Patents

Literature

45results about How to "Size fits" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method for AuSn20 alloy brazing filler metal used for packaging integrated circuit and usage thereof

ActiveCN102114584ASolve processabilitySolve product problemsWelding/cutting media/materialsSoldering mediaAlloyGraphite

The invention relates to a preparation method for an AuSn20 alloy brazing filler metal used for packaging an integrated circuit, which comprises the following steps: preparing gold and tin in proportions; placing the gold and tin into a casting furnace; sealing the furnace and vacuumizing the furnace; rising the temperature till the gold and tin are completely melted, controlling the temperature of the melt at 500-600 DEG C, refining for the purpose of alloying the gold and tin and degassing, and pouring the alloy in a graphite mould; placing an acquired AuSn20 alloy bar into a quartz tube and heating; sealing the furnace and vacuumizing till the pressure is 4-6Pa; rising the temperature and controlling the temperature rising; after melting the alloy bar, controlling the temperature of the melt to be 500-600 DEG C, and refining for 2-3 minutes; performing the melt-spinning process by using a vacuum quenching melt-spinning machine, controlling the temperature of the melt within 500-600 DEG C in the melt-spinning process, and introducing high-pressure nitrogen from an upper port of the quartz tube, wherein the nitrogen pressure is 10-15Pa; and spraying the alloy melt onto a speedily rotating metal wheel of the vacuum quenching melt-spinning machine from a bottom hole on the quartz tube, thereby acquiring a belt material. The belt material can be milled into a foil belt material or be punched into a slice or annular deeply processed product in the corresponding specification. By using the method, the product having excellent integrated circuit property can be prepared.

Owner:BEIJING INST OF NONFERROUS METALS & RARE EARTH

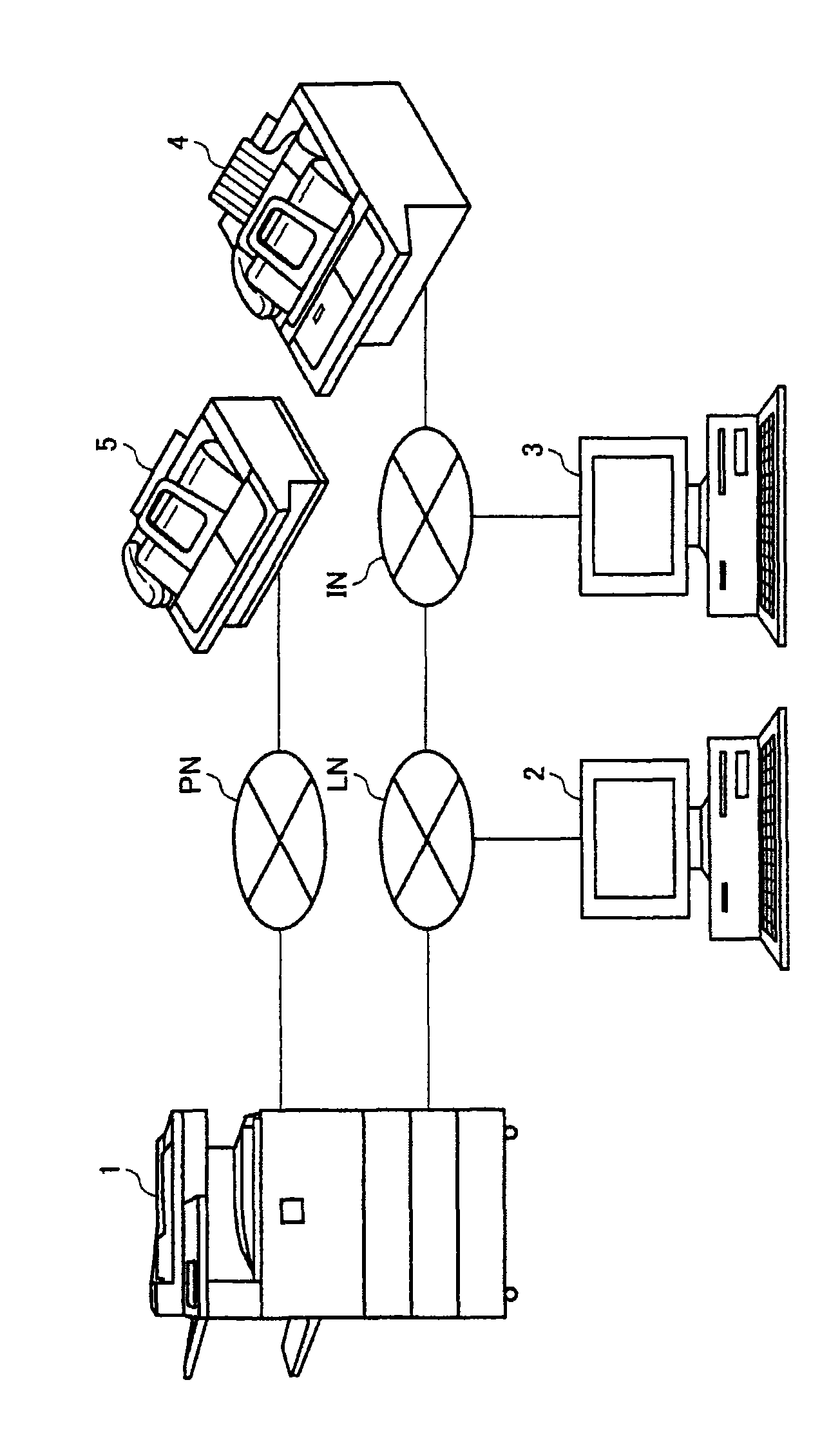

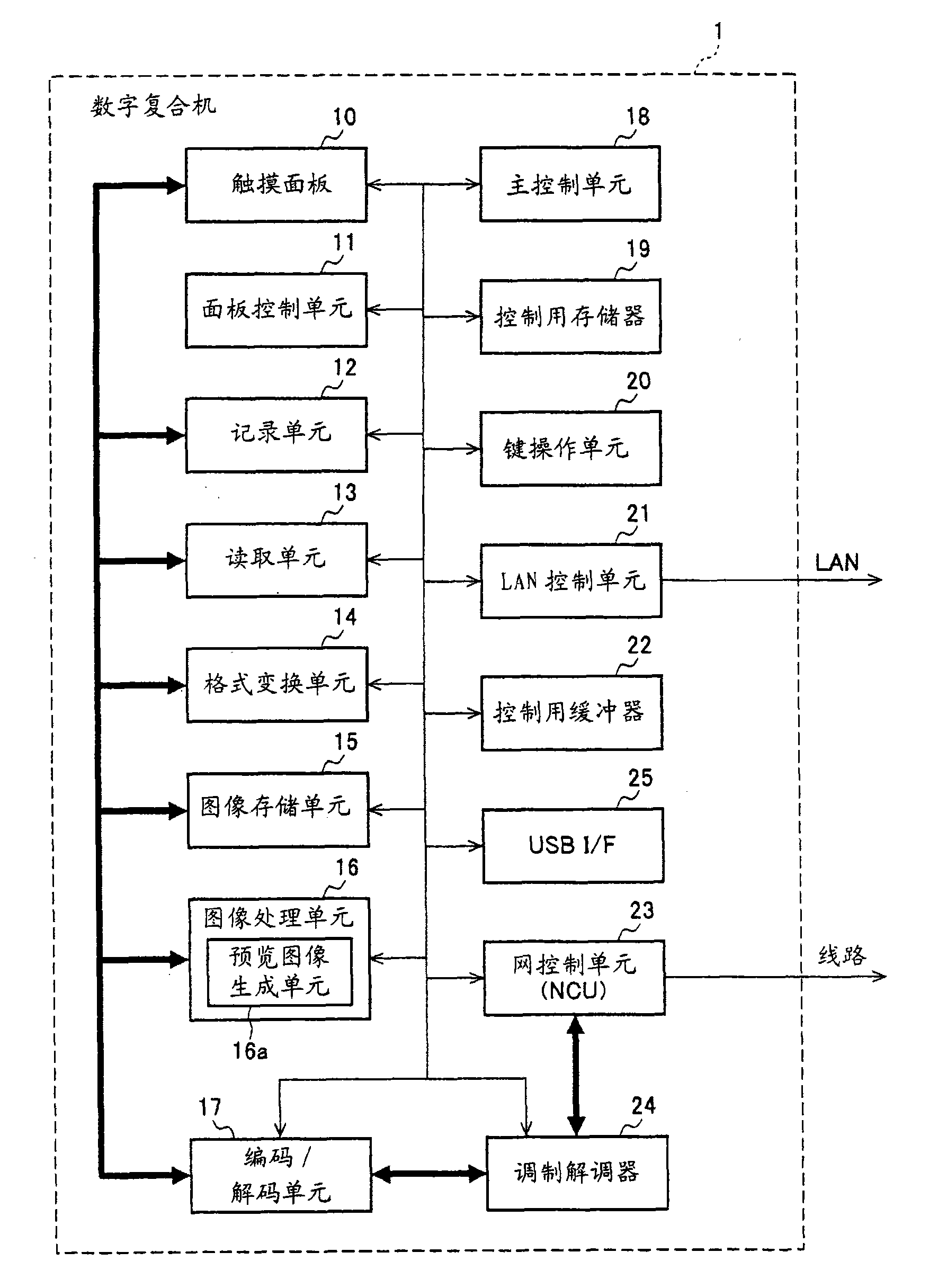

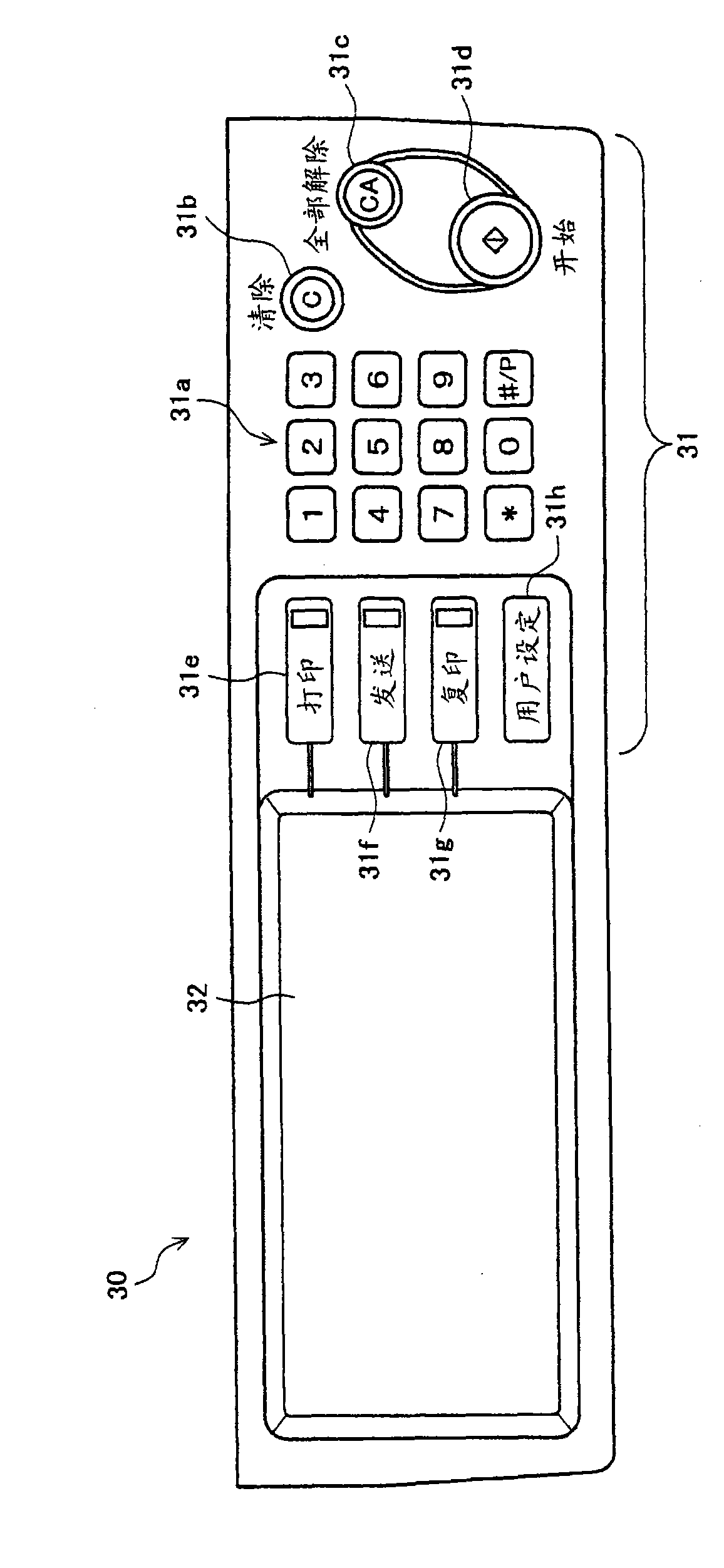

Image forming apparatus, recording medium, and preview display method

InactiveCN101640739AReduce image dataSize fitsPictoral communicationComputer graphics (images)Image formation

An image forming apparatus is provided that makes it possible to visually identify whether or not additional information is added to image data to be output in a screen in which a preview is displayedeasily. The image forming apparatus is provided with an image display portion such as a touch panel for displaying a preview of image data and is capable of outputting such as printing the image datawith additional information added thereto. When image data to be output is output with additional information added thereto, a digital multi-functional peripheral synthesizes an existence image showing an existence of the additional information, instead of the additional information, with a preview image to display on the image display portion in displaying the preview image.

Owner:SHARP KK

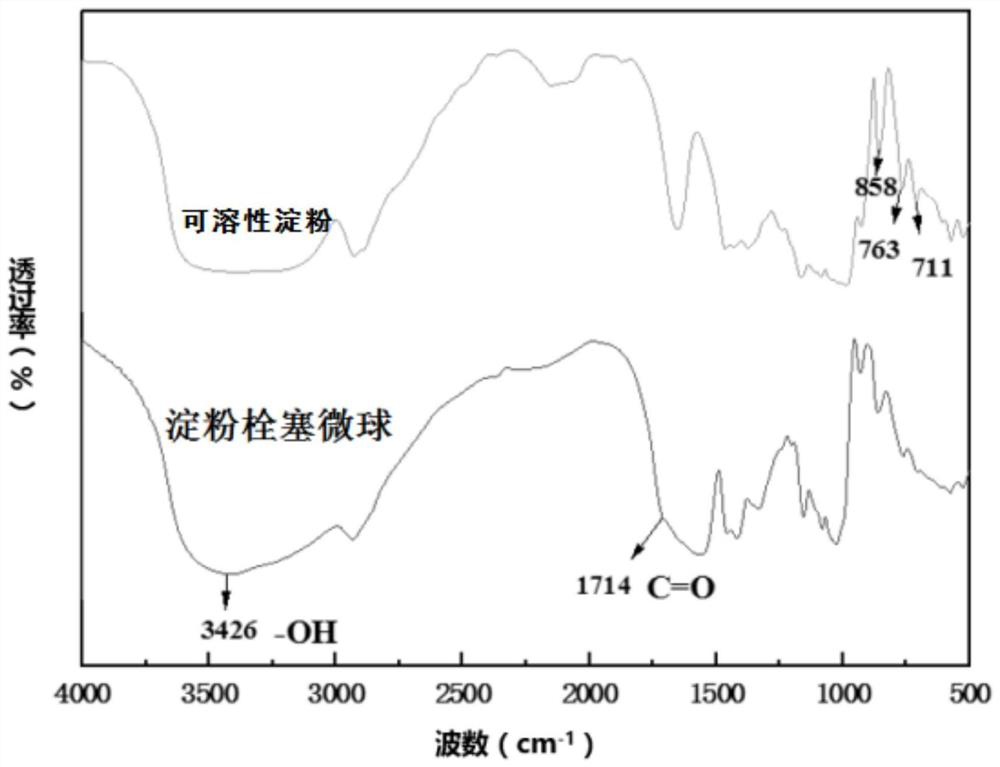

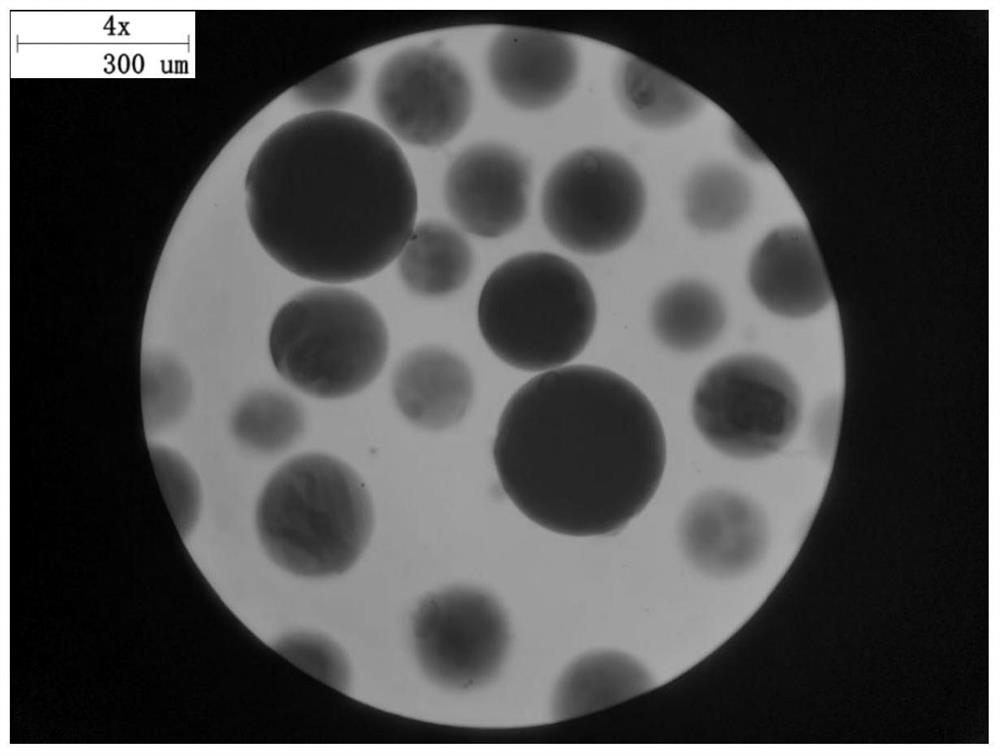

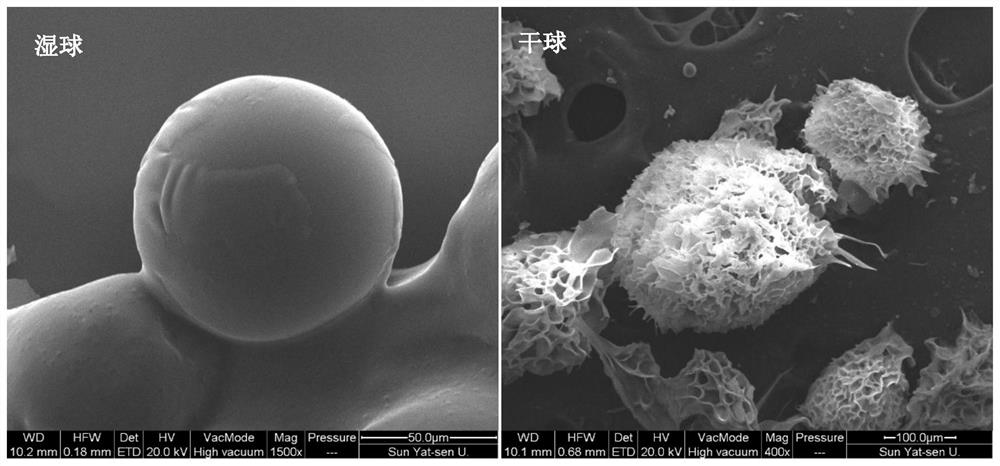

Embolism microsphere based on soluble starch as well as preparation and application of embolism microsphere

ActiveCN113694248ADrug sustained release effect is goodHigh drug loadingOrganic active ingredientsSurgical adhesivesMicrosphereActive agent

The invention provides an embolism microsphere based on soluble starch as well as preparation and application of the embolism microsphere. The embolization microsphere is prepared from soluble starch, an olefin polar monomer, an initiator and a cross-linking agent through a reversed-phase suspension polymerization technology, a continuous phase is an oil phase and a surfactant, and a dispersed phase is the soluble starch, the olefin polar monomer, the initiator and the cross-linking agent. According to the embolism microsphere, the olefin polar monomers and the soluble starch are subjected to free radical grafting and then cross-linking to obtain embolism microspheres, the embolism microspheres are of rich porous structures, pores extend towards the interiors of the microspheres, the specific surface area of the embolism microspheres is large, the surfaces of the embolism microspheres have a large number of hydrophilic polar groups, and the embolism microspheres can generate electrostatic adsorption with drugs, and a good drug sustained-release effect of the embolism microsphere is realized. The doxorubicin hydrochloride drug loading capacity of the embolism microspheres prepared by the method is as high as 191mg / g, the encapsulation efficiency is as high as 96%, and the drug loading capacity and the encapsulation efficiency of the starch embolism microspheres are effectively improved.

