Air frying pan

An air fryer and air circulation technology, which is applied in home appliances, roasters/barbecue grids, applications, etc., can solve the problems of low efficiency and long cooking time, and achieve the goals of reducing consumption, heating directly, and improving heating efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

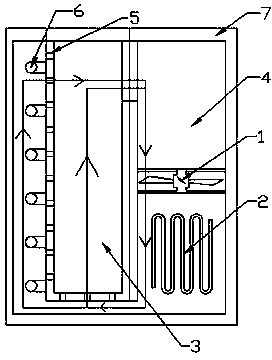

[0014] Such as figure 1 As shown, an air fryer includes a housing, a heater 6, an air circulation chamber 4 and a storage chamber;

[0015] The heater 6 is covered outside the material holding chamber, the air circulation chamber 4 includes an airflow driven fan 1 and an air circulation chamber casing, the airflow driven fan 1 is arranged inside the air circulation chamber casing, and drives the air circulation chamber casing The gas flow in the air circulation chamber shell is open at both ends, one end opening of the air circulation chamber shell communicates with the top of the material storage chamber, and the other end opening of the air circulation chamber shell communicates with the bottom of the material storage chamber;

[0016] The storage cavity includes a storage tank 3, the wall of the storage tank 3 is densely covered with through holes 5, the heater 6 is an electric heating tube, and the electric heating tube is coated on the periphery of the storage tank 3. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com