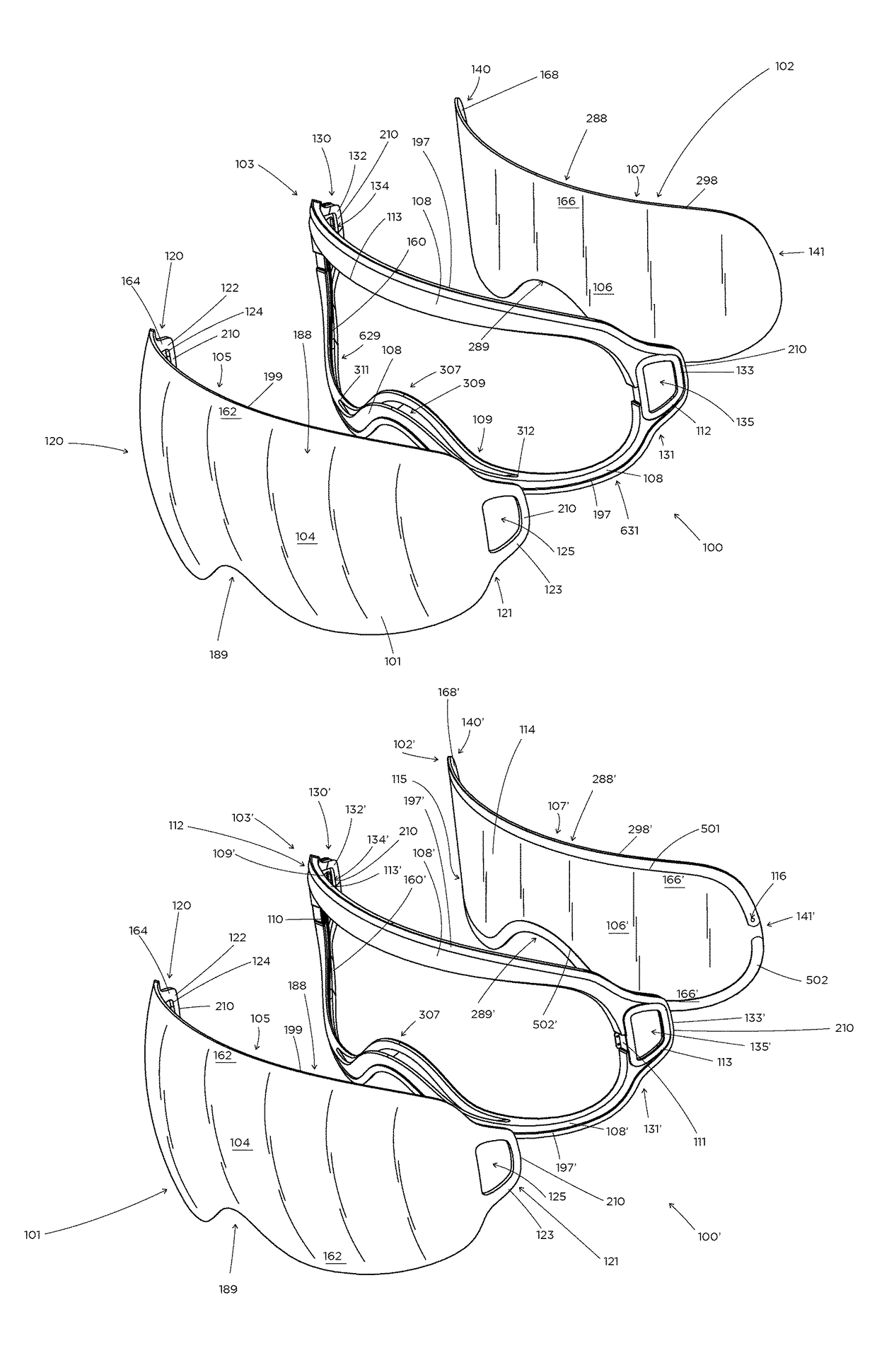

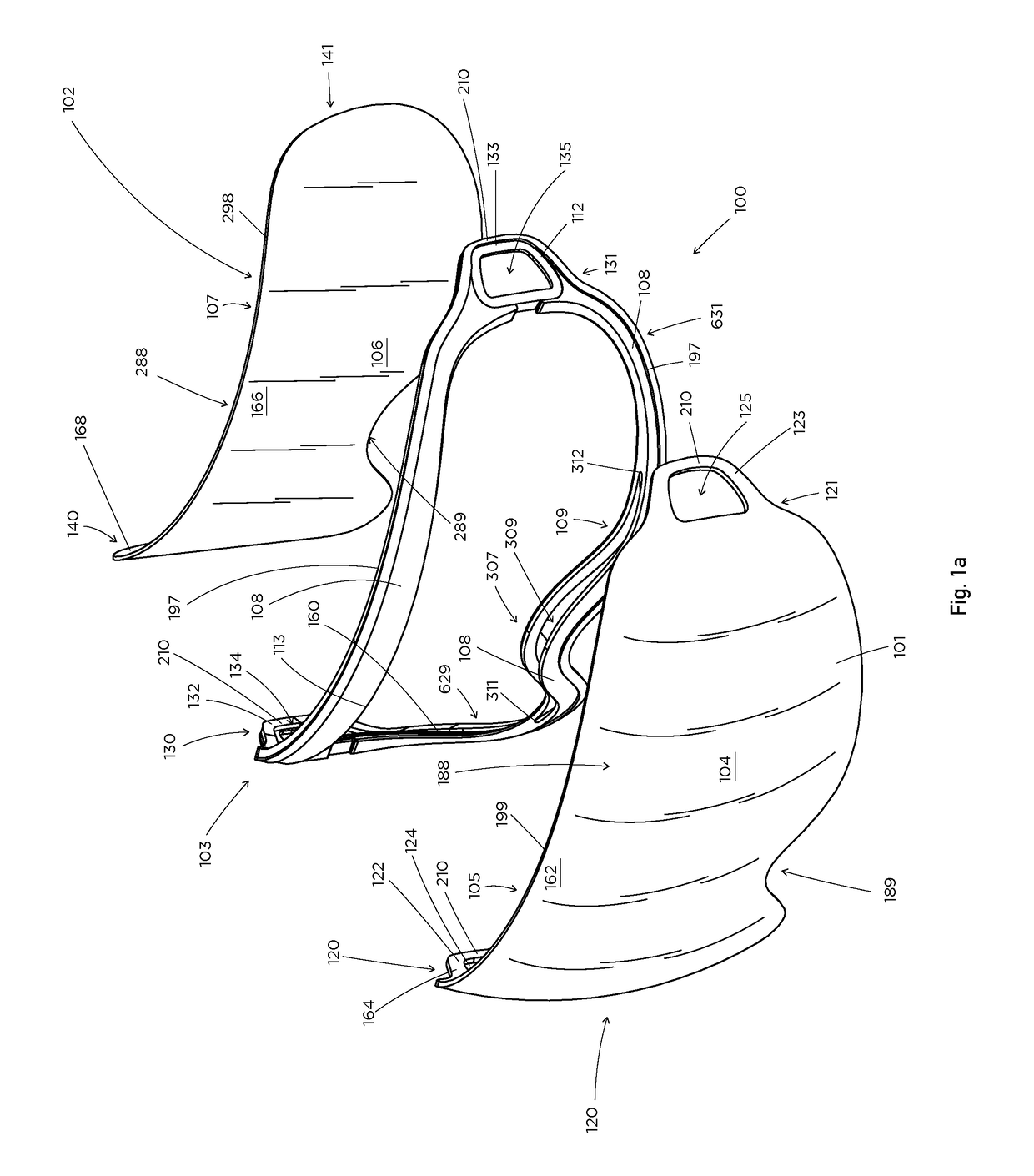

Multi-pane, multi-geometry goggle eye-shield

ActiveUS20160070120A1Easy and cost-effective to manufactureWide range of visionGogglesNon-optical adjunctsIndium tin oxideEye closure

A multi-pane, multi-geometry eye-shield adapted to be installed into a frame of an eye-shield, such as a goggle for protecting user's eyes, comprising a spherical anterior outer eye-shield member, a cylindrical posterior inner eye-shield member, an irregular-shaped gasket member between the anterior and posterior eye-shield members forming a water-tight and air-tight semi-annular space therebetween. The posterior cylindrical inner eye-shield member may further be adapted for heating to reduce condensation comprising a thin-film, electrically conductive heating element, such as Indium Tin Oxide (ITO), and electrical contact members to connect the thin-film heating element to a power source.

Owner:ABOMINABLE LABS LLC +1

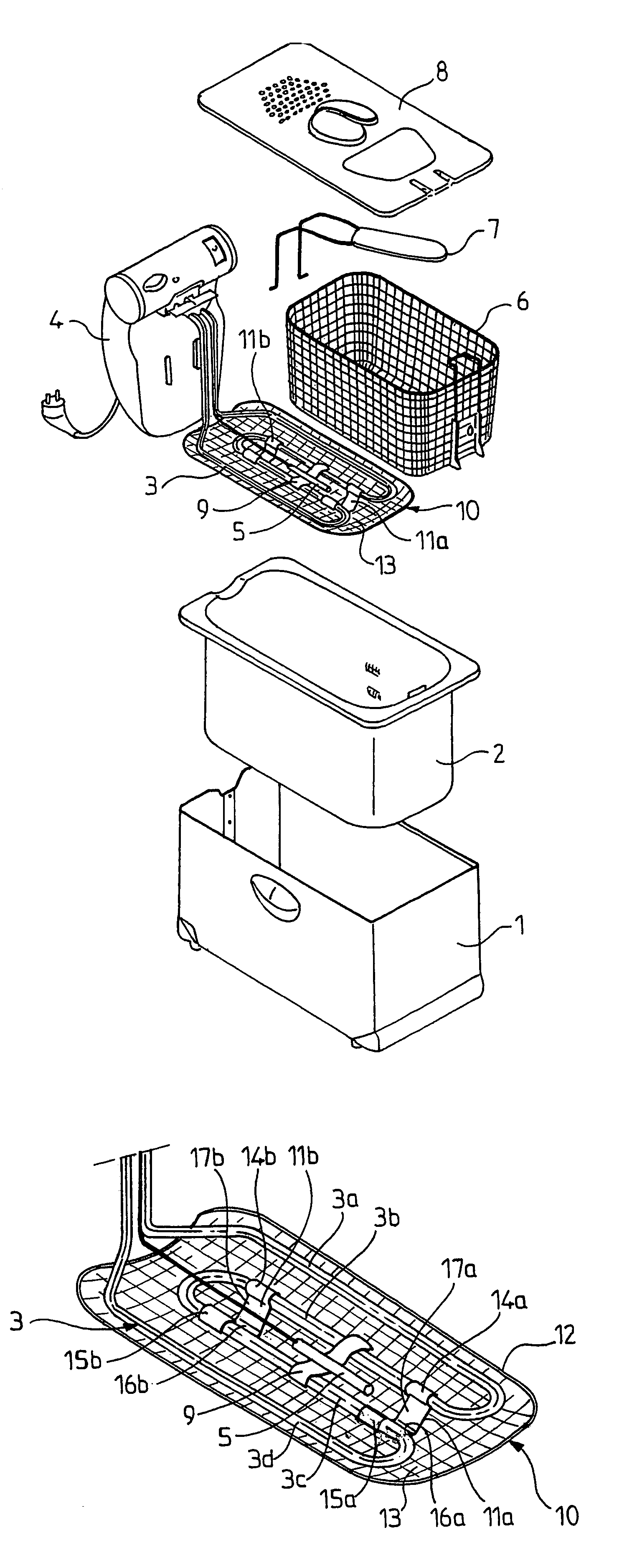

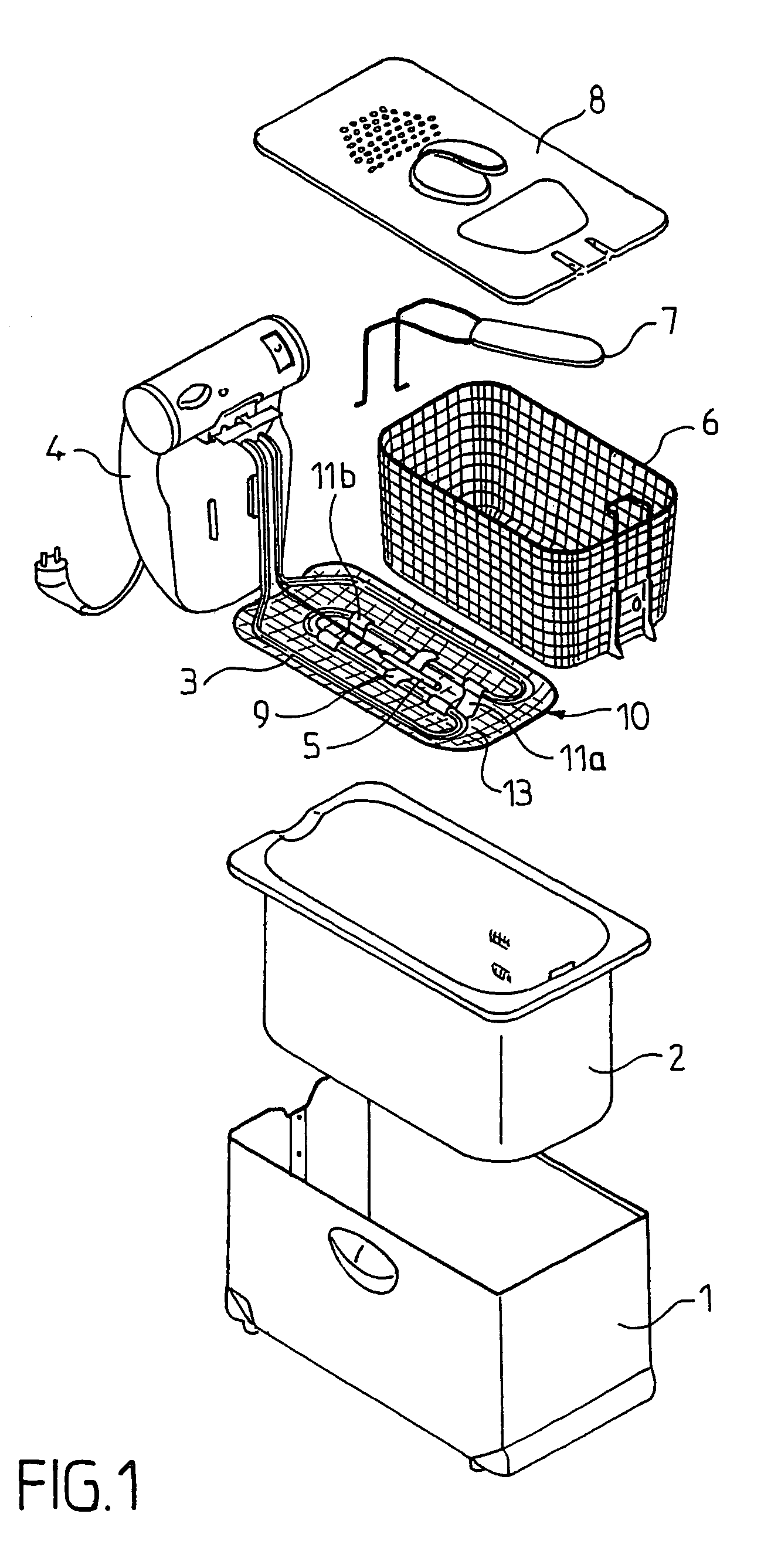

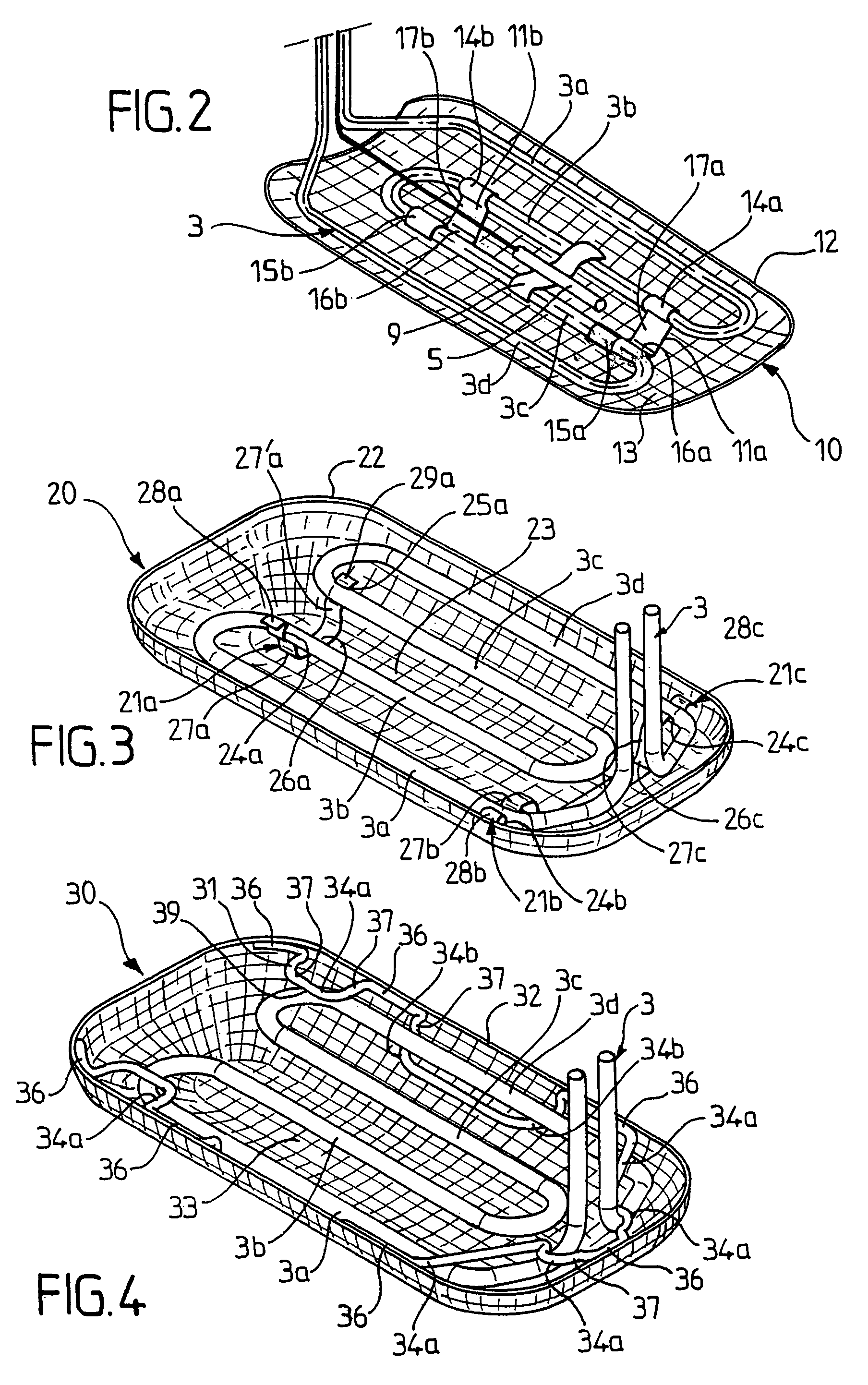

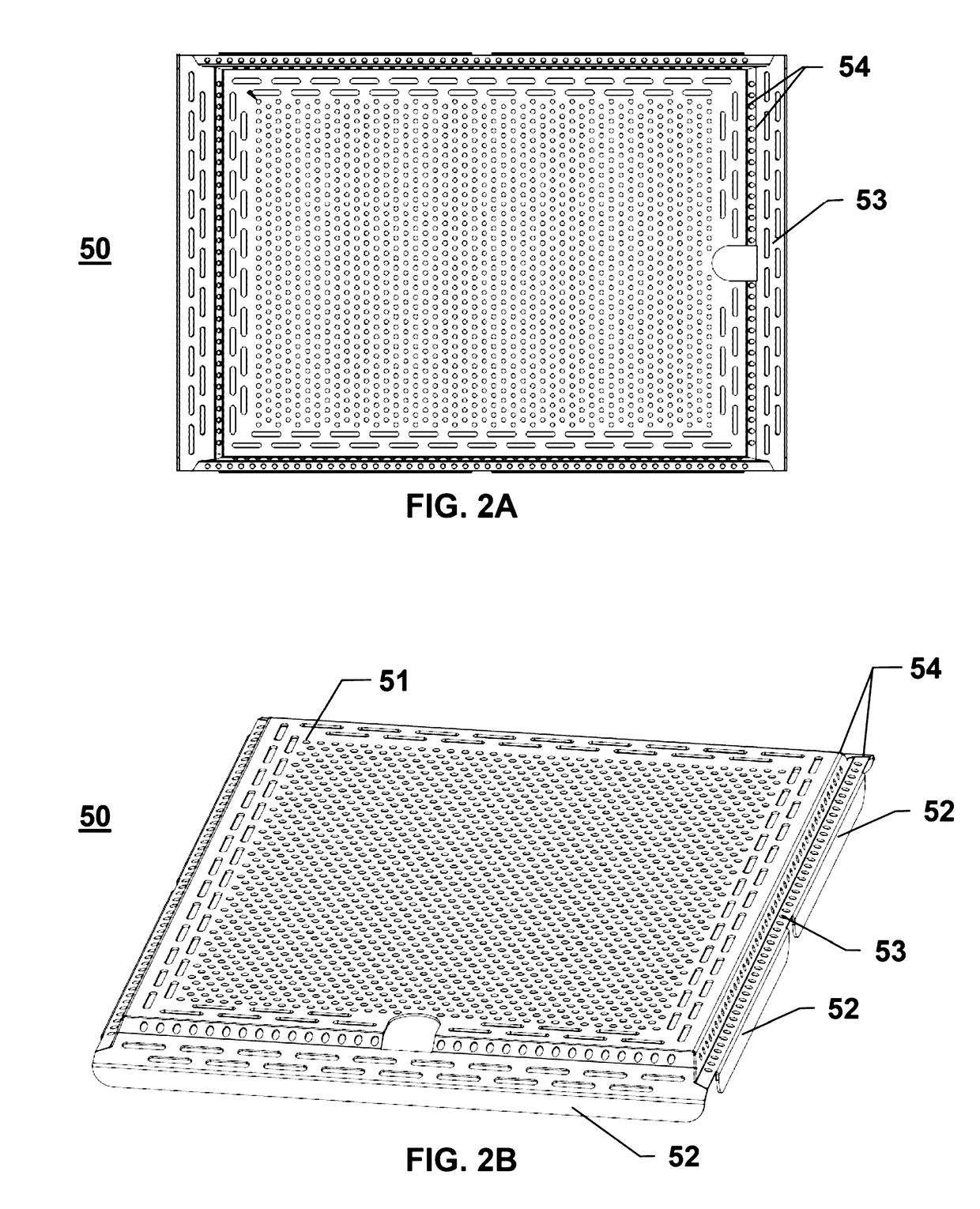

Device for filtration of the frying bath in an electric fryer having an immersed heating resistor

ActiveUS7098427B2Prevent degradationSimple wayElectric heating for furnacesDeep fat fryersFiltrationFuel tank

A device for filtering the frying bath of an electric fryer having a heating resistor that is immersed in a frying bath in a tank during frying, the device including: a filter screen adapted to extend beneath the immersed electric resistor; and at least one holding element for connecting said screen to the immersed electric resistor. An electric fryer composed of; a tank provided to receive a frying bath; an electric heating resistor provided to be immersed in the frying bath; and the device described above.