Owner:SUN YAT SEN UNIV

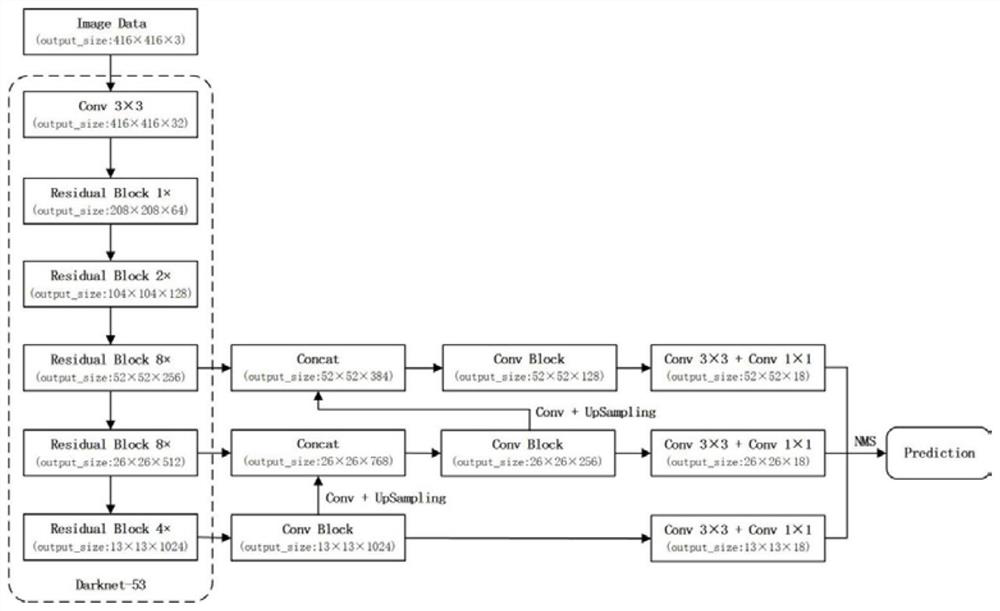

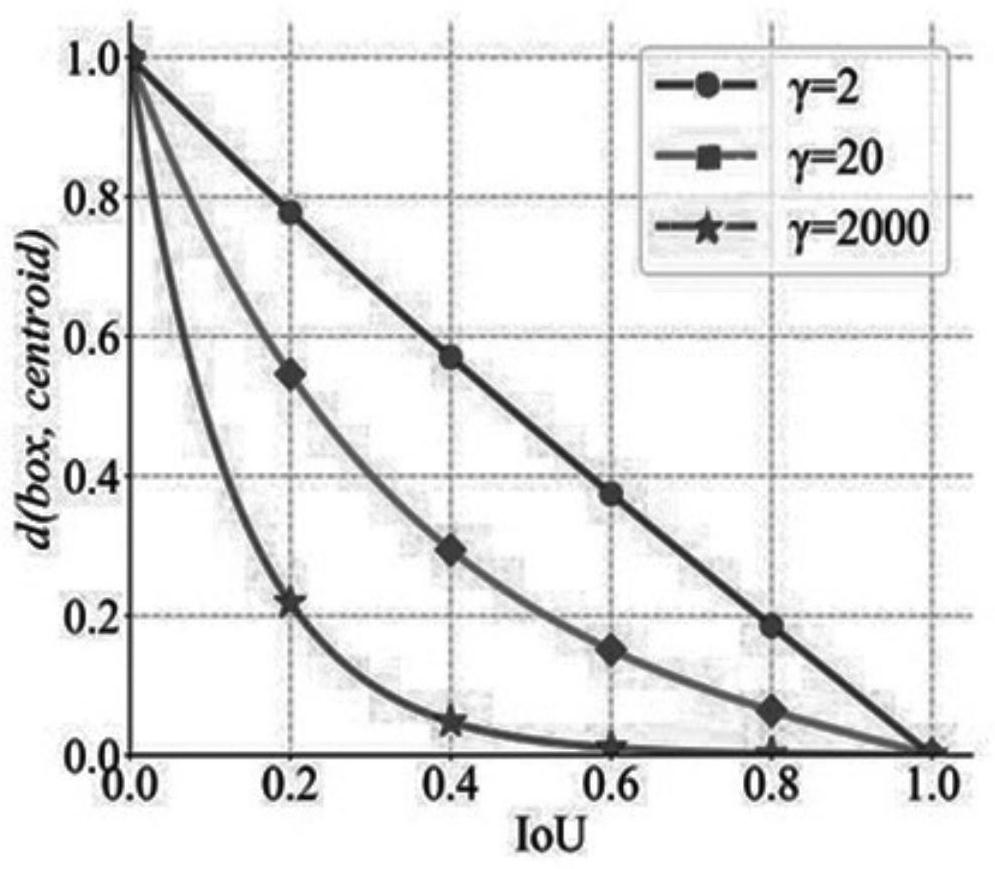

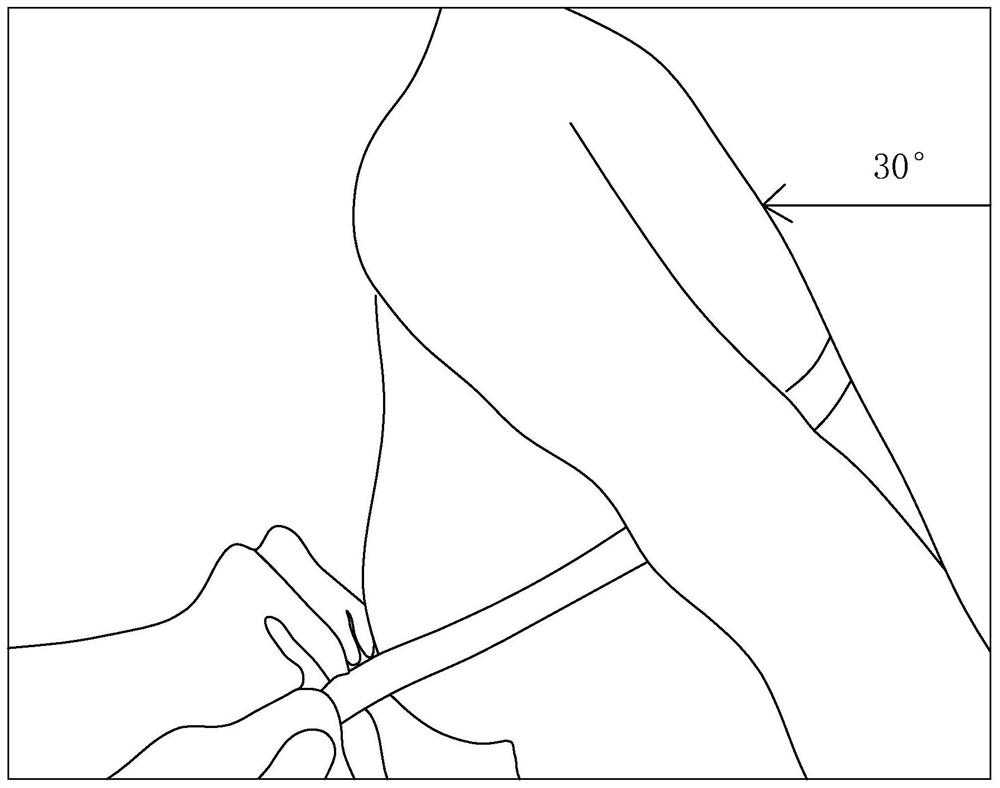

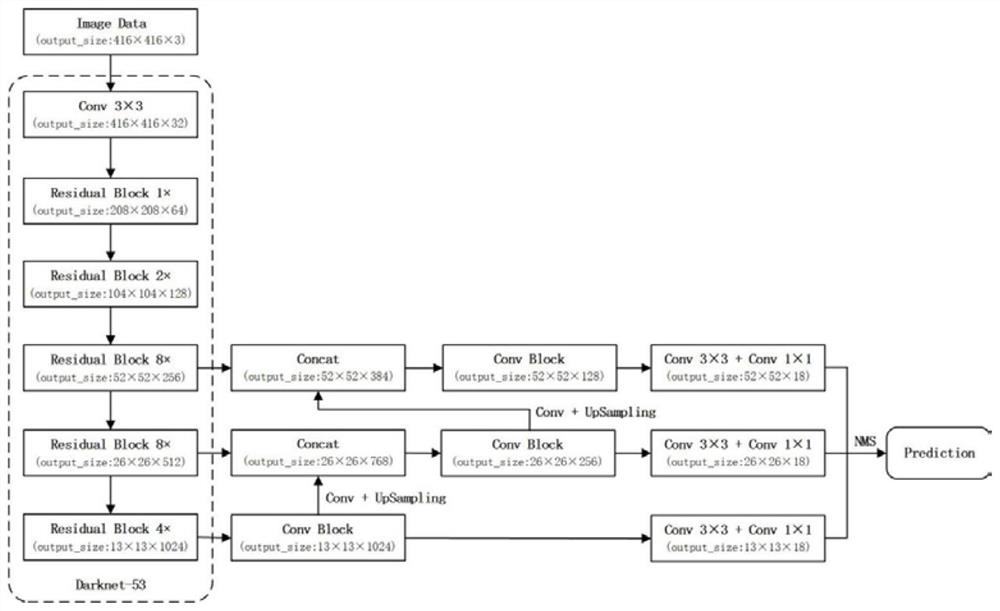

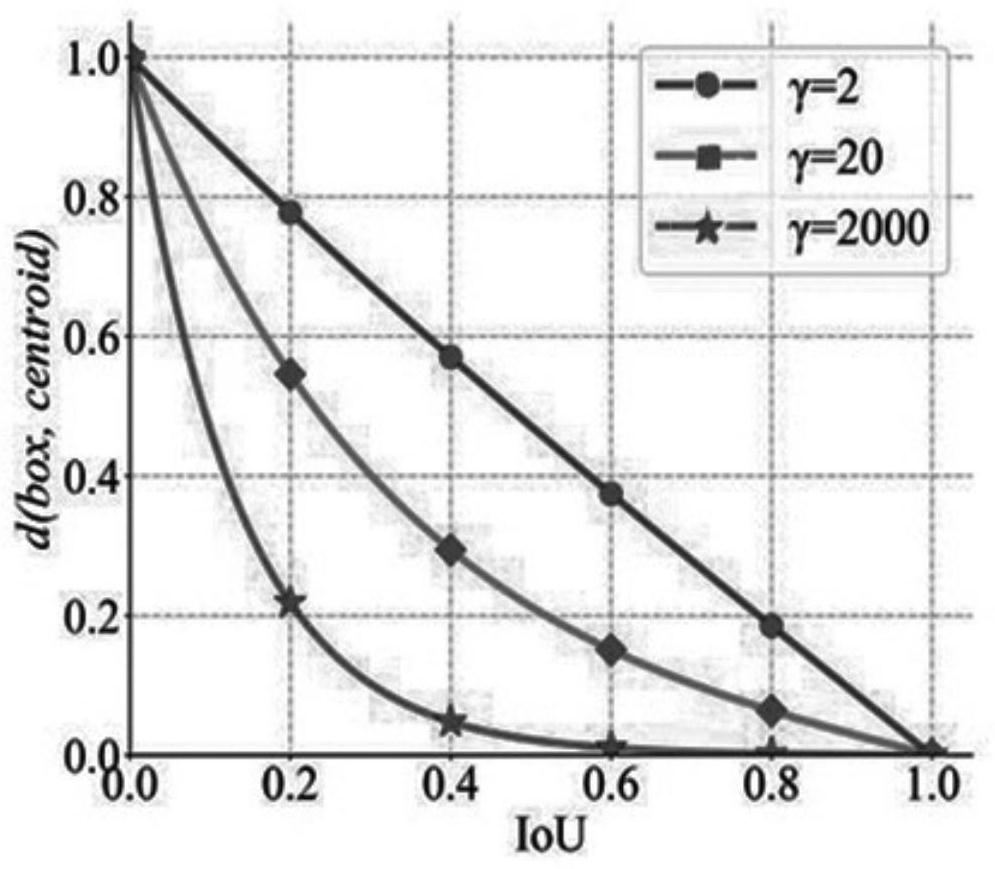

Vehicle detection method based on YOLO v3 improved algorithm

ActiveCN111860679ASize fitsQuality improvementCharacter and pattern recognitionNeural architecturesFeature extractionData set

The invention discloses a vehicle detection method based on a YOLO v3 improved algorithm. The method comprises the steps: S1, collecting a vehicle data set, wherein the vehicle data set comprises a plurality of images I of an object GT frame; S2, clustering the width and the height of the GT frame by using a dimension clustering method to generate the sizes of the width and the height of K prior frames; S3, inputting the image I into a skeleton network Darknet-53 of the YOLO v3 for feature extraction, and outputting feature maps of different scales; S4, averagely distributing the sizes of theK prior boxes to the feature maps of different scales for prediction and generating corresponding candidate boxes; S5, selecting a final prediction box according to the generated candidate box; S6, mapping the final prediction box to the original image according to the relationship between the feature map and the original image, and positioning the vehicle information in the image. According to the method, the distance calculation formula of the GT frame and the clustering center is improved, the sensitivity of the formula to the IOU value is reduced, the priori frame size obtained through clustering better conforms to the true value, the priori frame quality is improved, and therefore the performance of the YOLO v3 detection method is improved.

Owner:ZHEJIANG SCI-TECH UNIV

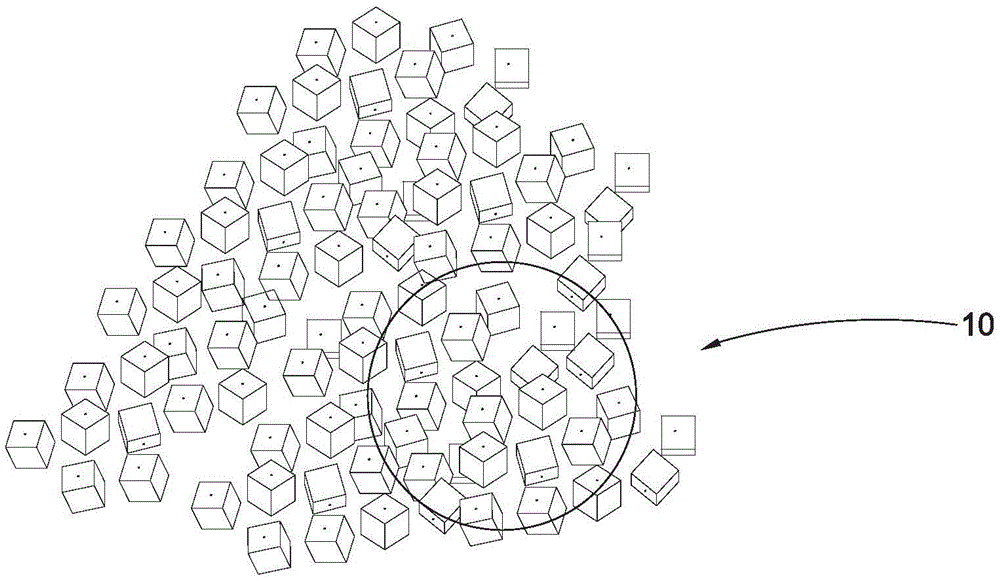

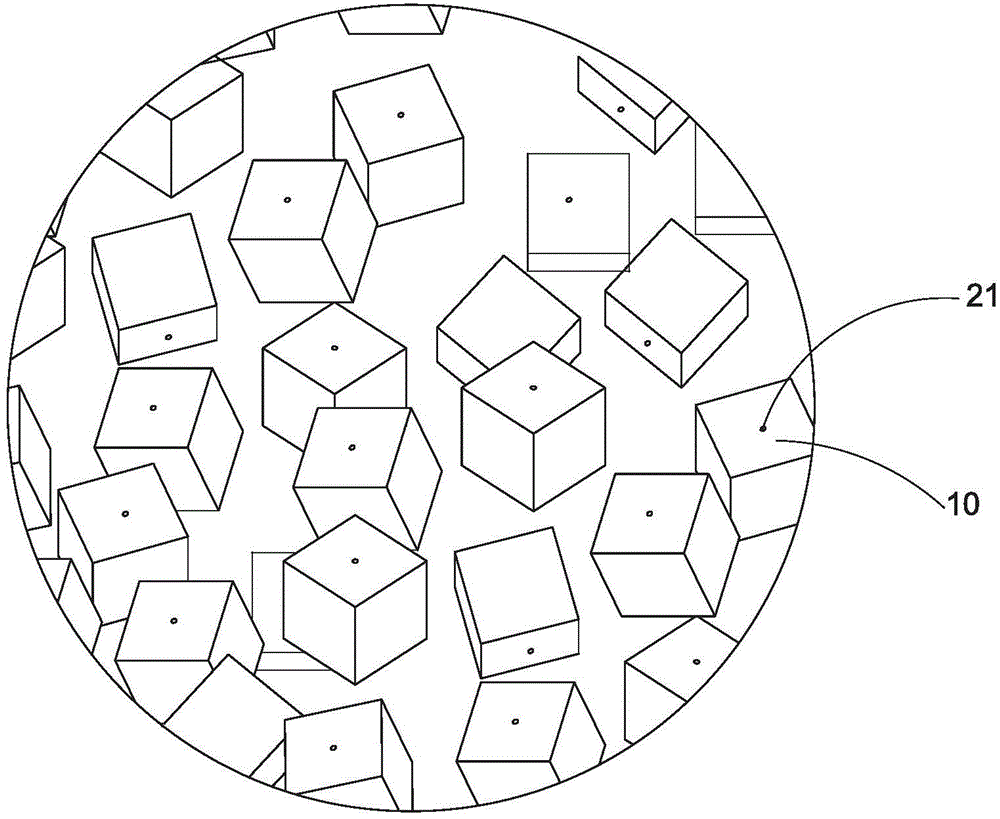

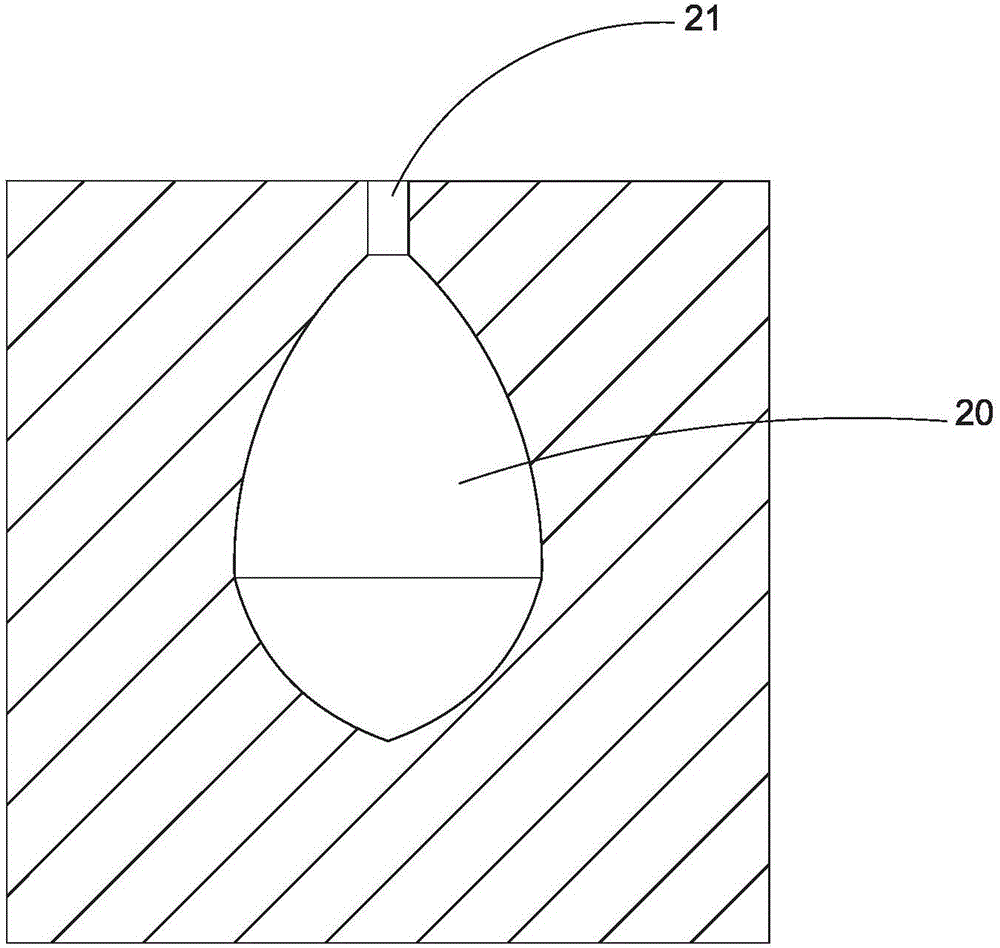

Badminton ball head and manufacturing method thereof

InactiveCN104801029AReduce manufacturing costConducive to compositional flexibilitySport apparatusManufactured materialEngineering

The invention relates to a man-made material particle which is applicable to manufacturing a badminton ball head or bottle plug and made of man-made materials. The man-made material particle comprises a particle body with polyhedral appearance and at least one air chamber arranged in the particle body.

Owner:戴见霖

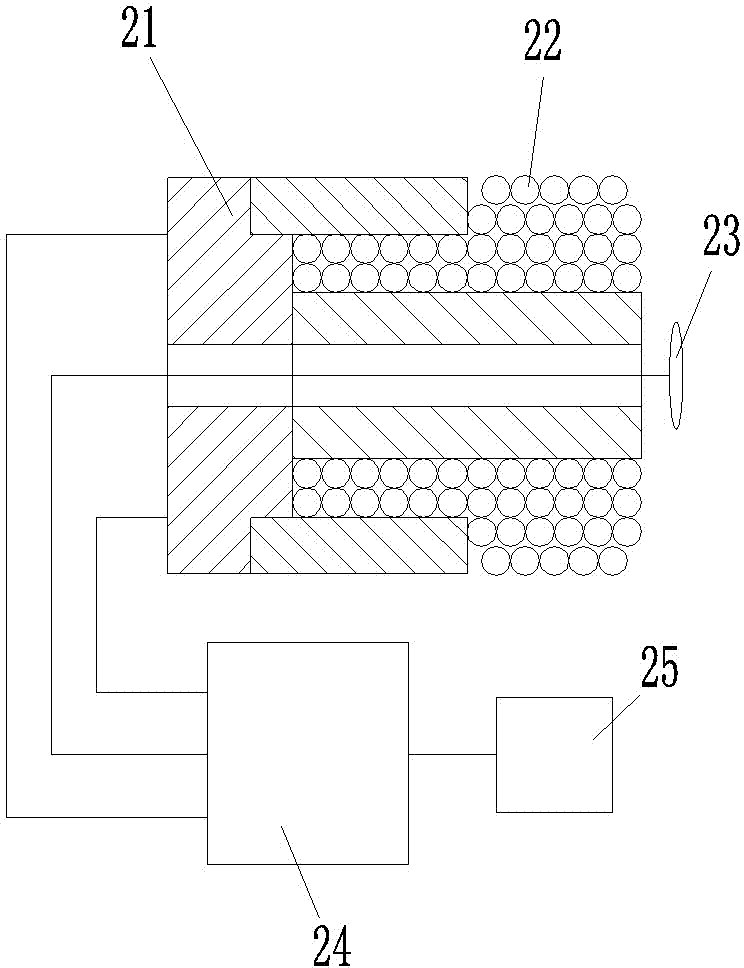

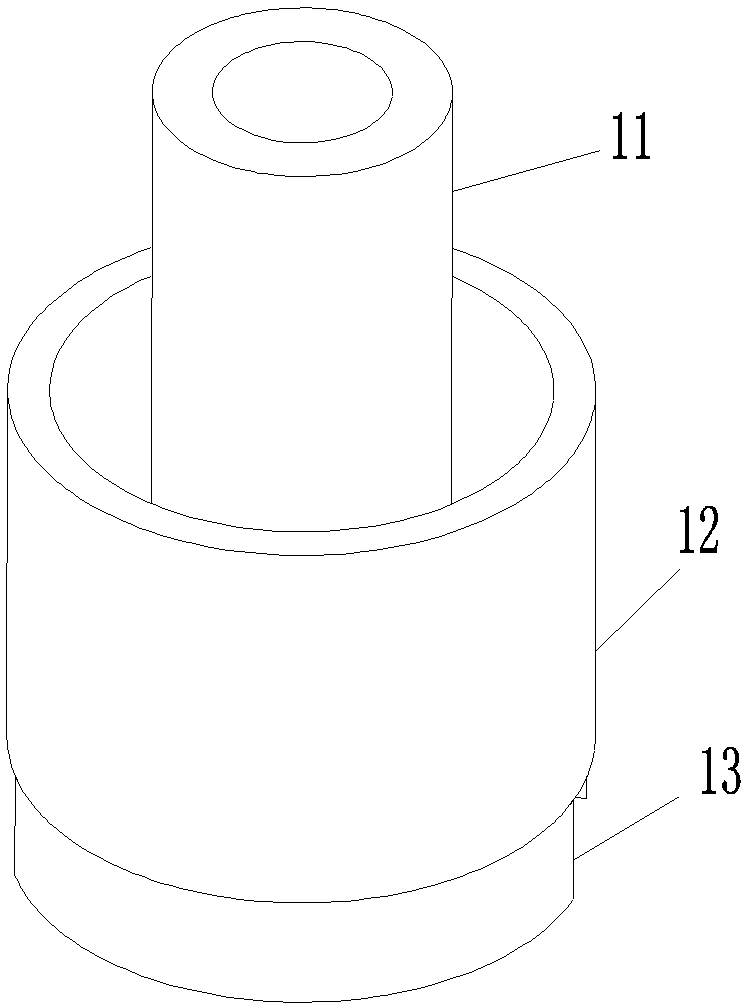

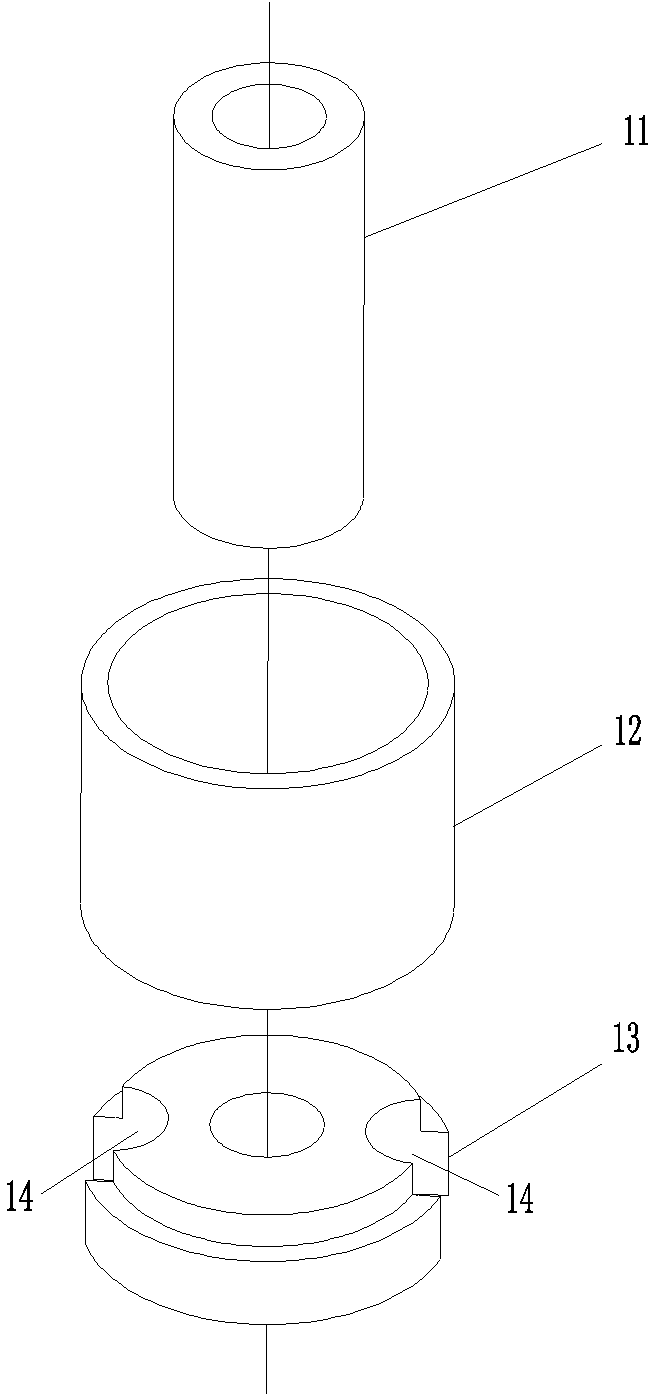

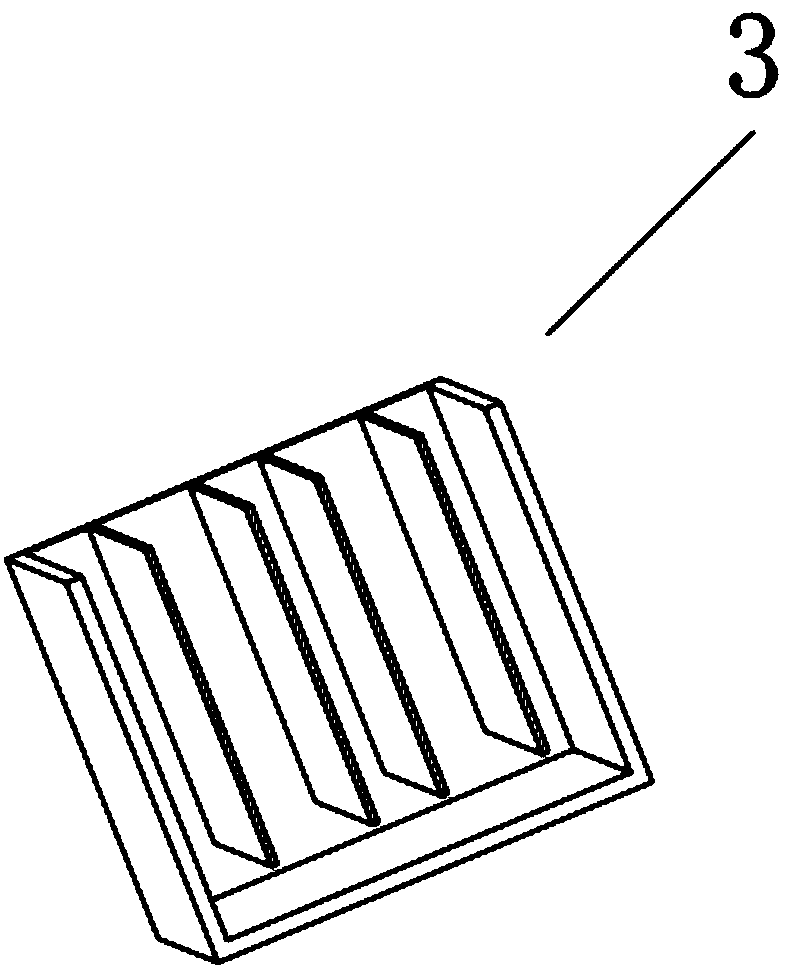

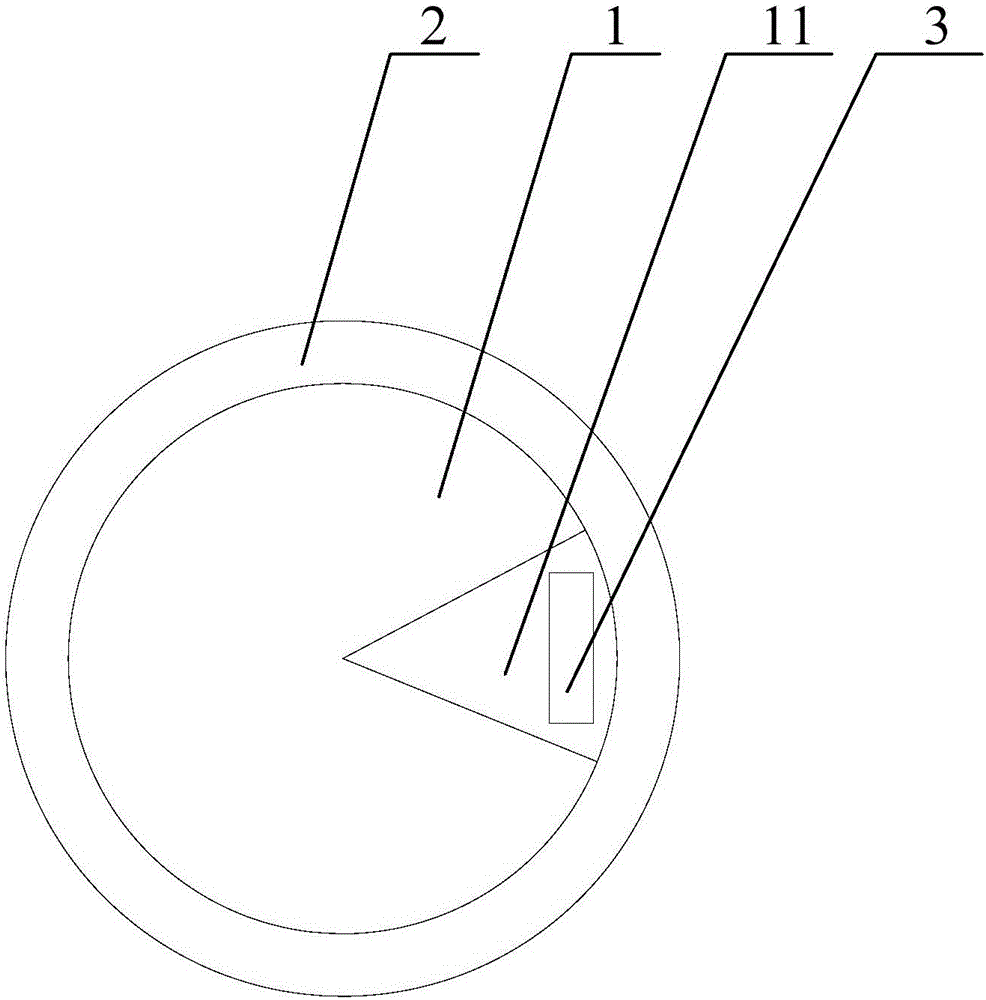

Non-contact power transmission system

InactiveCN104269945AWide power transmission distanceLong distanceElectromagnetic wave systemTransformersElectric power transmissionEngineering

