Patents

Literature

30results about How to "The size meets the requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method for AuSn20 alloy brazing filler metal used for packaging integrated circuit and usage thereof

ActiveCN102114584ASolve processabilitySolve product problemsWelding/cutting media/materialsSoldering mediaAlloyGraphite

The invention relates to a preparation method for an AuSn20 alloy brazing filler metal used for packaging an integrated circuit, which comprises the following steps: preparing gold and tin in proportions; placing the gold and tin into a casting furnace; sealing the furnace and vacuumizing the furnace; rising the temperature till the gold and tin are completely melted, controlling the temperature of the melt at 500-600 DEG C, refining for the purpose of alloying the gold and tin and degassing, and pouring the alloy in a graphite mould; placing an acquired AuSn20 alloy bar into a quartz tube and heating; sealing the furnace and vacuumizing till the pressure is 4-6Pa; rising the temperature and controlling the temperature rising; after melting the alloy bar, controlling the temperature of the melt to be 500-600 DEG C, and refining for 2-3 minutes; performing the melt-spinning process by using a vacuum quenching melt-spinning machine, controlling the temperature of the melt within 500-600 DEG C in the melt-spinning process, and introducing high-pressure nitrogen from an upper port of the quartz tube, wherein the nitrogen pressure is 10-15Pa; and spraying the alloy melt onto a speedily rotating metal wheel of the vacuum quenching melt-spinning machine from a bottom hole on the quartz tube, thereby acquiring a belt material. The belt material can be milled into a foil belt material or be punched into a slice or annular deeply processed product in the corresponding specification. By using the method, the product having excellent integrated circuit property can be prepared.