Owner:SEB SA

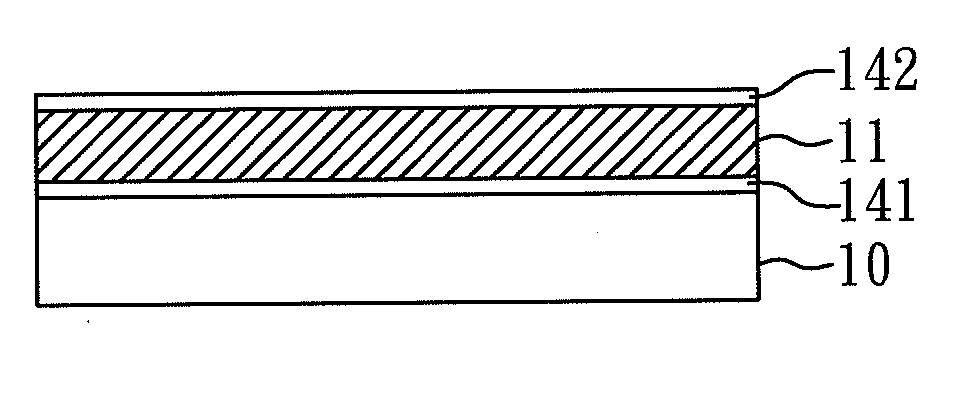

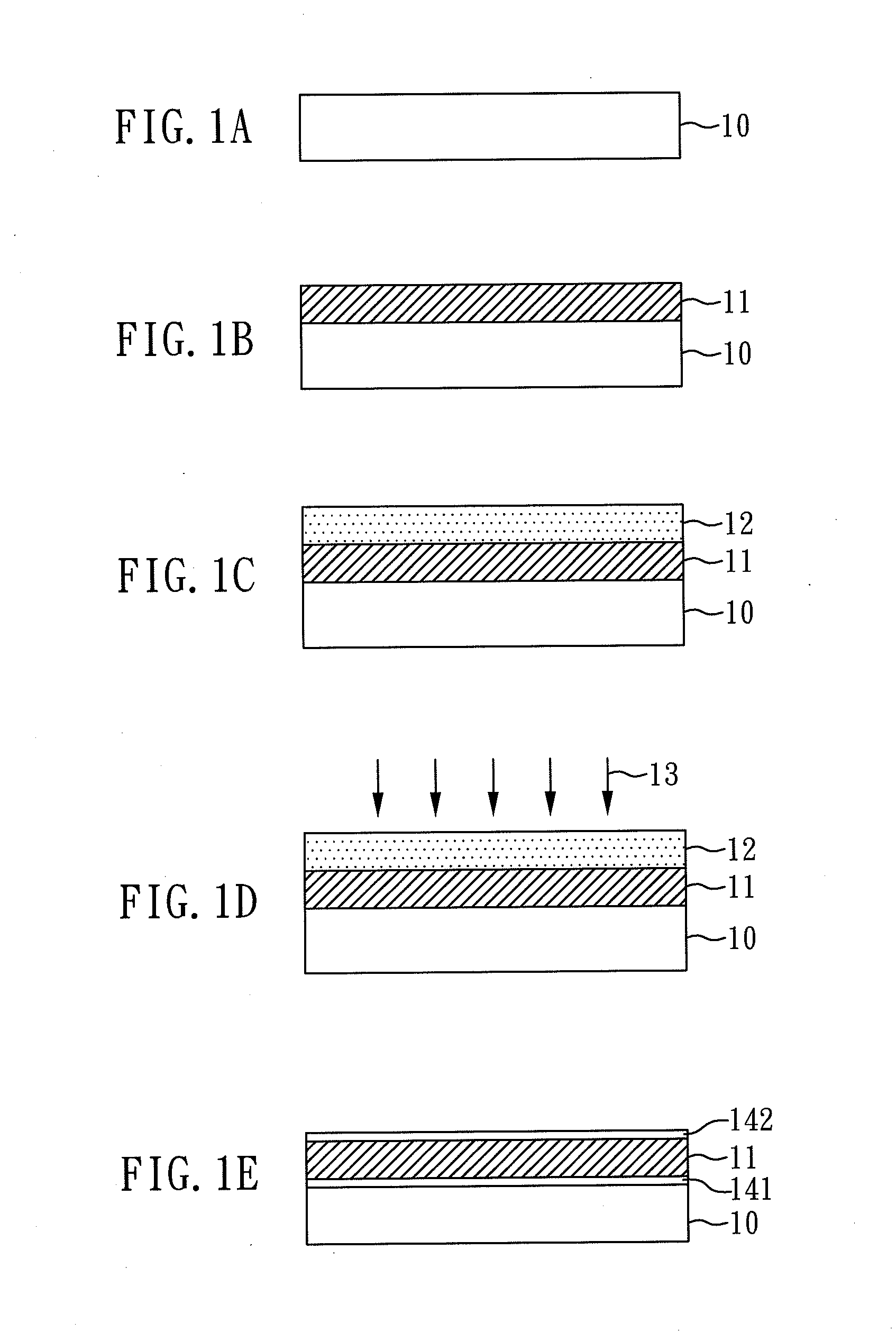

Process of preparing graphene by low-frequency electromagnetic wave

InactiveUS20130202813A1Large productionShort processing timeMaterial nanotechnologyGrapheneThermal energyCarbon source

The present invention relates to a process of inducing grapheme by low-frequency electromagnetic wave, which includes the following steps: (A) providing a substrate; (B) optionally forming a metal layer on the substrate; (C) providing a carbon source to form a carbon-containing layer locating on the metal layer; and (D) performing a treatment of the carbon-containing layer formed on the metal layer by using low-frequency electromagnetic wave, wherein the low-frequency electromagnetic wave is provided by microwave device. The electromagnetic energy from the microwave field device is converted to thermal energy by microwave absorber (for example, SiC) as a media to directly heat the carbon-containing layer, so that carbon atoms get kinetic energy to form grapheme layers on the surface of the metal layer and between the metal layer and the substrate.

Owner:NATIONAL TSING HUA UNIVERSITY

Gas sensor

ActiveUS20080092628A1Easy to produceHeating directlyAnalysing fluids using sonic/ultrasonic/infrasonic wavesUsing mechanical meansEngineeringGas concentration

This gas sensor is provided with: a detection element that measures a gas concentration of a detection target gas contained in an examination gas; a substrate having a heating element; and a supporting member that is fixed to the substrate, protrudes from the heating element, and supports the detection element.

Owner:HONDA MOTOR CO LTD

Gas sensor

ActiveUS7827847B2Heating directlyPrevented from reachingAnalysing fluids using sonic/ultrasonic/infrasonic wavesUsing mechanical meansEngineeringGas concentration

This gas sensor is provided with: a detection element that measures a gas concentration of a detection target gas contained in an examination gas; a substrate having a heating element; and a supporting member that is fixed to the substrate, protrudes from the heating element, and supports the detection element.