The invention relates to the field of electrical connectors, in particular to a non-contact power transmission system. The non-contact power transmission system comprises a transmitting end and a receiving end, wherein each of the transmitting end and the receiving end comprises a magnetic core and a coil; each magnetic core comprises an inner ring, an outer ring and a base; the inner ring and the outer ring are fixed on the base through corresponding ends respectively; the coil is wound on the inner ring; one end, away from the base, of the inner ring protrudes out of the corresponding end of the outer ring. According to the non-contact power transmission system, one end, away from the base, of each of the inner rings of the magnetic cores of each of the transmitting end and the receiving end protrudes out of the corresponding ends of the outer rings. Therefore, the electromagnetic field can be better guided to be distributed in a wider range, so that the non-contact power transmission system has a longer power transmission distance and a wider range, thereby reducing the requirements on the shape of the magnetic core. In conclusion, the non-contact power transmission system is not only consistent with the size of non-contact power transmission systems, but also to meets the requirements on transmission distance.

Owner:CHINA AVIATION OPTICAL-ELECTRICAL TECH CO LTD

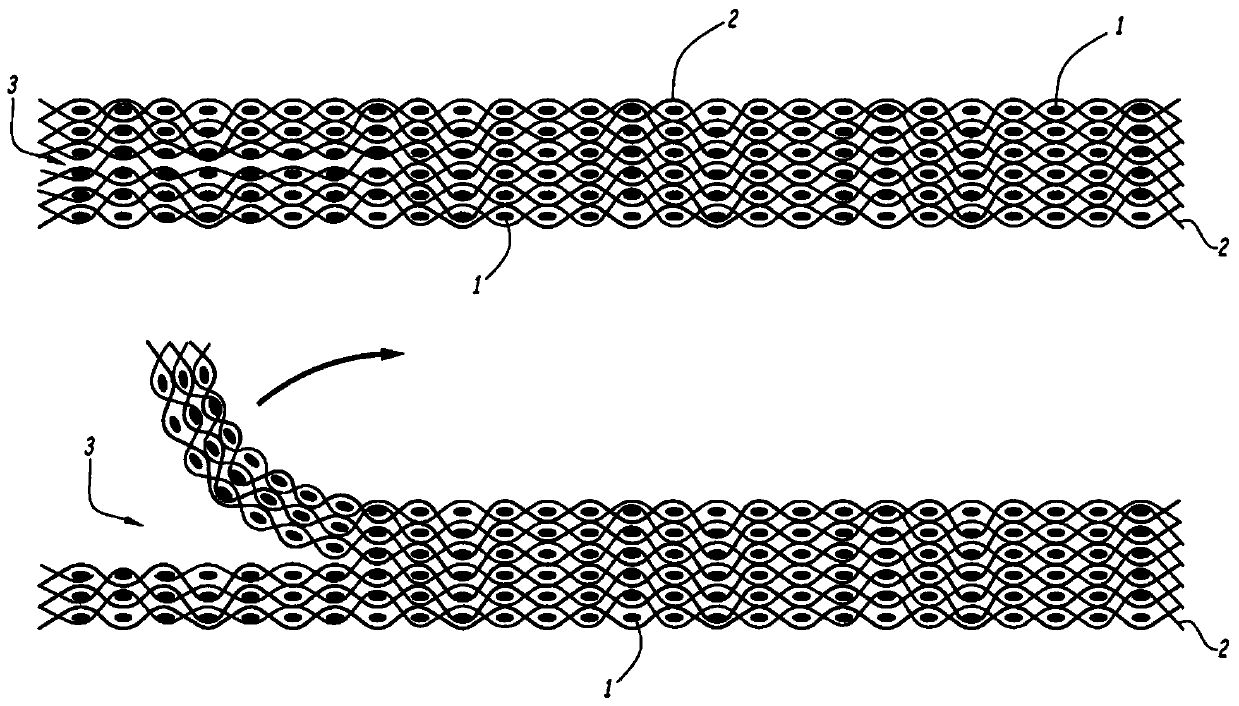

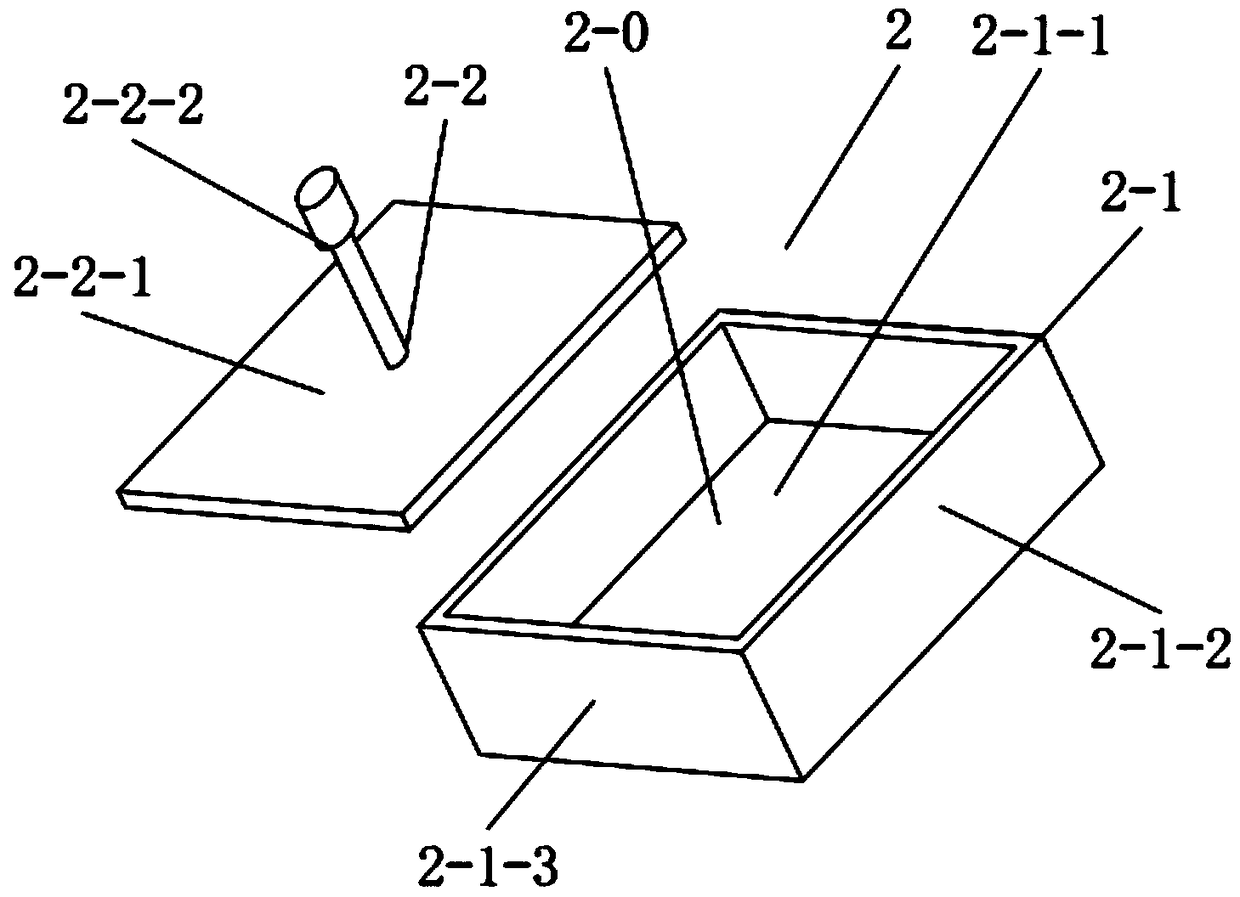

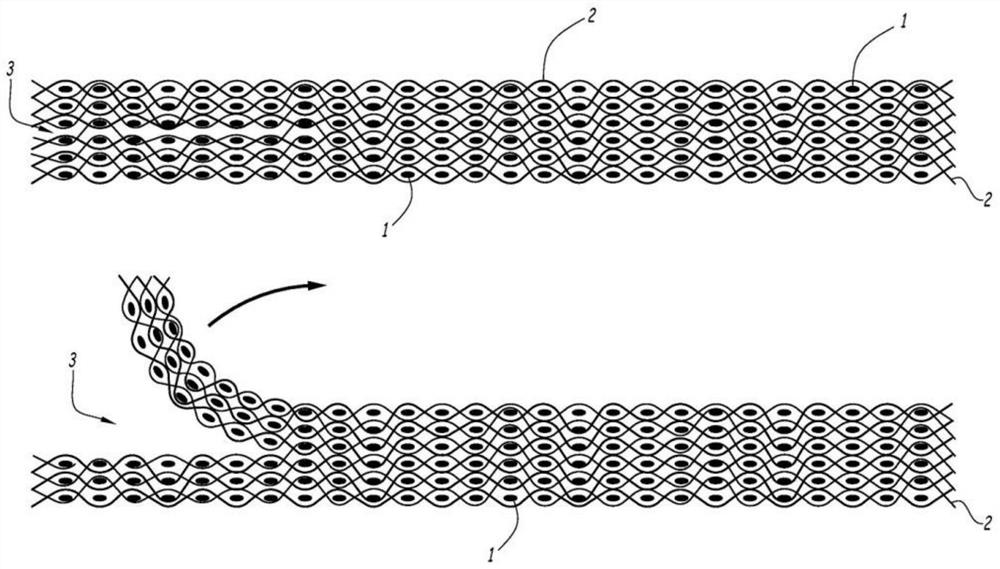

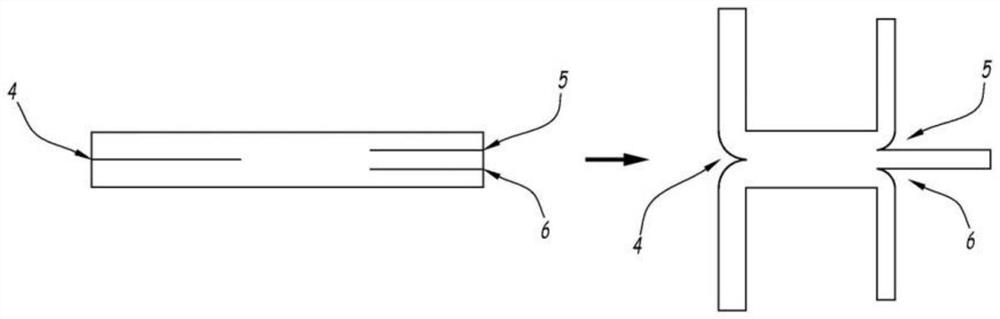

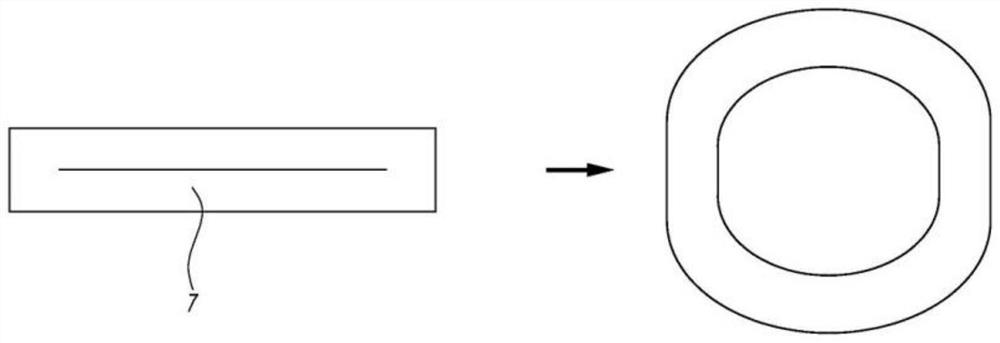

Fibrous structure and 3D preform for a composite part

The preform made of a 3D fibrous structure comprises at least 3 layers (1, 2) of weft yarns and / or warp yarns, the structure being woven as a single part by multilayer weaving between a plurality of layers of warp yarns and a plurality of layers of weft yarns. It comprises a predetermined distribution of points of intersection of warp yarn and weft yarn that are bonded by polymer. The polymer represents a mass of less than or equal to 10%. The preform comprises at least one thermoformed portion in which the warp yarns and the weft yarns are bonded at the intersections thereof by polymer whereat least one of the warp and / or weft yarns bears polymer.

Owner:PORCHER INDUSTRIES

Fabricated steel structure building with good anti-seismic effect and assembling method thereof

InactiveCN113668697AEasy to transportEasy to carryProtective buildings/sheltersBuilding material handlingEarthquake resistantEarthquake resistant structures

The invention discloses a fabricated steel structure building with a good anti-seismic effect and an assembling method thereof, and relates to the technical field of fabricated steel structure buildings. The problems that symmetry cannot be guaranteed during installation of an anti-seismic mechanism in an anti-seismic fabricated steel structure, and the anti-seismic effect is affected are solved. The fabricated steel structure building with the good anti-seismic effect comprises a building framework, an X-shaped anti-seismic structure, an I-shaped anti-seismic structure and fastening bolts, and the X-shaped anti-seismic structure and the I-shaped anti-seismic structure are arranged on the outer wall of the periphery of the building framework through the fastening bolts; the assembling method of the fabricated steel structure building with the good anti-seismic effect comprises the following steps that the X-shaped anti-seismic structure and the I-shaped anti-seismic structure are selected according to the actual situation of the building framework. According to the fabricated steel structure building with the good anti-seismic effect and the assembling method thereof, the X-shaped anti-seismic structure and the I-shaped anti-seismic structure can be split, so that transportation and carrying are convenient, meanwhile, the X-shaped anti-seismic structure or the I-shaped anti-seismic structure can be selected according to actual conditions, and the anti-seismic capacity of the building framework is further improved.

