Pallet as well as molds and production method thereof

A pallet and mold technology, applied in the fields of pallets and their molds and production, can solve the problems of uneven wall thickness of plastic products, slightly poor moisture-proof performance of paper pallets, limited application scope and occasions, etc. Long service life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0062] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

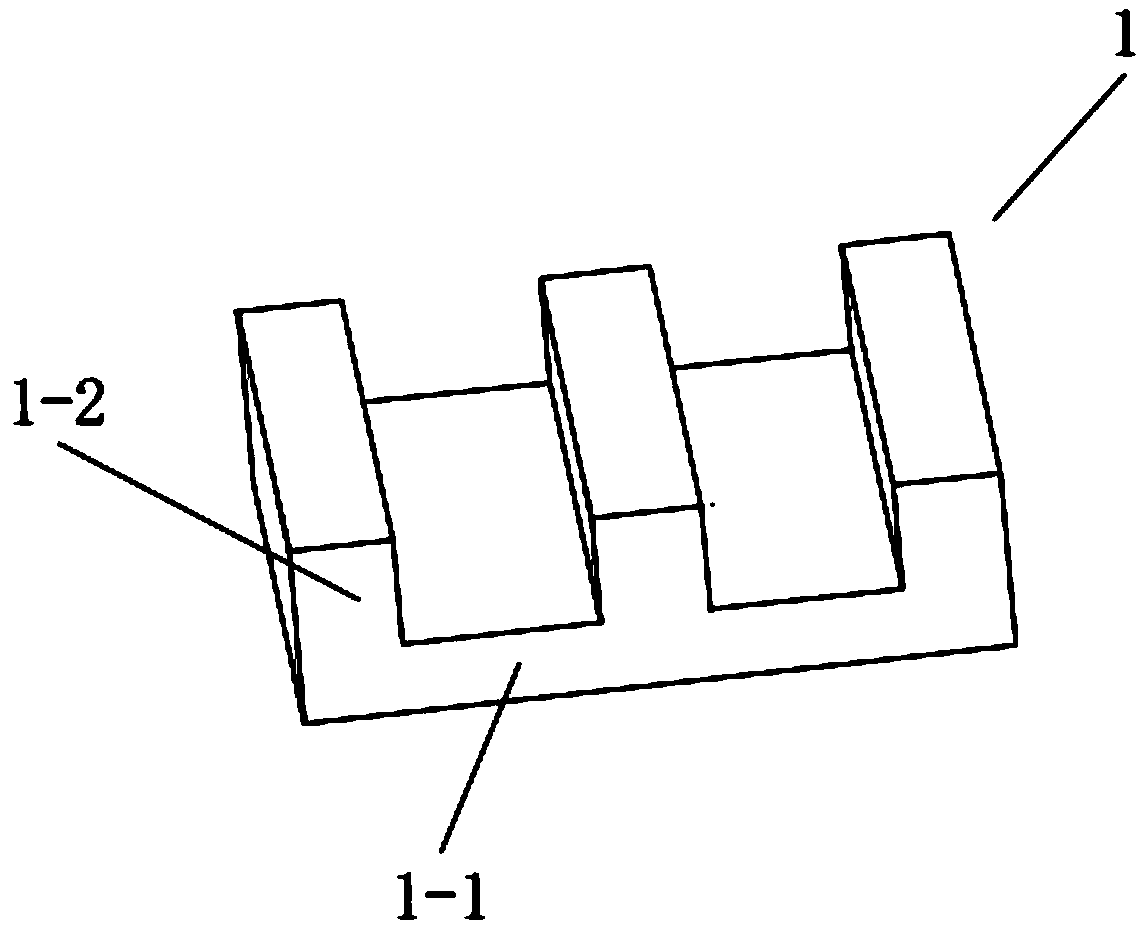

[0063] A kind of pallet of the present invention, as figure 1 As shown, it includes a supporting board 1-1 and a supporting leg 1-2; the supporting leg 1-2 is located under the supporting board 1-1; it is characterized in that: the supporting board 1-1 is made of bamboo bundles and glue It is formed by pressing and bonding, and the support leg 1-2 is formed by pressing and bonding bamboo bundles and glue, and is pressed into an integral piece with the supporting plate 1-1.

[0064] The shape characteristics and size parameters of a tray of the present invention are that the shape of the supporting plate 1-1 is rectangular; the supporting plate 1-1 is formed by pressing the bamboo bundles of multiple layers; Paralle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com