Owner:HONDA MOTOR CO LTD

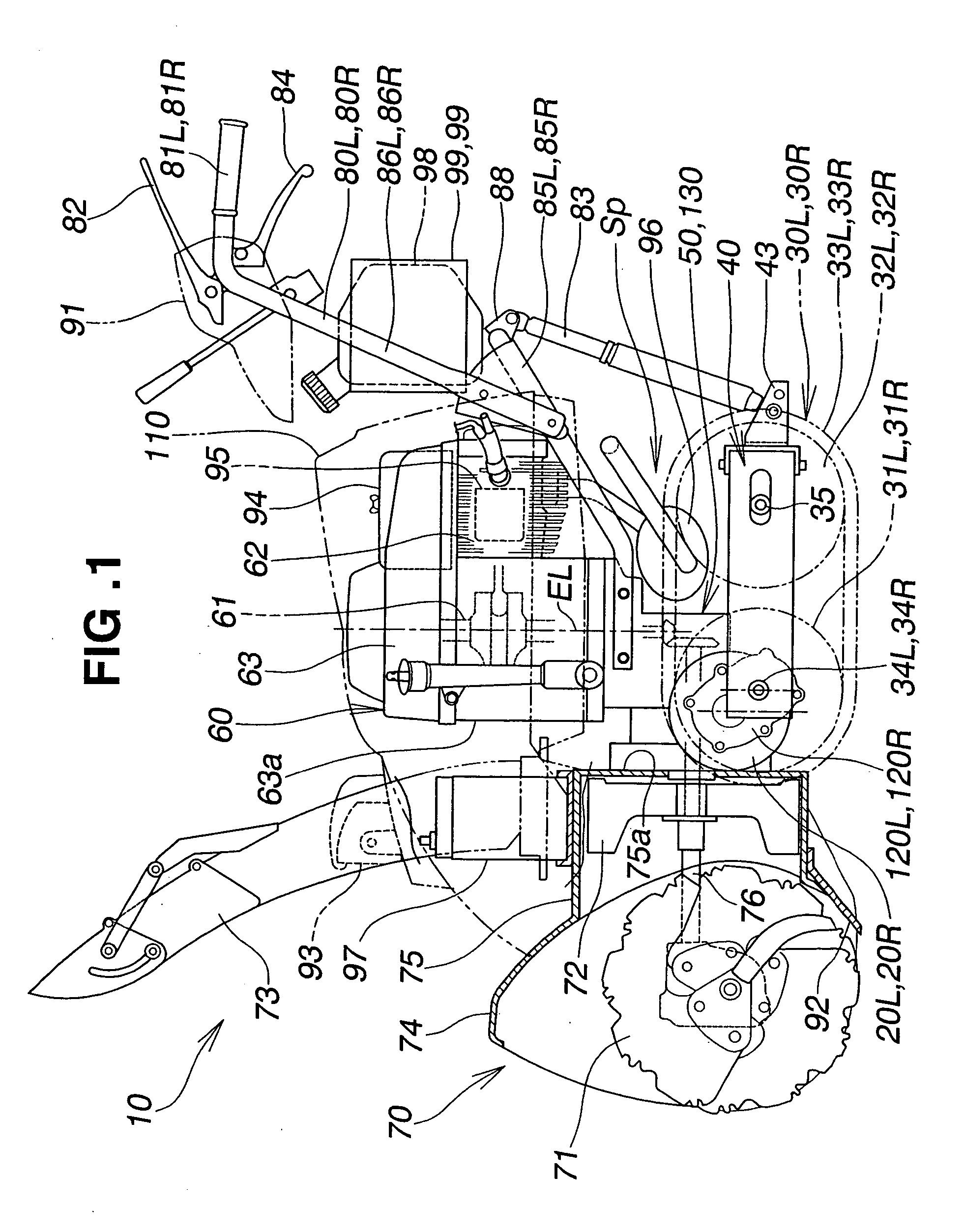

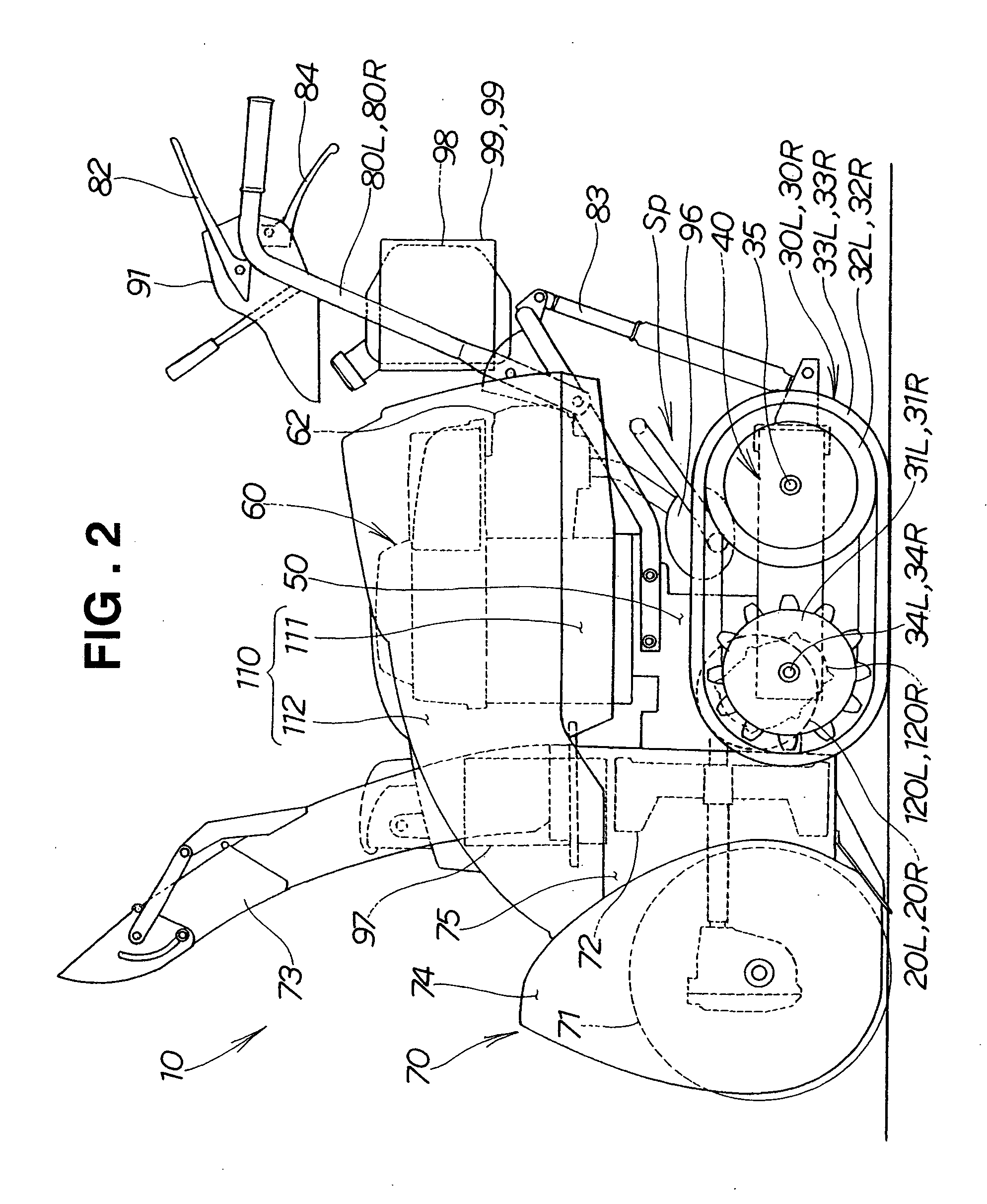

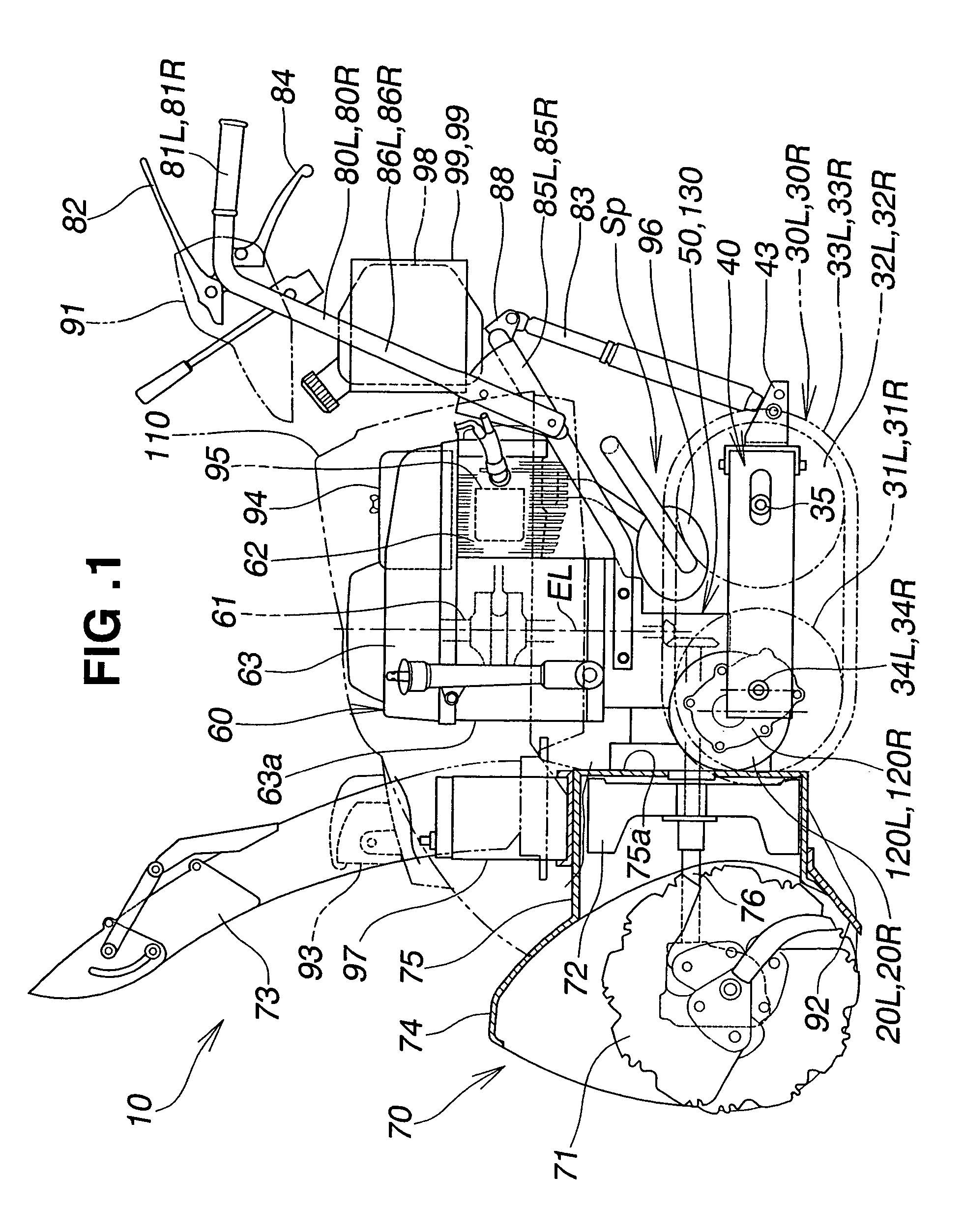

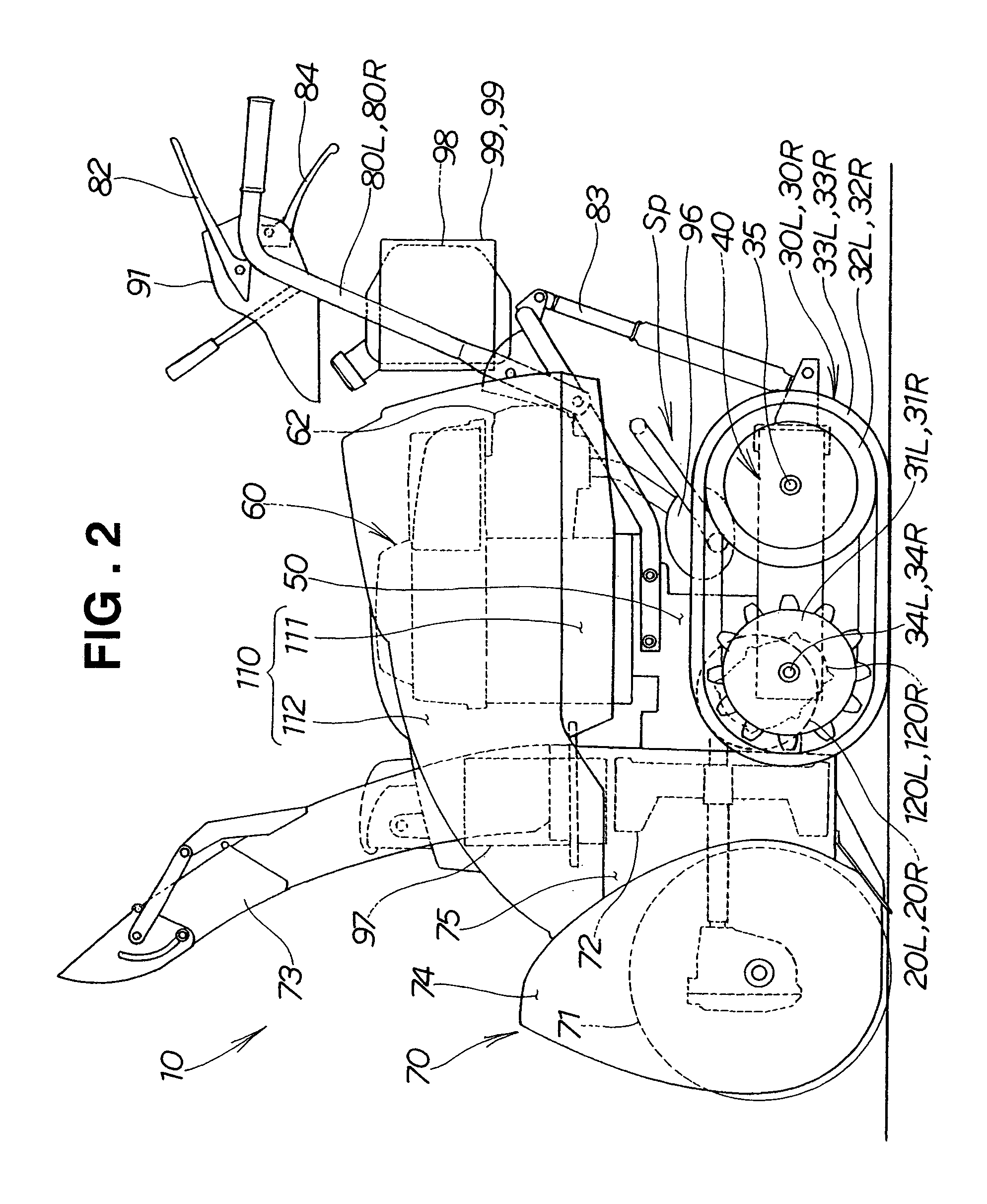

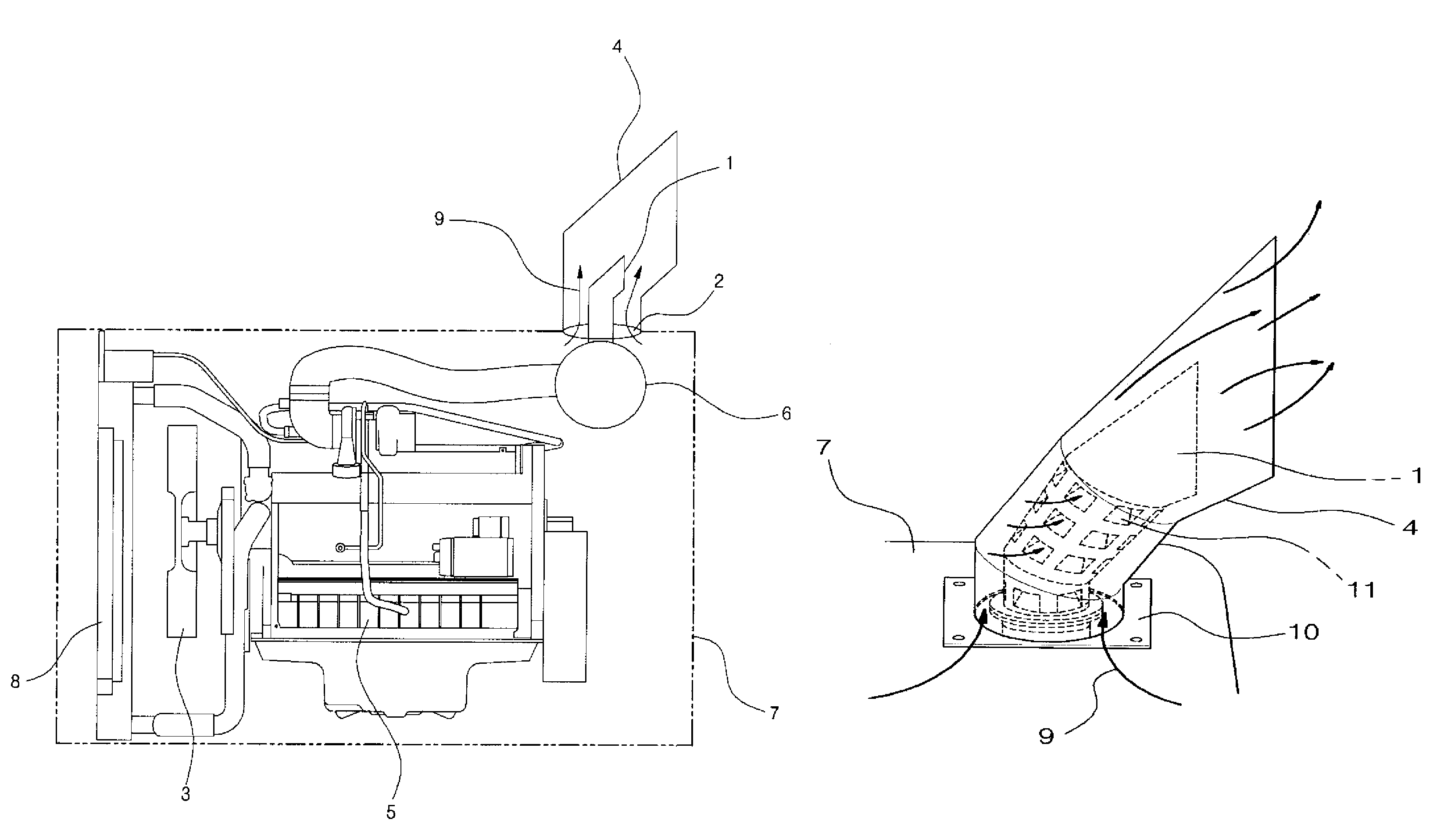

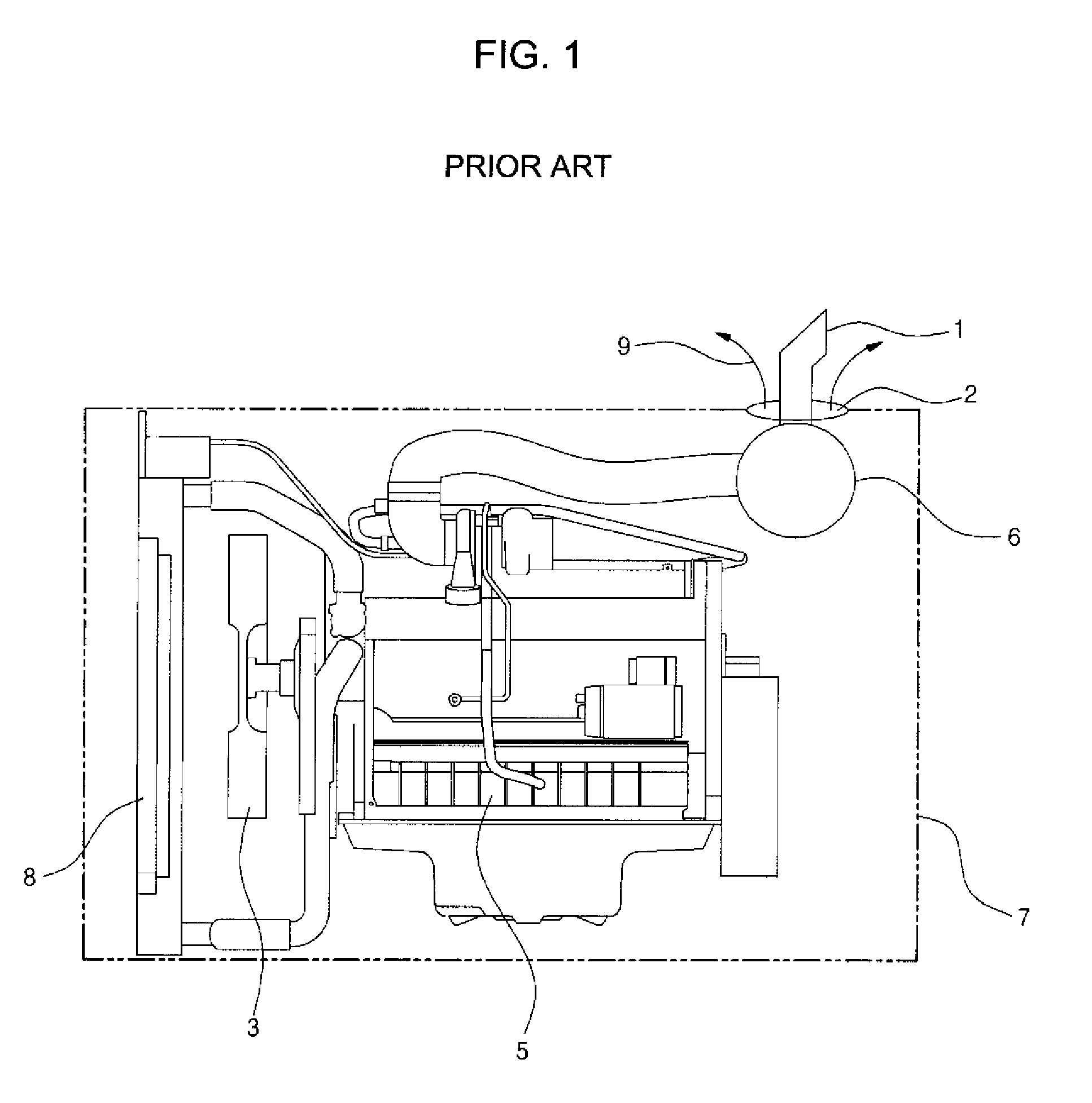

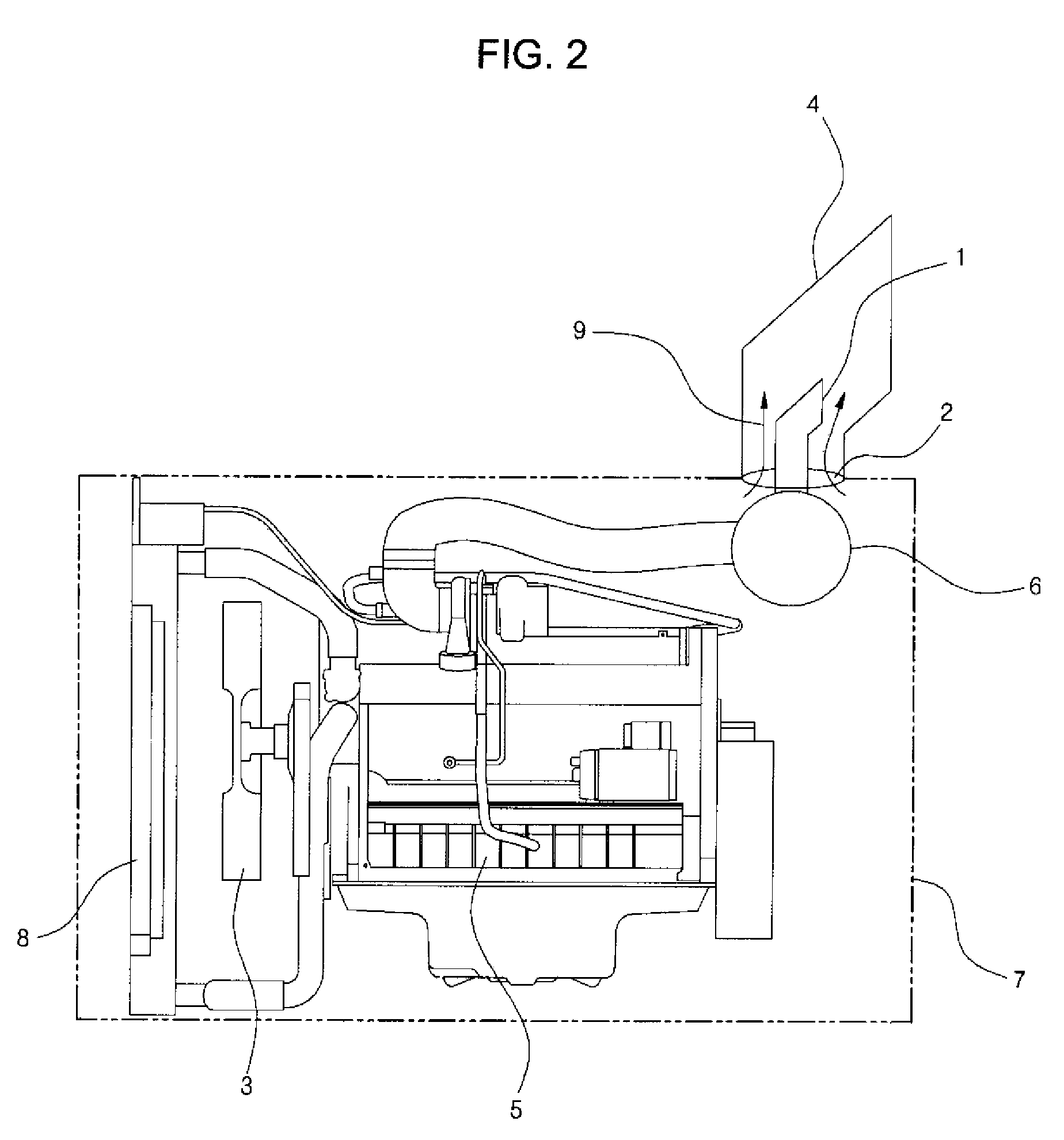

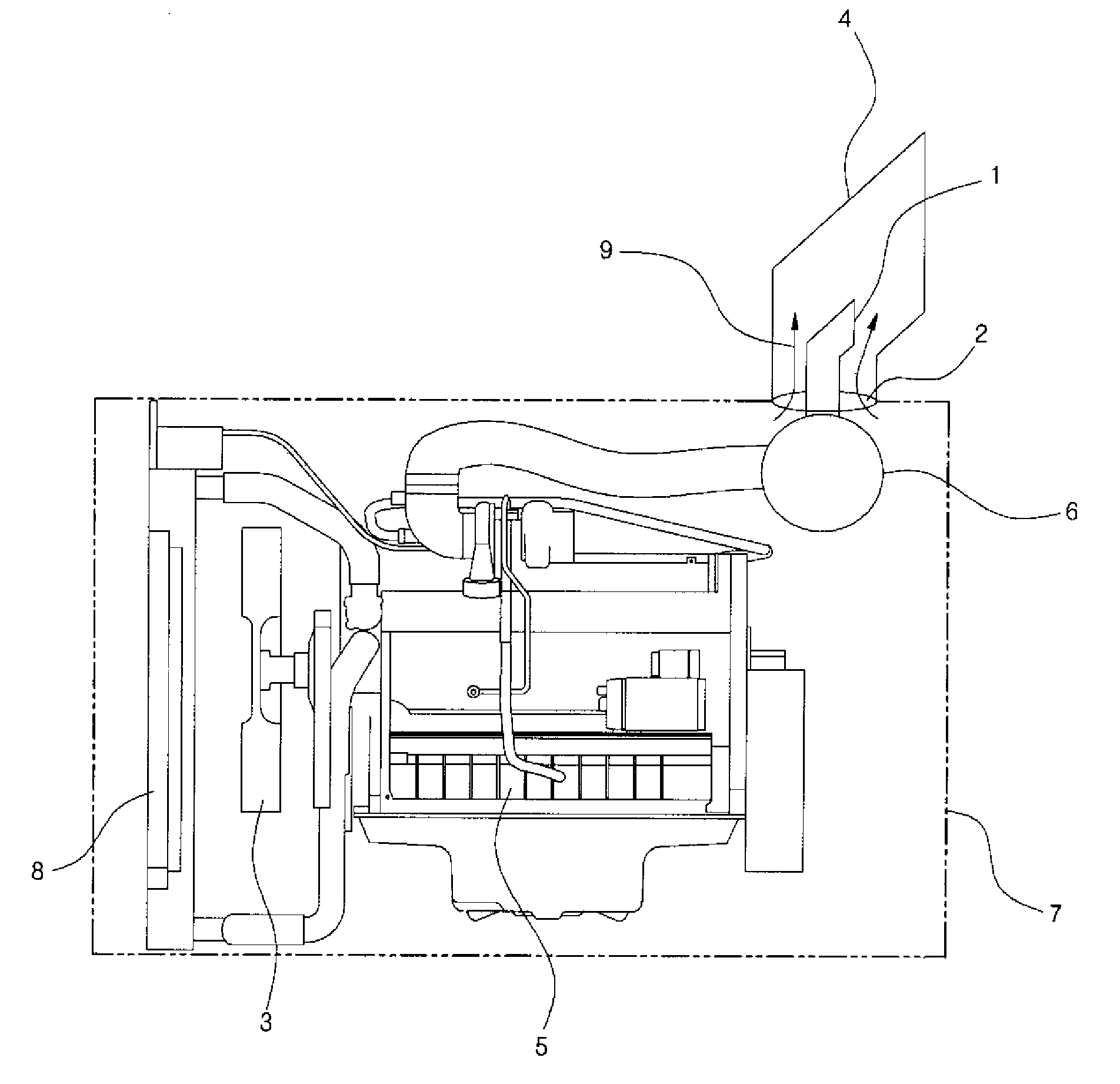

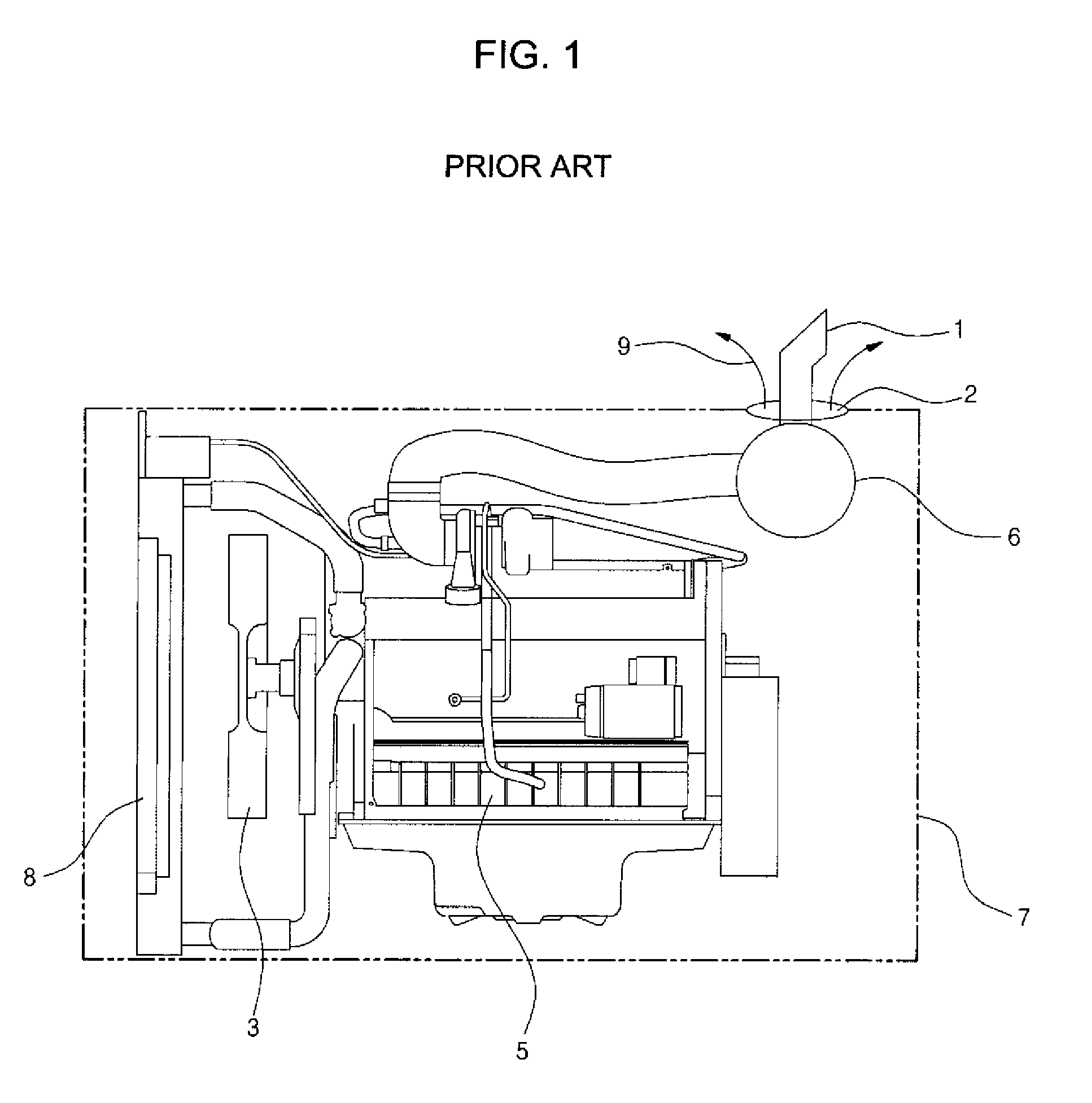

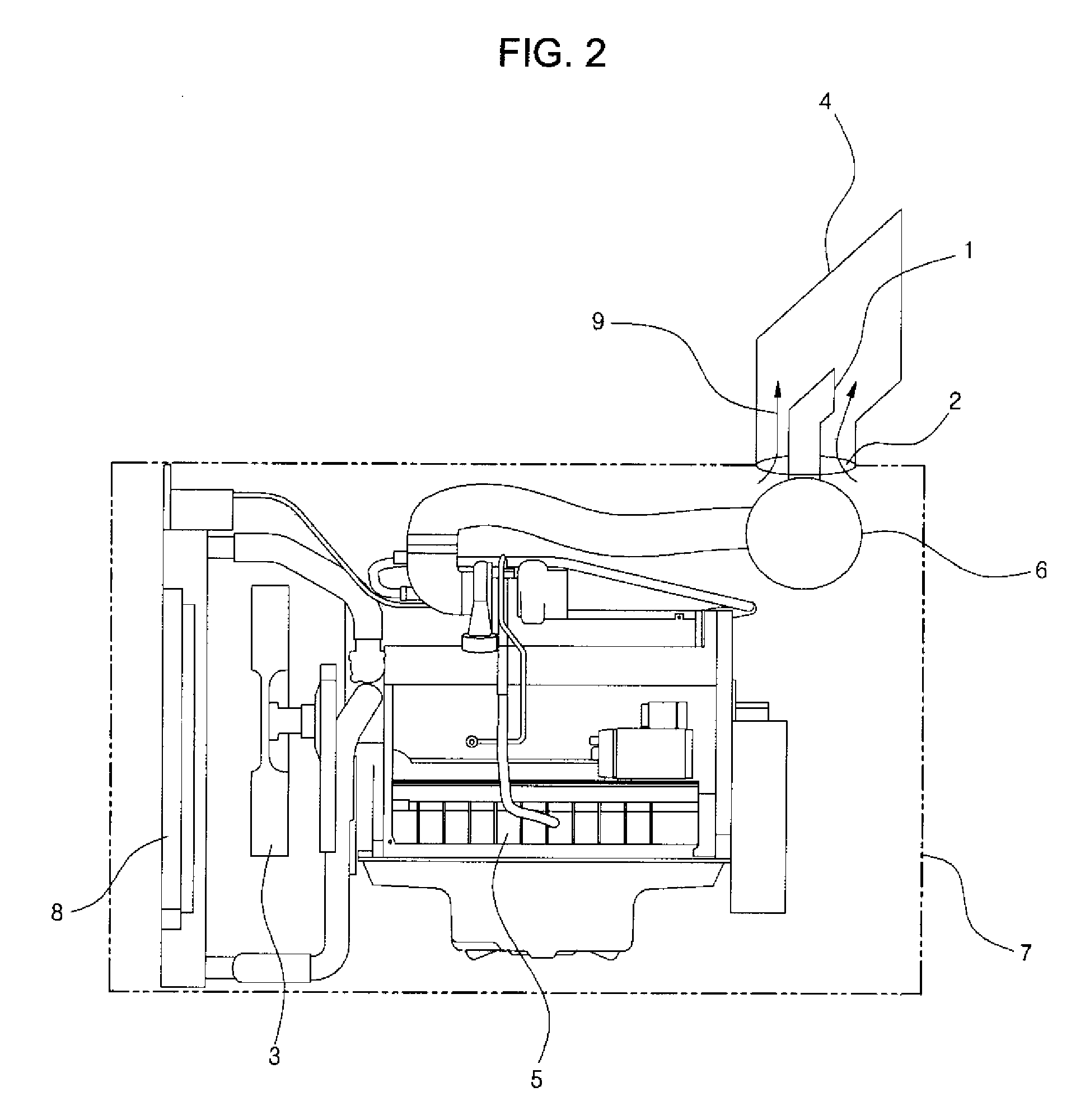

Apparatus for cooling overheated gas in engine room

ActiveUS8286422B2Reduce the temperatureSmooth bootInternal combustion piston enginesSilencing apparatusProduct gasDiesel particulate filter

An apparatus for cooling overheated gas generated from a diesel particulate filter which is connected between a diesel engine and an exhaust pipe of the diesel engine is disclosed. The apparatus includes a tail pipe for discharging outwardly the overheated gas discharged from the diesel particulate filter, a cooling fan, provided at one side of an engine room, for generating an air stream by sucking ambient air, and a diffuser enclosing an outer circumference of the tail pipe in such a way a space is formed between the diffuser and the tail pipe to prevent the diffuser from directly contacting the tail pipe. The engine room is provided with a through-hole penetrating one side of the engine room, and the tail pipe has one end connected to the diesel particulate filter, and the other end extended outwardly from the engine room through the through-hole.

Owner:VOLVO CONSTR EQUIP HLDG SWEDEN AB

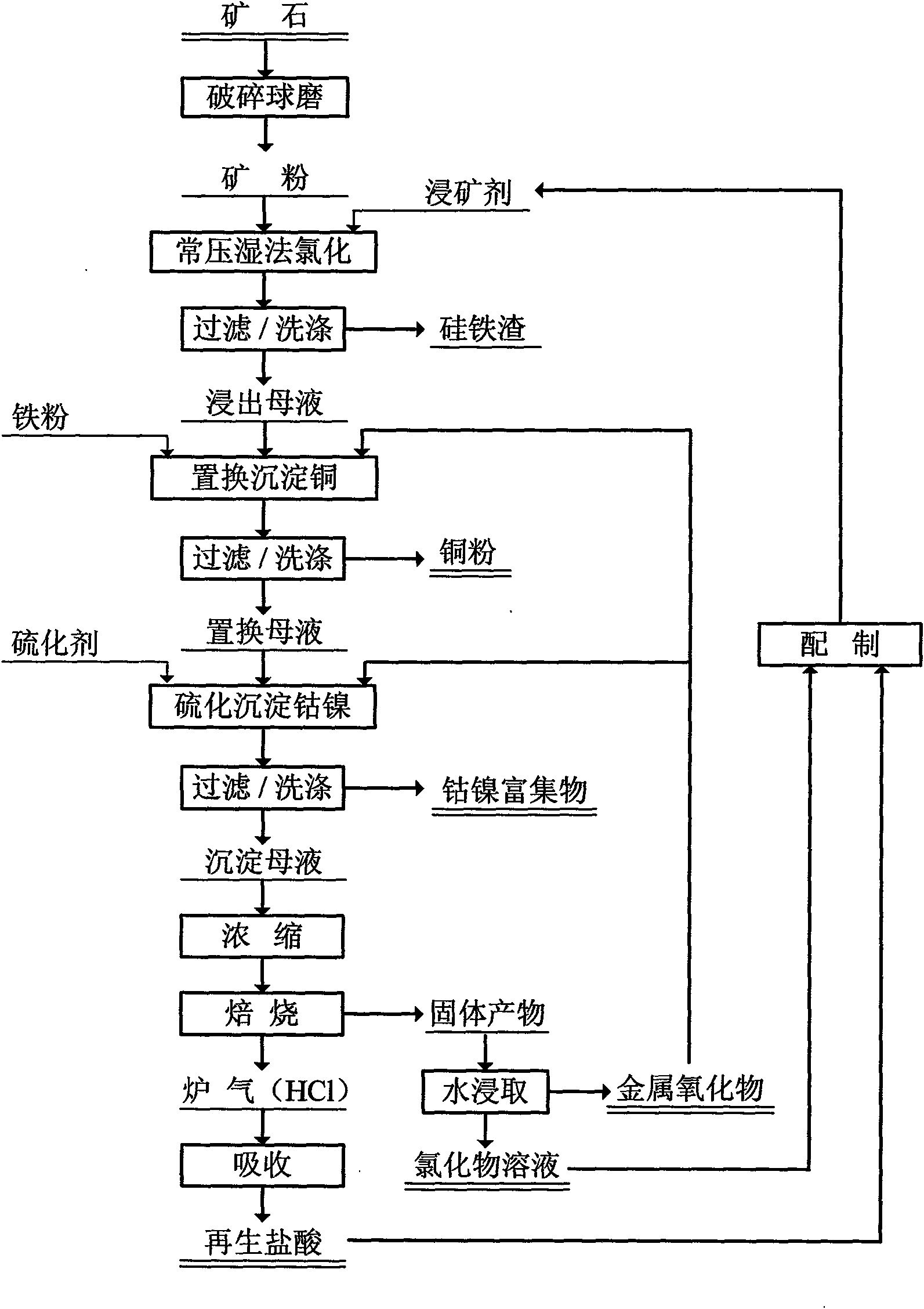

Method for separating and extracting copper and cobalt-nickel in low-grade complex mixed copper-cobalt ore

ActiveCN101575673AImprove leaching ratePromote circulationProcess efficiency improvementSlurrySulfide

The invention provides a method for separating and extracting copper and cobalt-nickel in low-grade complex mixed copper-cobalt ore, which uses low-grade complex mixed copper-cobalt ore (sulfide and oxide) as a raw material to extract an intermediate product of the copper and cobalt-nickel by adopting process flows of crushing and grinding ore into slurry, leaching the slurry with acidic villaumite by a wet method, extracting copper powder by reduction and replacement, vulcanizing and depositing nickel (cobalt), concentrating, drying, baking and hydrolyzing deposited mother solution at low temperature and the like. The method comprises main technical points that metallic elements in the mixed copper-cobalt ore are dissolved and leached by the acidic villaumite under normal pressure; copper in leaching liquor is reduced and deposited by a reducing agent; the cobalt and nickel are deposited by a vulcanizing agent to obtain the intermediate product; the mother solution is concentrated, dried, baked and hydrolyzed at low temperature after cobalt-nickel deposition to obtain metal oxide, metal oxychloride and hydrogen chloride containing iron, magnesium and the like; hydrogen chloride is reclaimed to obtain hydrochloric acid, and baked solid is leached into water to obtain chloride solution; and the hydrochloric acid and the chloride solution are used for leaching of ore slurry. The method comprehensively reclaims the copper, the cobalt-nickel and the like, and has the characteristics of high leaching rate of the copper and the cobalt-nickel, less energy consumption, low cost, closed circulation of chlorine (hydrochloric acid), less investment of project engineering and the like. The whole process is concise, clean and environment-friendly. The method is particularly applicable to large-scale industrial production.