Owner:黄朝辉

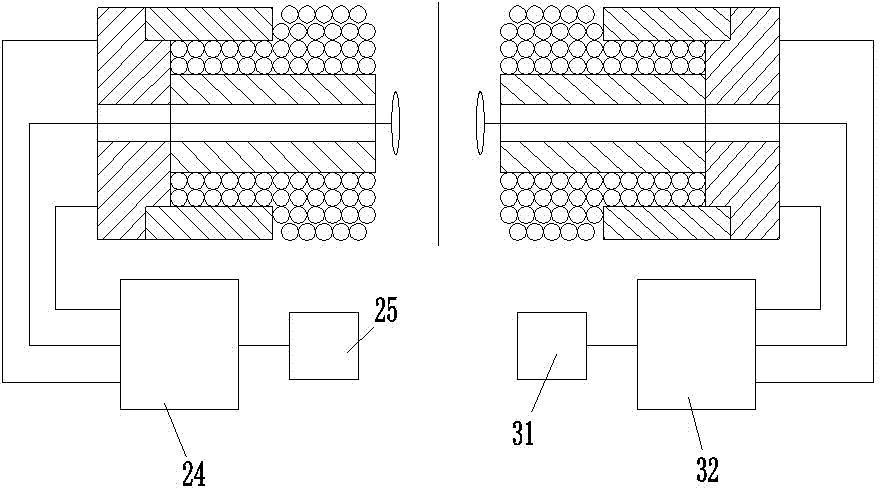

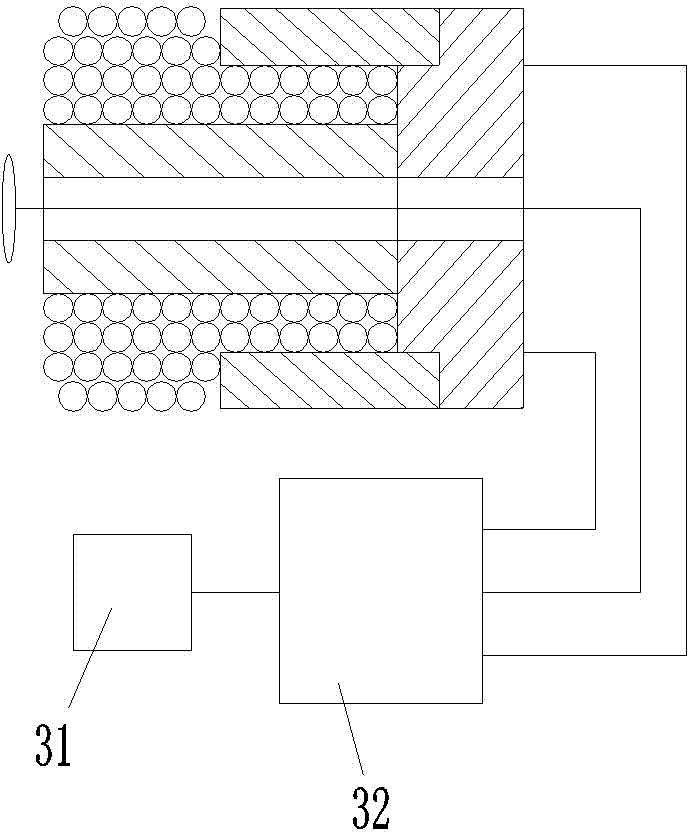

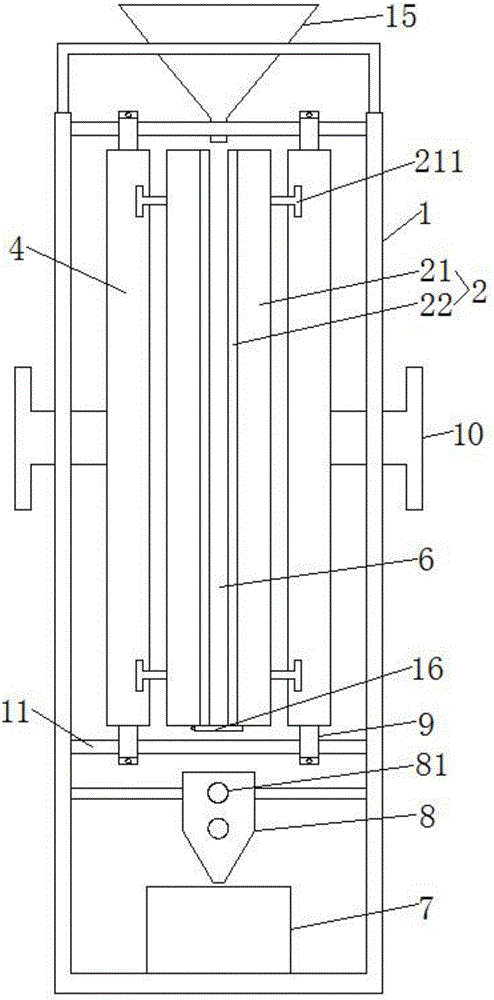

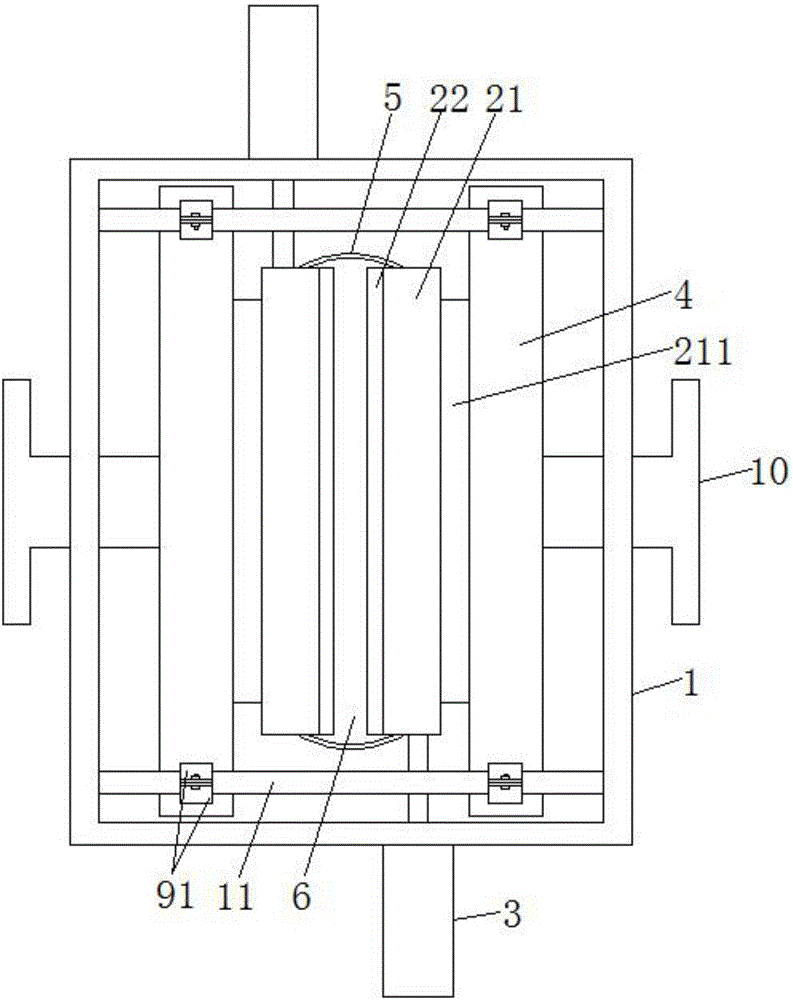

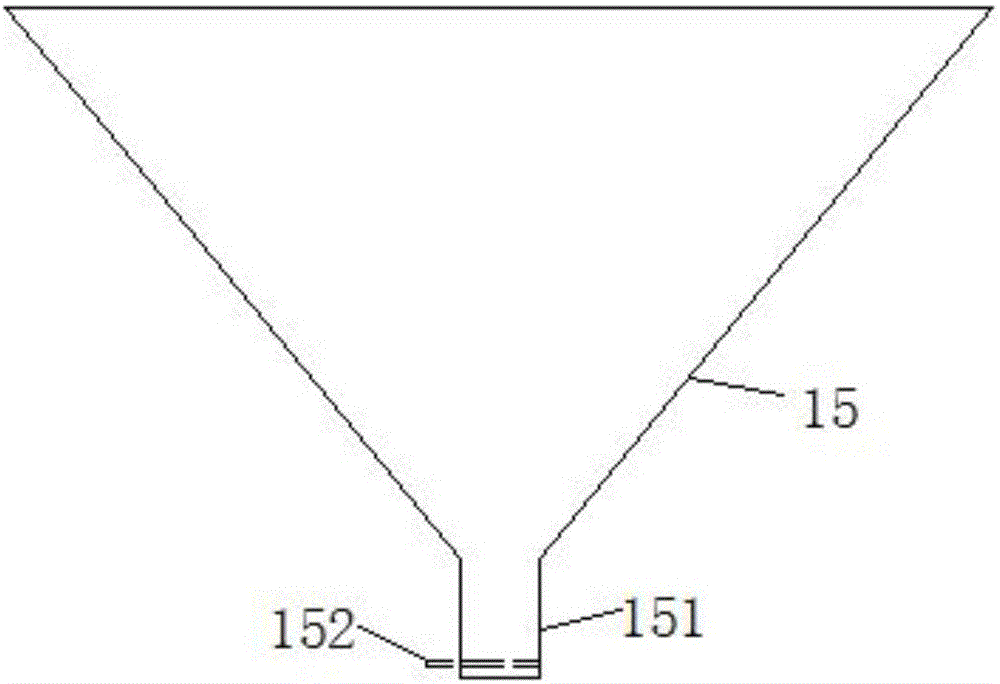

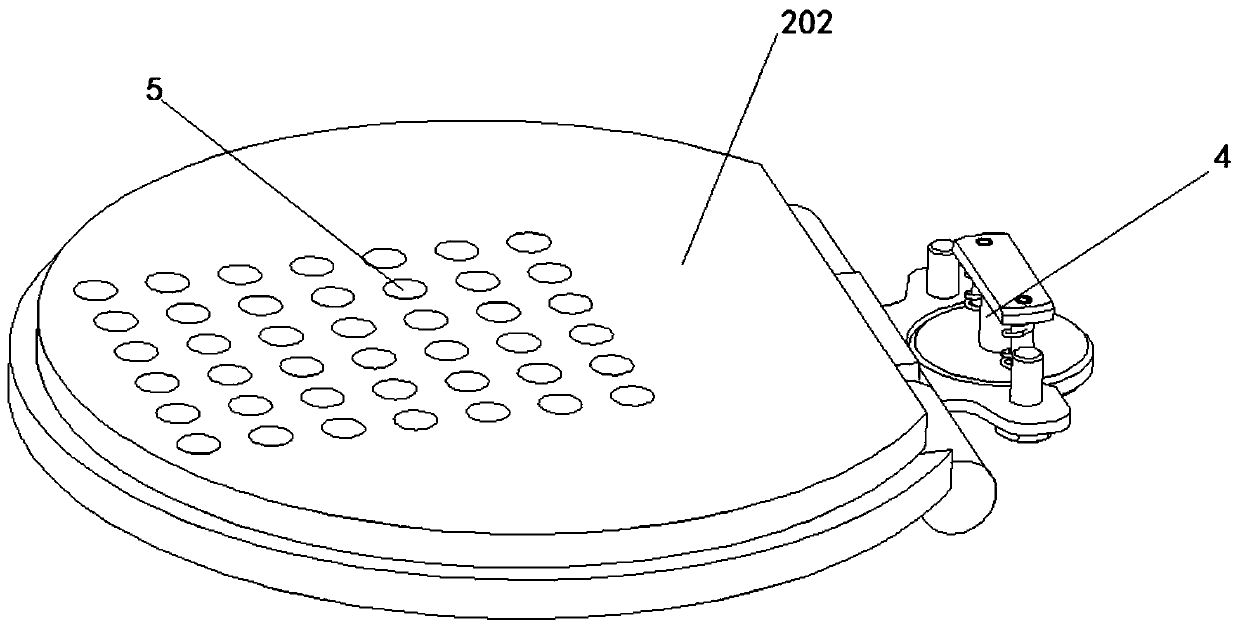

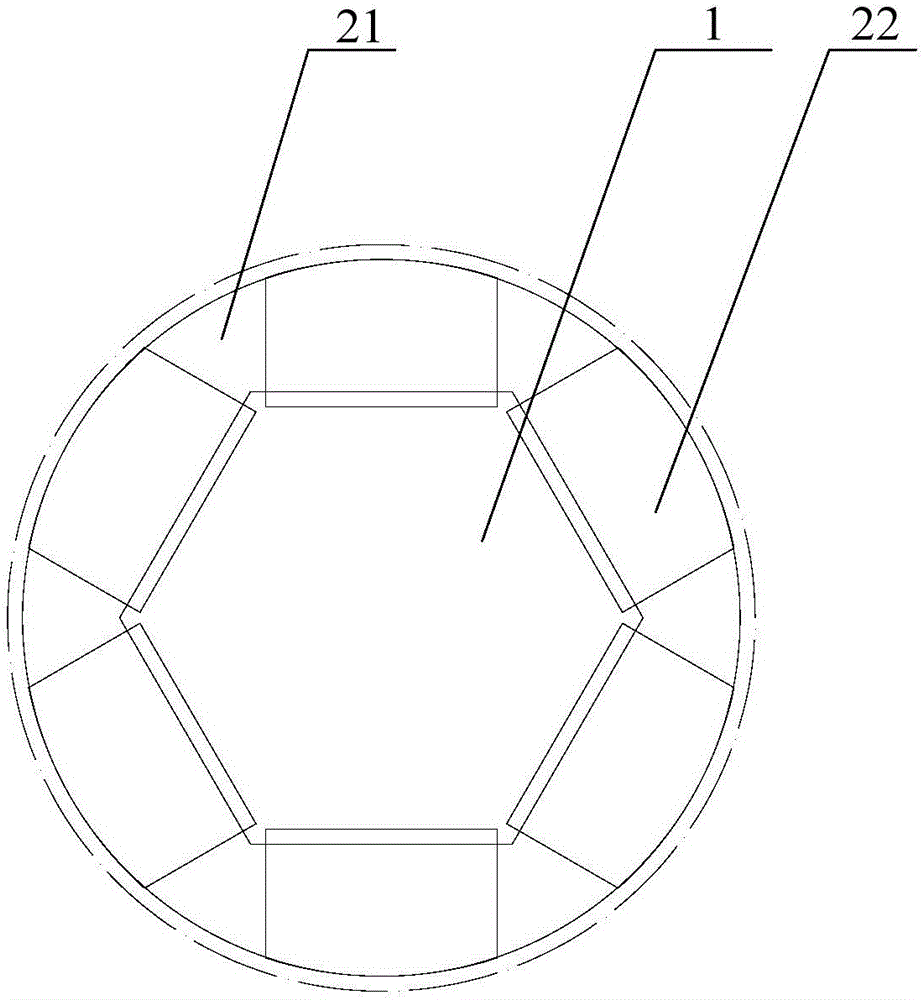

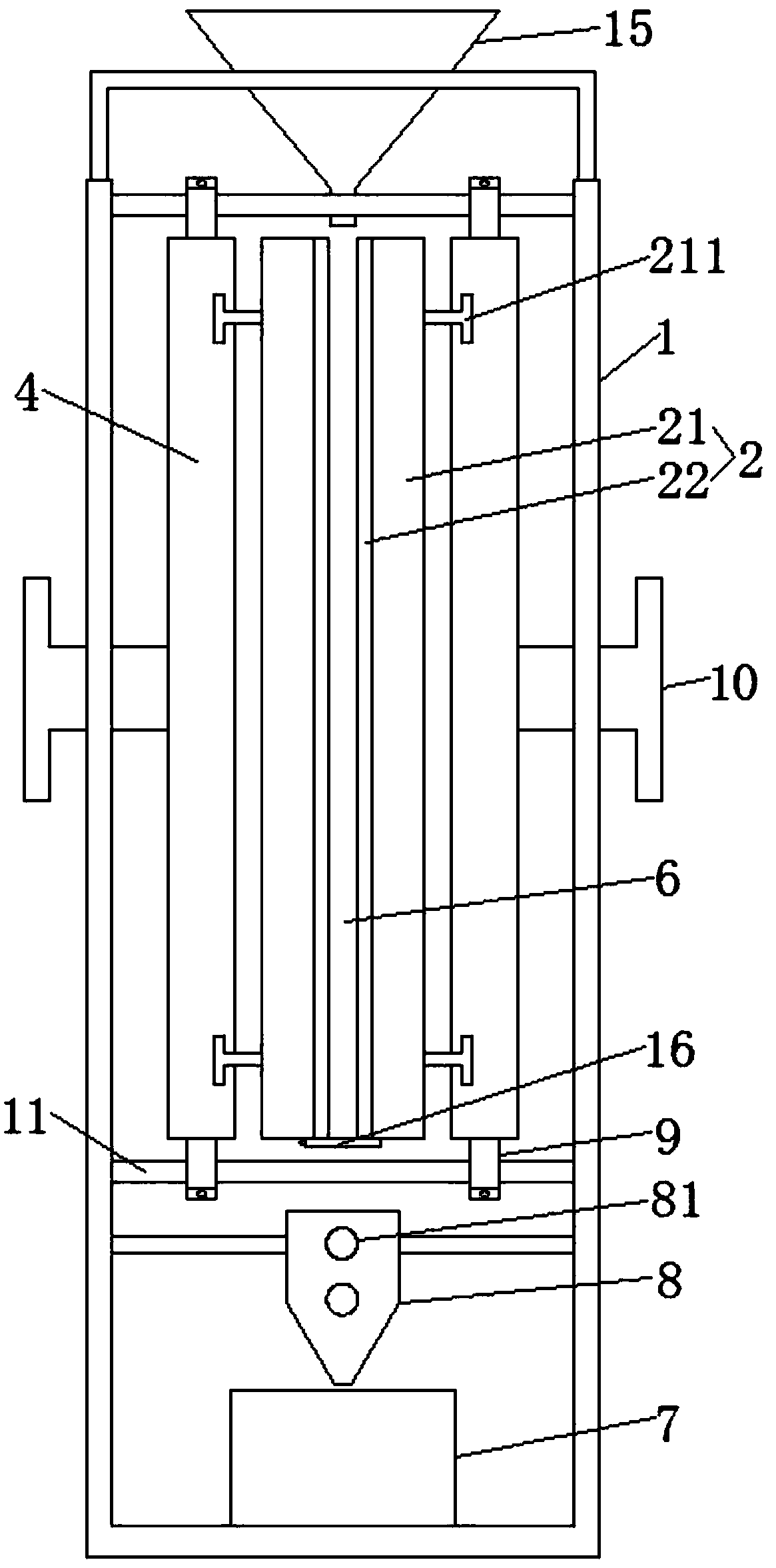

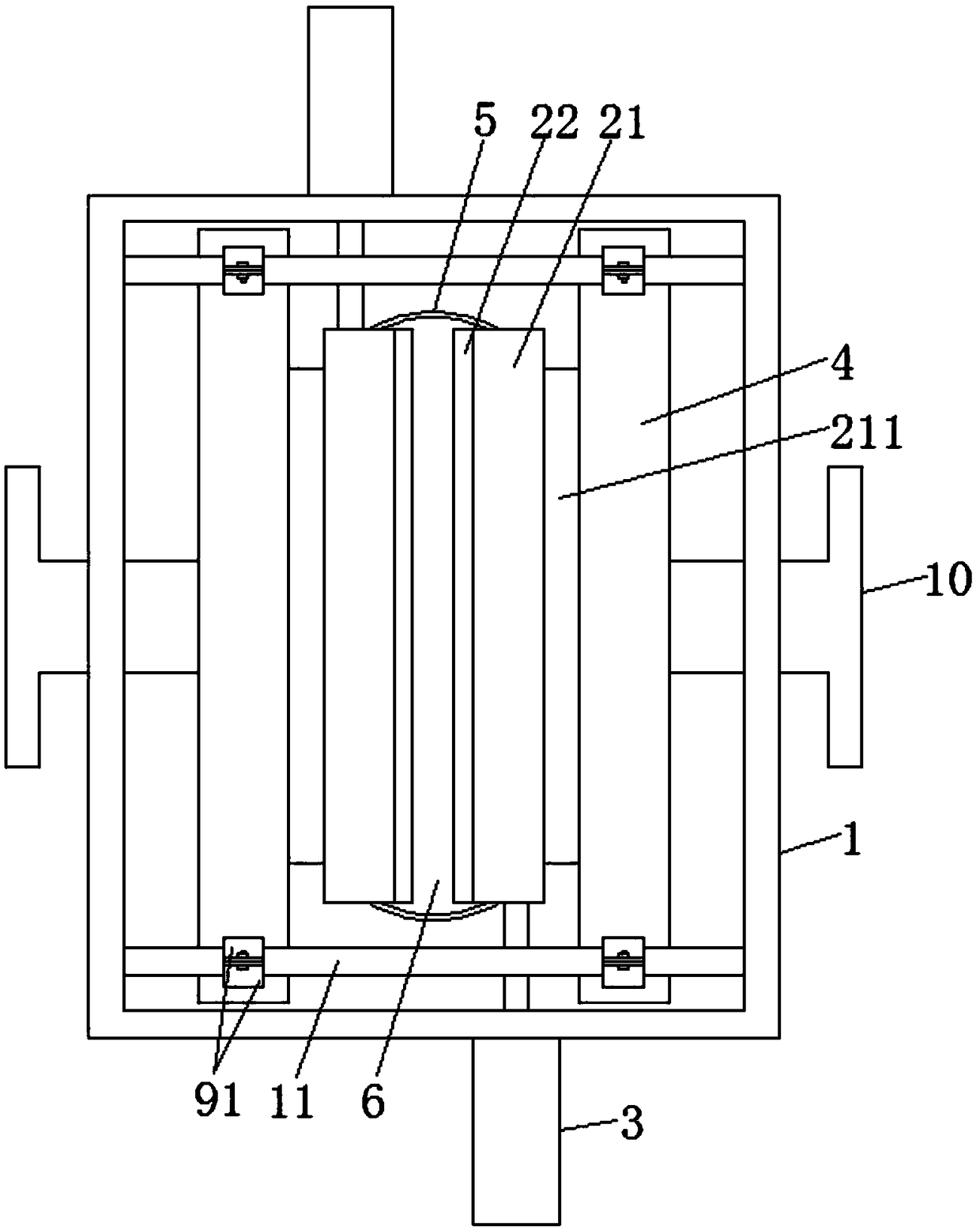

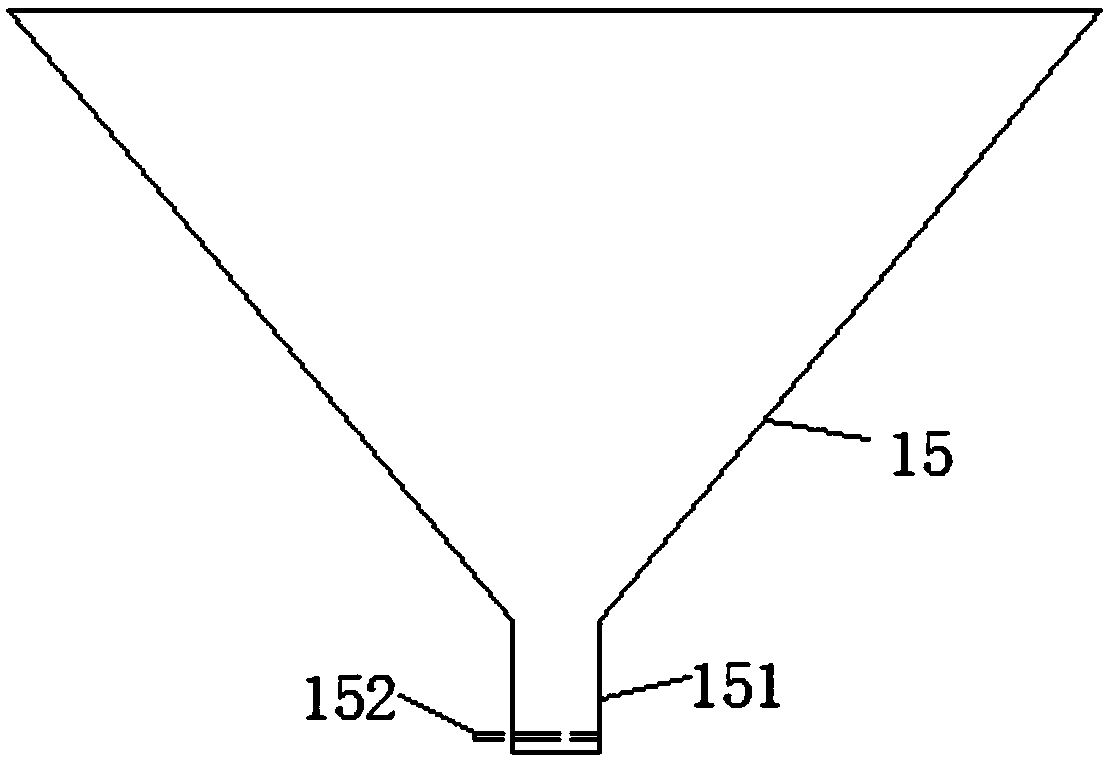

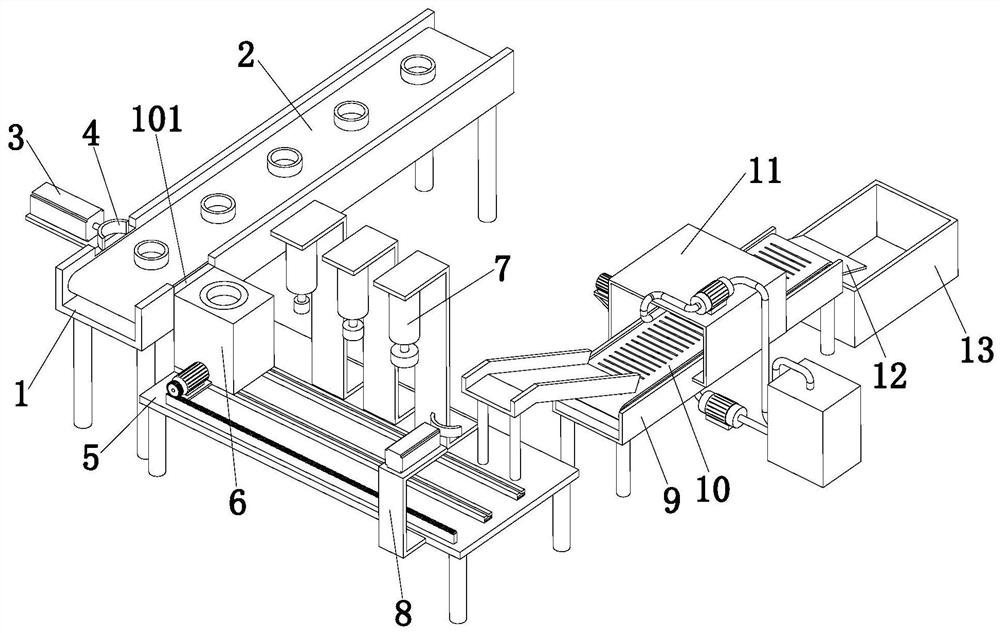

Bean polishing machine

ActiveCN106669882AEfficient removalImprove cleanlinessGrain huskingGrain polishingEngineeringMechanical engineering

The invention relates to a bean polishing machine. The bean polishing machine comprises a rack, two polishing plates, two drive devices and two sliding bases; the two sliding bases are vertical and are mounted in the rack at an interval in parallel, the two polishing plates are vertically arranged and are in one-to-one correspondence to the sliding bases, the polishing plates are mounted on the faces where the corresponding sliding bases close to each other in a sliding manner, a gap is arranged between the two polishing plates, the two sides of the two polishing plates are in sealed connection through a flexible belt, and a polishing chamber with the upper and the lower opened are defined by the two polishing plates and the flexible belt, the lower end of one polishing plate is rotatably provided with a brake plate, the brake plate can rotatably cover or open the opening in the lower end of the polishing chamber, the two drive devices are mounted at the positions, corresponding to the two polishing plates, of the two sides of the rack in a one-to-one correspondence manner, and the drive ends of the drive devices are fixedly connected with the side ends of the corresponding polishing plates. The bean polishing machine has the beneficial effects of being simple in structure, convenient to use, capable of effectively removing impurities, mildew and the like on bean surfaces, and ensuring smoothness of the bean surfaces, high in polishing efficiency and good in effect.

Owner:湖北天明粮油设备有限公司

Magnetic core of non-contact electric connector and non-contact electric connector

InactiveCN104347237ALong power transmission distanceWide power transmission distanceLoop antennas with ferromagnetic coreTransformersElectric power transmissionElectromagnetic field

The invention relates to the field of electric connectors, particularly to a magnetic core of a non-contact electric connector and the non-contact electric connector. The magnetic core of the non-contact electric connector comprises an inner ring, an outer ring and a base which is arranged at one ends of the inner ring and the outer ring, wherein the inner ring and the outer ring are respectively fixed on the base through the respective corresponding ends, and one end, which is far away from the base, of the inner ring is protruded outside the corresponding end of the outer ring. Because one end, which is far away from the base, of the inner ring of the magnetic core of the non-contact electric connector is protruded outside the corresponding end of the outer ring, an electromagnetic field can be preferably guided in the wider scope to be distributed, the distance of the power transmission of the non-contact electric connector is longer, the scope of the power transmission of the non-contact electric connector is wider, and the requirement for the shape of the magnetic core can be reduced. In conclusion, the magnetic core of the non-contact electric connector disclosed by the invention not only can conform to the size of the non-contact electric connector, but also can satisfy the requirement for the transmission distance.

