Magnetic core of non-contact electric connector and non-contact electric connector

An electrical connector, non-contact technology, applied in the field of magnetic cores and non-contact electrical connectors, can solve the problems of difficult application, large outer diameter of the magnetic core, short transmission distance of the magnetic core, etc., to reduce the requirements, meet the transmission distance, wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

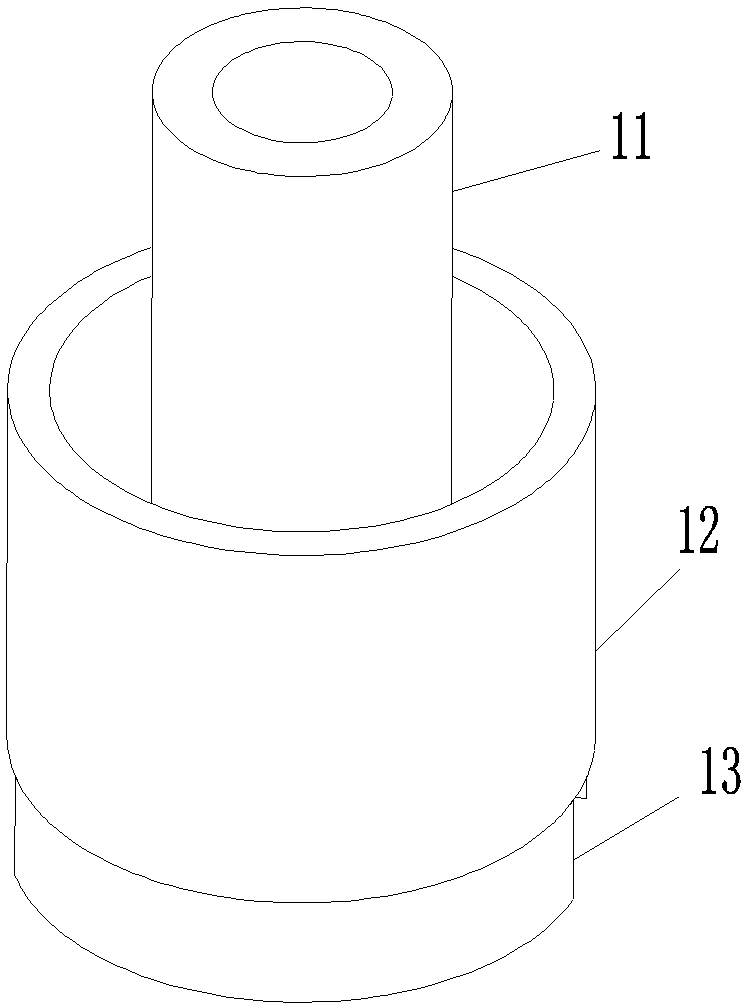

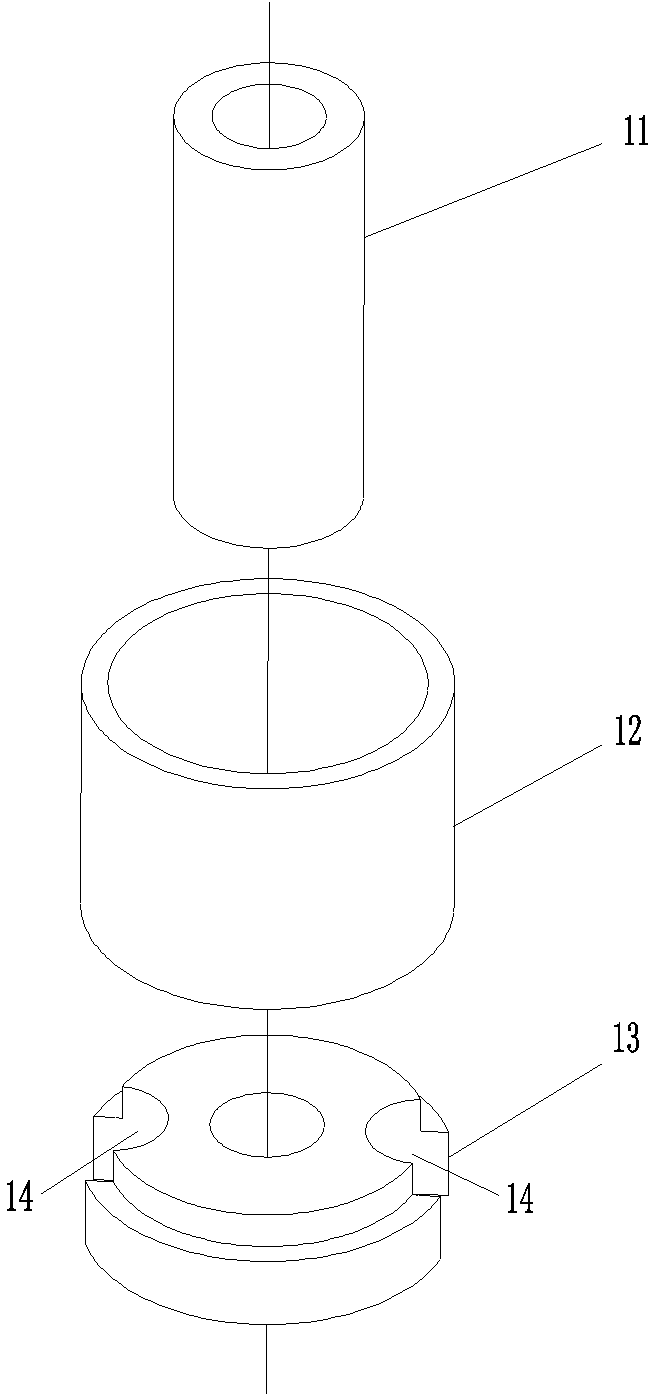

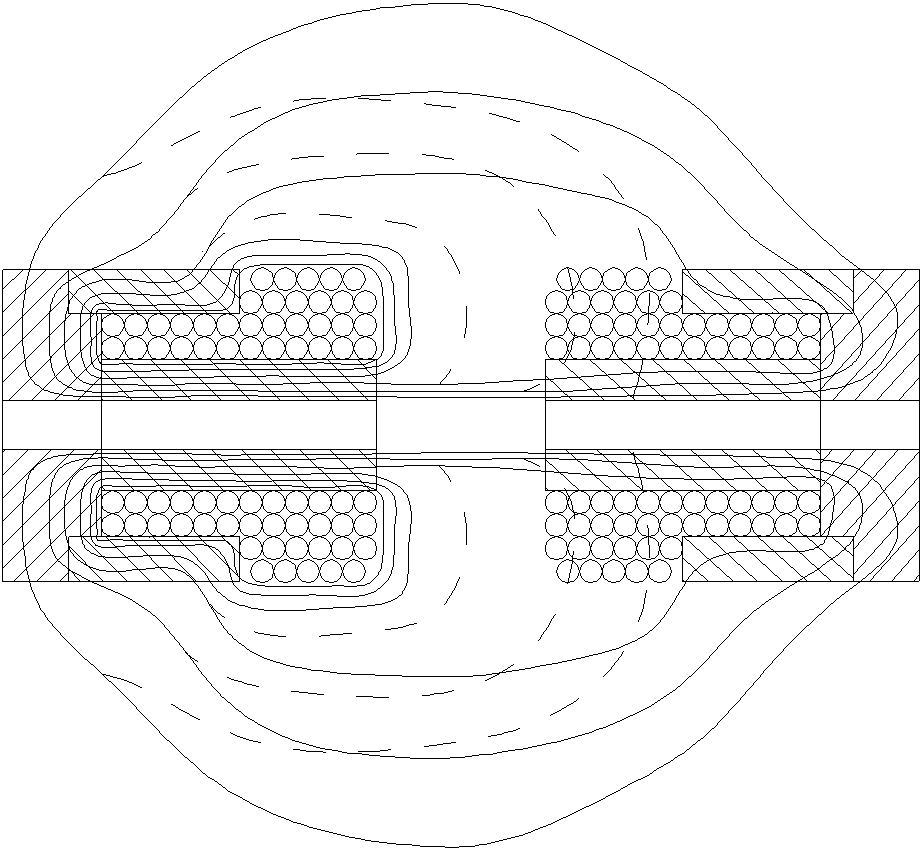

[0027] Examples of magnetic cores for non-contact electrical connectors, such as Figure 1-4 As shown, the magnetic core of the non-contact electrical connector includes an inner ring 11, an outer ring 12 and a base 13 arranged at one end of the inner ring and the outer ring.

[0028] In this embodiment, both the inner ring and the outer ring are circular sleeves and each has an integrated structure, wherein the inner ring 11 and the outer ring 12 are coaxially located in the outer ring 12, and the inner hole of the inner ring 11 is axially penetrated. , which are used for the corresponding cables to pass through.

[0029] Both the inner and outer rings are fixed on the base 13, and the base 13 is provided with a through hole corresponding to the inner hole of the inner ring, which is also for the passage of corresponding cables. In addition, the outer edge of the base is provided with Notch 14 , the notch 14 is provided for passing corresponding cables to be wound on the inn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com