Owner:福建常青新能源科技有限公司

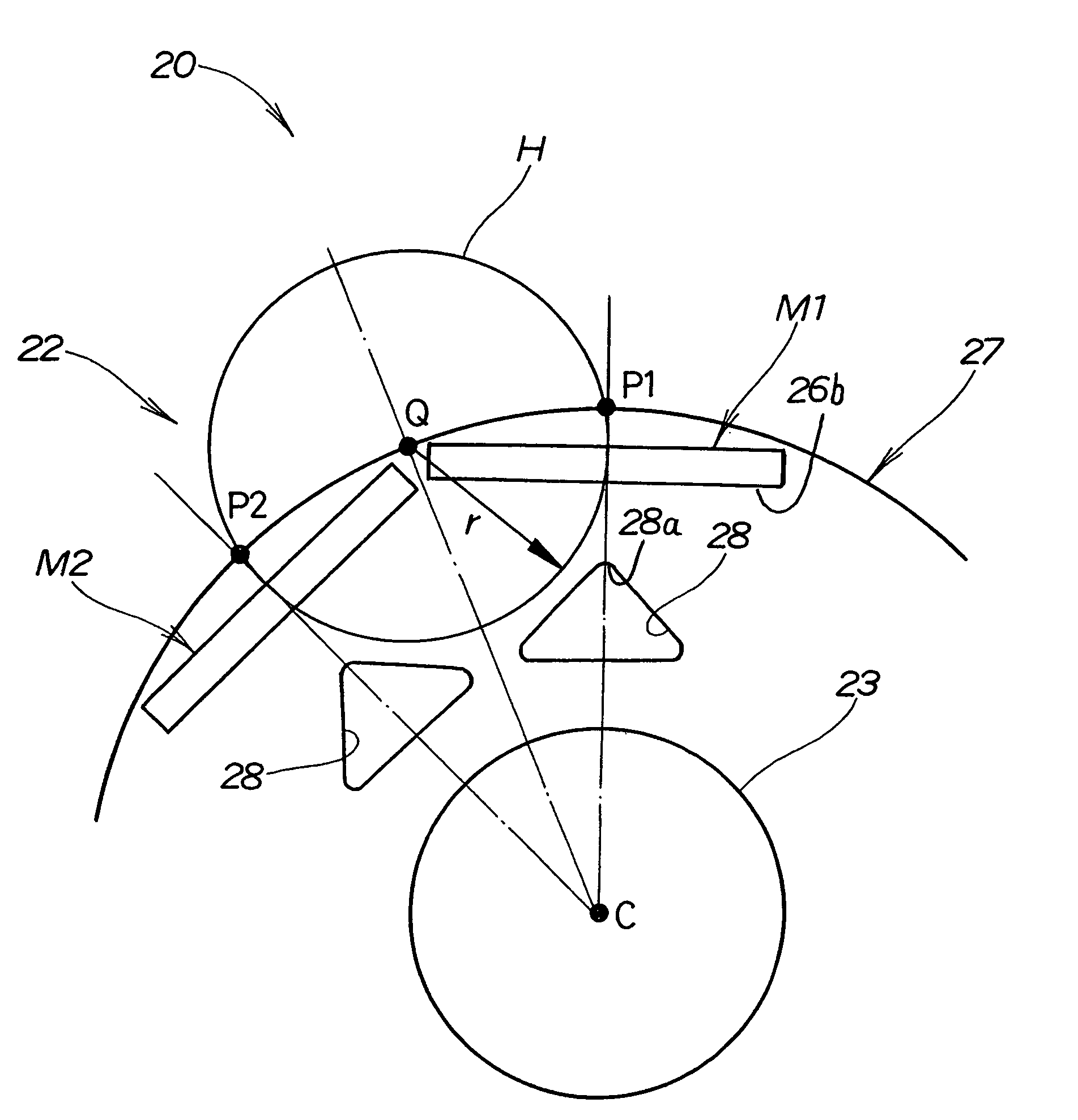

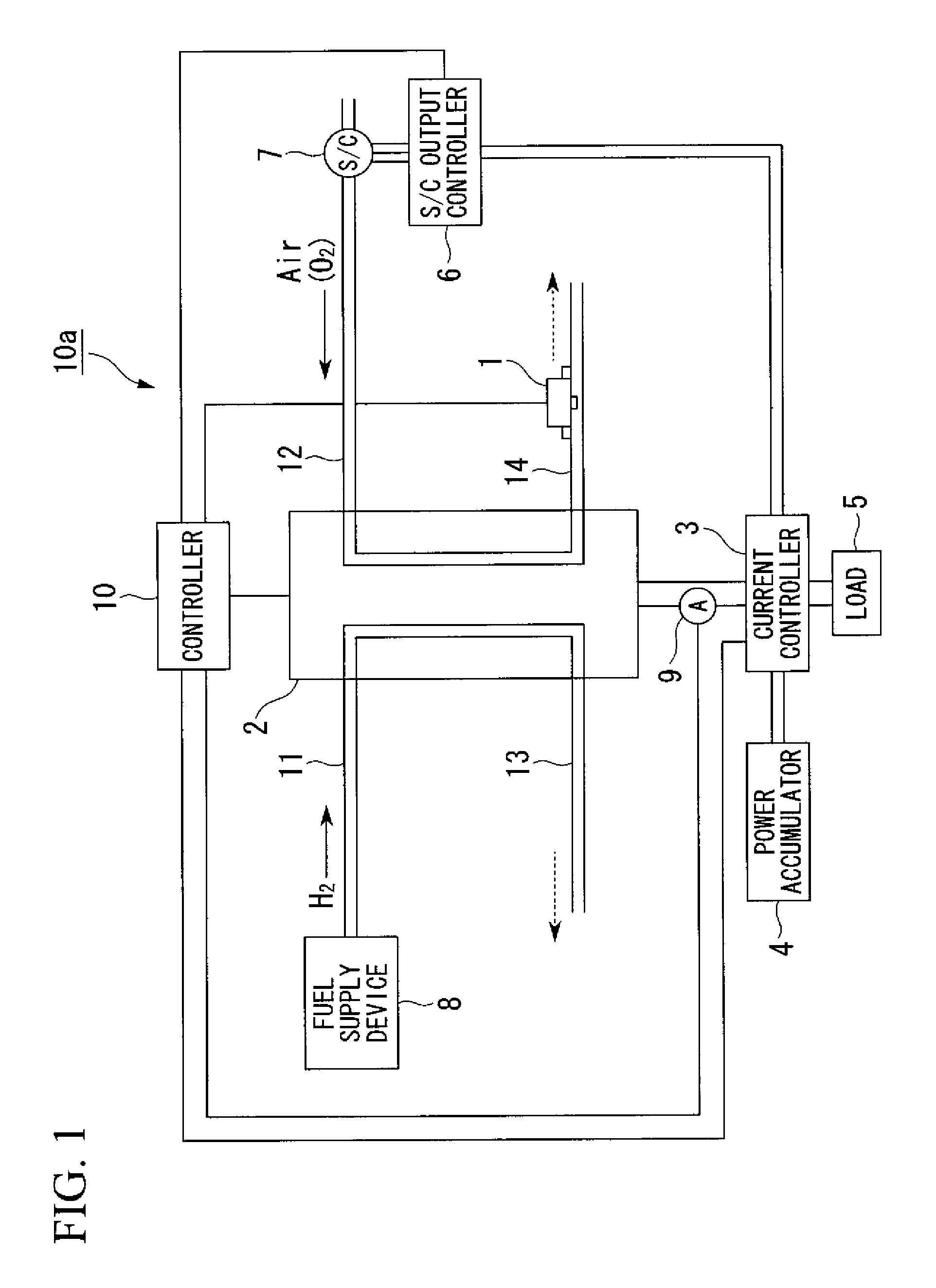

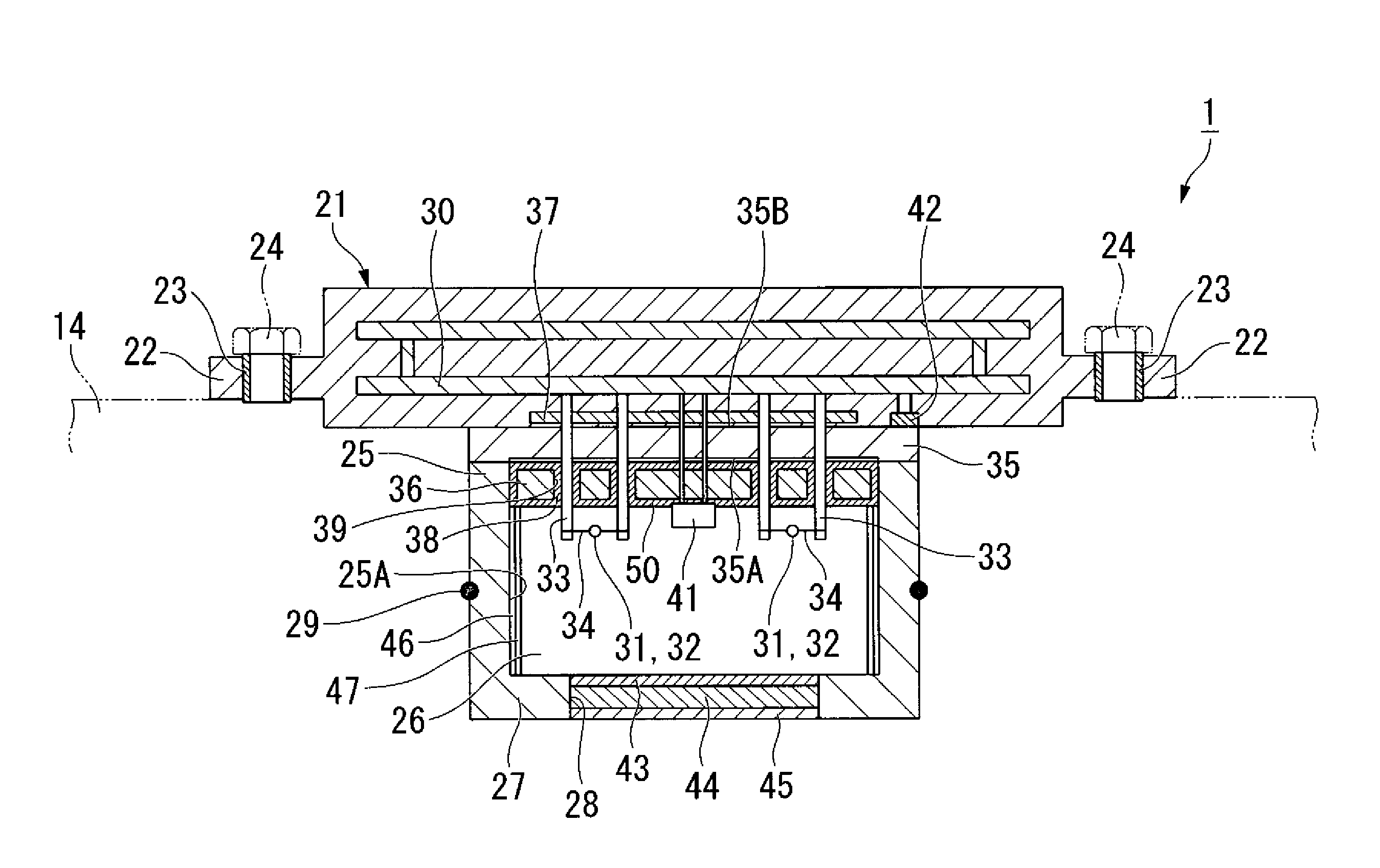

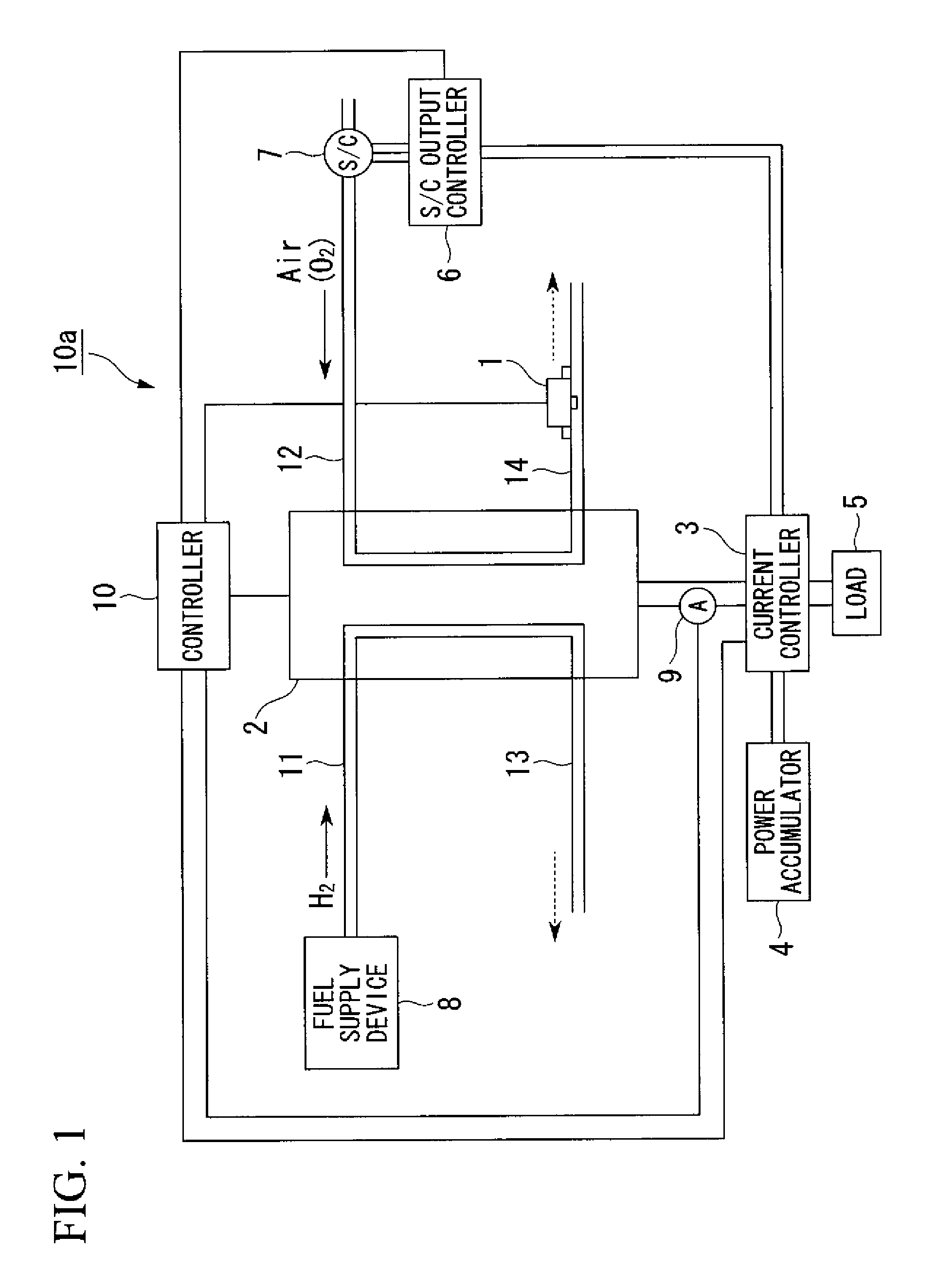

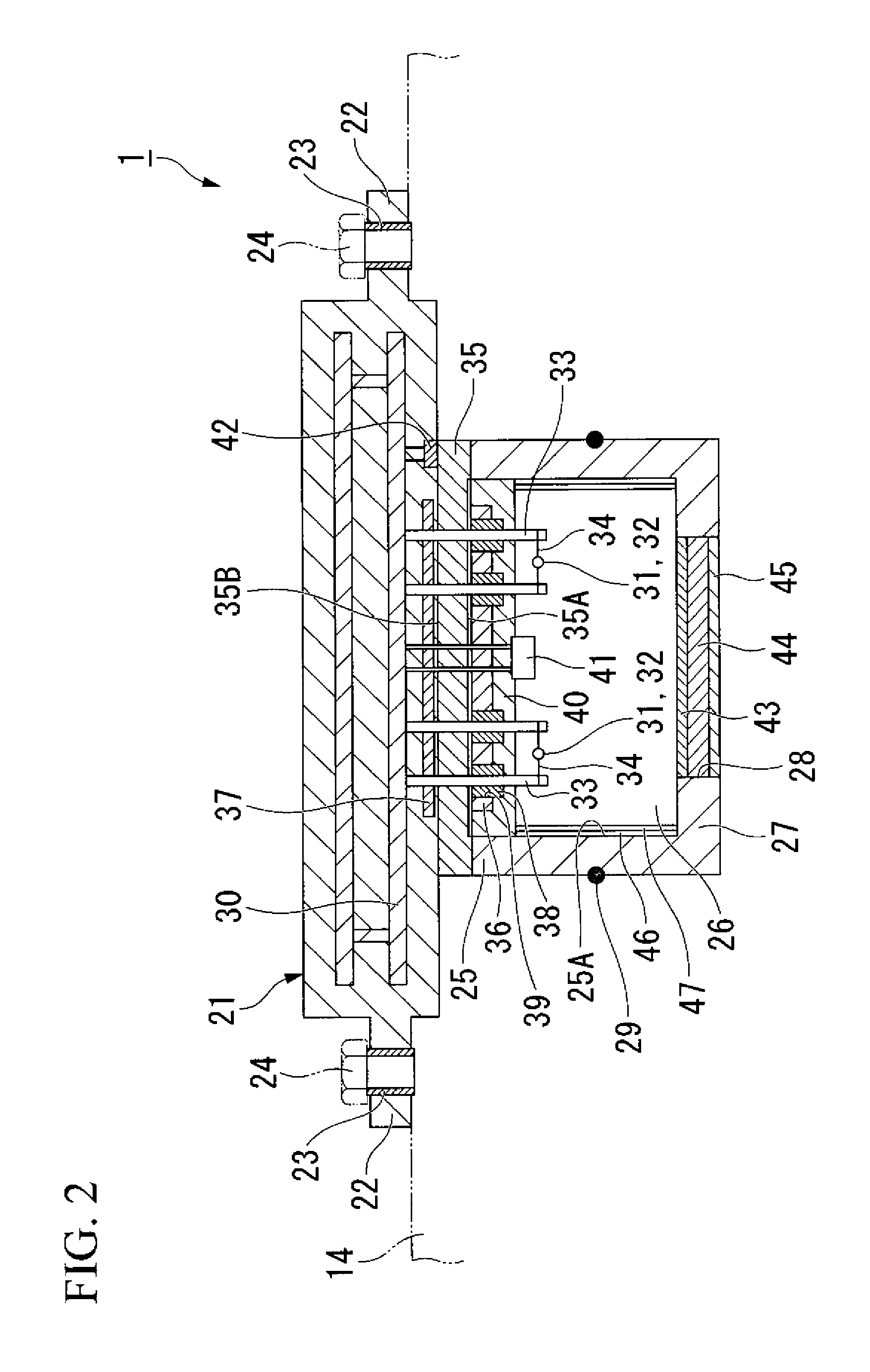

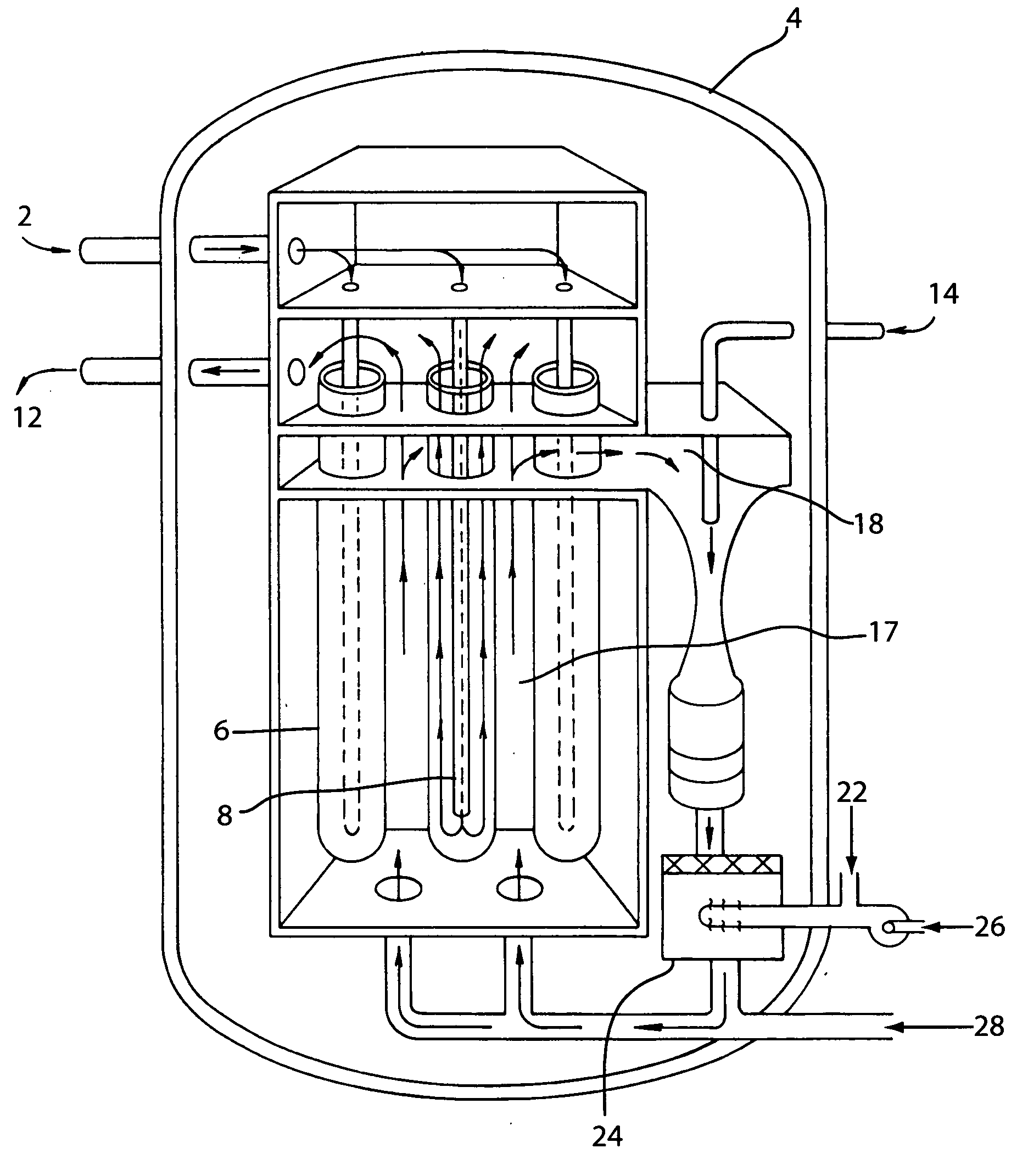

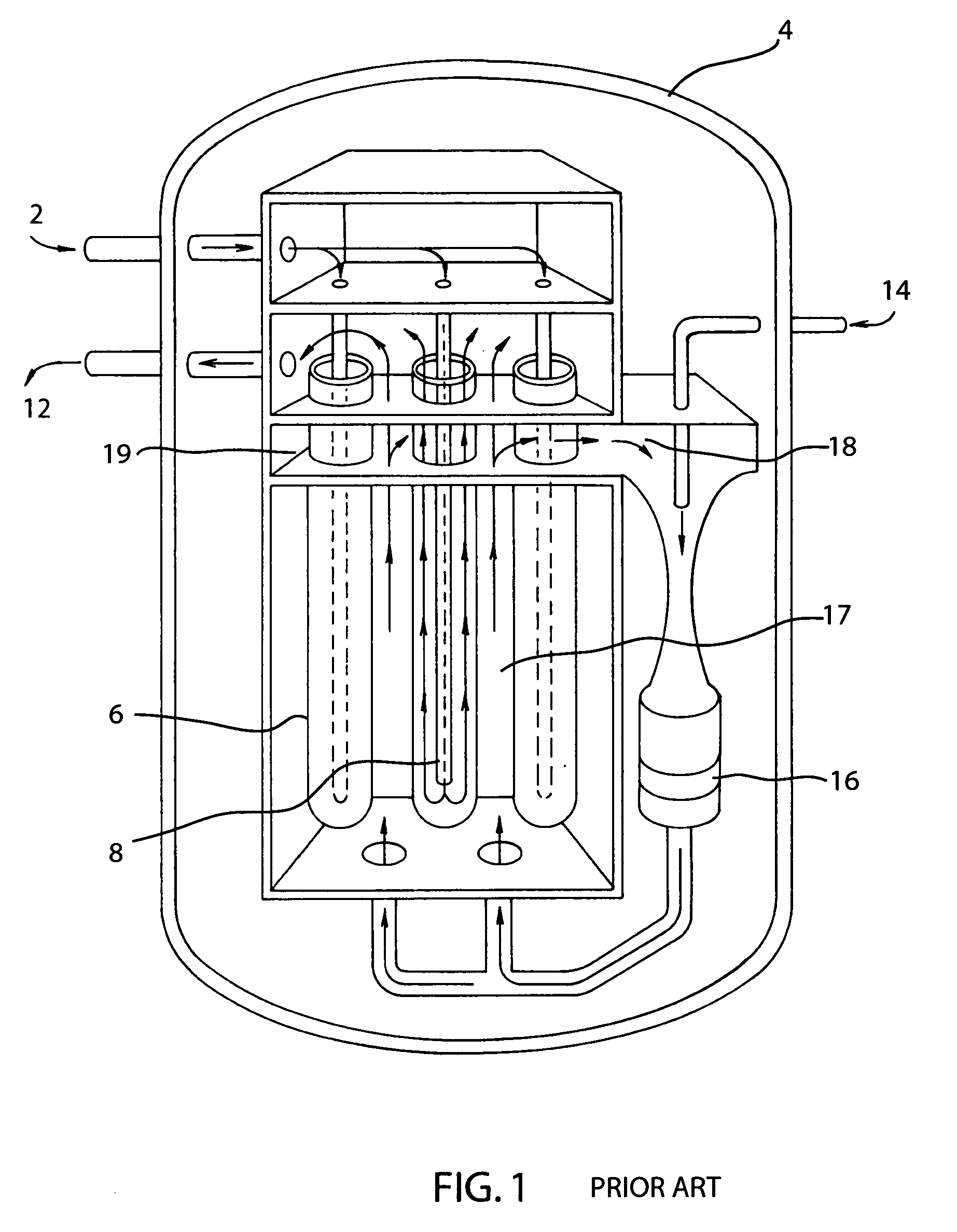

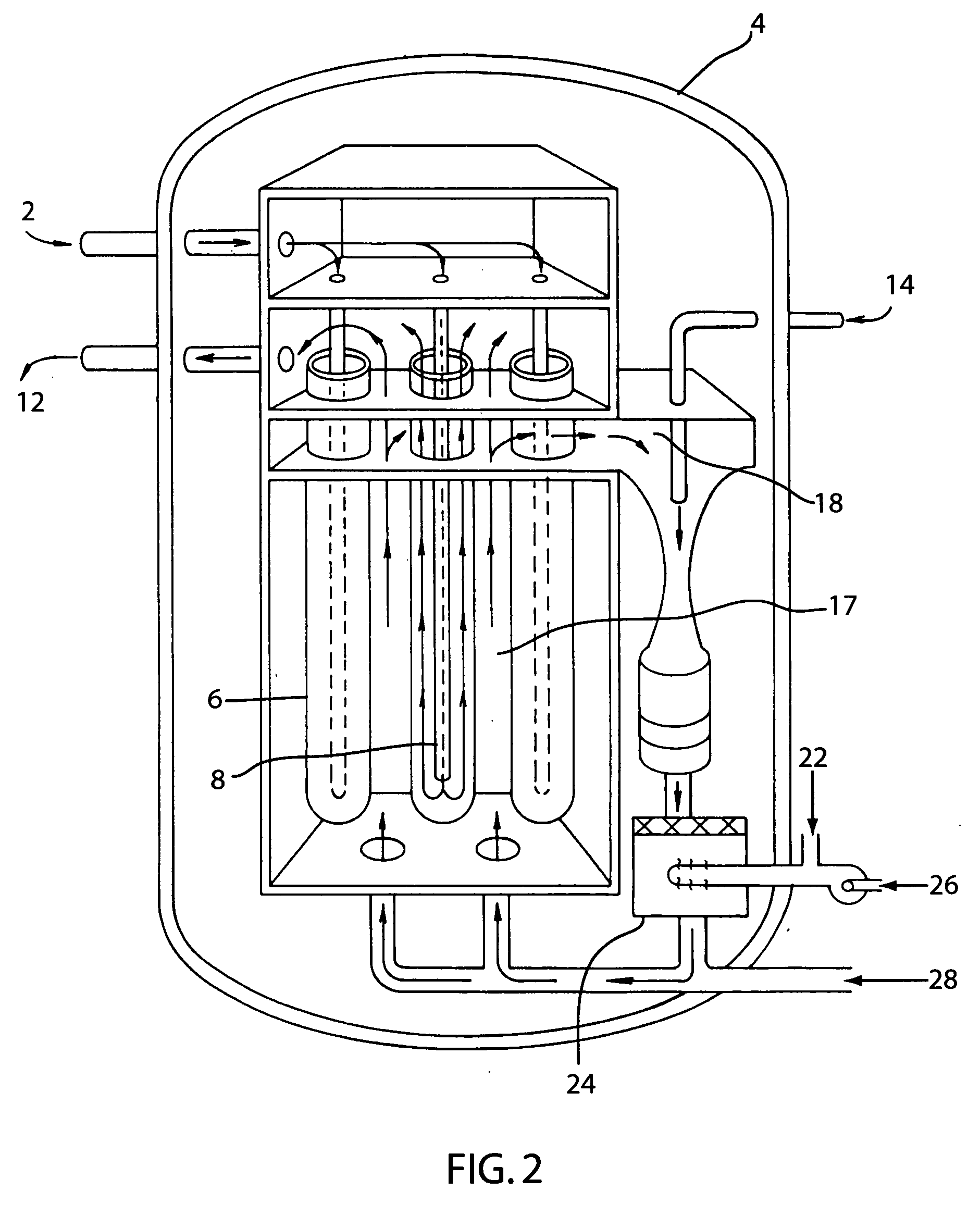

Anode gas stack start-up heater and purge gas generator

InactiveUS20070275282A1Improve the heating effectHeating directlyValve members for heating/coolingFuel cells groupingCombustorFuel cells

In one embodiment the present invention provides for an anode side gas flow heater for a fuel cell generator that comprises a recirculating anode gas flow 28, at least one burner 24, and an energy source 22. The energy source heats the burner, the anode gas flow passes over the at least one burner and is heated, and the heated anode gas flow is then passed through the anode side of the fuel cell generator 4, where the fuel cell generator is heated.