Owner:CHINA AVIATION OPTICAL-ELECTRICAL TECH CO LTD

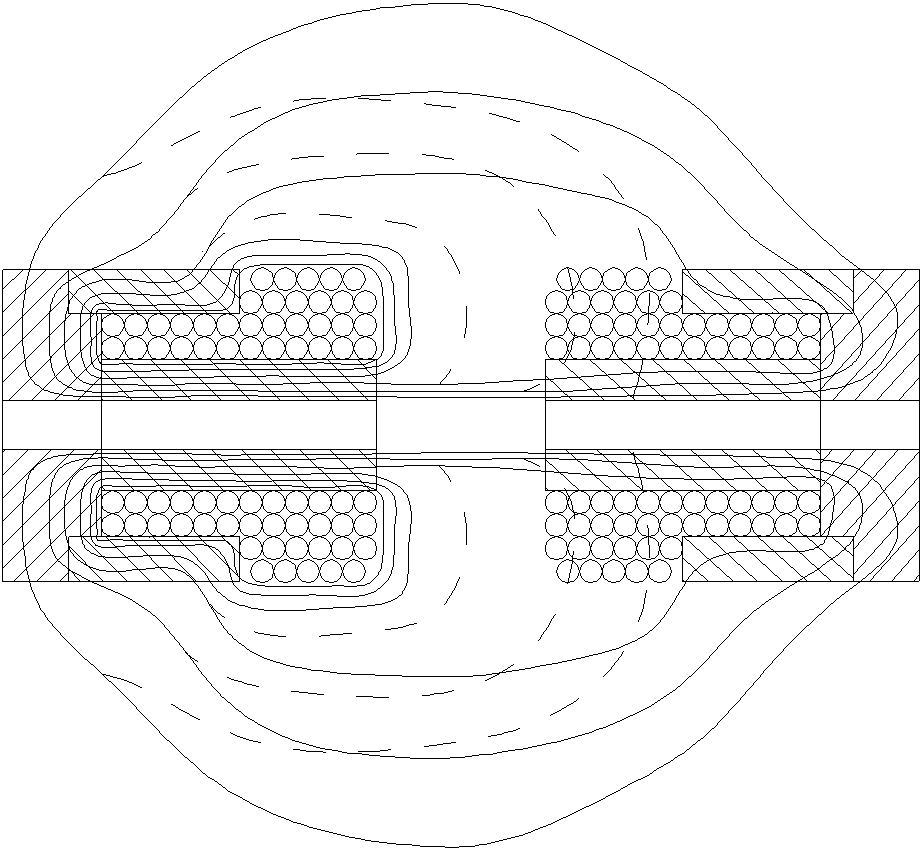

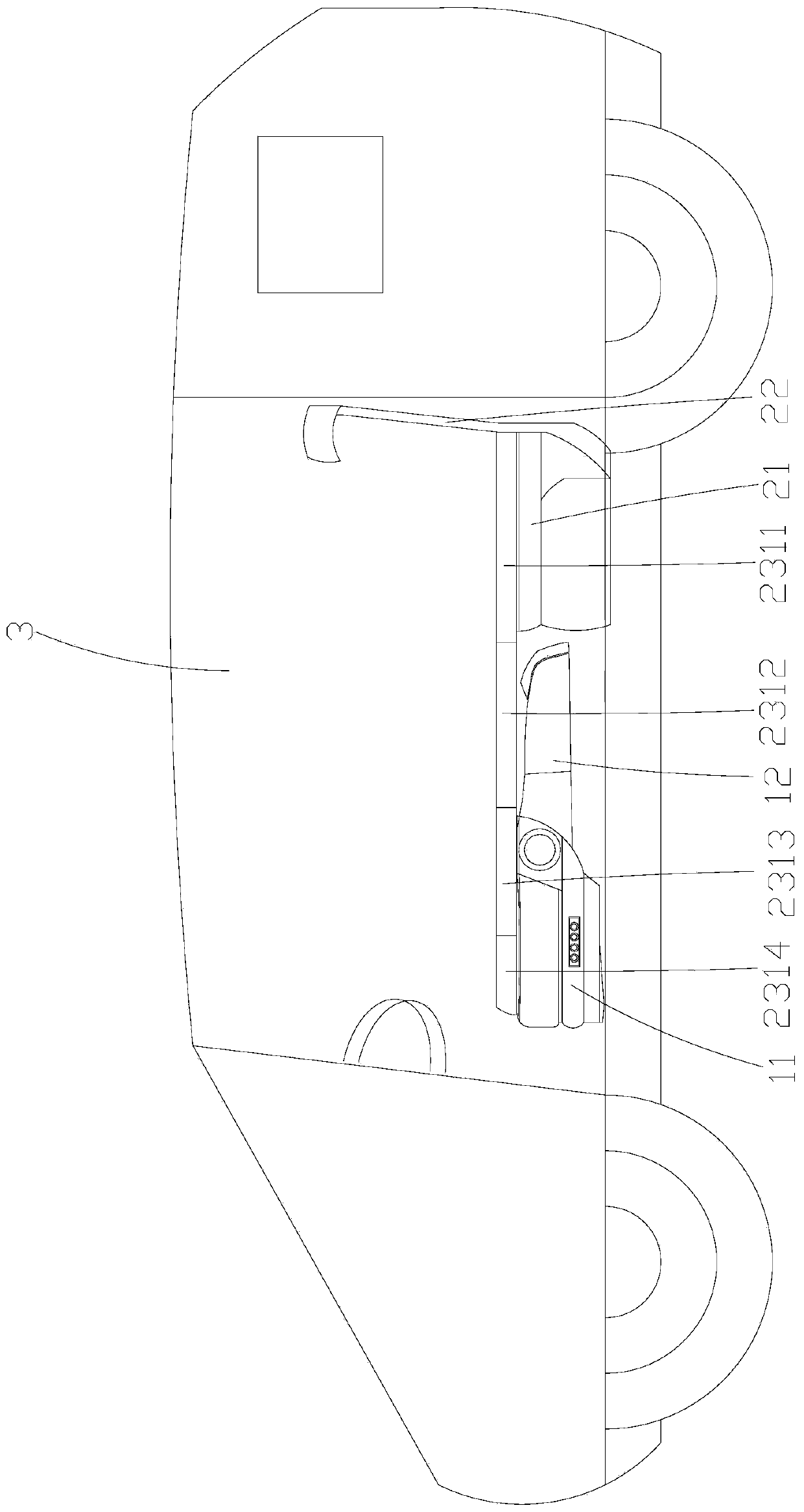

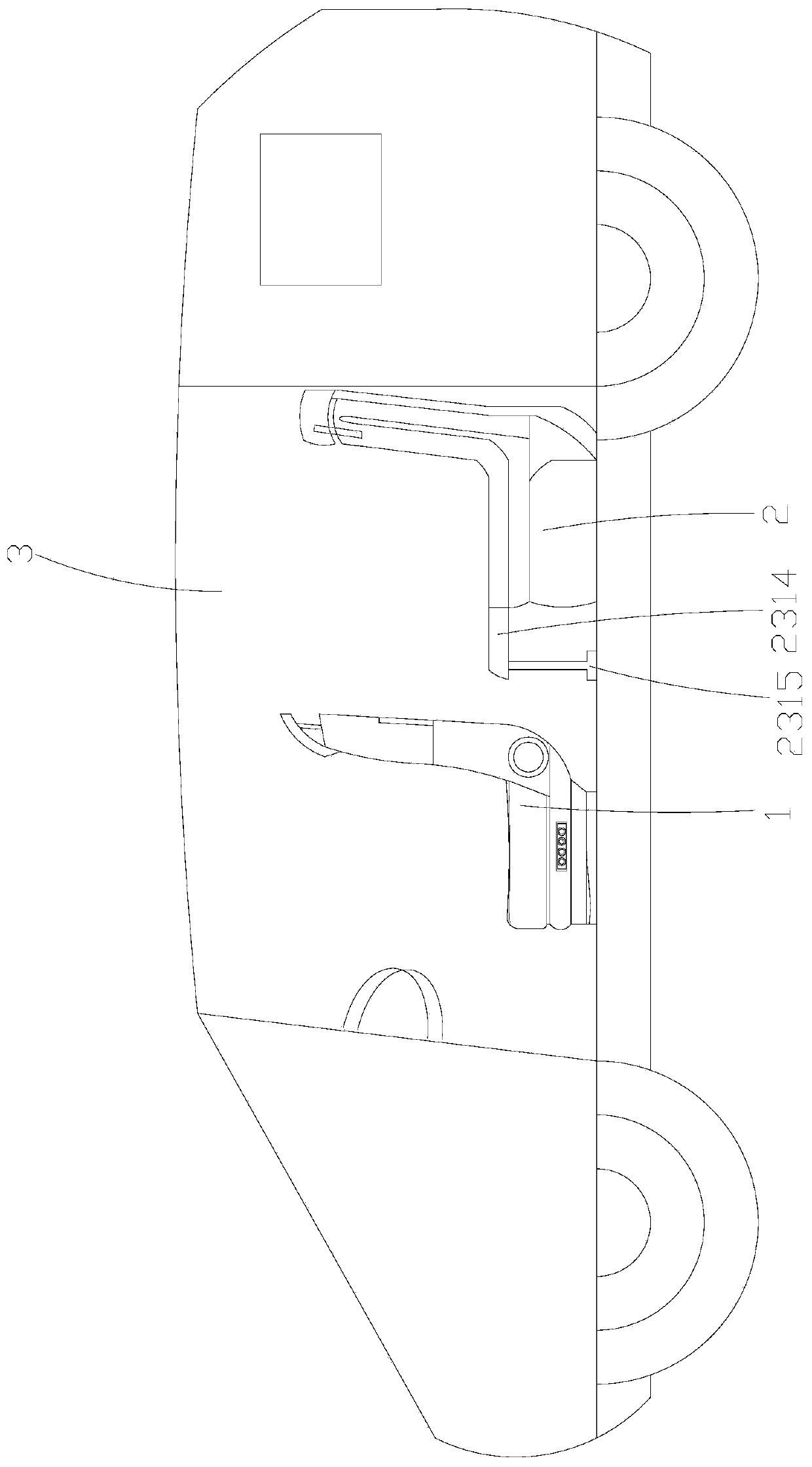

Recreational vehicle

InactiveCN111591180AEasy to useUnsightly feeling avoidBack restsThigh restsFoot cushionTransport engineering

The invention discloses a recreational vehicle, which comprises a vehicle body, front-row seats and rear-row seats, wherein the front-row seat comprises a front-row base and a front-row backrest; thefront-row backrest can be overturned backwards and put down relative to the front-row base; the rear-row seat comprises a rear-row base and a rear-row backrest; cushions capable of forming a back cushion, a seat cushion and a foot cushion of the rear-row seat are connected to the rear-row base; the cushions at least comprise a left cushion and a right cushion, the left cushion and / or the right cushion are / is of a foldable unfolding structure and can be forwards unfolded to form a first lying bed, and the rear-row backrest can be backwards overturned and put down relative to the rear-row base to form a second lying bed. The left cushion or the right cushion can be independently unfolded; during use, the left cushion or the right cushion only needs to be unfolded forwards, meanwhile, the corresponding front-row seat in the vehicle body is put down, then the unfolded left cushion or the unfolded right cushion is flatly laid on the corresponding front-row seat, the bed capable of being used for lying can be independently formed, the use flexibility and convenience of the cushions are improved, and diversified use functions are brought to a user.

Owner:徐世贤

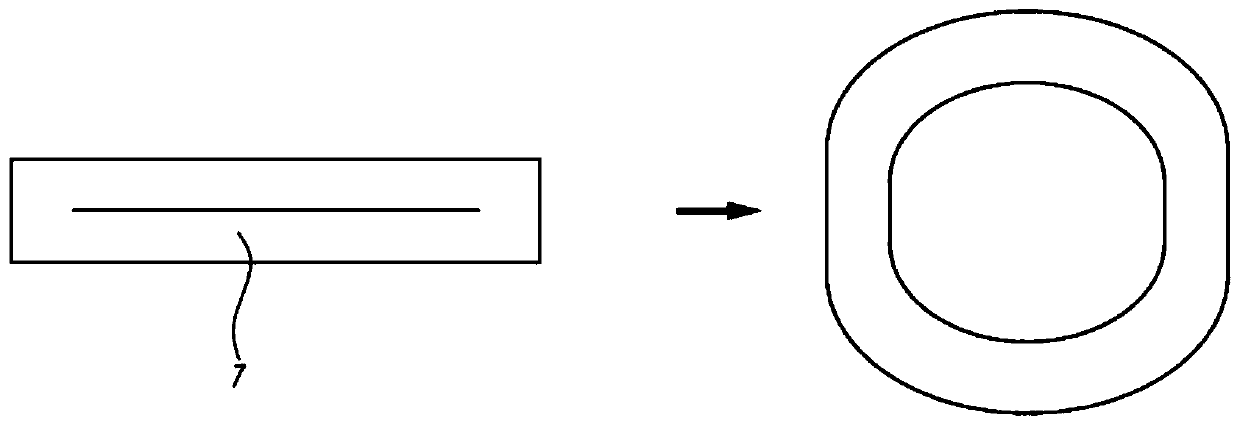

Preparation method for AuSn20 alloy brazing filler metal used for packaging integrated circuit and usage thereof

ActiveCN102114584BUniform compositionSize fitsWelding/cutting media/materialsSoldering mediaAlloyNitrogen gas

The invention relates to a preparation method for an AuSn20 alloy brazing filler metal used for packaging an integrated circuit, which comprises the following steps: preparing gold and tin in proportions; placing the gold and tin into a casting furnace; sealing the furnace and vacuumizing the furnace; rising the temperature till the gold and tin are completely melted, controlling the temperature of the melt at 500-600 DEG C, refining for the purpose of alloying the gold and tin and degassing, and pouring the alloy in a graphite mould; placing an acquired AuSn20 alloy bar into a quartz tube and heating; sealing the furnace and vacuumizing till the pressure is 4-6Pa; rising the temperature and controlling the temperature rising; after melting the alloy bar, controlling the temperature of the melt to be 500-600 DEG C, and refining for 2-3 minutes; performing the melt-spinning process by using a vacuum quenching melt-spinning machine, controlling the temperature of the melt within 500-600 DEG C in the melt-spinning process, and introducing high-pressure nitrogen from an upper port of the quartz tube, wherein the nitrogen pressure is 10-15Pa; and spraying the alloy melt onto a speedily rotating metal wheel of the vacuum quenching melt-spinning machine from a bottom hole on the quartz tube, thereby acquiring a belt material. The belt material can be milled into a foil belt material or be punched into a slice or annular deeply processed product in the corresponding specification. By using the method, the product having excellent integrated circuit property can be prepared.

Owner:BEIJING INST OF NONFERROUS METALS & RARE EARTH

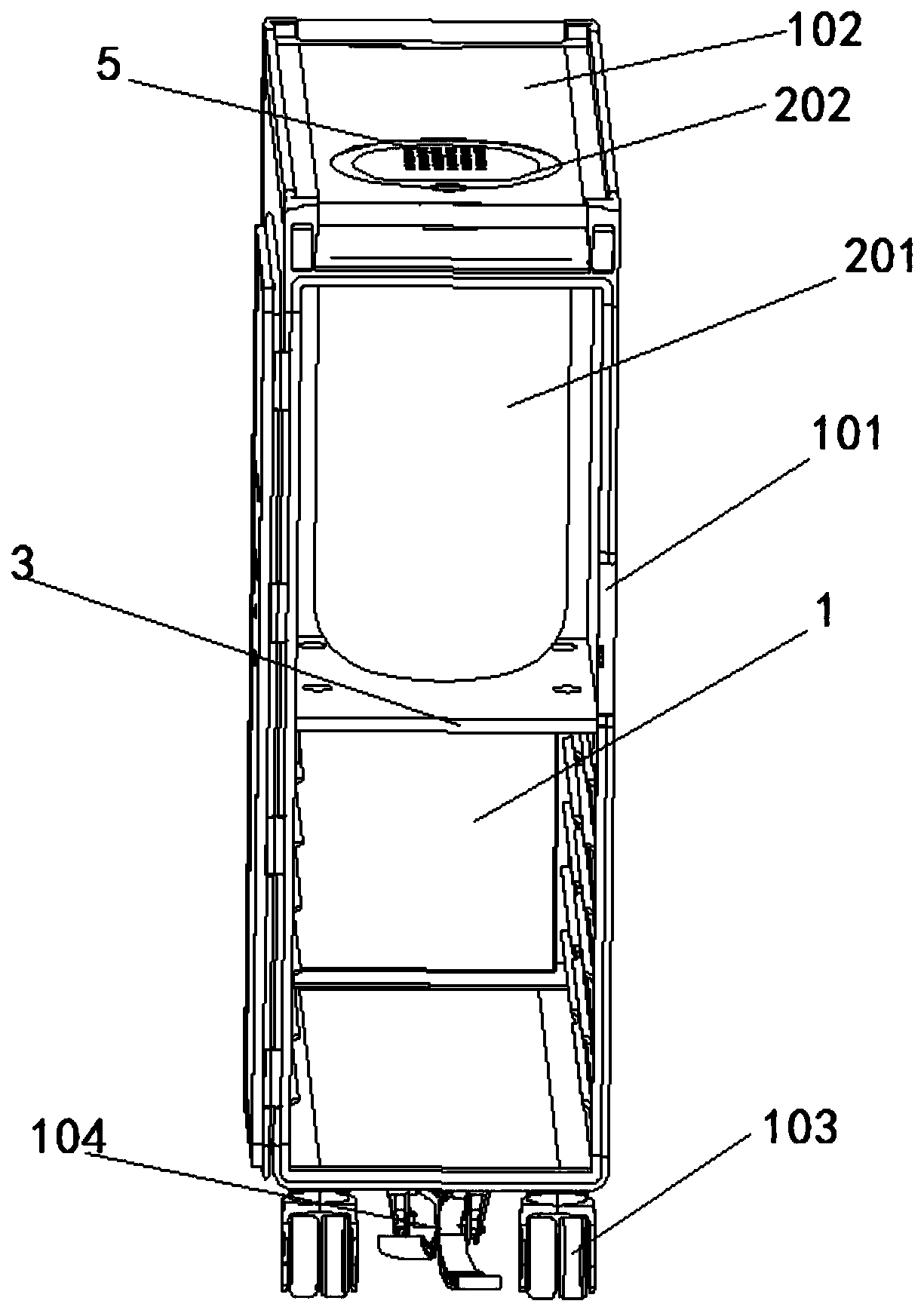

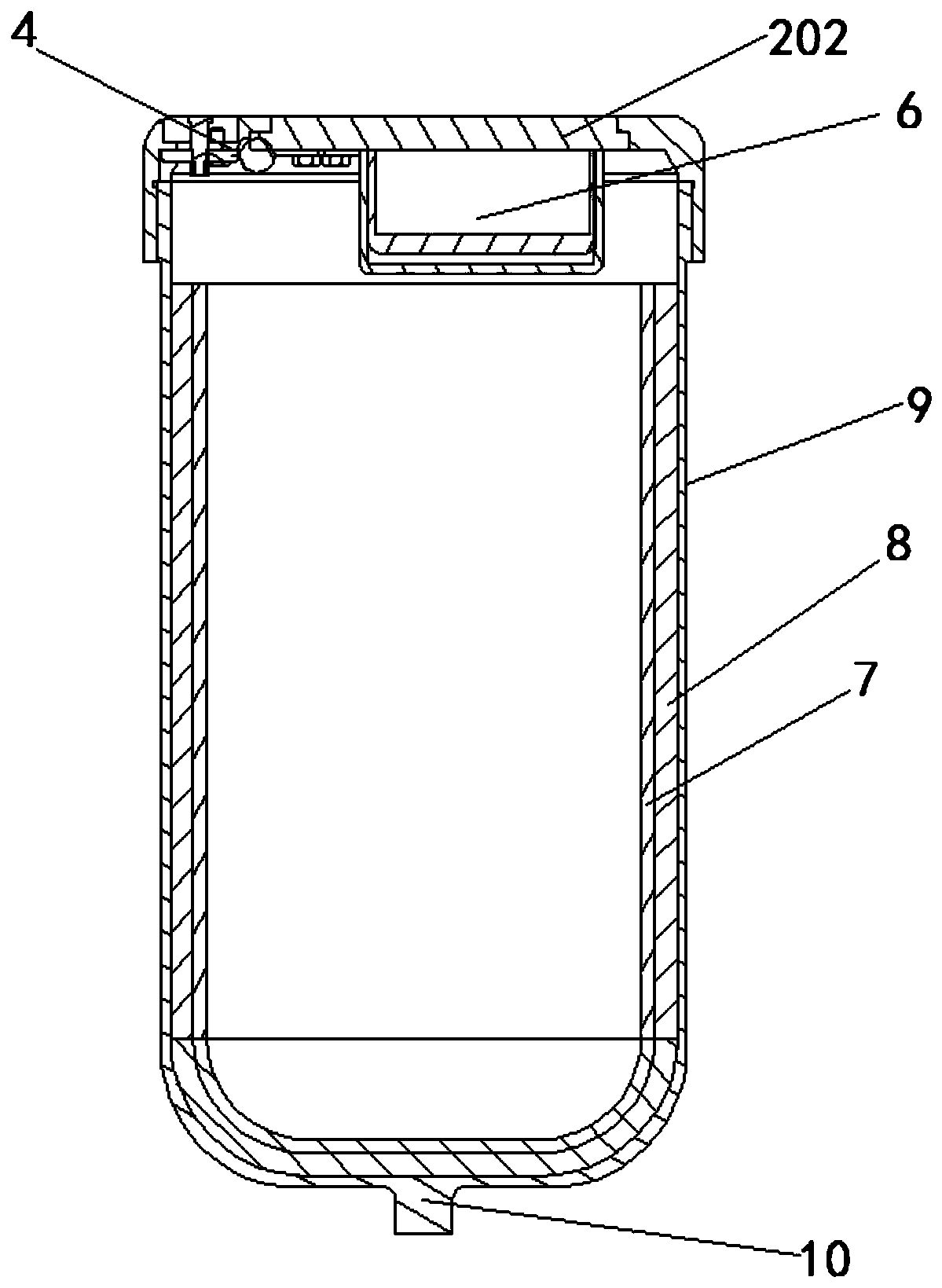

Explosion-proof aviation cart

PendingCN110696884AImprove emergency response capabilitiesSave parking spaceFire rescueBlastingCartAutomotive engineering

The invention provides an explosion-proof aviation cart, and belongs to the technical field of aviation carts. The cart comprises a cart main body, an explosion-proof tank and a partition plate, the cart main body comprises a main body frame and a top plate, and an opening is formed in the top plate; the anti-explosion tank is fixed in the cart body through a partition plate and comprises a tank body and a tank cover which is installed on the tank body and can be opened or closed relative to the tank body, and the tank cover is installed on an opening of the top plate. The explosion-proof aviation cart can improve the emergency treatment capacity of lithium ion batteries and explosives of aircrafts, has the functions of flame retardance, explosion prevention and toxic gas purification, canflexibly move in the aircrafts, is small in parking space, meets the size of conventional aviation carts, and does not need to specially modify the aircrafts or occupy other storage spaces of the aircrafts.

Owner:THE SECOND RES INST OF CIVIL AVIATION ADMINISTRATION OF CHINA

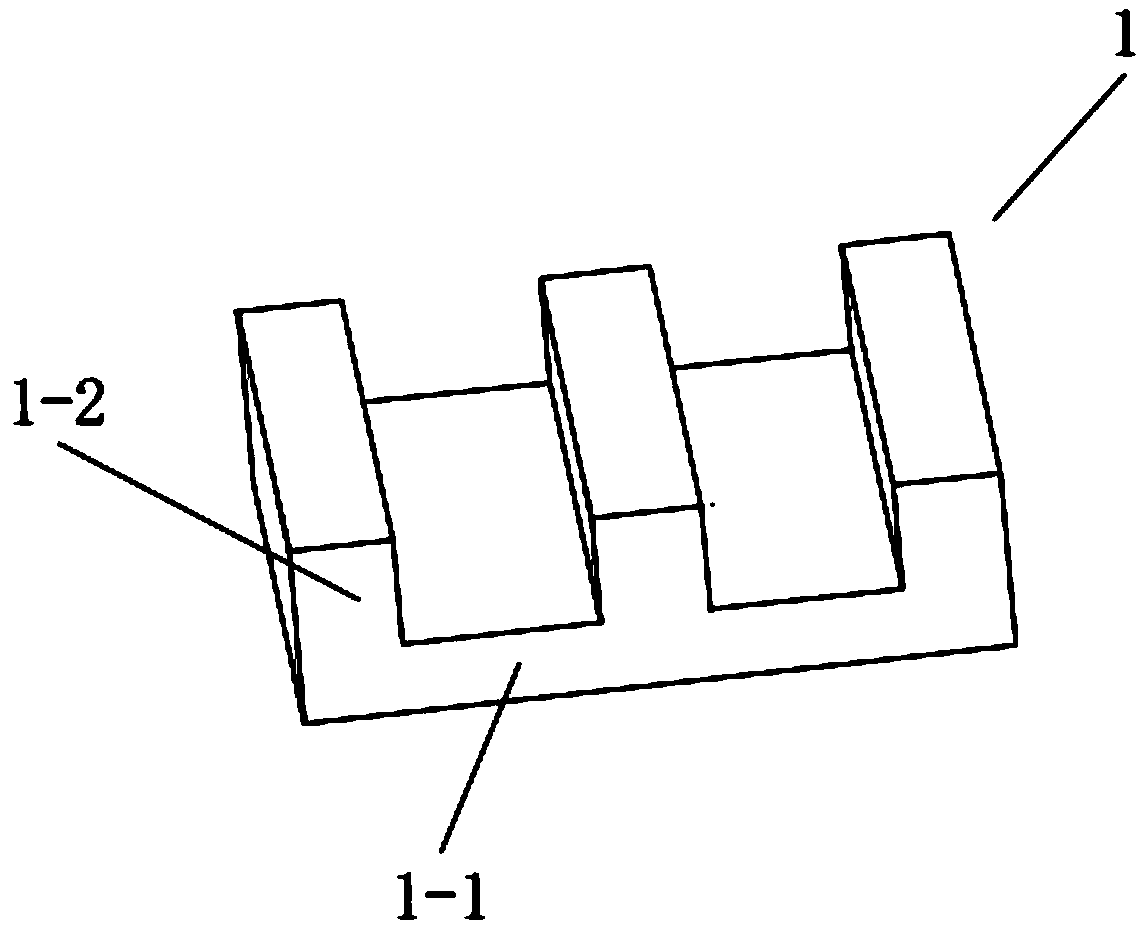

Pallet as well as molds and production method thereof

ActiveCN109279141AThe size meets the requirementsAccurate settingBio-packagingCane mechanical workingEngineeringUltimate tensile strength

The invention discloses a pallet as well as a production method and molds thereof. The pallet comprises a supporting plate and supporting legs, wherein the supporting legs are located below the supporting plate, the supporting plate is formed by pressing and bonding bamboo bundles and glue, the supporting legs are formed by pressing and bonding the bamboo bundles and the glue, and the supporting legs and the supporting plate are pressed into a whole. The molds of the pallet comprise the supporting plate mold and the pallet mold, the supporting plate mold comprises a supporting plate mold mainbody and a supporting plate pressurizing part, the pallet mold comprises a pallet mold main body, a pallet cavity with an opening in the side surface and a pallet pressurization part. The production method of the pallet comprises the following steps that firstly, the bamboo bundles are placed into a first supporting plate cavity to be pressed into the supporting plate, then the supporting plate manufactured by pressing is placed in a second supporting plate cavity of the pallet mold, the bamboo bundles are placed in a supporting leg cavity of the pallet mold, and the pallet mold is used to press the supporting plate and the bamboo bundles into the pallet. According to the pallet as well as the production method and the molds thereof, bamboo is utilized to be processed and integrated into the bamboo pallet, so that the pallet has the advantages of being high in strength, high in corrosion resistance, low in cost, light, easy to carry and convenient to carry.