Owner:SIEMENS ENERGY INC

Apparatus for cooling overheated gas in engine room

ActiveUS20100186395A1Reduce the temperatureSmooth bootInternal combustion piston enginesSilencing apparatusEngineeringProduct gas

An apparatus for cooling overheated gas generated from a diesel particulate filter which is connected between a diesel engine and an exhaust pipe of the diesel engine is disclosed. The apparatus includes a tail pipe for discharging outwardly the overheated gas discharged from the diesel particulate filter, a cooling fan, provided at one side of an engine room, for generating an air stream by sucking ambient air, and a diffuser enclosing an outer circumference of the tail pipe in such a way a space is formed between the diffuser and the tail pipe to prevent the diffuser from directly contacting the tail pipe. The engine room is provided with a through-hole penetrating one side of the engine room, and the tail pipe has one end connected to the diesel particulate filter, and the other end extended outwardly from the engine room through the through-hole.

Owner:VOLVO CONSTR EQUIP HLDG SWEDEN AB

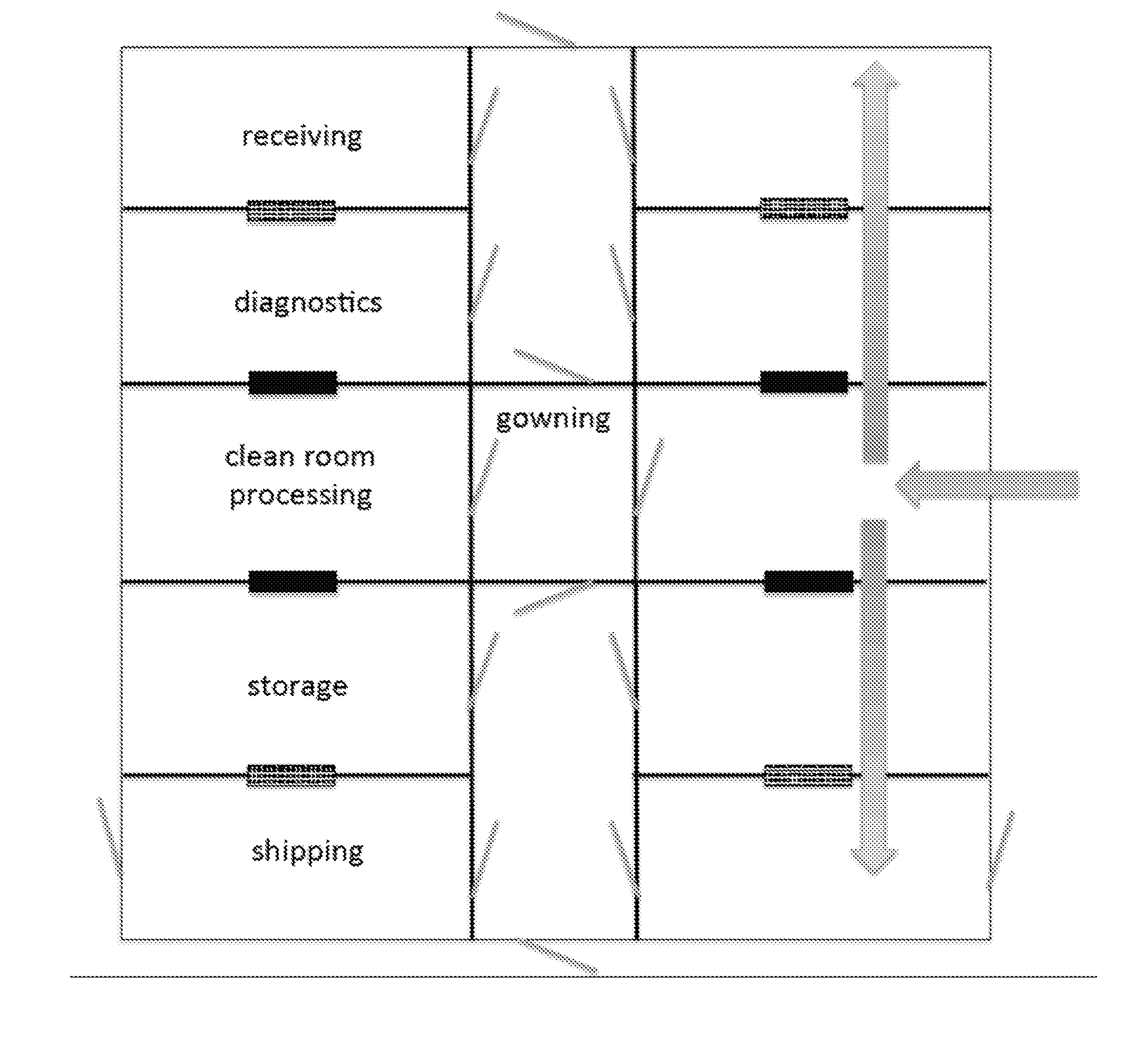

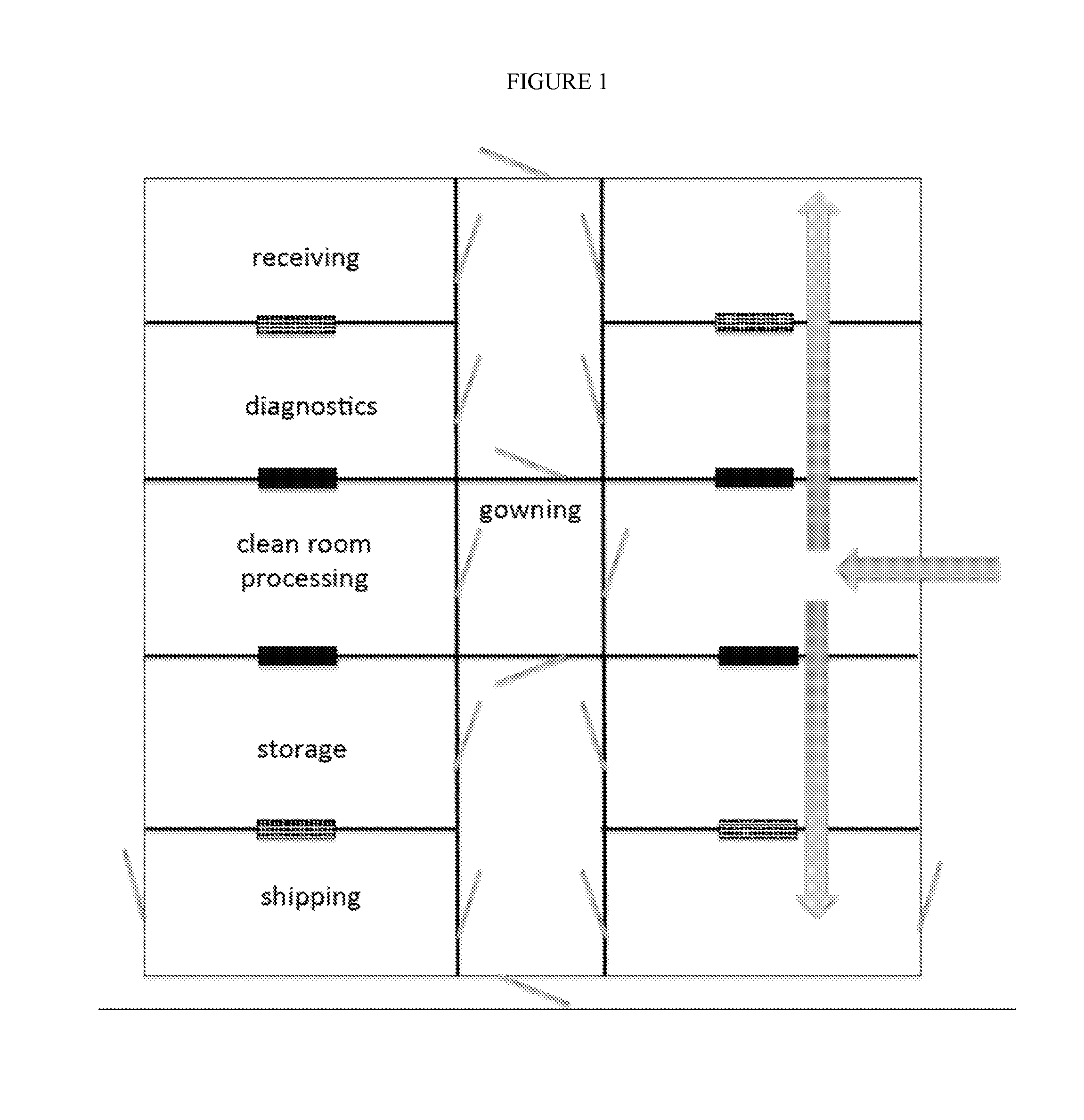

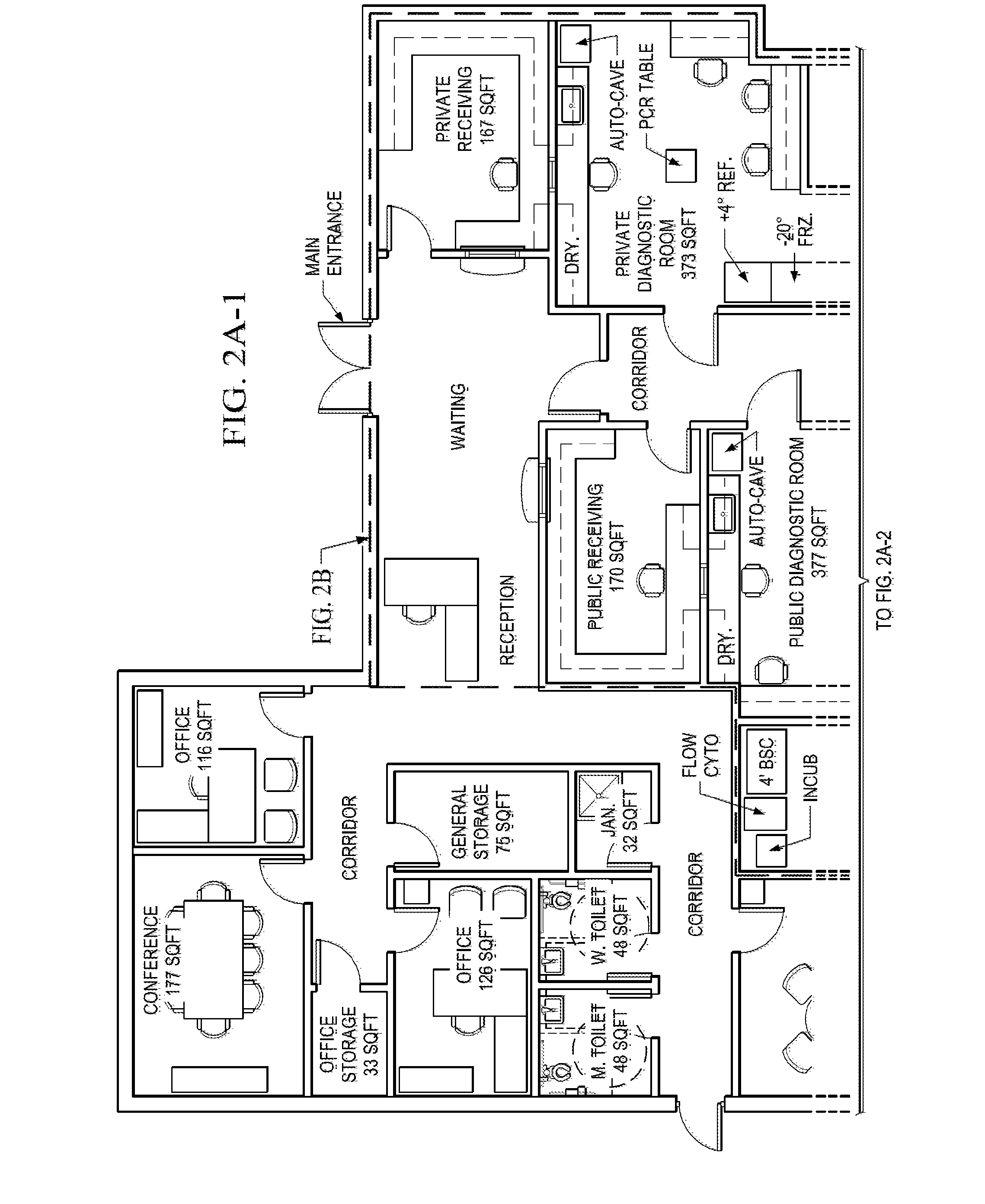

Facilities for hybrid tissue banks

ActiveUS20130025221A1Heating directlyEasy to implementHospitalsSpecial buildingPrivate FacilityEngineering

A system, workflow and facilities for hybrid tissue banks are provided with a central access way having spaces on both sides for public and private diagnostic areas, public and private clean room areas for processing, culturing and other manufacturing steps, public and private storage areas, wherein air flow is into said clean rooms and out of said diagnostic areas and said storage areas, and wherein all public facilities are on one side of the central access-way and private facilities are on the other side, and wherein there are sample pass-throughs between each area, and at least the sample pass-through into and out of the clean room processing areas comprise small enclosed chambers having two access panels (one leading to each space), wherein only one panel can open at a time. Preferably, these areas are preceded by receiving spaces and terminated by shipping spaces, which also have pass-through chambers.

Owner:STEM CELL RESERVE

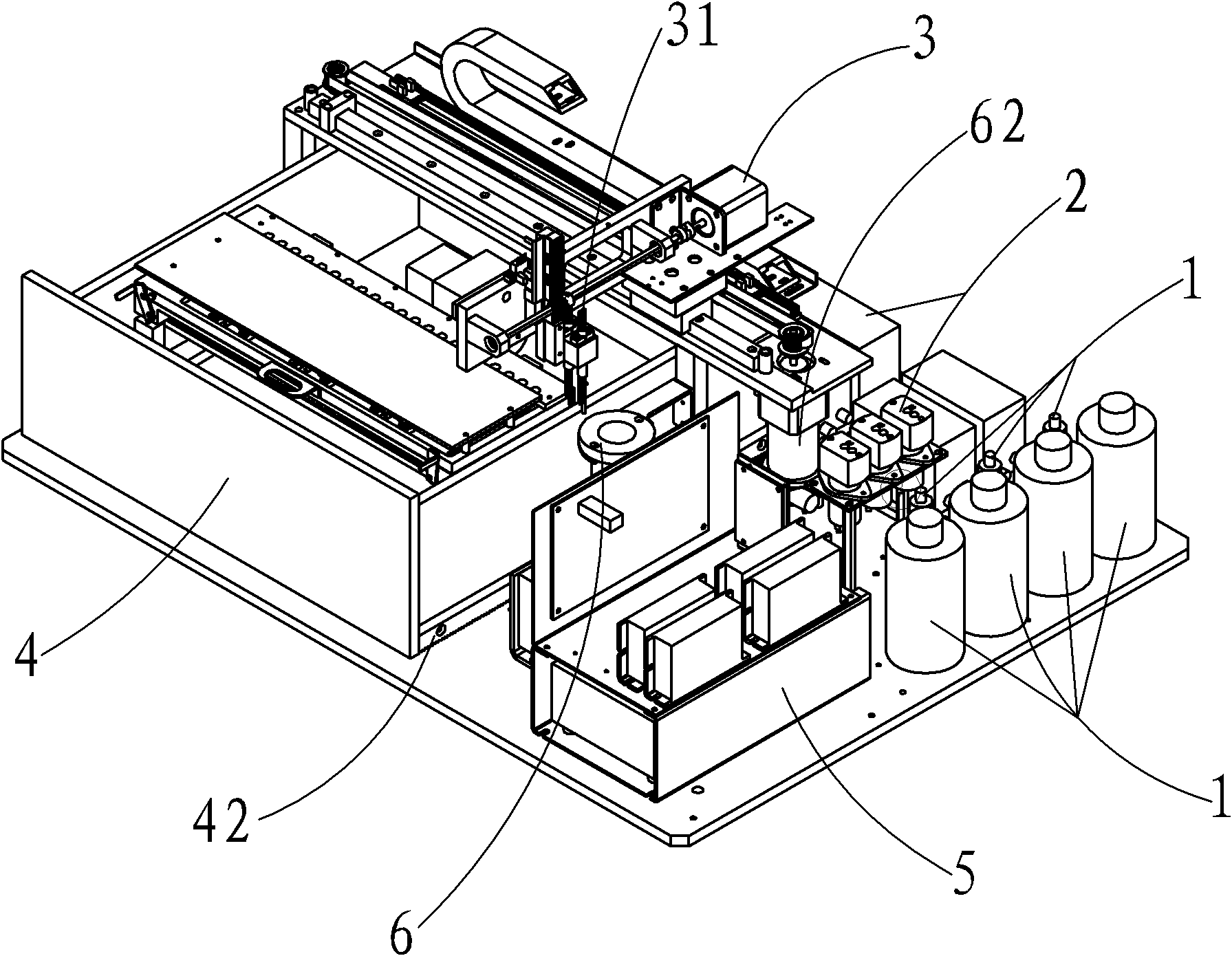

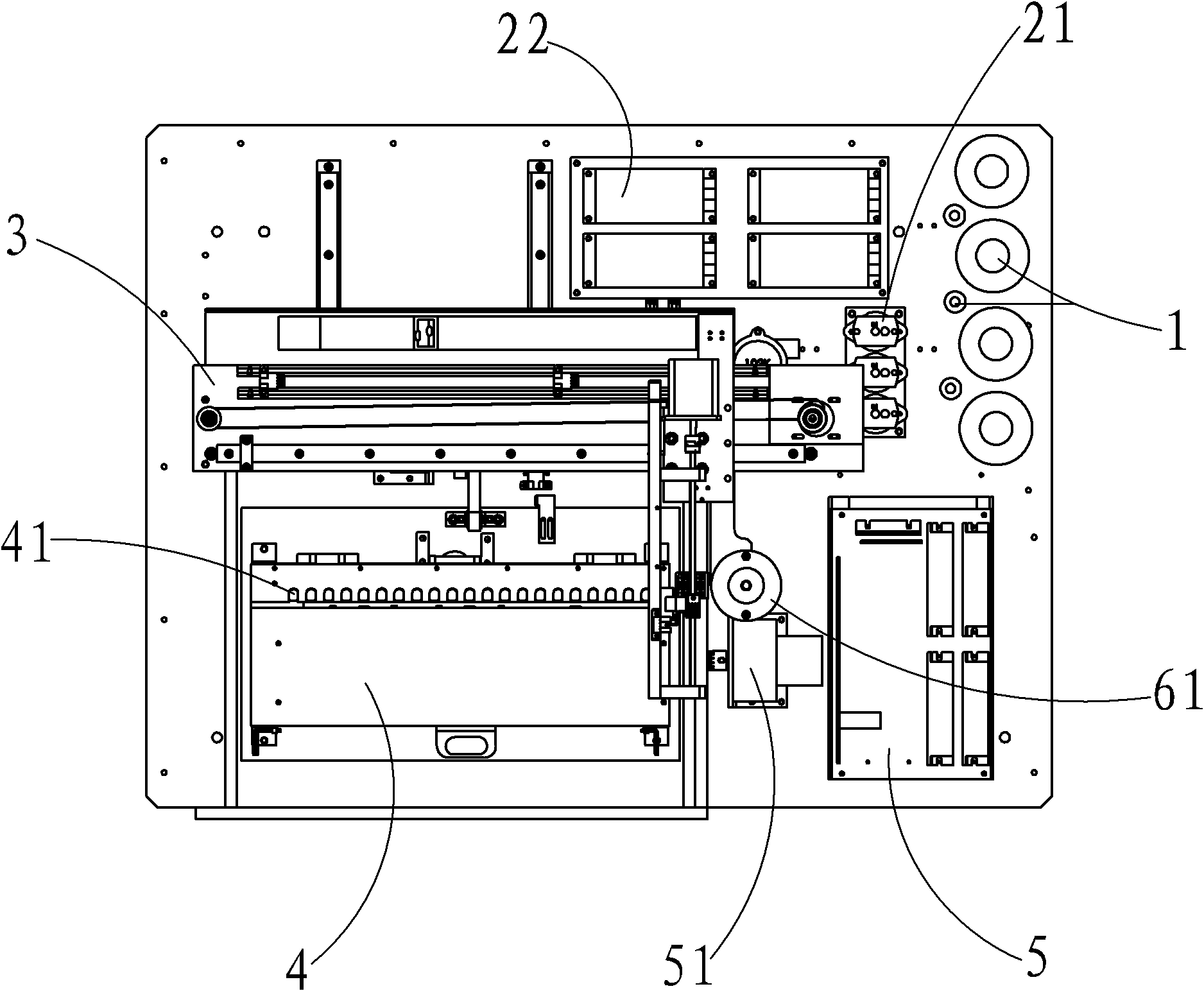

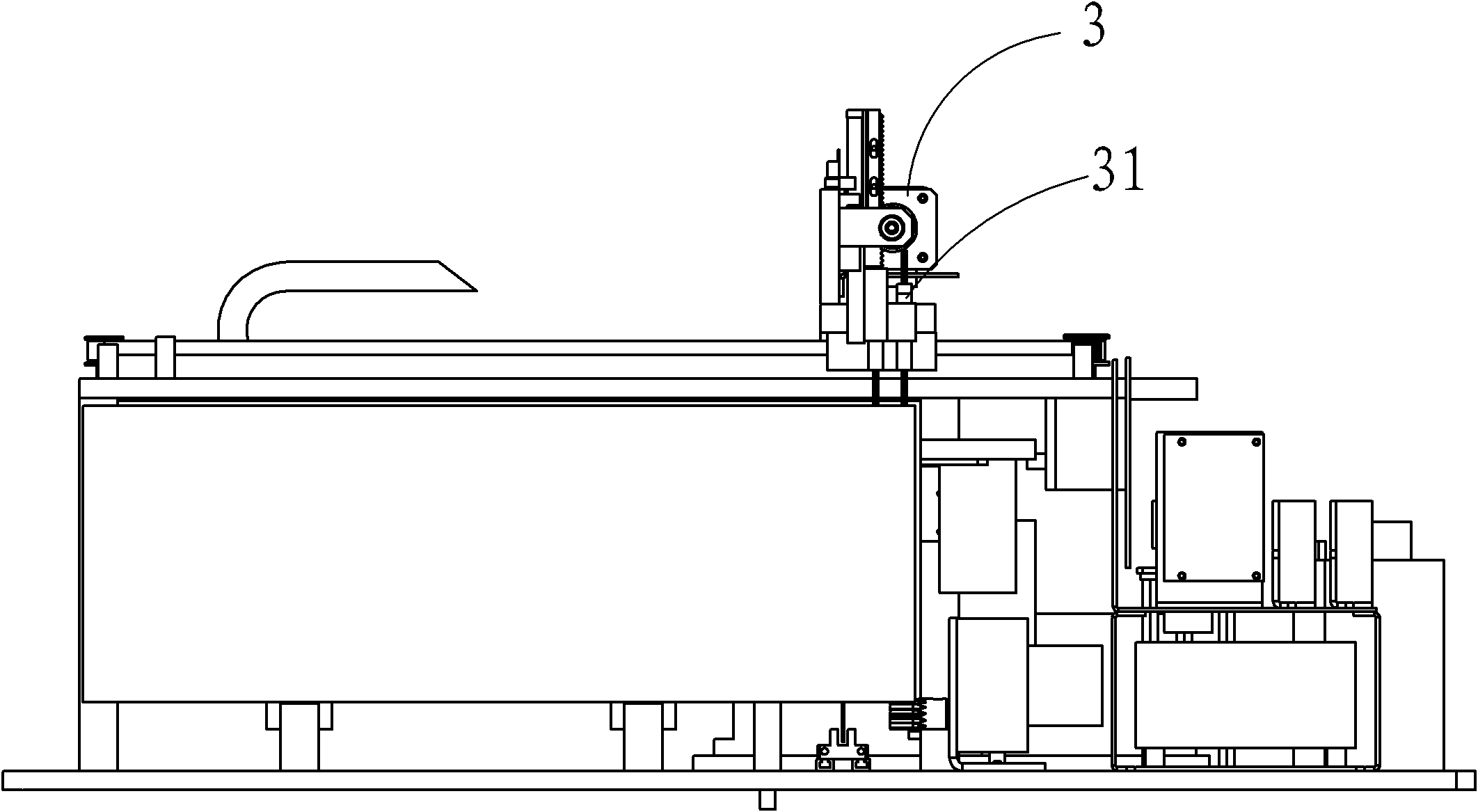

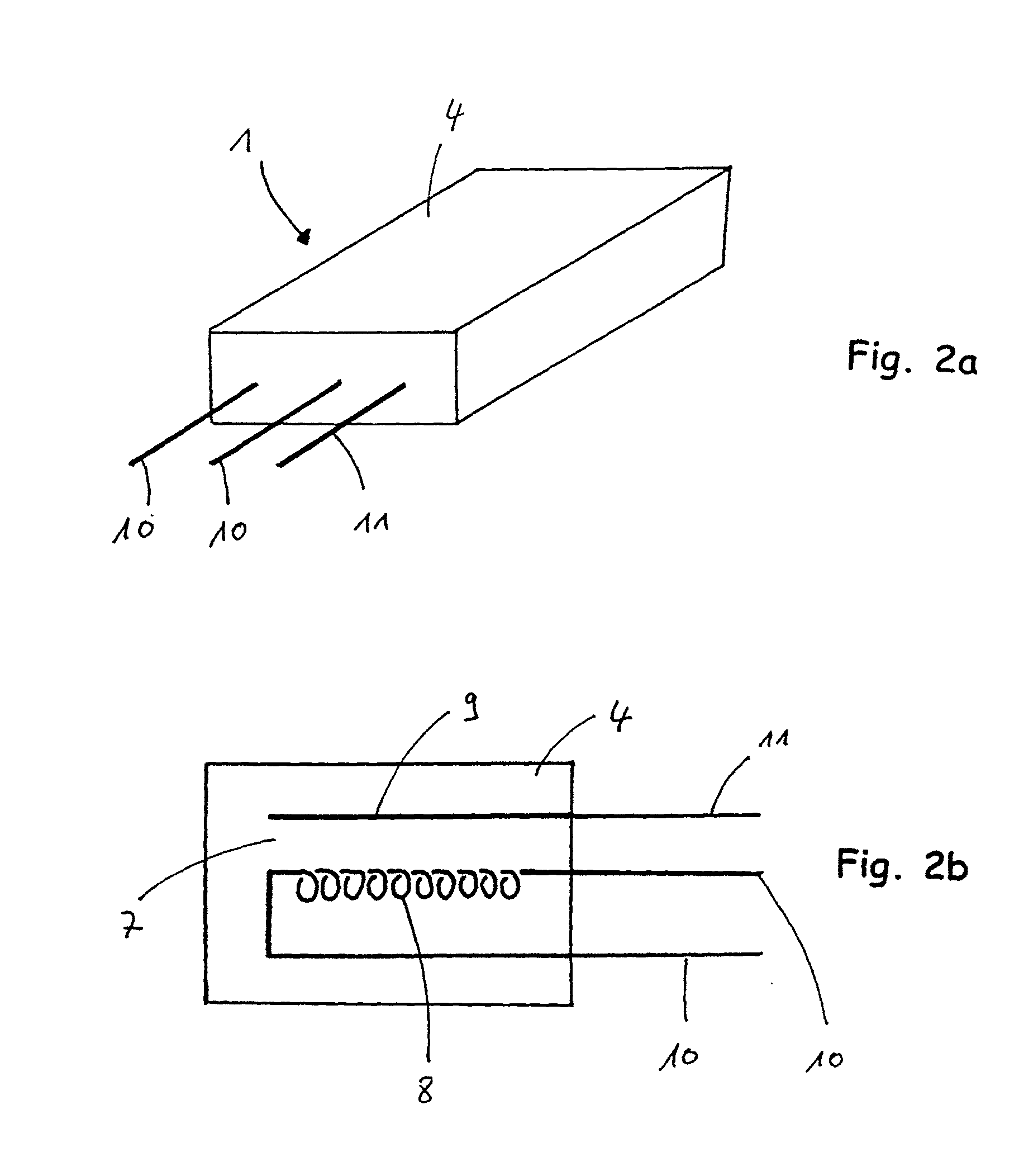

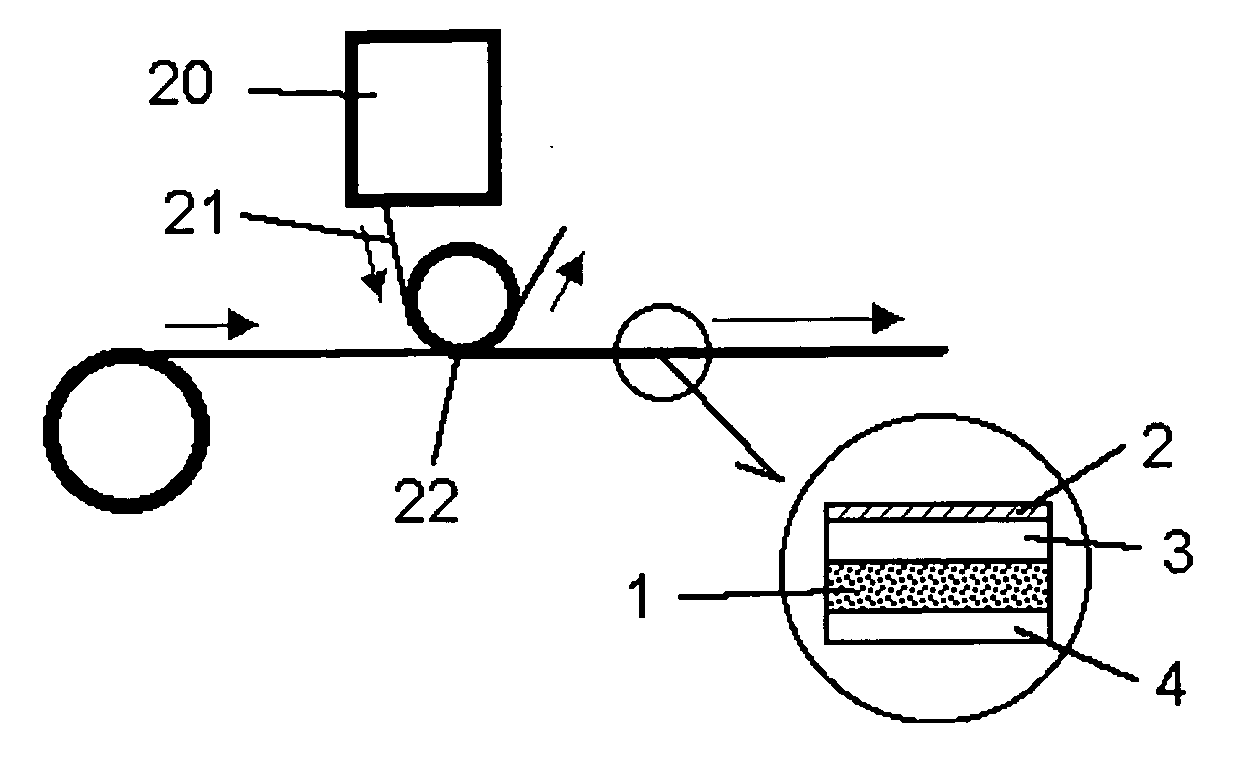

Nucleic acid hybridization method and nucleic acid hybridization instrument utilizing same

ActiveCN102134552AShorten the timeFastBioreactor/fermenter combinationsBiological substance pretreatmentsControl systemReagent bottle

The invention discloses a nucleic acid hybridization instrument comprising a reagent bottle, a liquid inlet device, a liquid-transferring device, a vibrating trough device and a control system, wherein the liquid inlet device is connected with the liquid-transferring device and provided with a micropump and a membrane pump, and the micropump and the membrane pump are used for driving reagents to flow into the liquid-transferring device from the reagent bottle; the liquid-transferring device is arranged parallel to the vibrating trough device and provided with a needle tube device, the vibrating trough is provided with a hybridization trough, and the needle tube device is used for adding the reagents into the corresponding hybridization trough for hybridization; and the control system is connected with the liquid inlet device, the liquid-transferring device and the vibrating trough device through a controller. The nucleic acid hybridization instrument can carry out full-automatic experiments so as to save a great deal of time, and adopts the liquid inlet device and the liquid-transferring device for sucking and feeding liquid so as to achieve high speed and convenient operation; the vibrating trough device vibrates automatically, and a heating plate is used for carrying out constant temperature heating so that heating can be more direct and fast; and the control device is used for controlling operation so as to improve the accuracy of the experiment and reduce experimental errors.