Owner:BEIJING WUZI UNIVERSITY

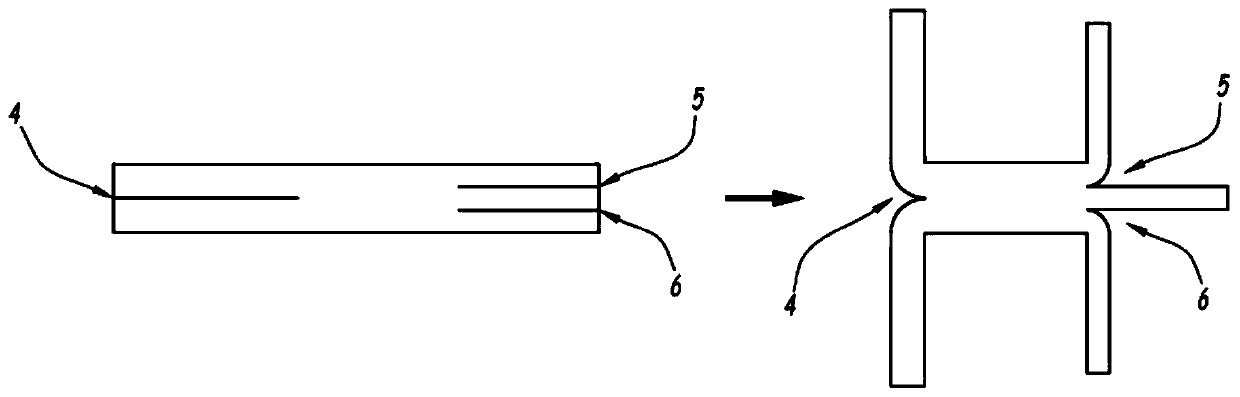

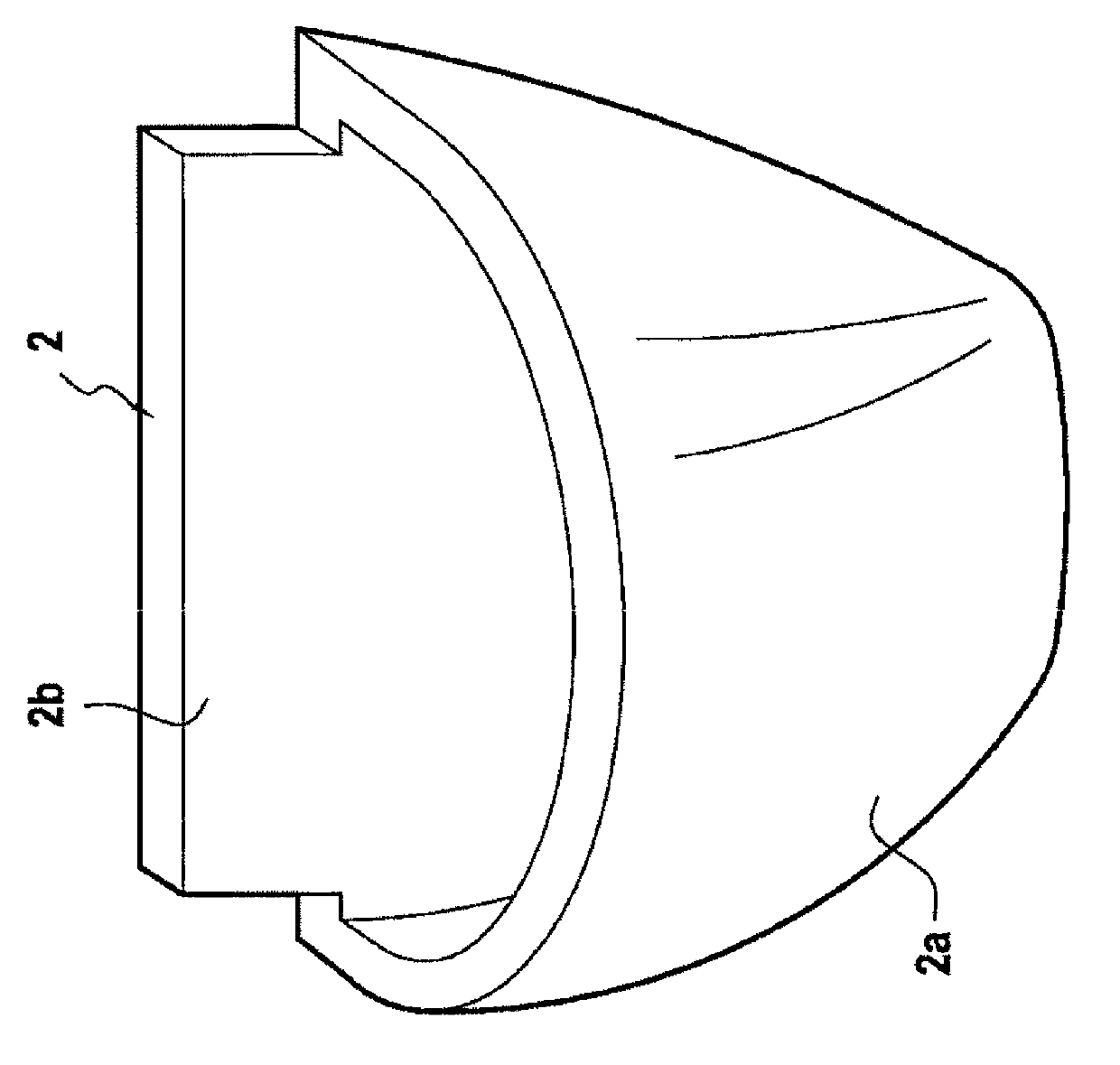

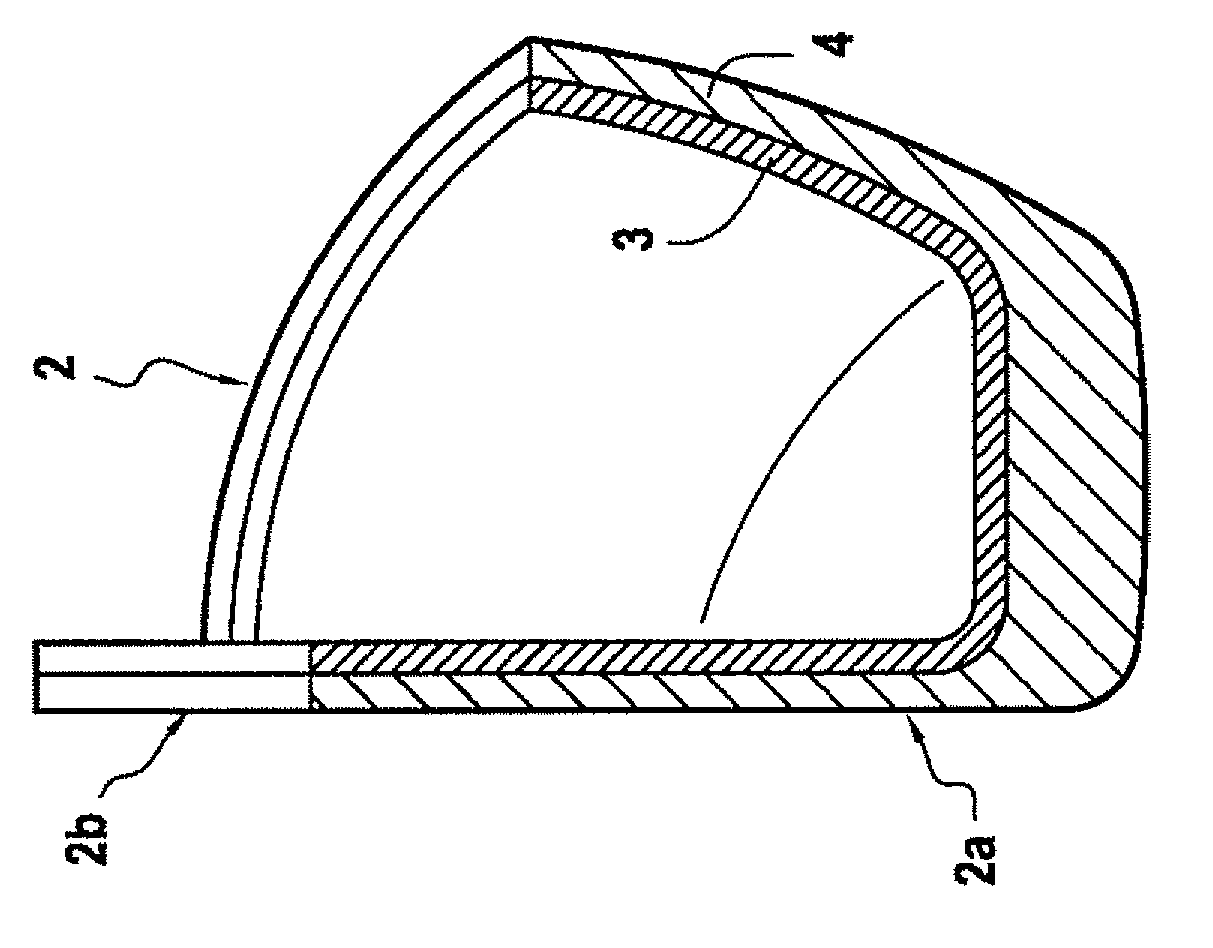

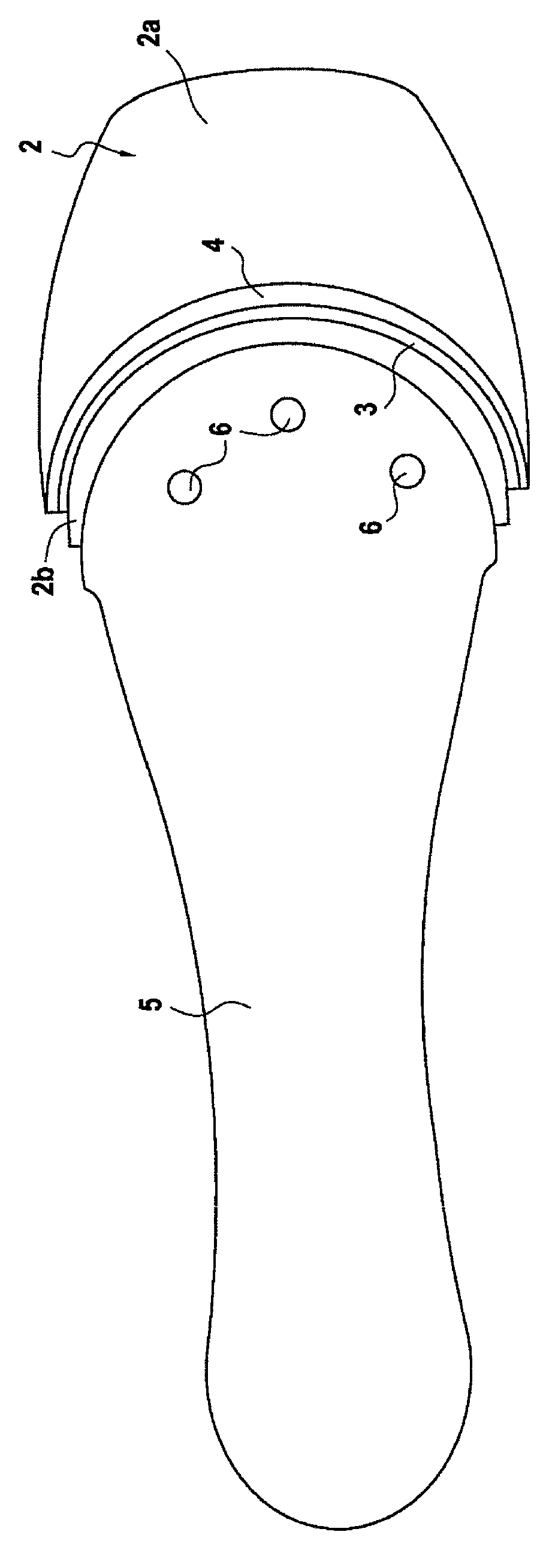

Protective element for footwear, particularly dance shoe

InactiveCN102905572ADoes not interfere with the sensation of contactSize fitsSolesInsolesHardnessBiomedical engineering

The invention relates to a protective element for footwear, to footwear having the protective element built therein, and to a method for manufacturing said protective element, with use in the field of dance shoes. The protective element is to be inserted into the front portion of the footwear and includes a shell 2 for enclosing the toes of the user. Said shell forms a one-piece assembly including an internal portion 3, for making contact with the toes of the user and formed of a resilient material having a first hardness, and an outer portion 4, opposite the inner portion and formed of a rigid material having a second hardness that is greater than the first hardness. The outer portion is formed by injecting the rigid material, having a second hardness, into a first mold. The inner portion is formed by injecting the resilient material, having a first hardness less than the second hardness, into a second overmolding mold wherein the outer portion 1 is positioned.

Owner:DECATHLON SA

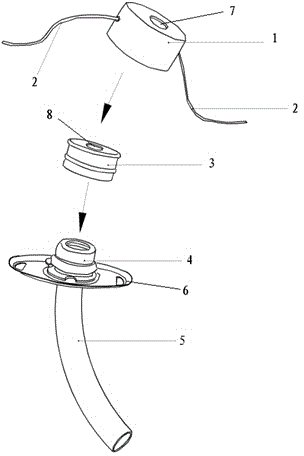

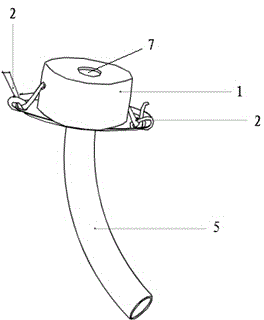

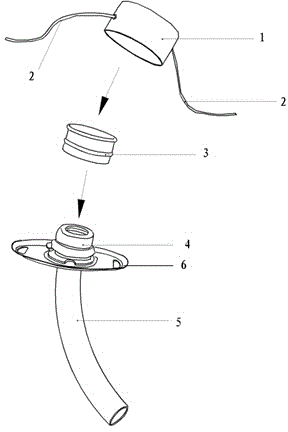

Metal endotracheal tube slippage-preventing cap and self-making method thereof

The invention relates to the field of medical instruments, and particularly discloses a metal endotracheal tube slippage-preventing cap, which comprises a cap body, fixing straps are arranged on the cap body, and the slippage-preventing cap is fixed on the port of a metal endotracheal tube by the fixing straps. The invention also discloses a self-making method for the metal endotracheal tube slippage-preventing cap, which includes: (Step 1) making of the cap body: a plastic bottle cap is chosen, and two small holes are respectively made in both sides; (Step 2) making of the fixing straps: two thin straps are chosen, and through the small holes of both sides of the cap body, the thin straps and the cap body are combined as a whole. The metal endotracheal tube slippage-preventing cap disclosed by the invention meets the requirement of hospital infection management, effectively prevents a tube plug from shifting and coming off, increases the success rate of endotracheal tube blockage, and promotes the recovery of a patient, moreover, the materials can be conveniently obtained, and the metal endotracheal tube slippage-preventing cap is economical and practical, and is convenient to use clinically.

Owner:蔡木辉

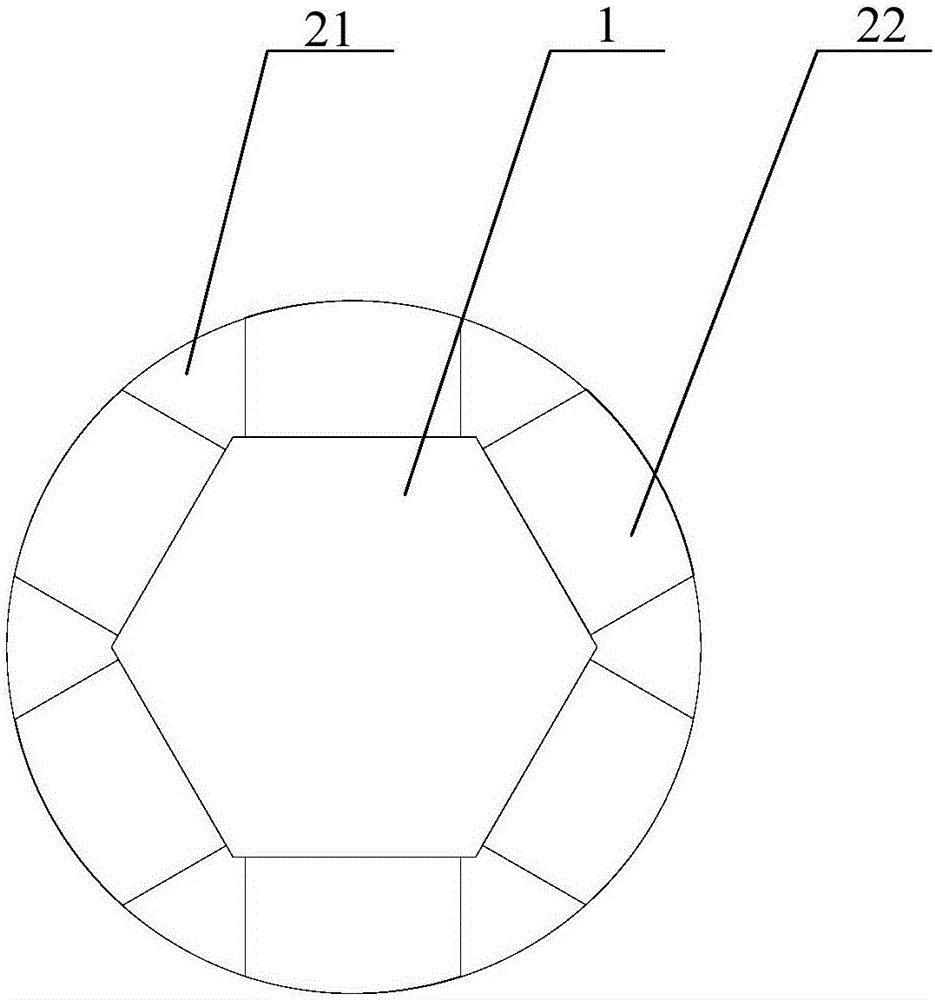

Platform used for tower barrel, tower barrel assembly and draught fan

InactiveCN106224171AImprove standardizationShort manufacturing cycleFinal product manufactureWind motor supports/mountsMarine engineeringModularity

The invention relates to the technical field of draught fan manufacturing, in particular to a platform used for a tower barrel, a tower barrel assembly and a draught fan. The platform used for the tower barrel comprises a benchmark platform and an annular adjusting platform. The benchmark platform is located in the adjusting platform, and the adjusting platform is connected with the benchmark platform. According to the provided platform used for the tower barrel, a user only needs to manufacture different-size adjusting platforms which are used for being matched with benchmark platforms of which the sizes are the same as the sizes of the adjusting platforms according to the sizes of the inner walls of tower barrels, so that the platform is modular, the standardization of the platform is improved, and the manufacturing period of the platform is shortened.

Owner:SANY ELECTRIC CO LTD

A bean polishing machine

The invention relates to a bean polishing machine. The bean polishing machine comprises a rack, two polishing plates, two drive devices and two sliding bases; the two sliding bases are vertical and are mounted in the rack at an interval in parallel, the two polishing plates are vertically arranged and are in one-to-one correspondence to the sliding bases, the polishing plates are mounted on the faces where the corresponding sliding bases close to each other in a sliding manner, a gap is arranged between the two polishing plates, the two sides of the two polishing plates are in sealed connection through a flexible belt, and a polishing chamber with the upper and the lower opened are defined by the two polishing plates and the flexible belt, the lower end of one polishing plate is rotatably provided with a brake plate, the brake plate can rotatably cover or open the opening in the lower end of the polishing chamber, the two drive devices are mounted at the positions, corresponding to the two polishing plates, of the two sides of the rack in a one-to-one correspondence manner, and the drive ends of the drive devices are fixedly connected with the side ends of the corresponding polishing plates. The bean polishing machine has the beneficial effects of being simple in structure, convenient to use, capable of effectively removing impurities, mildew and the like on bean surfaces, and ensuring smoothness of the bean surfaces, high in polishing efficiency and good in effect.

Owner:湖北天明粮油设备有限公司

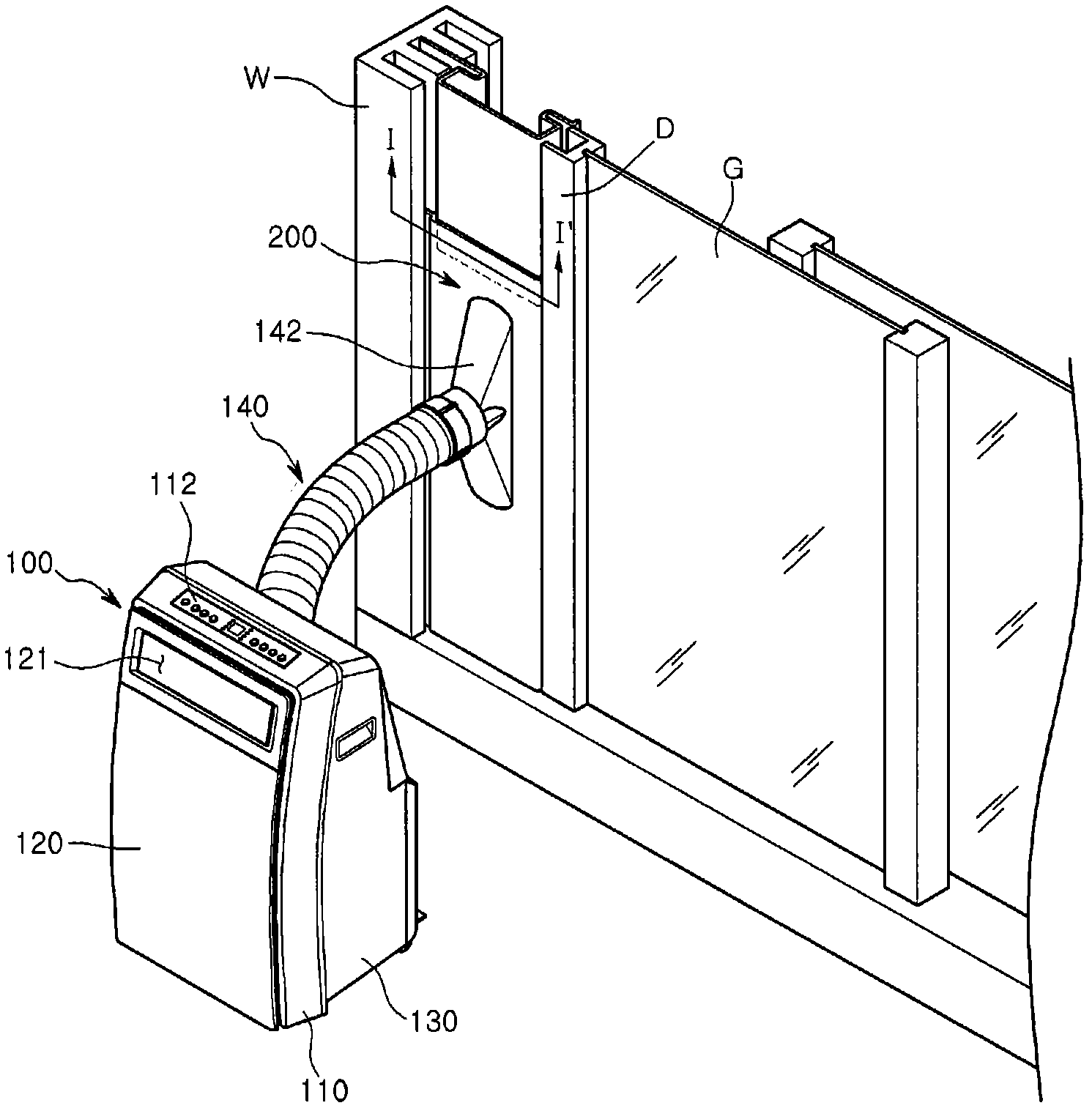

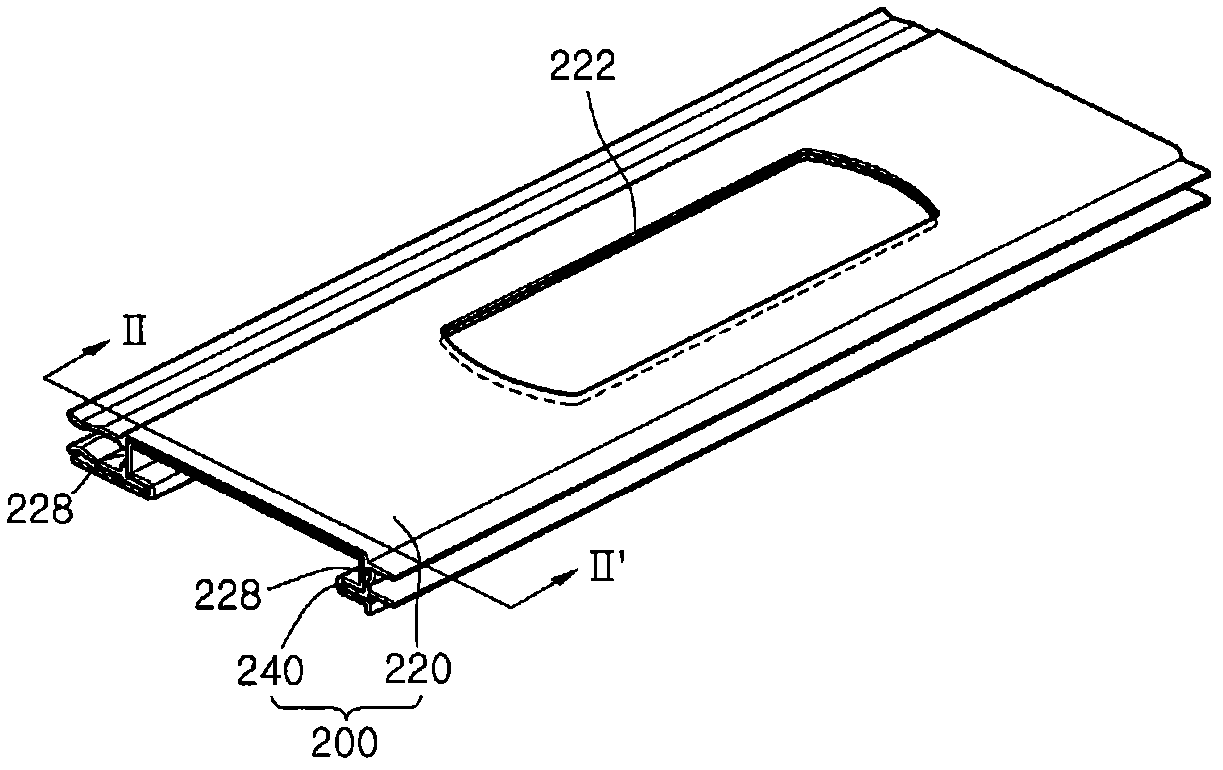

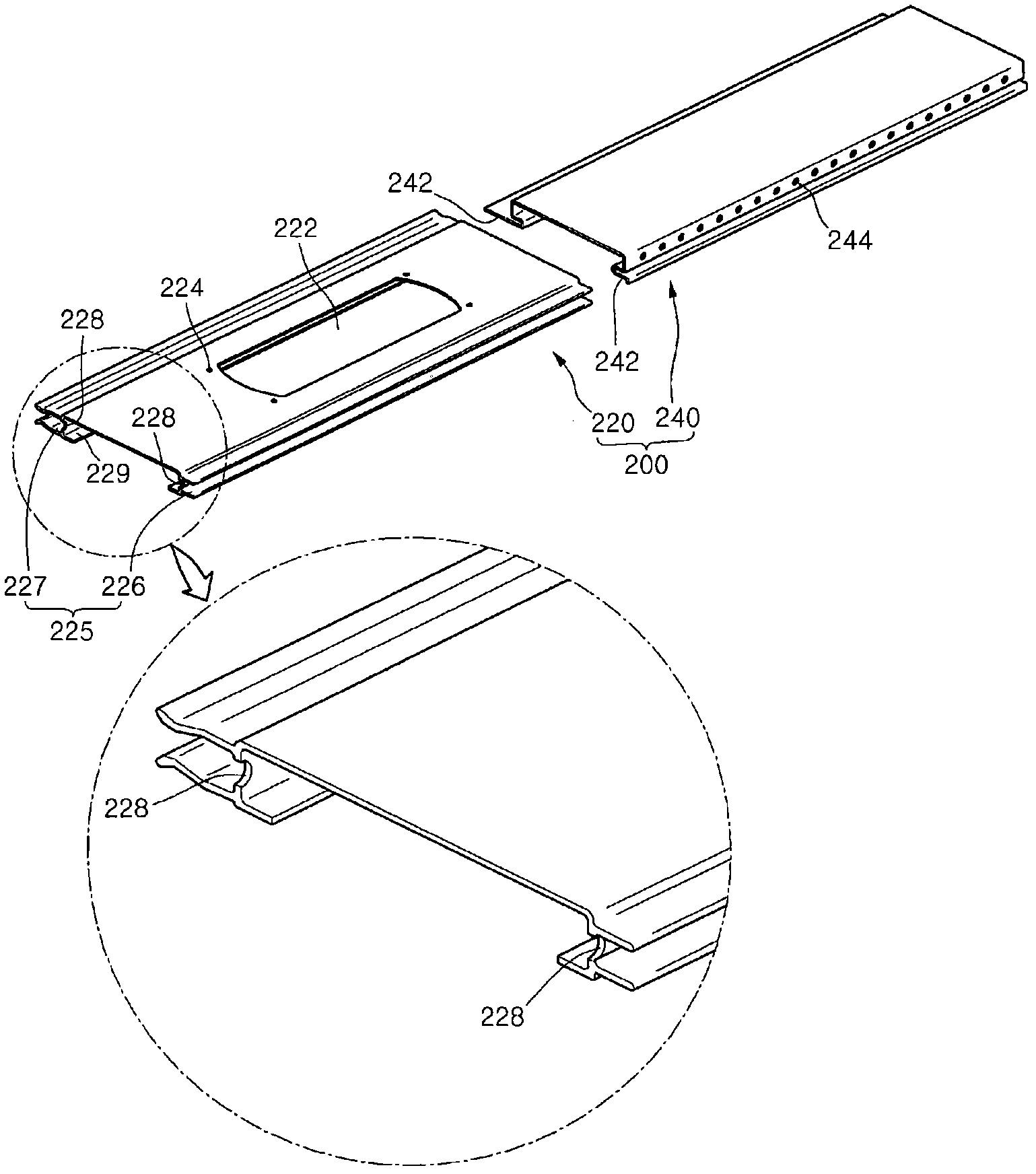

Movable air conditioner

ActiveCN102149893BEasy to fixSize fitsLighting and heating apparatusVentilation arrangementEngineering

Owner:LG ELECTRONICS INC

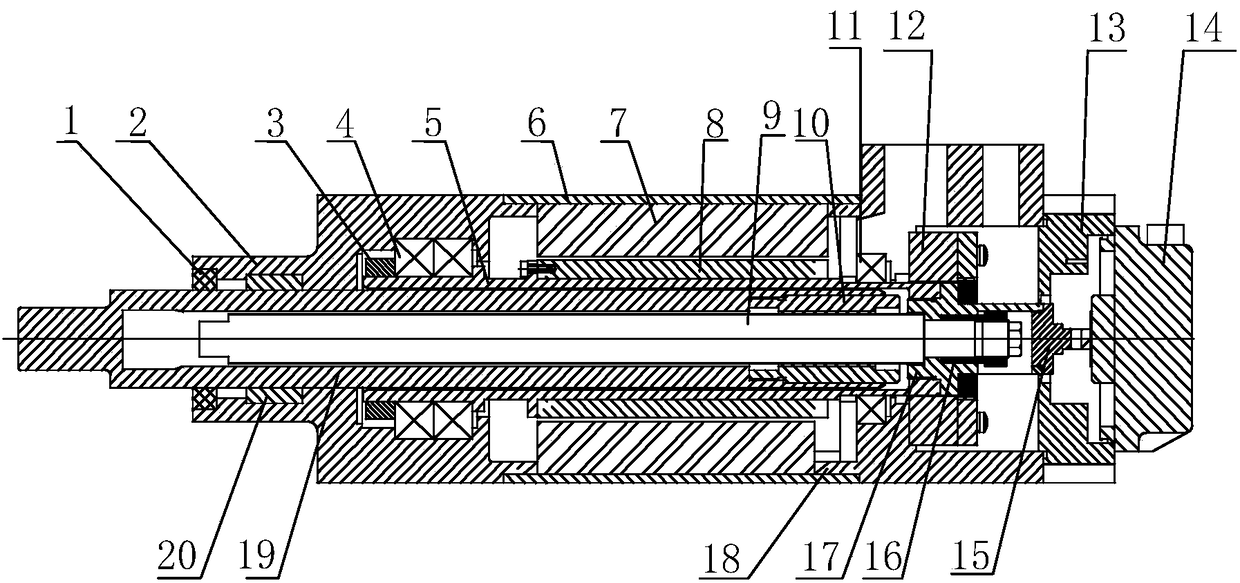

Integrated servo electric cylinder

ActiveCN103730979BSimple structureImprove performanceMechanical energy handlingTorque transmissionEngineering

The invention discloses an integrated servo electric cylinder which comprises a cylinder body, a lead screw and a nut. The two ends of the cylinder body are an opening end and a sealed end. A front supporting cover is arranged at the opening end. A back end cover is arranged at the sealed end. The middle portion of the cylinder is of a hollow structure. The lead screw is arranged in the cylinder body. The nut is arranged on the lead screw and can move in a reciprocating-straight-line mode along the axis of the lead screw. The nut is connected with a power pipe in a thread mode. The lead screw is connected with a torque transmission connector through a lead screw connecting sleeve. The torque transmission connector is connected with a rotor shaft which is fixedly connected with a rotor. A stator is fixed in the cylinder body. The rotor shaft is supported by a front bearing and a back bearing. The integrated servo electric cylinder has the advantages of being simple in structure, great in performance and convenient to maintain, and the size meets working requirements.

Owner:力姆泰克(廊坊)传动设备有限公司

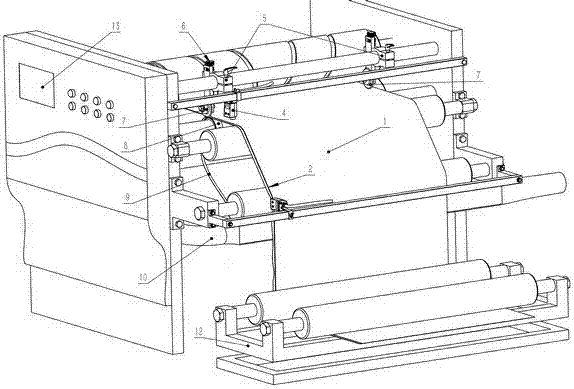

Trimming device for gravure printing machine

The invention discloses a trimming device for a gravure printing machine. The trimming device comprises a machine body, a centering mechanism used for putting a printing product straight, a cutting mechanism used for cutting the edge part of the printing product along a scanning line, a negative pressure scrap suction mechanism used for removing wool fibers produced after trimming by suction and a conveying mechanism used for driving the printing product to move, wherein in the conveying direction of the printing product, the cutting mechanism is positioned in front of the centering mechanism; the cutting mechanism comprises a knife holder, a slitting knife used for slitting the edge part of the printing product and a base used for being propped against the printing product to be convenient for the slitting knife to perform force application; the slitting knife is connected with the knife holder; and the base is positioned below the slitting knife. The trimming device for the gravure printing machine has the advantage that the rejection rate is reduced by trimming wool fibers on the edge part of the printing product.

Owner:GUIZHOU XINIUWANG PRINTING

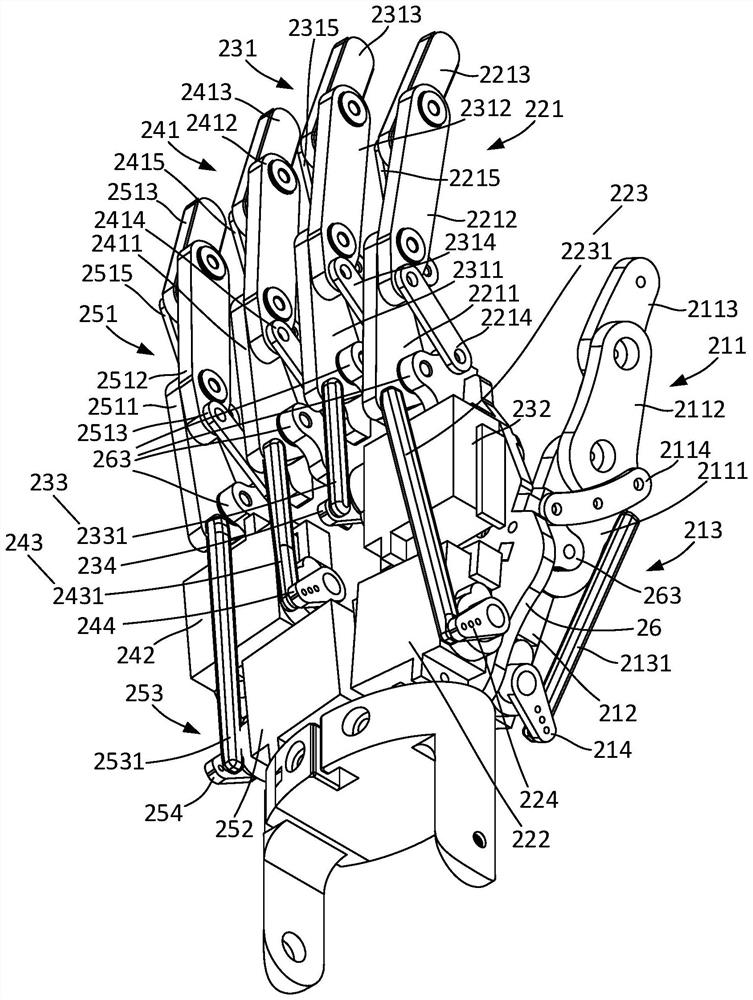

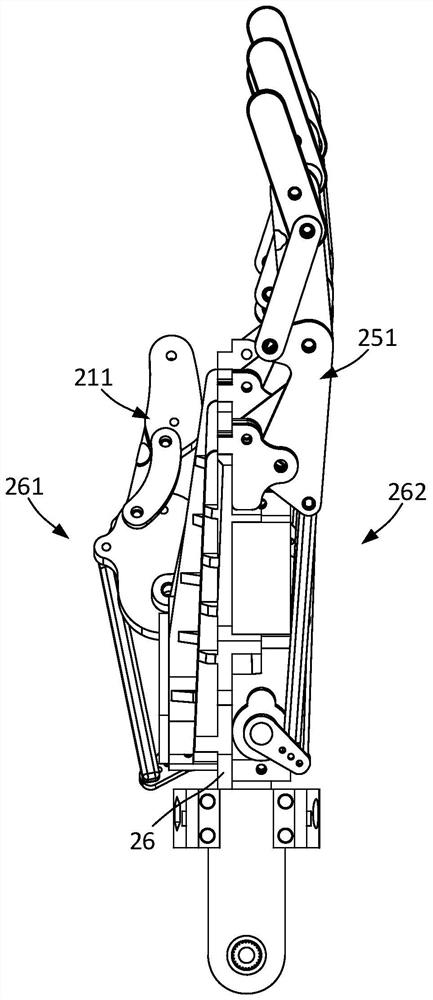

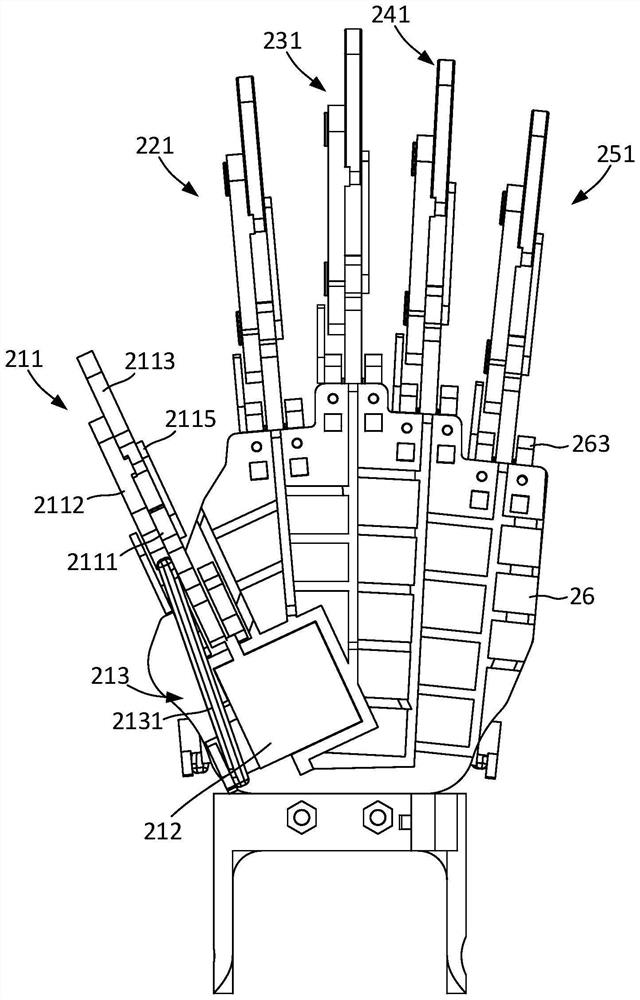

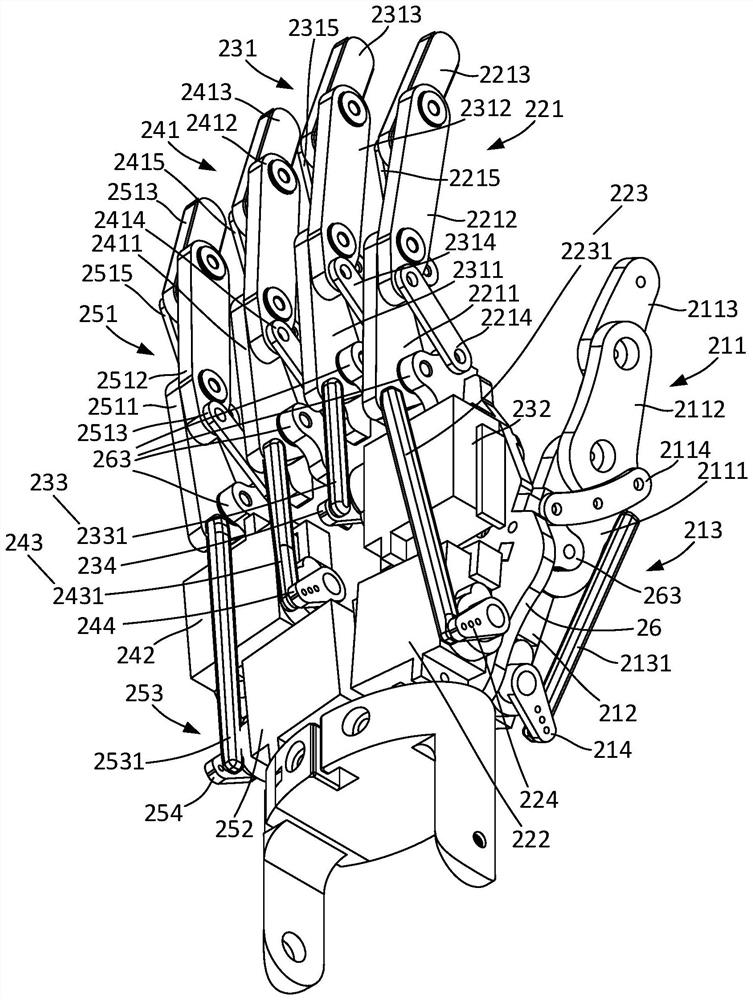

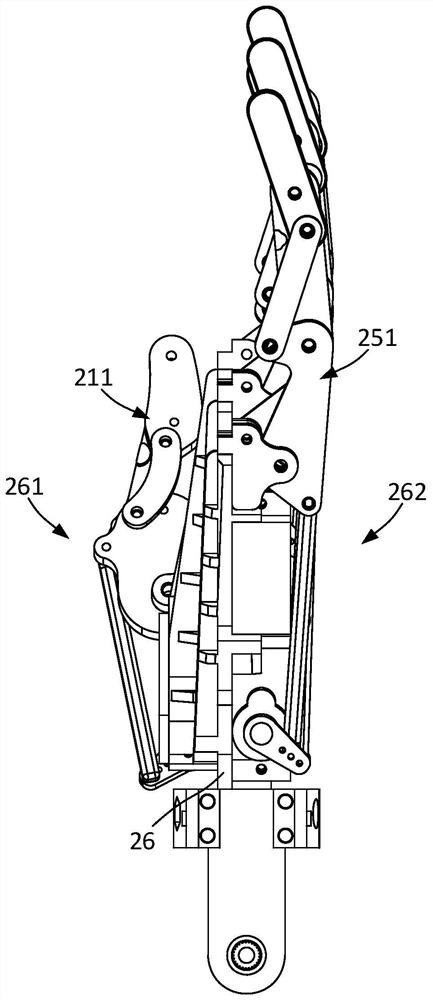

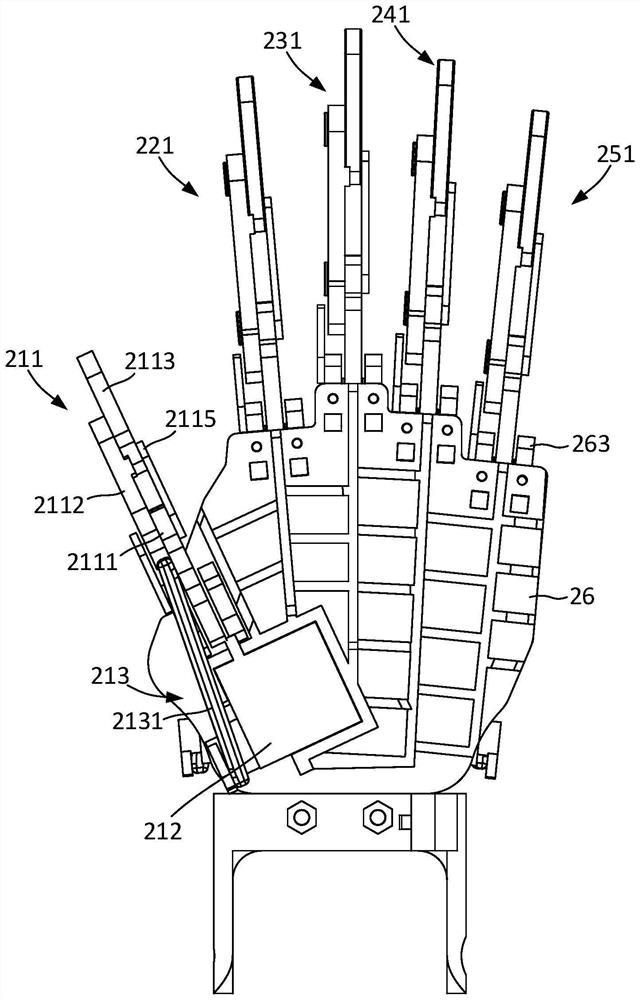

Humanoid robot palm structure

The invention relates to a palm structure of a humanoid robot, comprising: a palm skeleton; a plurality of link mechanisms rotatably mounted on the palm skeleton for simulating fingers; a drive motor arranged on the palm skeleton, which passes through a ball The web connecting rod is drivingly connected with the corresponding link mechanism; one of the five driving motors is arranged on the palm side, and four are arranged on the palm side, and are arranged in a close up and down arrangement. The present invention reduces the size of the width, length and height of the palm by reasonably arranging the driving motors of each finger, so that the size of the palm is more in line with the size of the palm of a real person. And the drive motor drives the corresponding link mechanism through the ball-spoke link, so that the motor shaft of the drive motor and the rotation axis of the link mechanism are not on the same plane, which can solve the space problem of the drive motor layout, thereby effectively reducing the size of the palm of the hand. size.

Owner:上海清宝引擎机器人有限公司

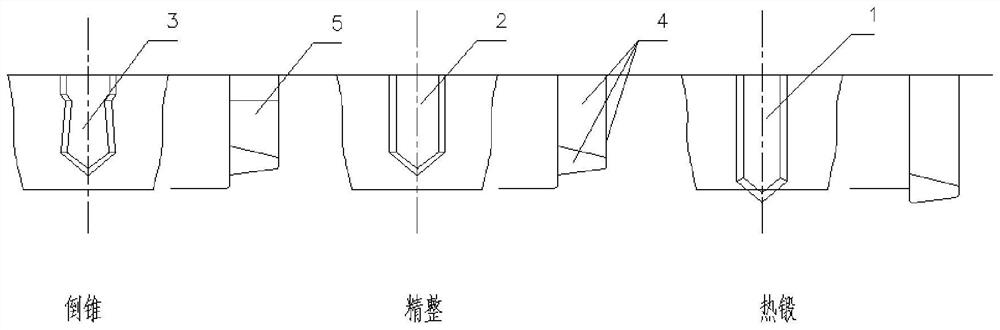

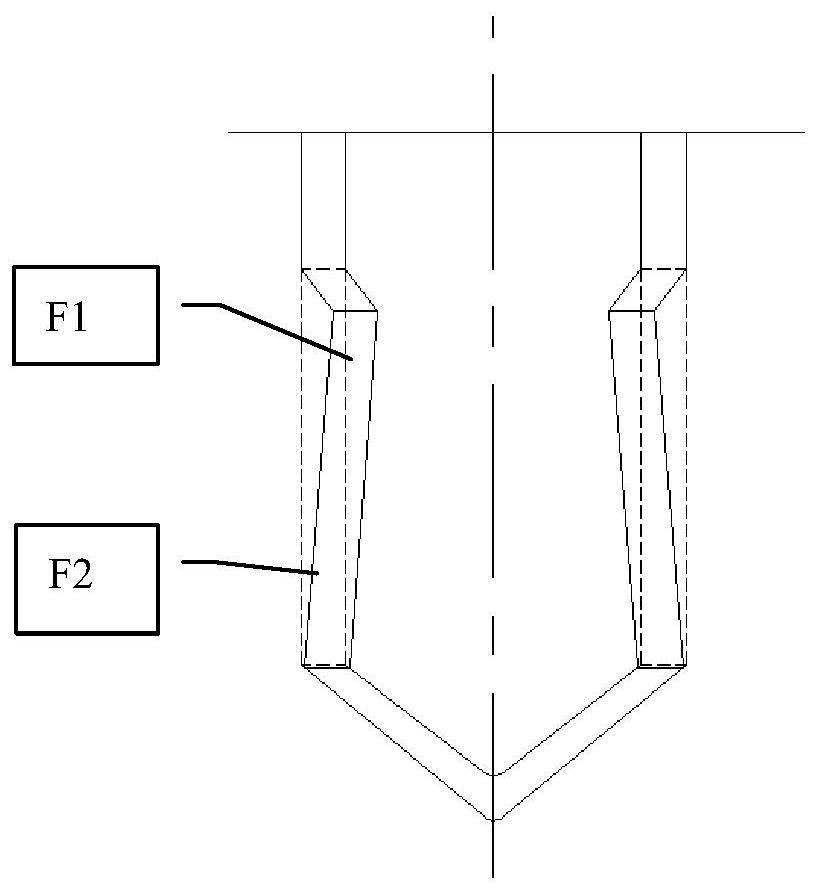

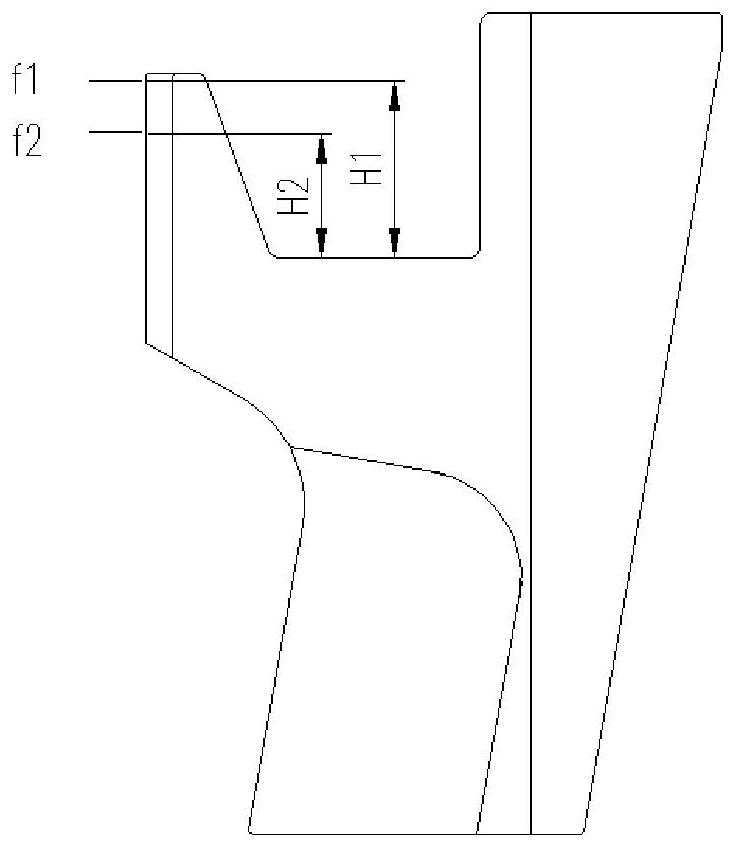

A forging process for combining teeth

Owner:江苏智造新材有限公司

Special electric soldering iron device for disassembling electronic components

PendingCN111992837AIntegrity guaranteedGuaranteed reliabilitySoldering bitsSoldering ironPower switchingDamping torque

The invention discloses a special electric soldering iron device for disassembling electronic components. The special electric soldering iron device comprises a handle, an adjusting mounting seat, a damping adjusting frame, adjusting connecting rods, damping torque hinge sliding blocks, heating unit assemblies and a power line; a plurality of power switches are mounted on the handle, and the lowerend of the handle is in threaded connection with the adjusting mounting seat; the outer wall of the lower end of the adjusting mounting seat is connected with the damping adjusting frame, and the multiple adjusting connecting rods are mounted on the damping adjusting frame; the damping torque hinge sliding blocks are mounted at the other ends of the adjusting connecting rods; the heating unit assemblies are movably mounted at the lower ends of the damping torque hinge sliding blocks, and a plurality of soldering bits are detachably mounted at the lower ends of the heating unit assemblies, wherein positioning holes are formed in the damping torque hinge sliding blocks; and the power line is electrically connected with the power switches and the heating unit assemblies. The special electricsoldering iron device can be adjusted and used according to shapes and sizes of the different components to quickly and completely disassemble the components at a time, thus the disassembly efficiency is improved, and the reliability of the components and circuits can be guaranteed better.

Owner:750 TEST SITE OF CHINA SHIPBUILDING IND CORP

Humanoid robot palm structure

The invention relates to a humanoid robot palm structure which comprises a palm skeleton, a plurality of connecting rod mechanisms which are rotatably mounted on the palm skeleton and are used for simulating fingers and driving motors which are arranged on the palm skeleton and are in driving connection with the corresponding connecting rod mechanisms through ball amplitude connecting rods, wherein one of the five driving motors is arranged on the palm center side, and the four driving motors are arranged on the palm side and are tightly arranged up and down. For the humanoid robot palm structure disclosed by the invention, through reasonable layout of the driving motors of the fingers, a width, a length and the size in a height direction of the palm are reduced, so that the size of the palm better conforms to the size of a palm of a real person; and the driving motors drive the corresponding connecting rod mechanisms to act through the ball amplitude connecting rods, so that motor shafts of the driving motors and rotating shafts of the connecting rod mechanisms are not located on a same plane, the space problem of layout of the driving motors can be solved, and thus the size of the palm is effectively reduced.