Owner:福州泰普生物科学有限公司

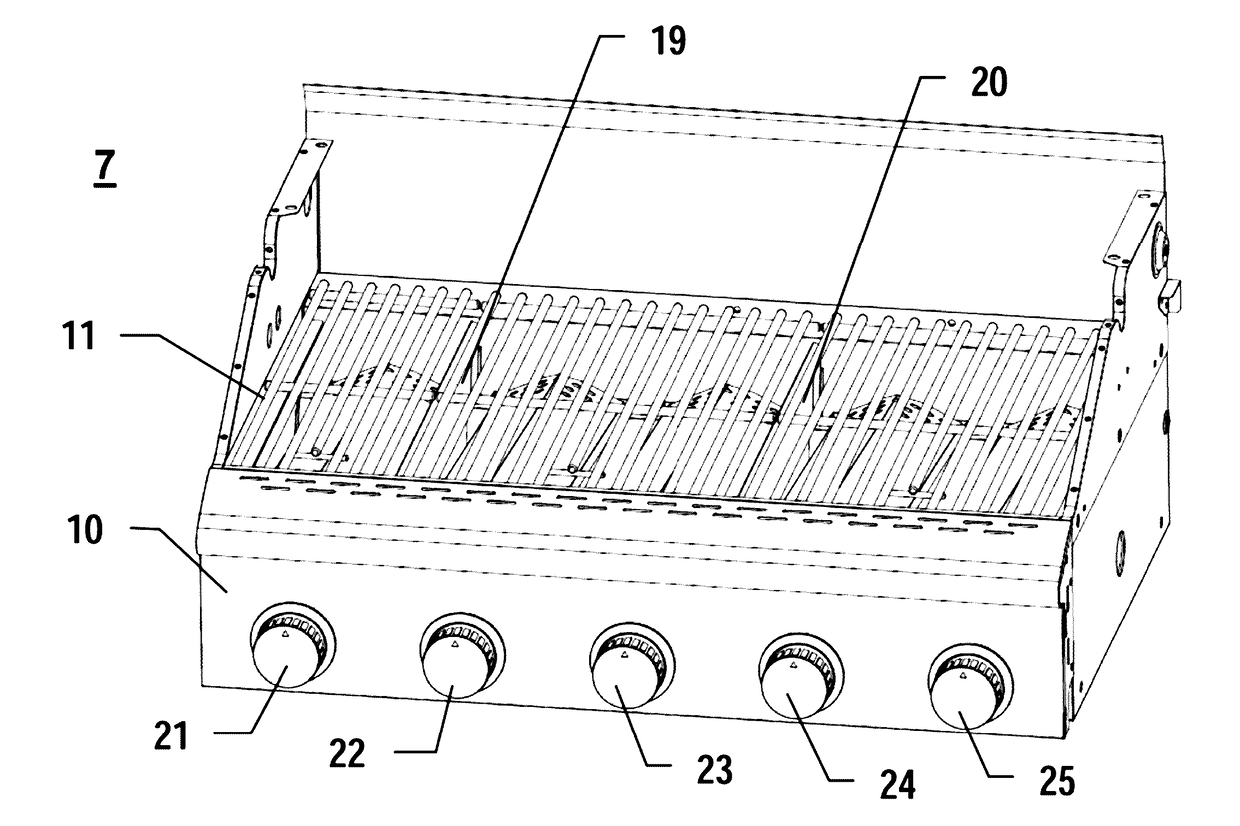

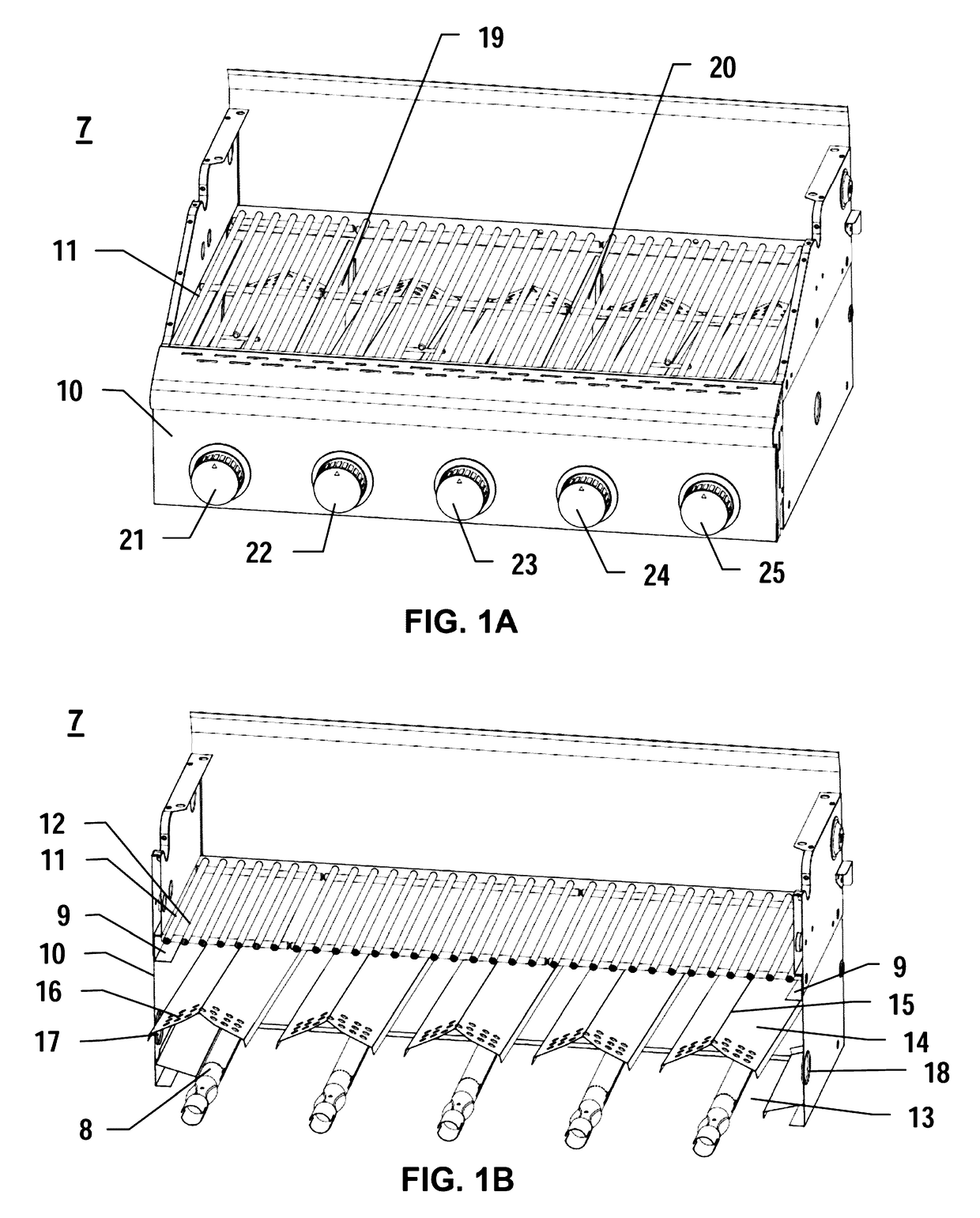

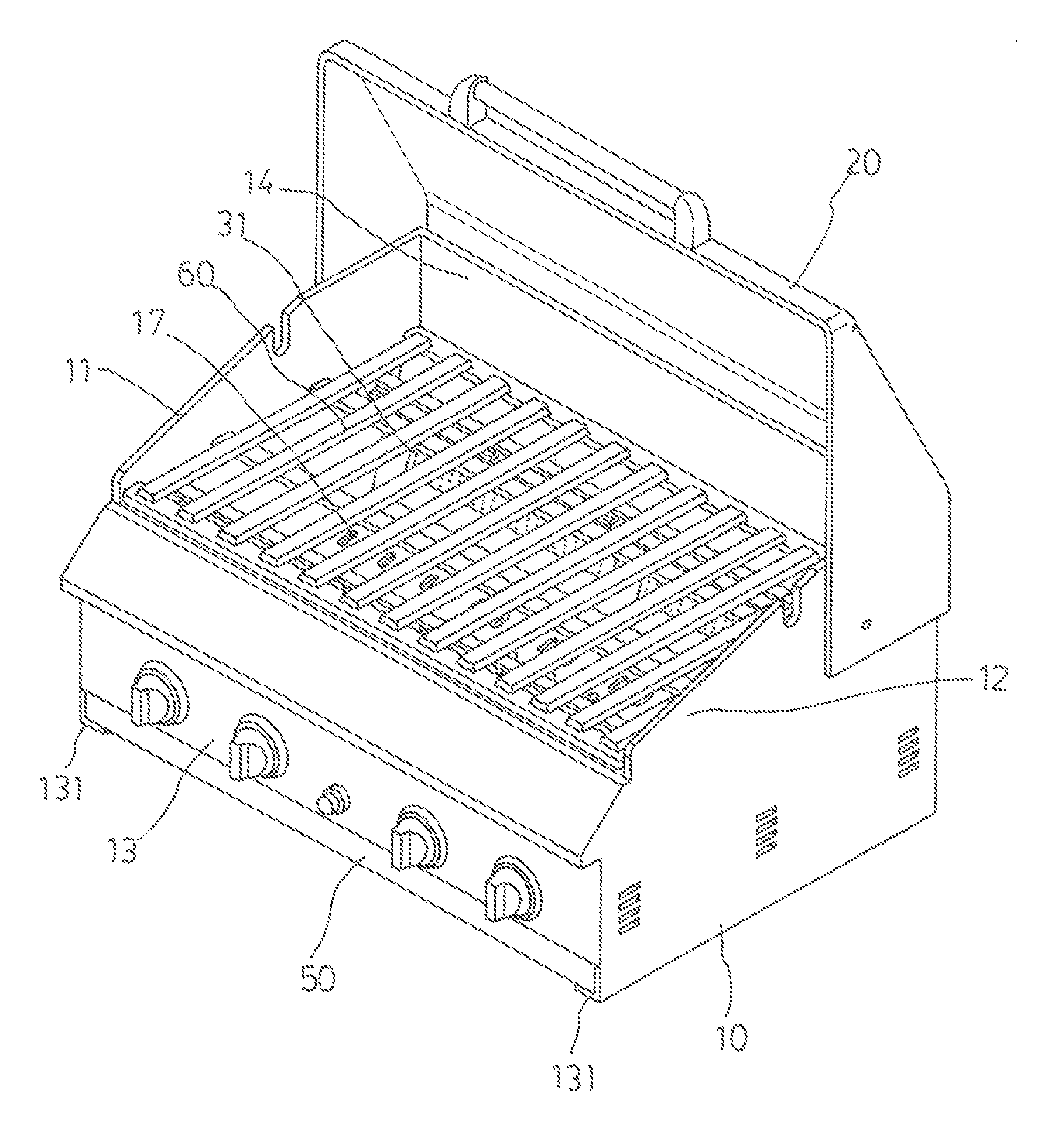

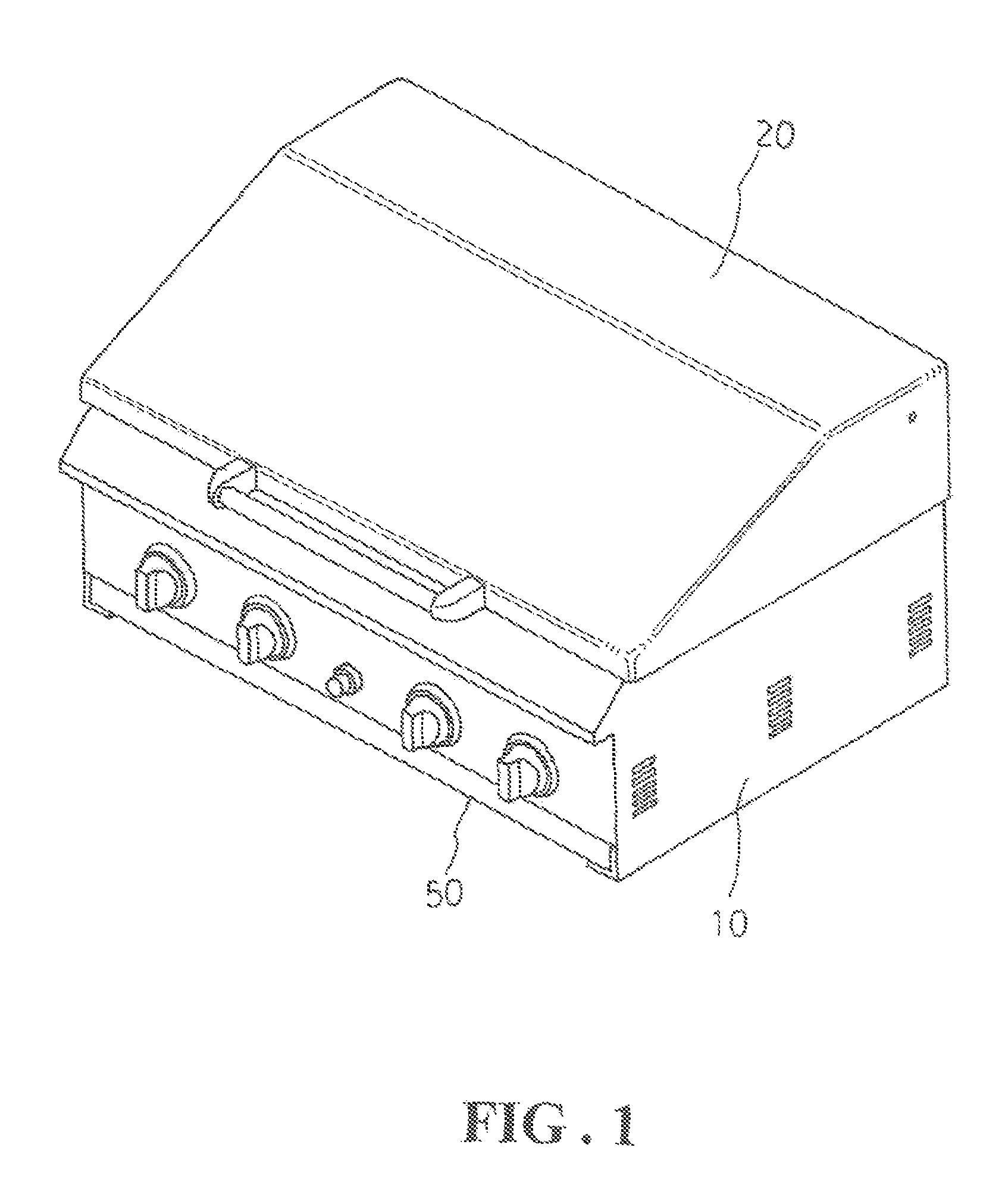

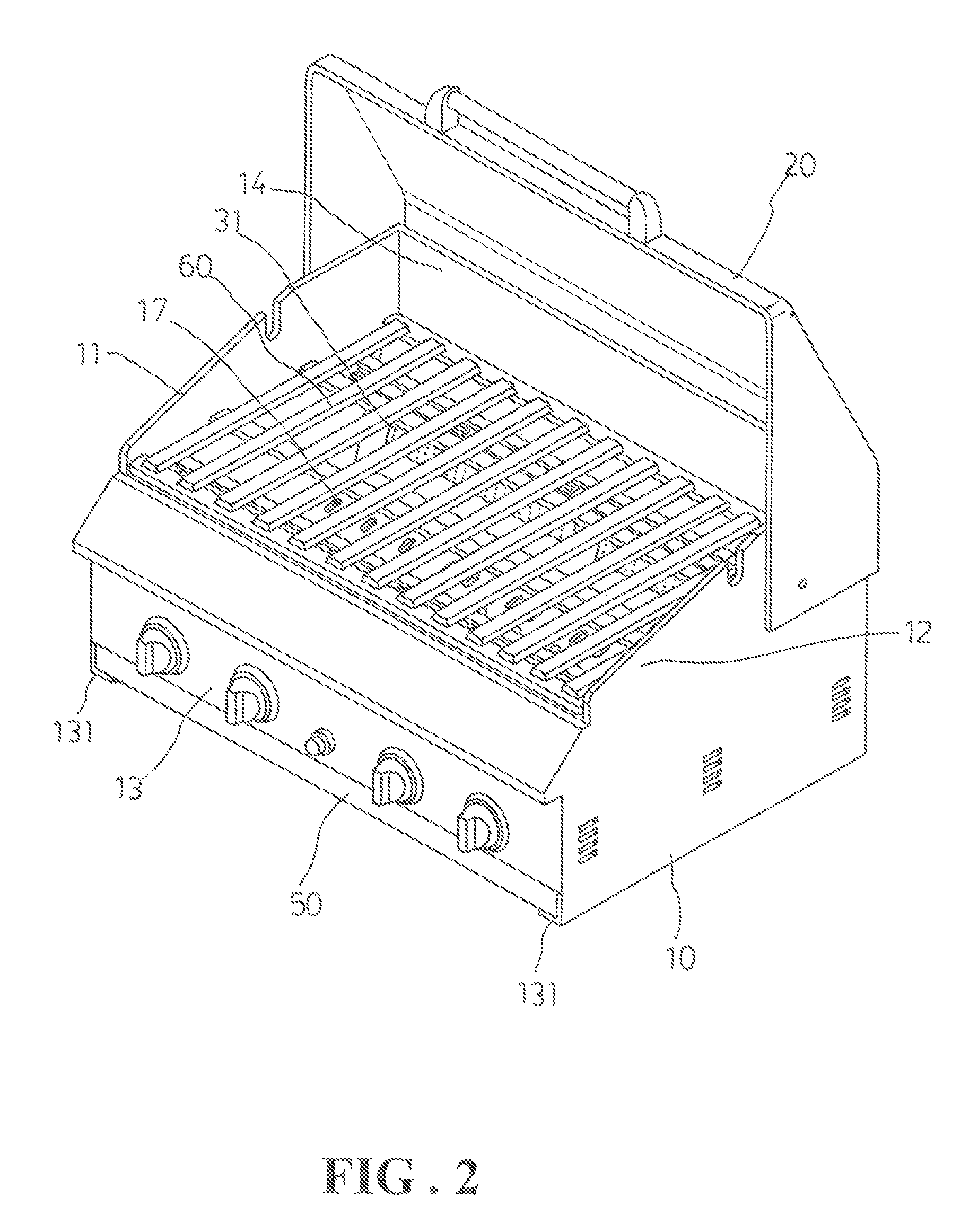

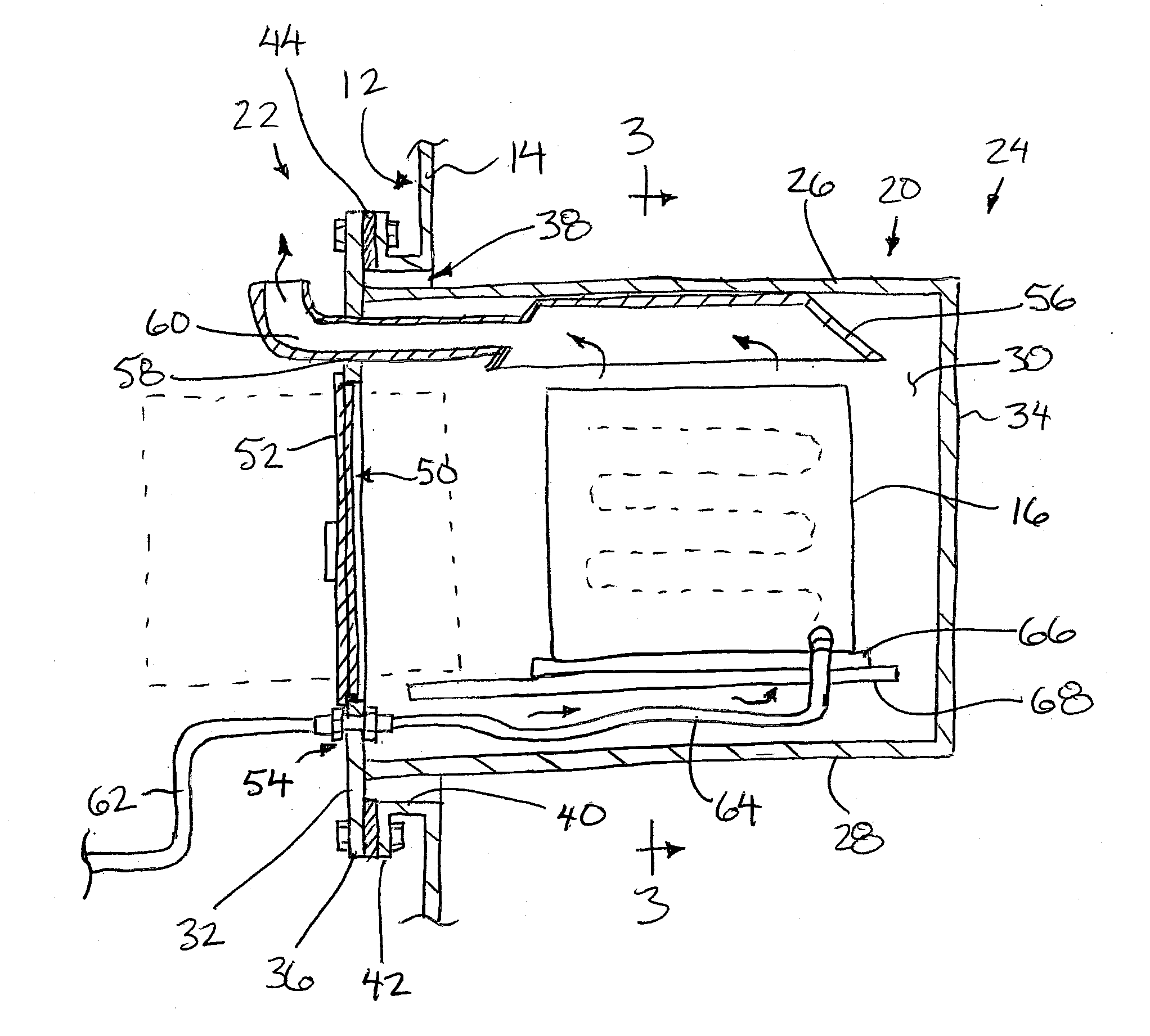

Barbecue Grill Heating and Smoking Plates and Method

ActiveUS20170130966A1Heating directlyDomestic stoves or rangesLighting and heating apparatusEngineeringCooking methods

A cooking grill with apparatus by which food may be cooked using direct convective heat, indirect radiative heat, broiling (direct radiative heat), and smoking features as well as the method for transforming the grill to use any one of these cooking features, or combinations of these cooking pictures, at any given time is disclosed. The method of heating employed depends on the placement of one or more movable and removable heat plates of the present invention with respect to the grid or grids of the grill. The grill of the present invention provides versatility in introducing a grill with a plurality of cooking systems as well as grill cooking methods.

Owner:NEXGRILL INDS

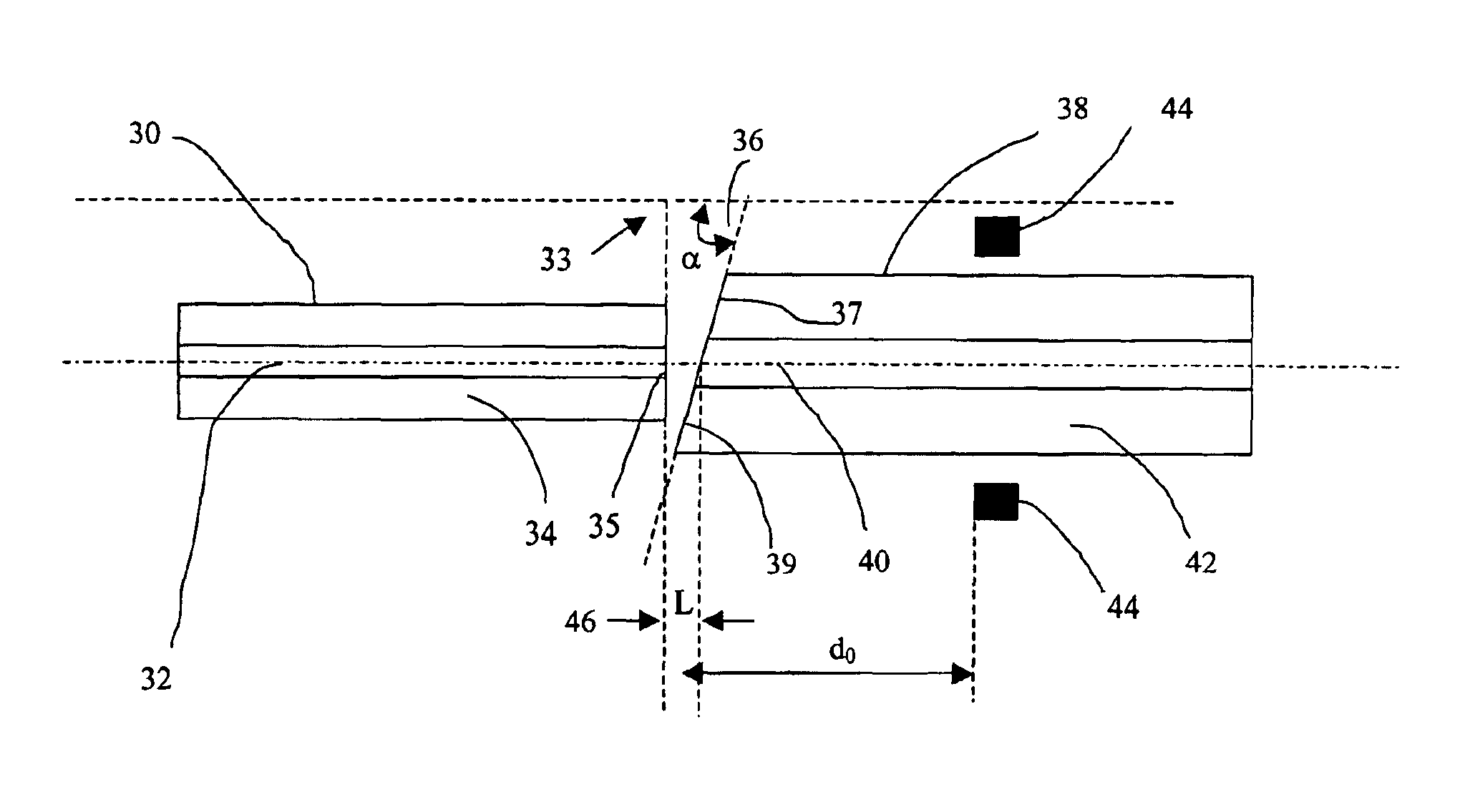

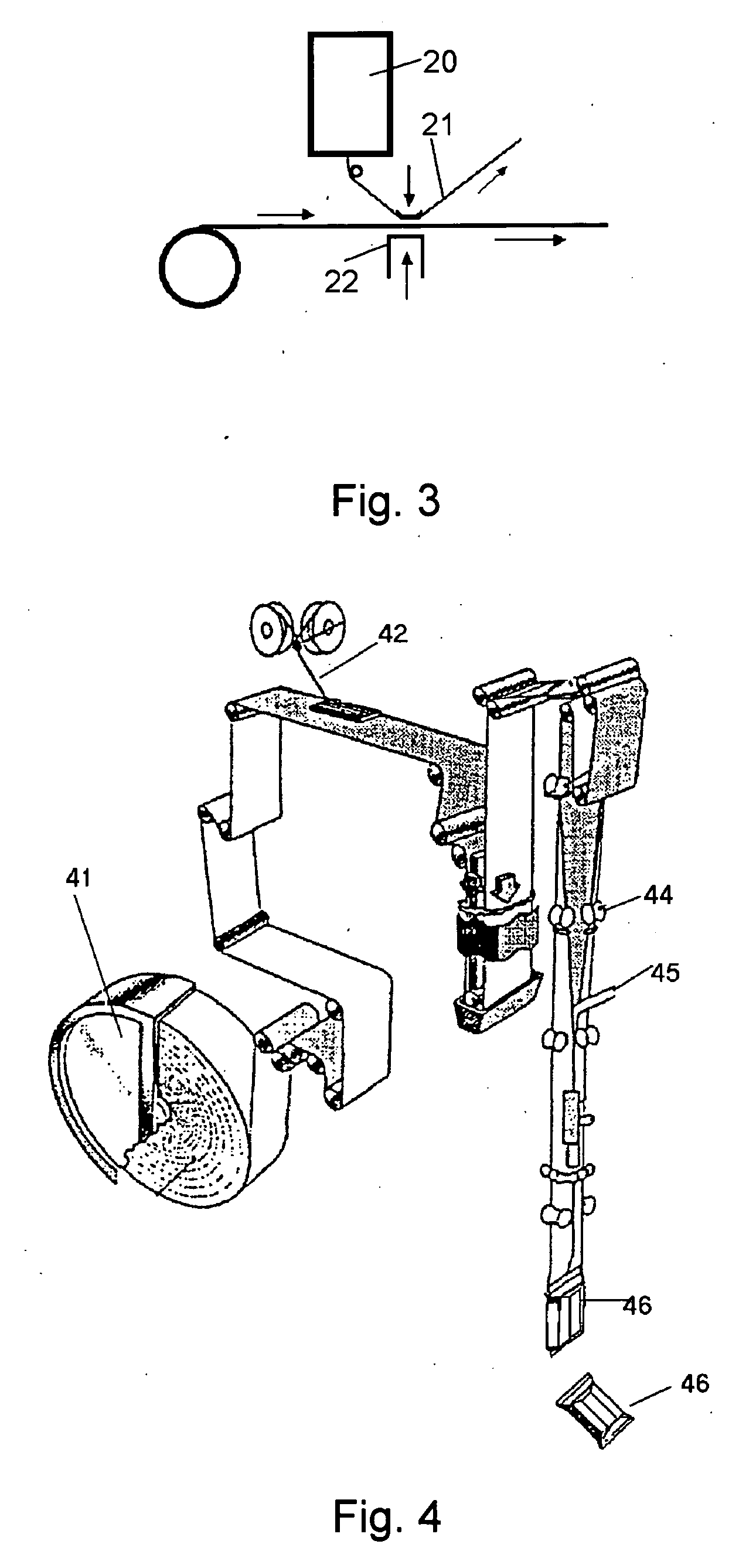

Method of angle fusion splicing silica fiber with low-temperature non-silica fiber

InactiveUS6866429B2Reduce back reflectionMechanically robustGlass making apparatusCoupling light guidesRange of motionSilica fiber

A low-cost approach is provided for forming a low splice loss, low back reflection loss and mechanically robust angle-fusion splice between a standard silica fiber and a low-temperature non-silica glass fiber. This is accomplished by angle cleaving the silica fiber, square cleaving the non-silica fiber and then asymmetrically heating the fibers to form an angle fusion splice. A matched angle at the end of the non-silica fiber is generated in situ during the splicing process. The tip of the angle-cleaved silica fiber may be polished flat back to the edge of the core to reduce the range of motion of the non-silica fiber during splicing thereby further reducing splice loss and enhancing the mechanical strength of the joint.

Owner:NP PHOTONICS A CORP OF DELAWARE

Antifuse structure having an integrated heating element

InactiveUS7323761B2Heating directlySemiconductor/solid-state device detailsSolid-state devicesElectrical conductorEngineering

The present invention provides antifuse structures having an integrated heating element and methods of programming the same, the antifuse structures comprising first and second conductors and a dielectric layer formed between the conductors, where one or both of the conductors functions as both a conventional antifuse conductor and as a heating element for directly heating the antifuse dielectric layer during programming.

Owner:GLOBALFOUNDRIES INC

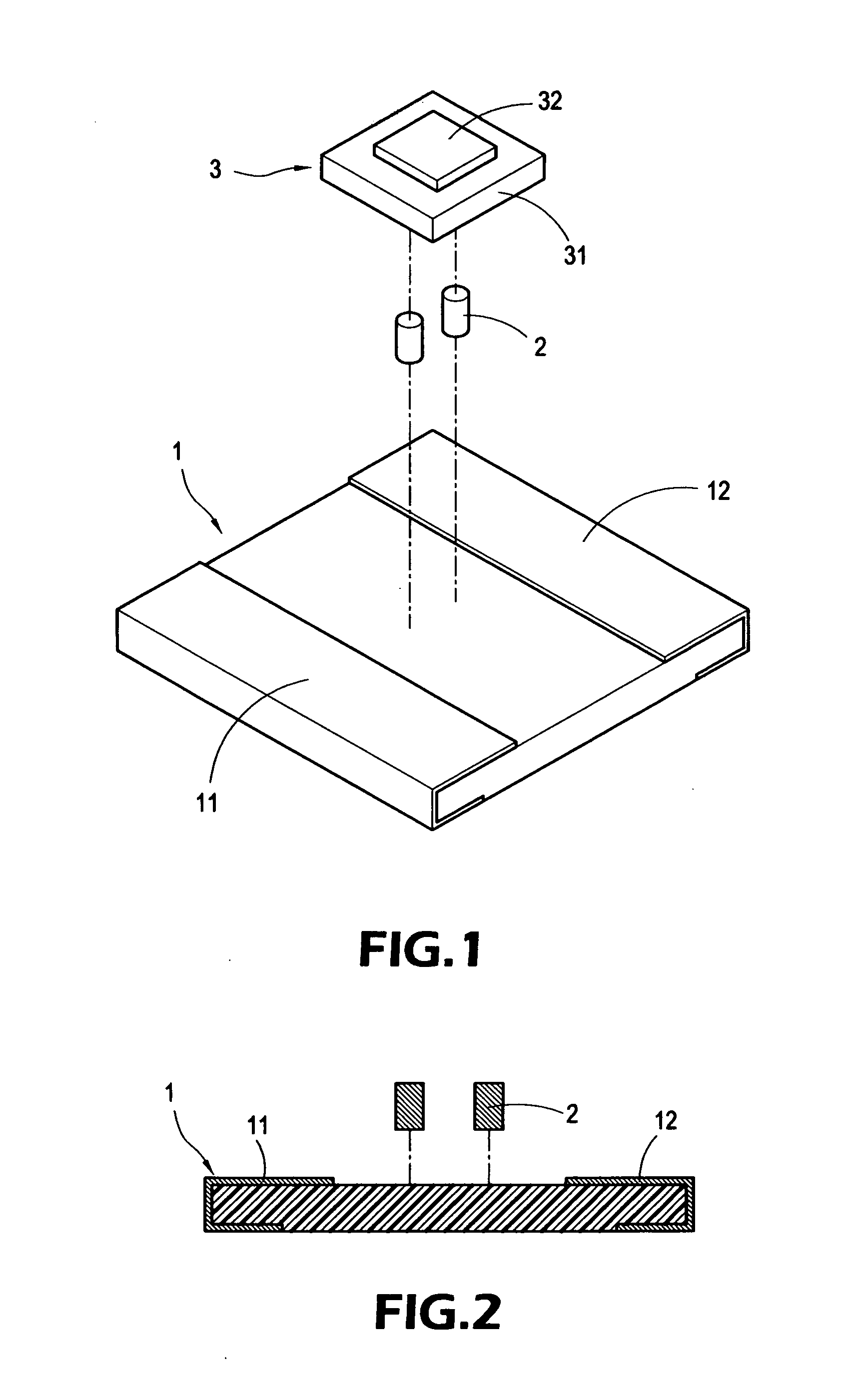

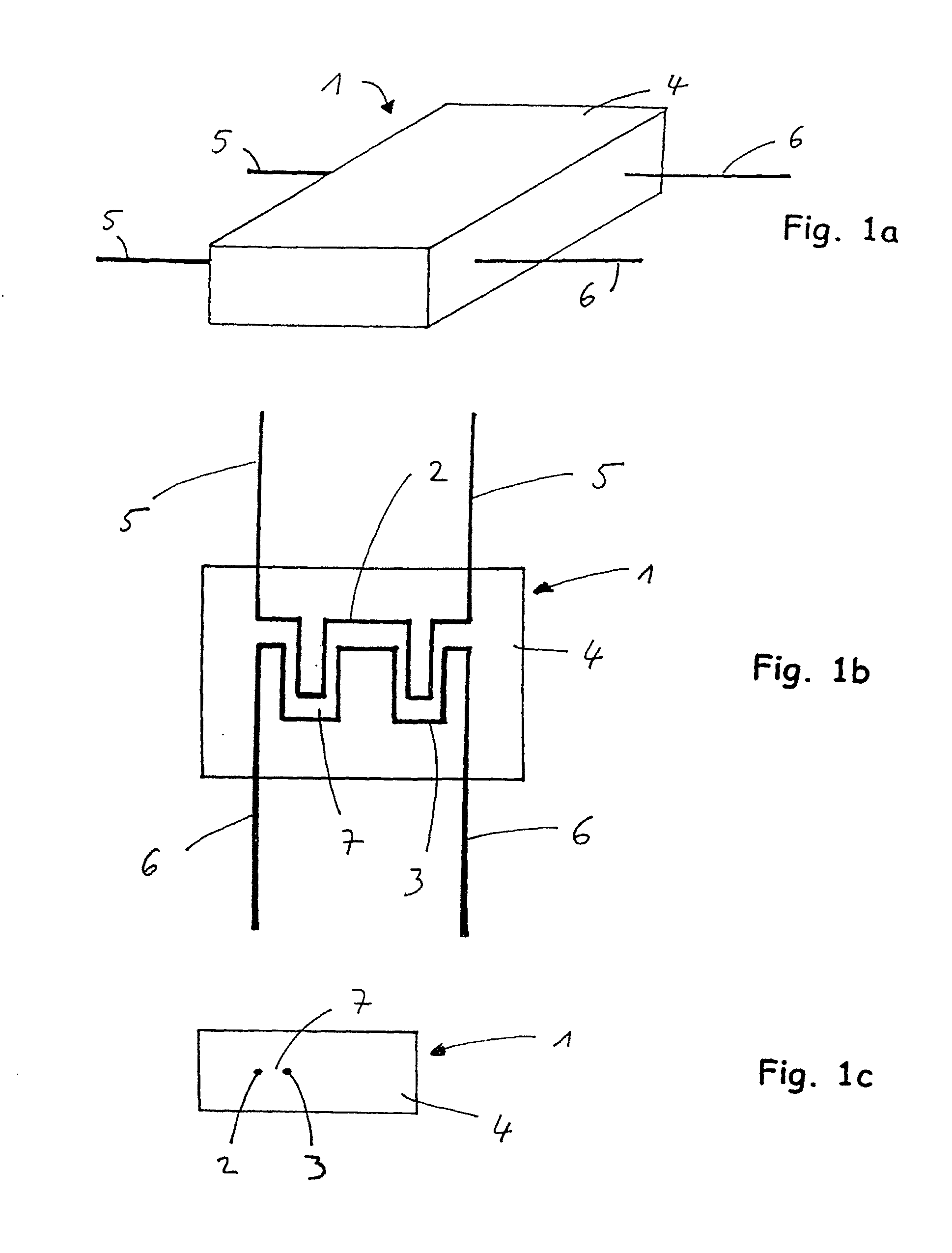

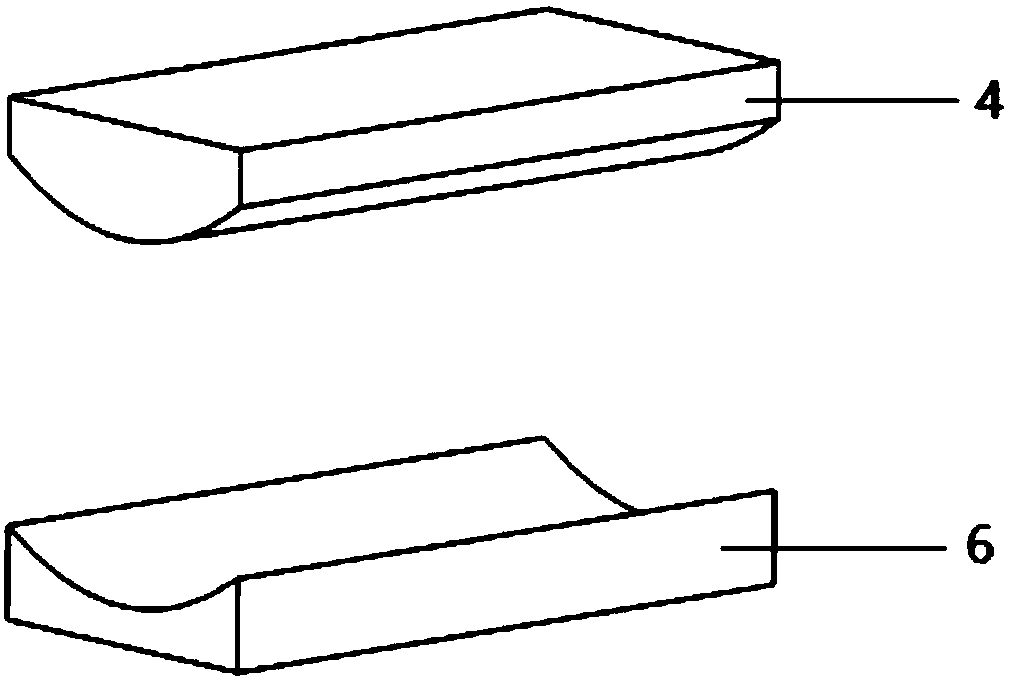

Heatable gas sensor and method for the production thereof

InactiveUS20120272720A1Easy to manufactureSimple designLine/current collector detailsGas analyser construction detailsProduct gasReducing substances

The invention relates to a heatable gas sensor (1) for gases containing reducing substances, comprising a gas-sensitive porous metal oxide (4) and electrical elements (2, 3, 8, 9, 14, 15, 16, 18) spaced apart from one another both for heating the metal oxide (4) and for measuring a conductivity of the metal oxide (4), wherein each electrical element (2, 3, 8, 9, 14, 15, 16, 18) is spatially embedded in the metal oxide (4). The invention further relates to a method for producing the gas sensor.

Owner:WIESNER MANFRED +1

Multi-pane, multi-geometry goggle eye-shield

Owner:ABOMINABLE LABS LLC +1

Air frying pan

InactiveCN103720371AReduce wear and tearImprove heating efficiencyRoasters/grillsAir cycleEngineering

The invention discloses an air frying pan. The air frying pan comprises a shell, a heater, an air circulating cavity and a containing cavity, wherein the heater wraps the containing cavity; the air circulating cavity comprises an air flow driving fan and an air circulating cavity shell; the air flow driving fan is arranged in the air circulating cavity shell and drives gas in the air circulating cavity shell to flow; openings are formed in two ends of the air circulating cavity shell; the opening in one end of the air circulating cavity shell is connected with the top of the containing cavity; the opening in the other end of the air circulating cavity shell is connected with the bottom of the containing cavity; the containing cavity comprises a containing barrel; through holes are densely distributed in the wall of the containing barrel; the heater comprise electric heating tubes; the electric heating tubes wrap the containing barrel; and a gap is formed between each electric heating tube and the containing barrel. The heating efficiency is improved by using the electric heating tubes and the auxiliary air heater, the electric heating tubes are distributed around the containing barrel, heating is direct, and loss of hot air when the hot air flows is reduced.

Owner:WUJIANG JUNCHENG PRECISION MACHINERY

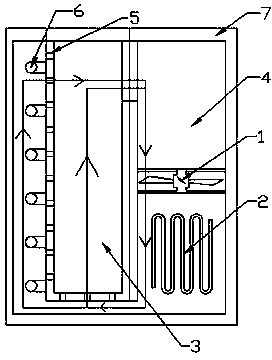

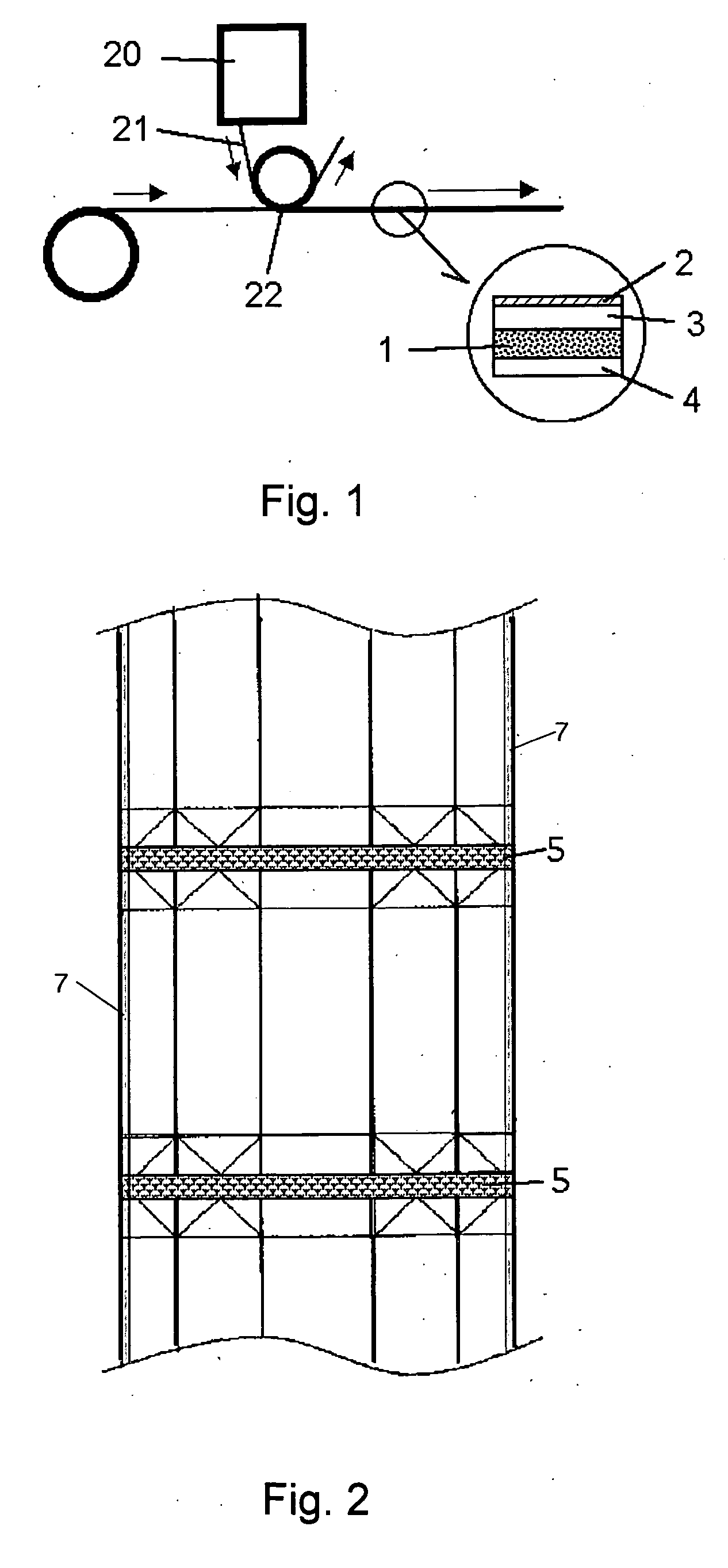

Method for producing packaging laminated material

InactiveUS20070034330A1Thin and inexpensiveEfficient executionWrappersDecorative surface effectsThermoplasticEngineering

A method for producing a laminated material, which comprises providing a raw material roll containing a support layer, drawing out a support layer in a web form from the raw material roll, transferring a silver-based thin film layer on an inner face of the inside of the support layer including a zone to be heat-sealed by the high frequency induction heating for the formation of a container, prior to or after the transferring step, laminating a heat-sealable inner layer on the inside of the support layer, printing the design of the container on the outside of the support layer in a long web form, and forming one or more thermoplastic layers of the same type or different types, at the same time or sequentially, on the outside and the inside of the printed support layer in a web form. The method allows a sealing zone to be formed so as to have an antibacterial atmosphere.

Owner:TETRA LAVAL HLDG & FINANCE SA

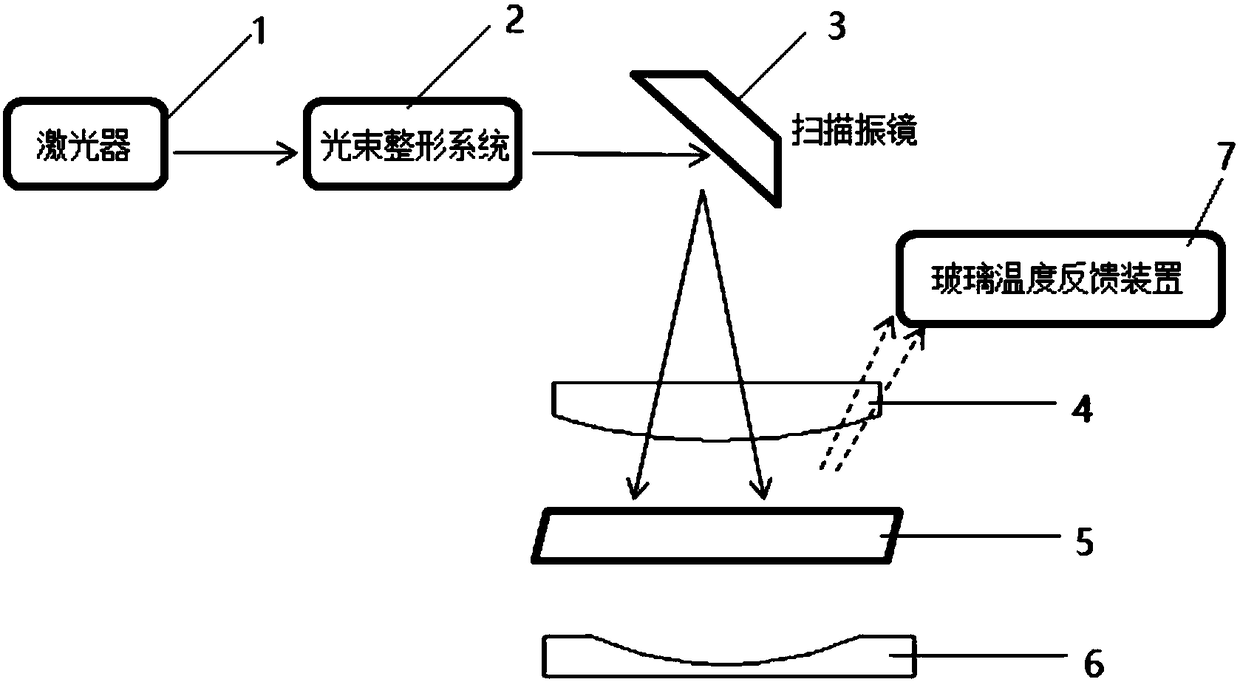

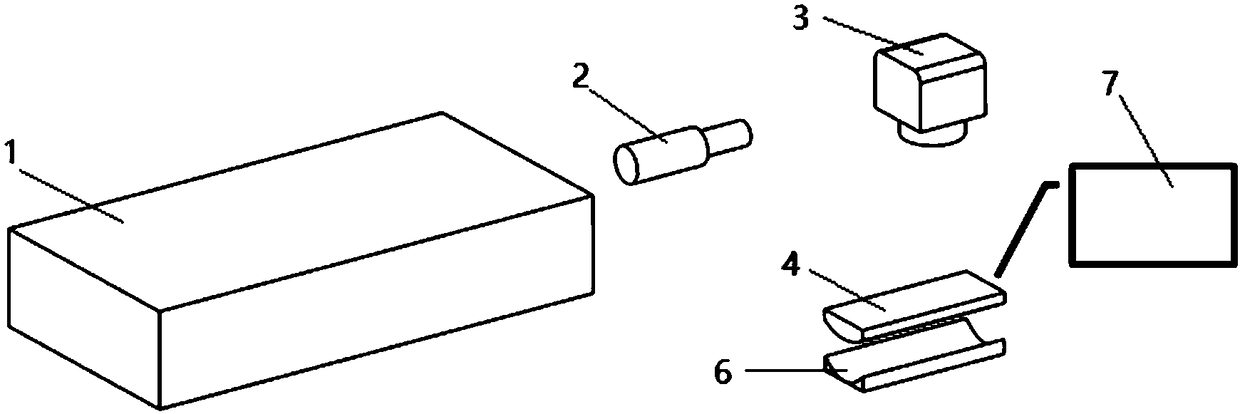

Curve surface glass shaping device and shaping method

PendingCN108558188AImprove the heating effectHeating directlyGlass reforming apparatusLight beamOptoelectronics

The invention discloses a curve surface glass shaping device and a shaping method. The device comprises a laser, a light beam shaping system, a scanning vibration lens and a curve surface shaping mold, wherein the laser is used for giving out laser suitable for softening treatment on glass; the light beam shaping system is arranged behind the laser, and is used for collimating the laser given outby the laser into a required laser beam; the scanning vibration lens is arranged behind the light beam shaping system, and is used for controlling a laser beam deflection direction for scanning; the curve surface shaping mold is made of a laser transmission hard material; the laser beam transmits the curve surface shaping mold in a scanning mode to heat the glass; the heat distribution of the glass is debugged in a scanning mode; the curve surface shaping mold is used for performing pressing shaping on the glass subjected to heating softening. The heat distribution on the glass can be controlled through controlling the scanning of the laser beam; the curve surface glass shaping efficiency and the controllability are greatly improved; the shaping quality is improved; the energy waste can also be reduced.

Owner:SHENZHEN SUNSHINE LASER & ELECTRONICS TECH CO LTD

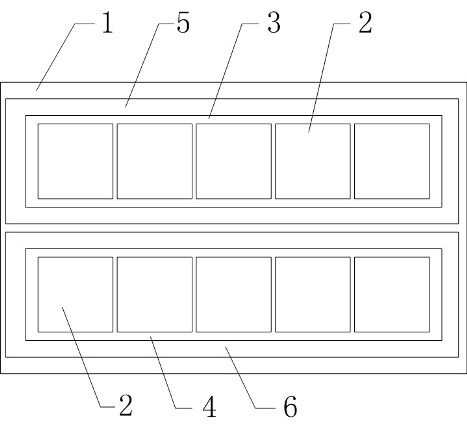

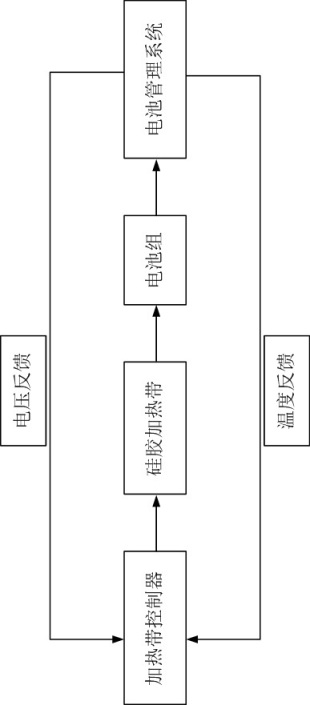

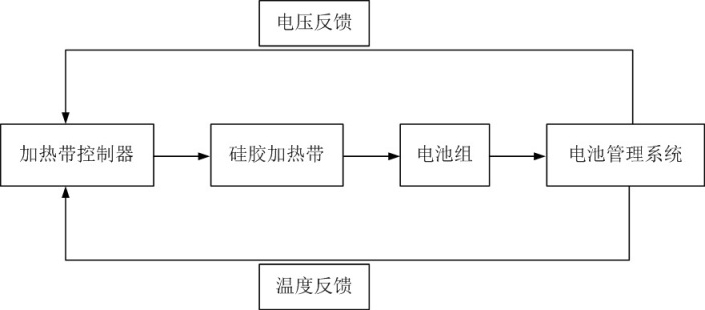

Thermal management system for power battery

InactiveCN102593398ASmall footprintWide operating temperatureCell temperature controlCell component detailsElectricityPower battery

The invention discloses a thermal management system for a power battery, which comprises a battery frame. A battery pack which consists of a plurality of battery units is arranged in the battery frame; a silica gel heating tape is attached between the battery frame and the battery pack; and the silica gel heating tape is electrically connected with a heating tape controller. The thermal management system for the power battery also comprises a battery management system used for performing real-time monitoring the temperature and the voltage of the battery pack; the heating tape controller is electrically connected with the battery management system. According to the thermal management system for the power battery, the disadvantages that the efficiency is low and the consumption is high by adopting traditional outer circulation heating are overcome by adopting the silica gel heating tape; the battery pack and the battery frame are heated directly, evenly and rapidly, and thereby, the energy of the power battery of a pure electromobile is effectively saved; the silica gel heating tape is wide in working temperature, is long in service life and is small in occupied space and is waterproof. The silica gel heating tape is also capable of performing a collision buffering action on the battery.

Owner:苏州奥杰汽车工业有限公司

Smokeless barbecue grill

ActiveUS7475632B2Equally distributedHeating directlyDomestic stoves or rangesLighting and heating apparatusInfraredWater vapor

An infrared barbecue grill which includes a body, a pair of infrared burners, a first shield member, a first baffle installed on the outer edge of the first shield member, a second shield member, a second baffle having a first edge installed on the outer edge of the second shield and having a lug, a grate placed on the body, a heat dissipator arranged on a bottom of the body, and a water basin mounted under the heat dissipator, whereby the baffles will guide the heat through the holes thereon to the region of the grate where the infrared ray emitted from the infrared burners cannot cover, the lug will prevent the rear infrared burner from emitting infrared rays directly to the user, and the water basin will provide water vapor to add moisture to the food on the grate thereby making the food juicy and delicious to eat.

Owner:GRAND HALL ENTERPRISE COMPANY

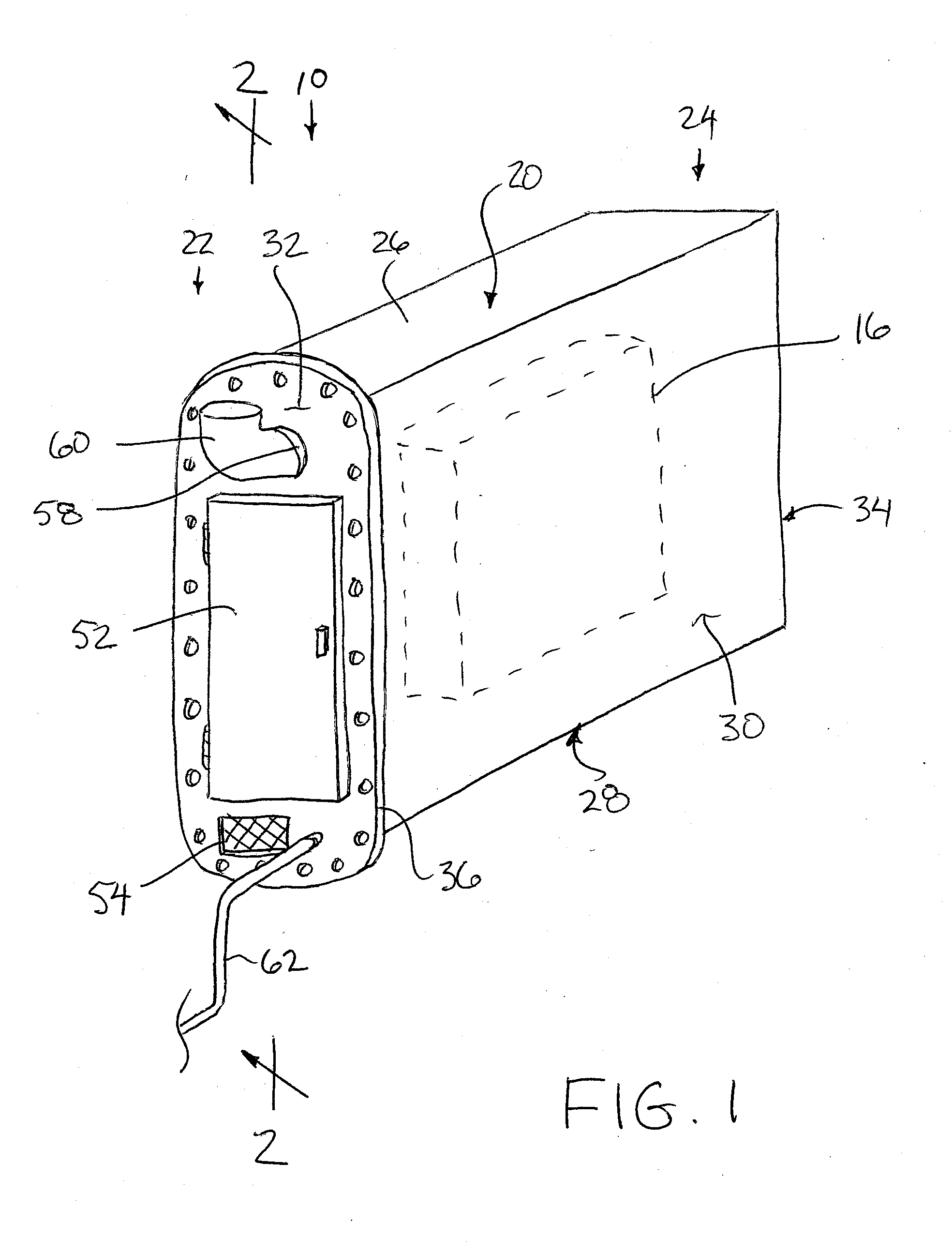

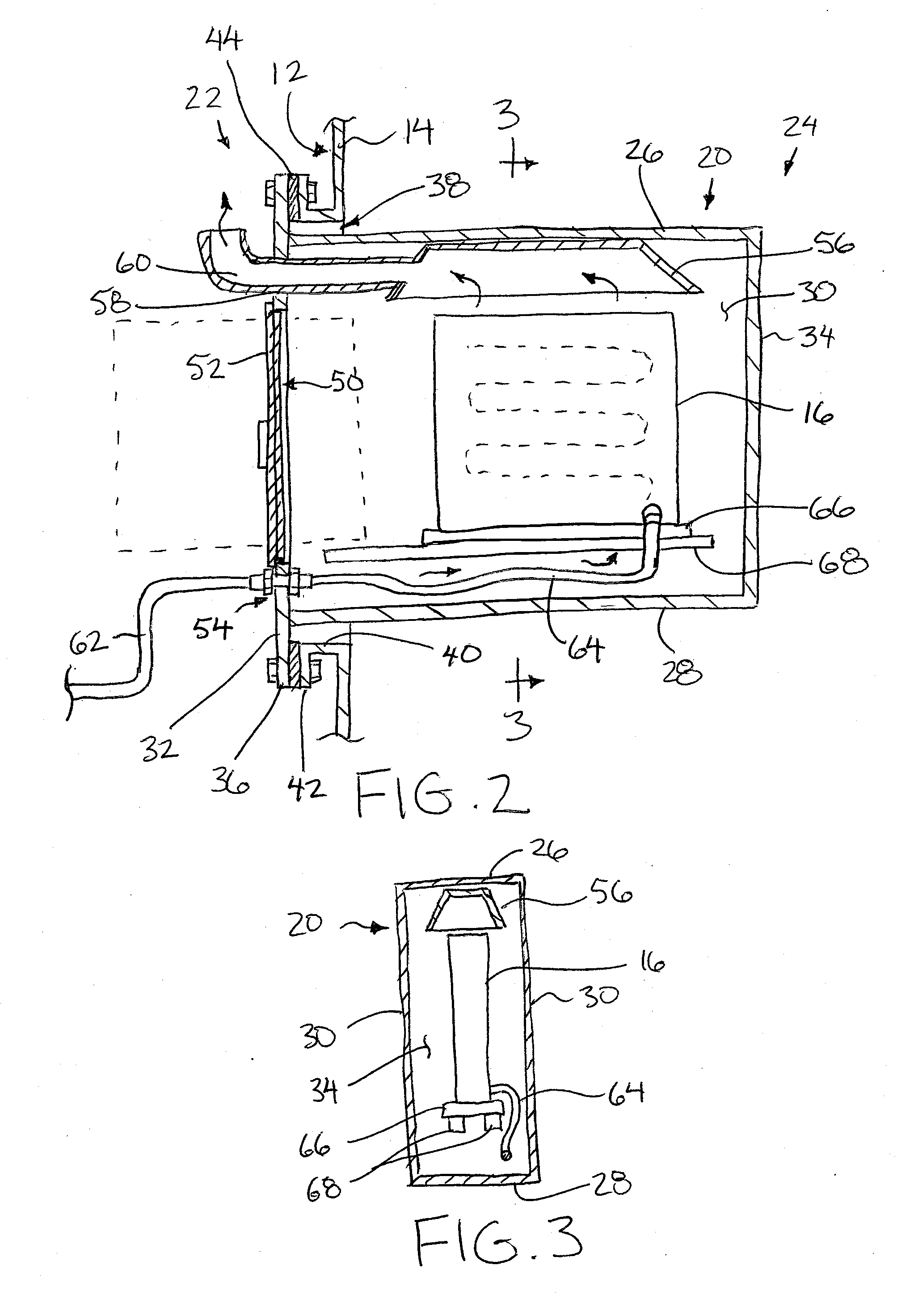

Catalytic Heating Assembly for an Oil Storage Tank

ActiveUS20150298900A1Efficient heat transferRobust constructionLarge containersLiquid transferring devicesFuel tankOil storage

In an oil storage tank having an interior oil storage chamber and a tank opening in one of the boundary walls, a heating assembly is supported to extend into the interior oil storage chamber from the tank opening. The assembly includes a casing of walls surrounding with a casing mounting flange mountable in sealing engagement relative to a tank mounting flange about the full perimeter of the tank opening such that the casing protrudes into the interior oil storage chamber of the oil storage tank. The heating chamber is suitable sized and configured to operably receive a catalytic heater therein. The heating chamber further accommodates entry of combustion air and combustion fuel into the heating chamber and exhaust of emissions therefrom.

Owner:ENVIRO PRODN SYST INC +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com