Owner:上海清宝引擎机器人有限公司

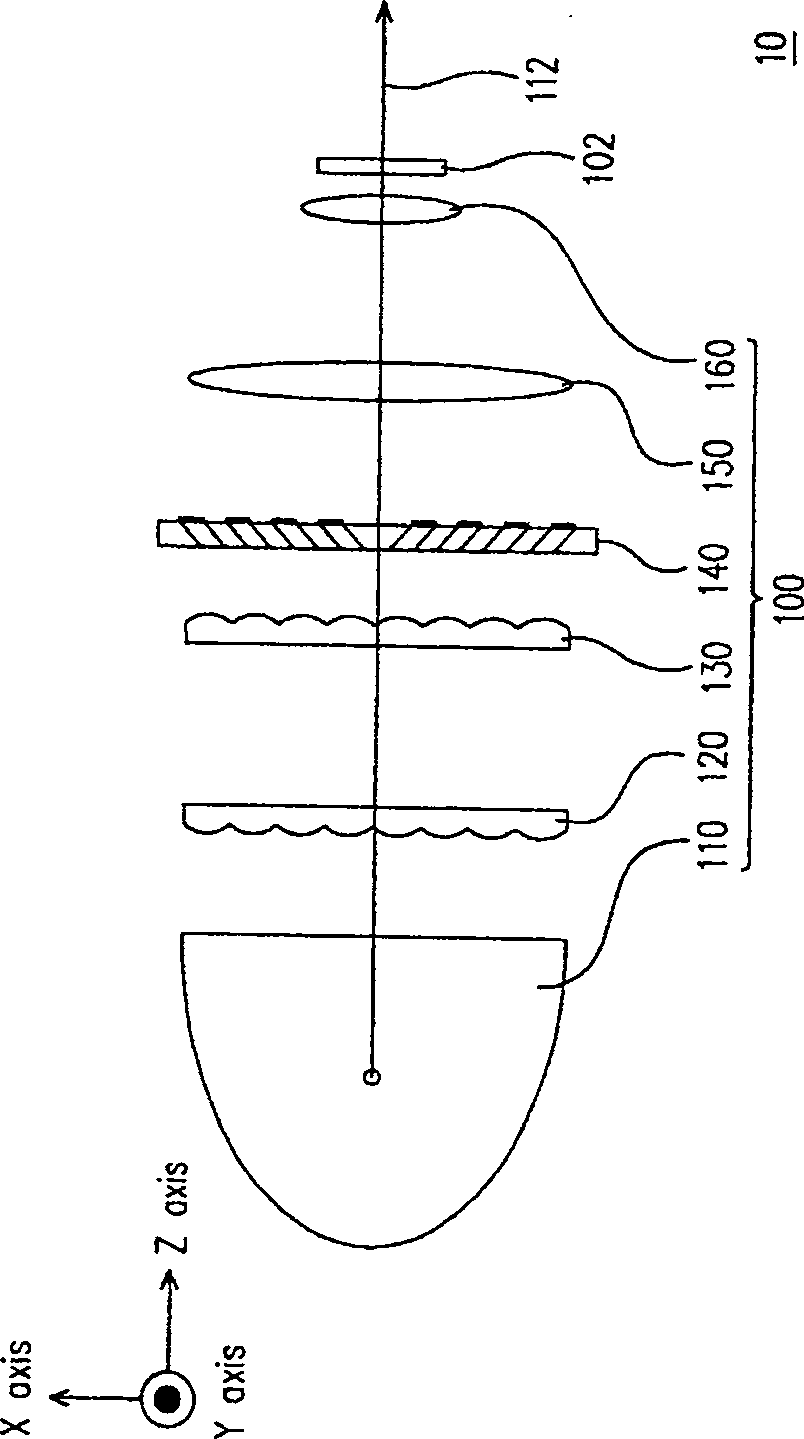

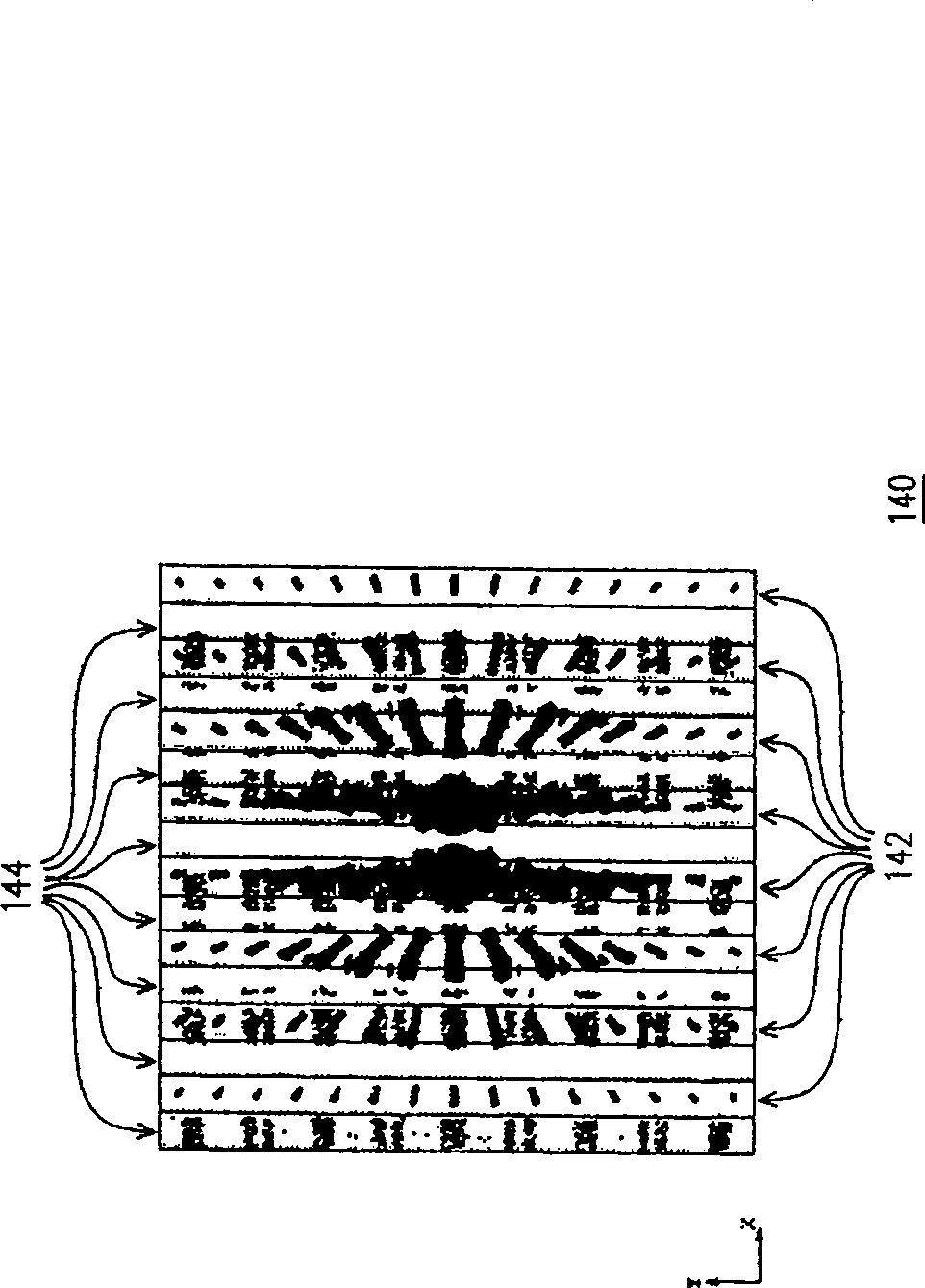

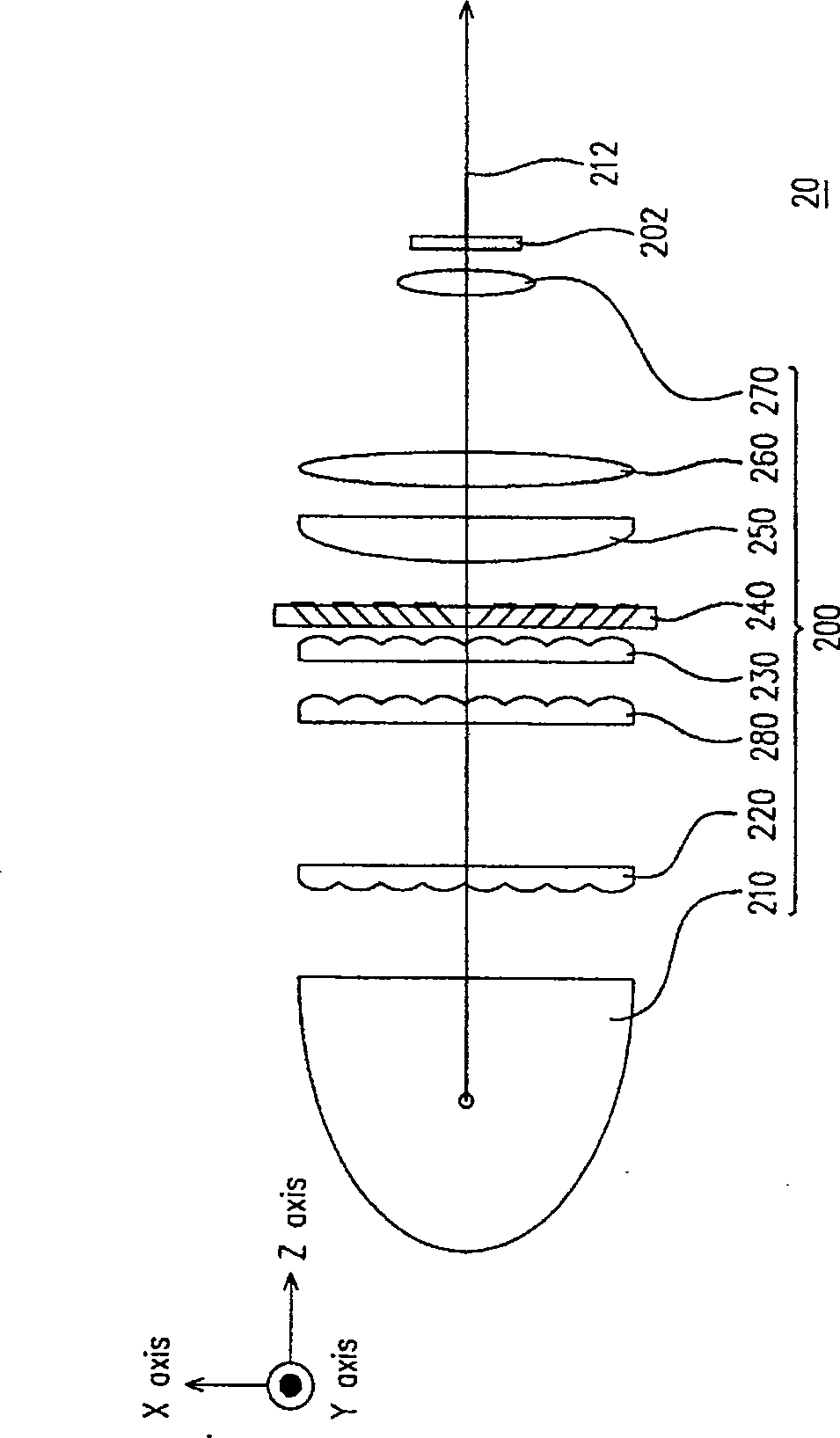

Lighting system and projecting system

InactiveCN100538507CImprove light utilizationSize fitsProjectorsNon-linear opticsArray data structureLight spot

A lighting system comprises a light source module, the first integral array lens, a column-shaped array lens, a polarized light splitting transducer, a column-shaped lens, a condensing lens and a collimating lens. The light source module is used to send out the white light, while the first integral array lens, the column-shaped array lens, the polarized light splitting transducer, the column-shaped lens, the condensing lens and the collimating lens are arranged successively along the light path of the white light, so that the column-shaped array lens can adjust the shape of the light spot focused by the white light. Thus, the light spot almost penetrates the polarized light splitting transducer thoroughly, so as to increase the optical utilization ratio of the lighting system. In addition, a projection system is also brought forward. Such projection system includes the lighting system and a LCD panel.

Owner:CHUNGHWA PICTURE TUBES LTD

Fiber structures and 3d preforms for composite parts

3D fibrous structure preform comprising at least 3 layers (1, 2) of weft and / or warp yarns, the structure being formed by multi-layer weaving between a plurality of layers of warp yarns and a plurality of layers of weft yarns And woven into a component. It consists of a predetermined distribution of intersections of warp and weft threads bonded by polymers. The weight of the polymer is less than or equal to about 10%. The preform includes at least one thermoformed portion in which the warp and weft yarns are polymer-bonded to their intersections at which at least one of the warp and / or weft yarns carry the polymer.

Owner:PORCHER INDUSTRIES

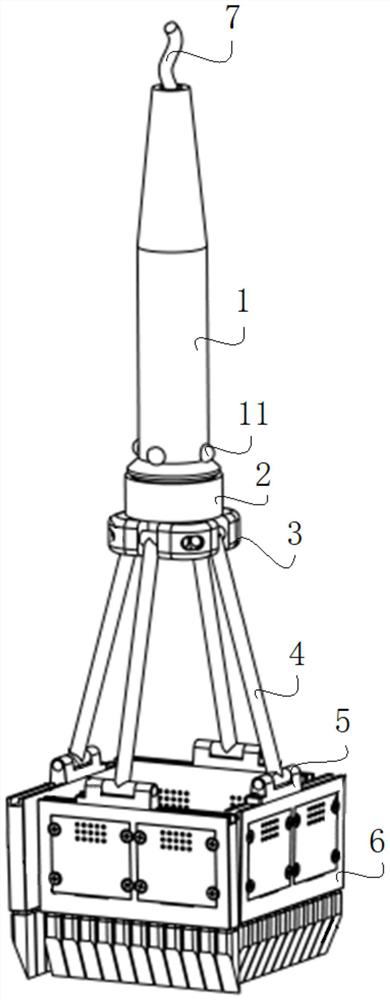

An automatic forging device for bearing inner ring sleeve

ActiveCN110935839BTo achieve the purpose of automatic forgingNo manual operationEngine componentsHandling devicesTransmission beltEngineering

The invention discloses an automatic forging device for an inner ring of a bearing, which belongs to the technical field of bearing production and includes a mounting frame, a billet conveyor belt, a feeding cylinder, a feeding push plate, a forging table, a forging moving assembly, a forging assembly, a blanking assembly, Bearing frame, finished material conveyor belt, water spray cooling assembly, inclined plate and finished material loading box, the installation frame is set on the ground, the billet conveyor belt is set in the installation frame, and the feeding cylinder is set horizontally on the installation On the outer wall of the rack, the feeding push plate is fixedly connected to the output end of the feeding cylinder, the forging moving assembly, forging assembly and unloading assembly are all set on the forging table, and the finished material conveyor belt is set on the carrier frame Inside, the water spray cooling assembly is installed on the carrier. The invention solves the problem that in the production process of the existing bearing inner ring, it is necessary to manually place the heated blanks in different forging equipment for forging for many times, and the degree of automation is low, which seriously affects the production efficiency.

Owner:常山县鑫龙轴承有限公司

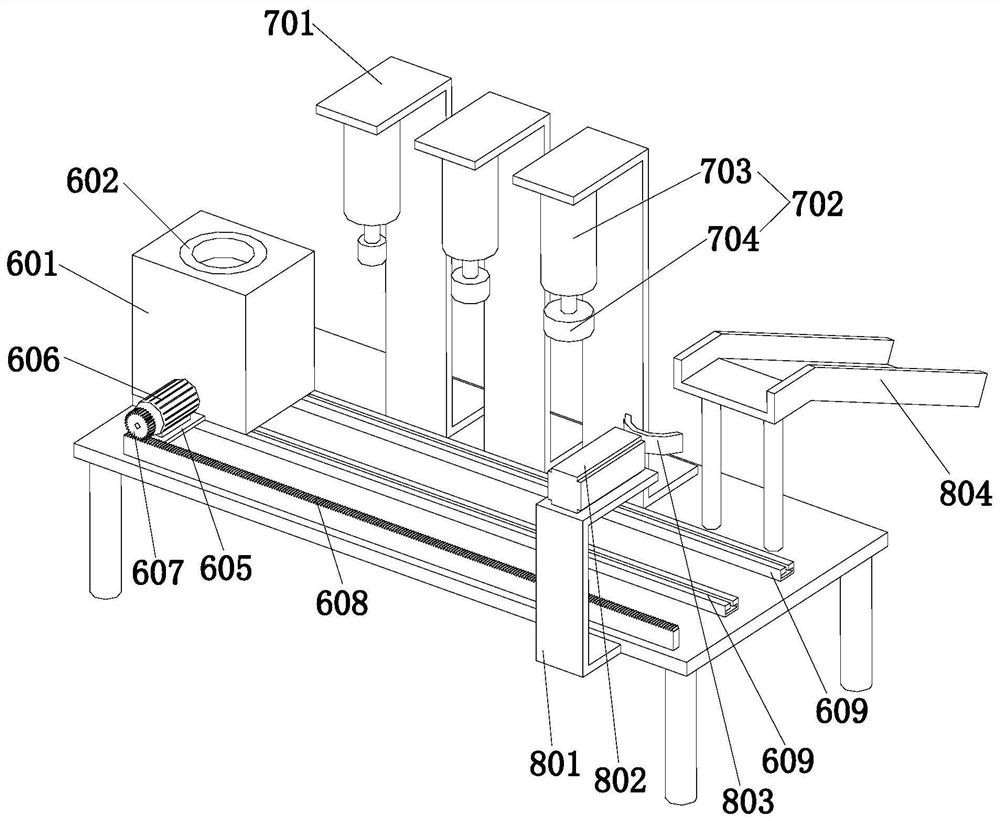

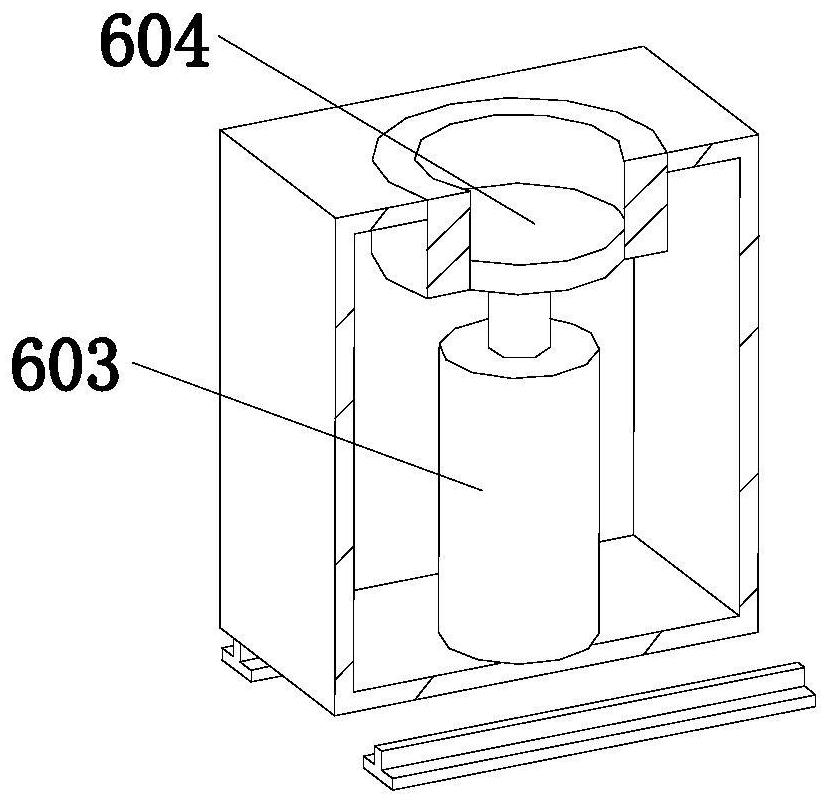

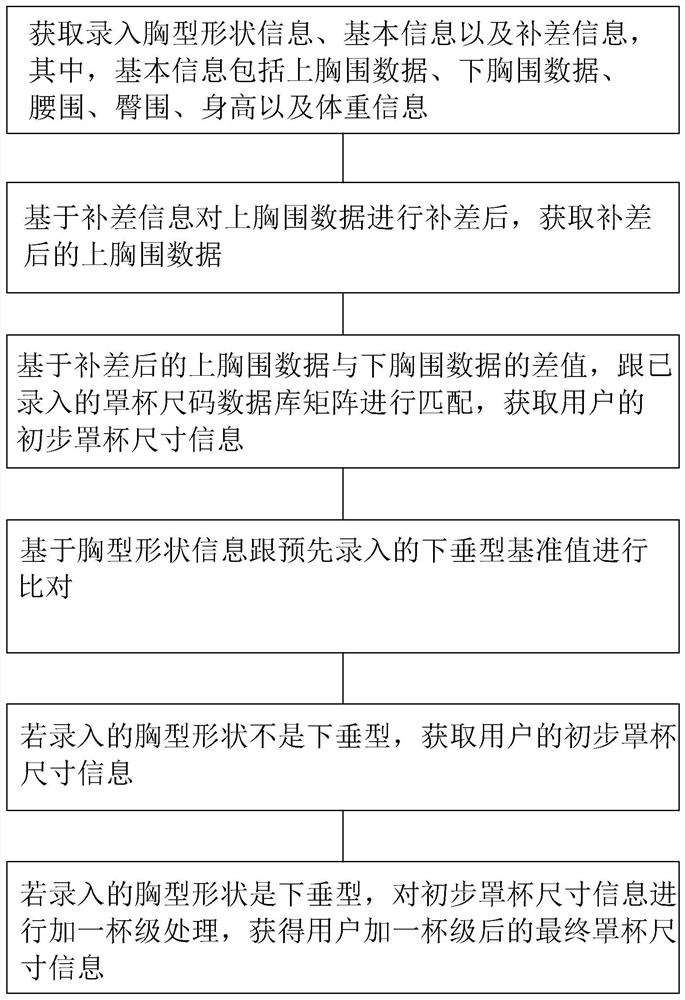

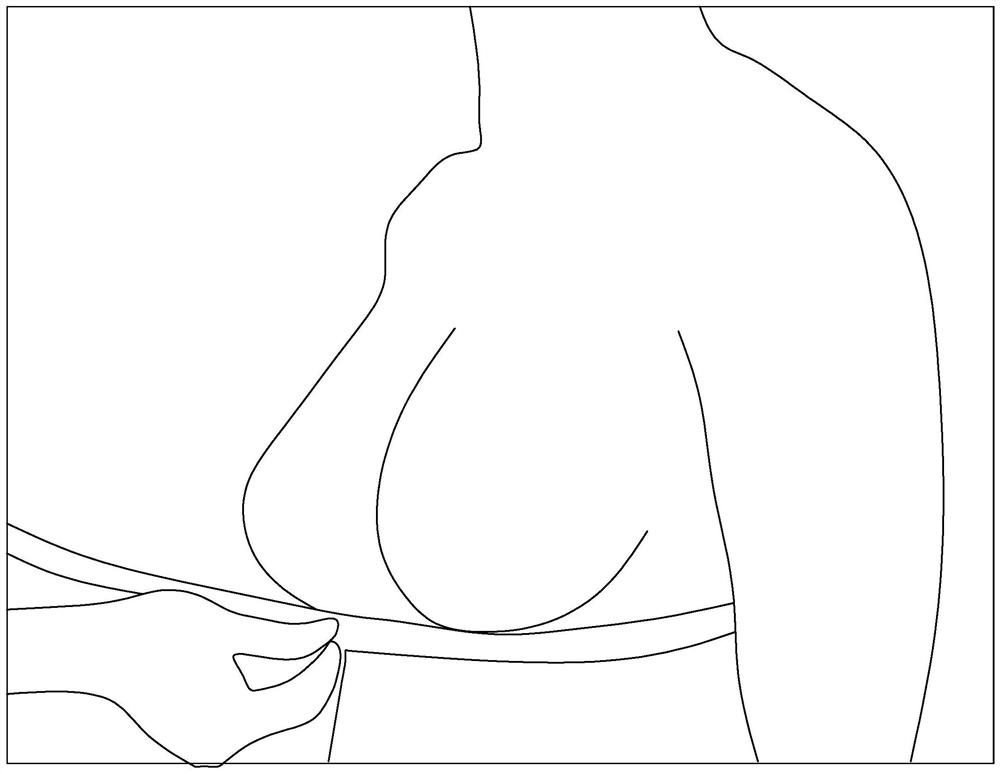

Underwear size selection method

PendingCN113221624AIncreased growth comfortEasy to growDigital data information retrievalBiometric pattern recognitionComputer visionChest circumference

The invention relates to an underwear size selection method which comprises the steps of: obtaining input breast shape information, basic information and difference compensation information, wherein the basic information comprises upper chest circumference data, lower chest circumference data, waist circumference, hip circumference, height and weight information; after performing difference compensation on the upper chest circumference data based on the difference compensation information, acquiring the upper chest circumference data after difference compensation; based on the difference value of the upper chest circumference data and the lower chest circumference data after difference compensation, matching with an input cup size database matrix, and obtaining initial cup size information of the user; comparing the breast shape information with a pre-recorded sagging type reference value; if the input breast shape is not a sagging shape, acquiring initial cup size information of the user; and if the input breast shape is a sagging shape, performing one-cup-level adding processing on the initial cup size information to obtain final cup size information after one-cup-level adding processing of the user. The underwear size selection method has the effect of conveniently and accurately matching underwear for customers.

Owner:任锋

A vehicle detection method based on yolo v3 improved algorithm

ActiveCN111860679BSize fitsQuality improvementCharacter and pattern recognitionNeural architecturesFeature extractionData set

The invention discloses a vehicle detection method based on the YOLO v3 improved algorithm. Including steps: S1. Collect a vehicle data set, the vehicle data set contains multiple images I of the GT frame of the object; S2. Use a dimensional clustering method to cluster the width and height of the GT frame, and generate the width and height of K a priori frames. High size; S3. Input the image I into the skeleton network Darknet‑53 of YOLO v3 for feature extraction, and output feature maps of different scales; S4. Evenly distribute the K a priori frame sizes to the feature maps of different scales. Predict and generate the corresponding candidate frame; S5, select the final prediction frame according to the generated candidate frame; S6, map the final prediction frame to the original image according to the relationship between the feature map and the original image, and locate the vehicle information in the image . This method improves the calculation formula of the distance between the GT frame and the cluster center, reduces the sensitivity of the formula to the IoU value, makes the size of the a priori frame obtained by clustering more in line with the real value, and improves the quality of the prior frame. Improved the performance of the YOLO v3 detection method.

Owner:ZHEJIANG SCI-TECH UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com