Owner:BEIJING INST OF NONFERROUS METALS & RARE EARTH

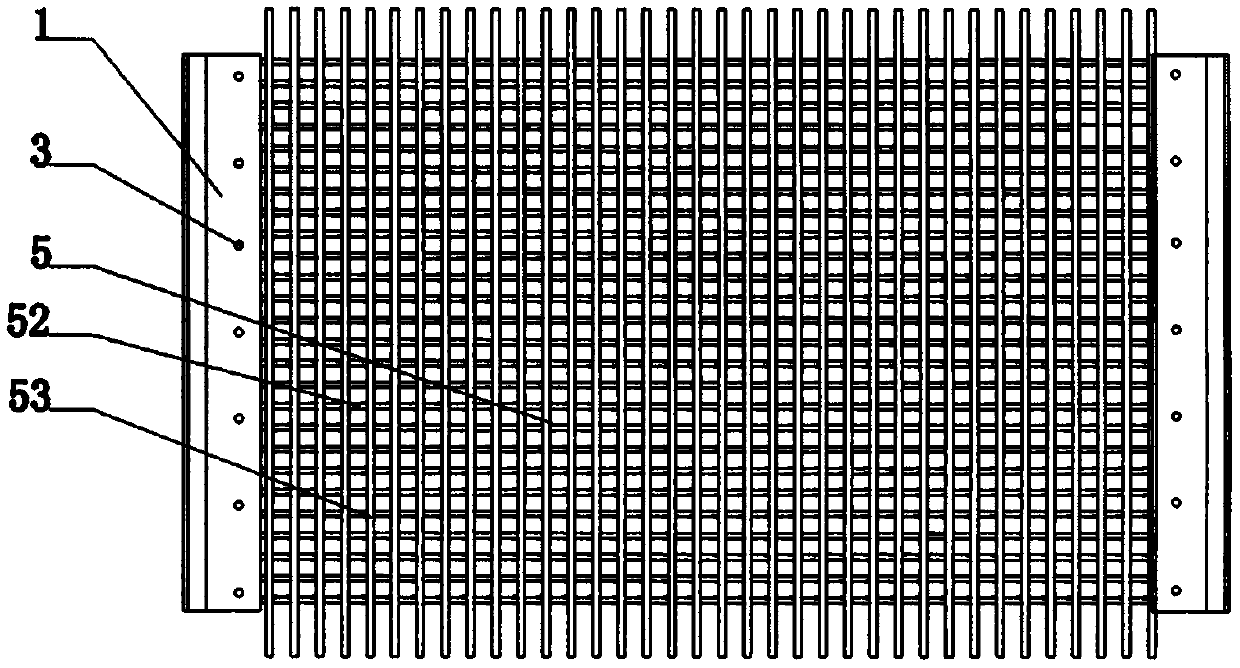

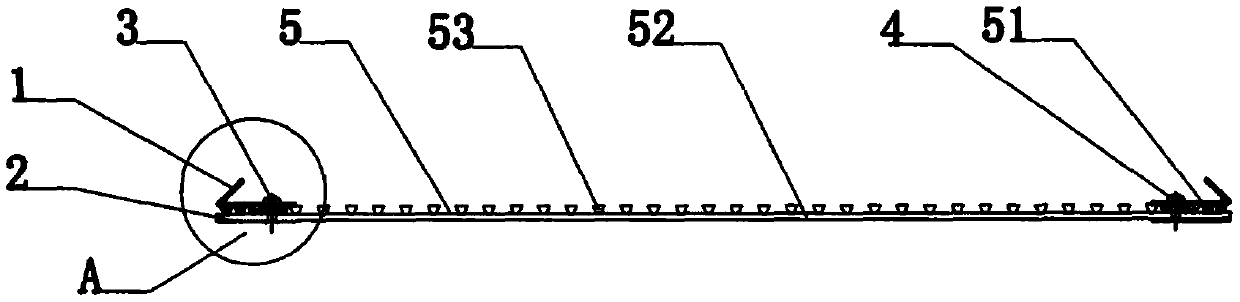

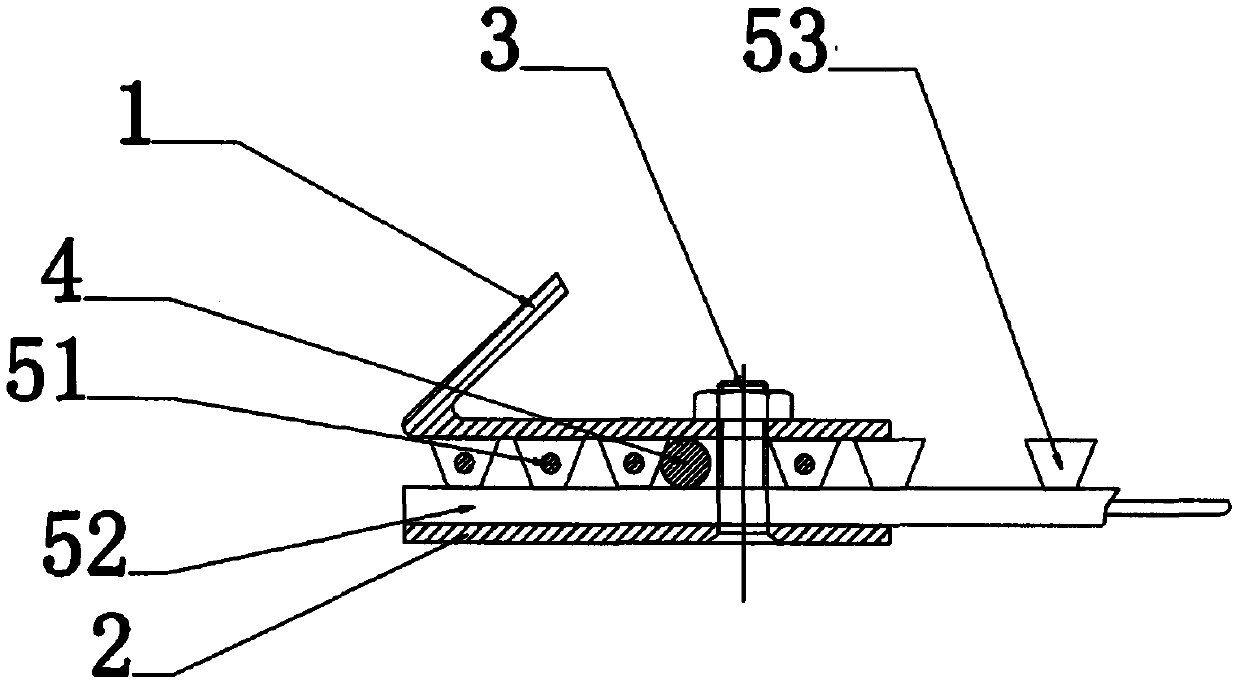

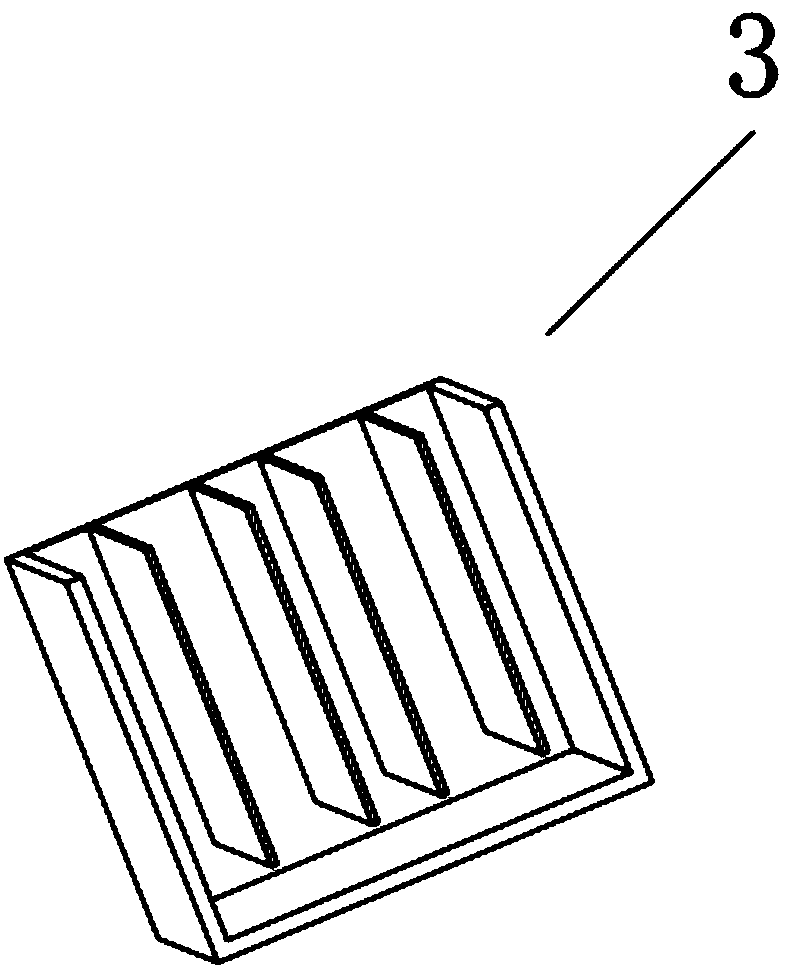

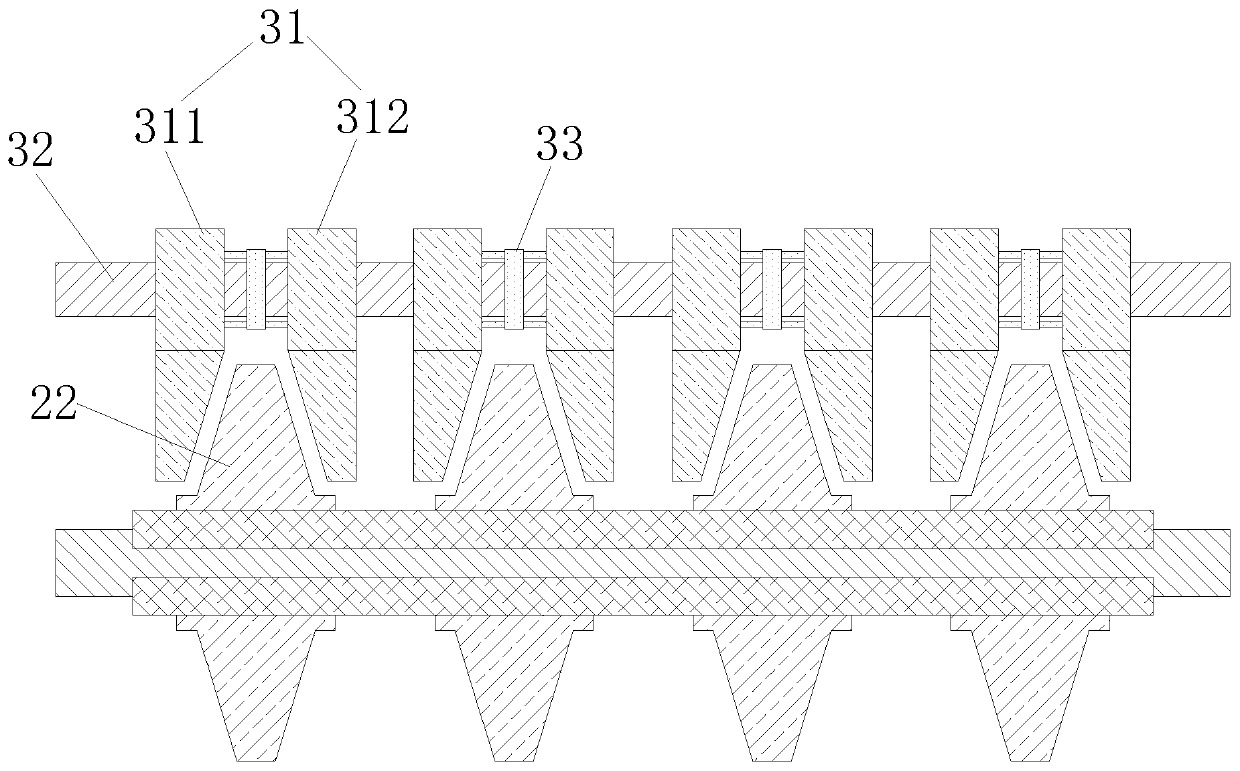

High-resilience anti-blocking polyurethane bar screen and preparation method thereof

InactiveCN111014028AWear-resistantStrong toughnessSievingScreeningPolymer scienceHigh wear resistance

A high-resilience anti-blocking polyurethane bar screen is composed of tensioning hooks, a fixing plate, bolts, round steel and a polyurethane bar screen surface. The polyurethane bar screen surface is characterized in that a steel wire rope core polyurethane coated rubber bar is used as a reinforcing area, aramid fiber rope core polyurethane coated rubber bars are used as warps, frameless polyurethane coated rubber bars are used as wefts, and joint points are subjected to hot melting welding to form screening areas; and all screen pores of the screen surface are inverted-cone-shaped. The production process comprises the following steps: firstly, trapezoidal-section coated rods are produced on an extruder by taking a steel wire rope, an aramid rope or frameless different materials as corewires; secondly, hot melting welding is conducted on screen mesh joint points according to hole pattern requirements, the steel wire rope core polyurethane coated bar is arranged at the installation position of a tensioning hook, the aramid fiber rope core polyurethane coated rubber bars are set as the warps, the frameless polyurethane coated rubber bars are set as the wefts; and thirdly, the tensioning hook, the round steel and a fixing plate are tightened through bolts at the edge of the screen. The high-resilience anti-blocking polyurethane bar screen has the characteristics of high wear resistance, good elasticity, strong toughness, strong screen pore deformability and excellent self-cleaning effect.

Owner:ANHUI FANGYUAN PLASTIC & RUBBER

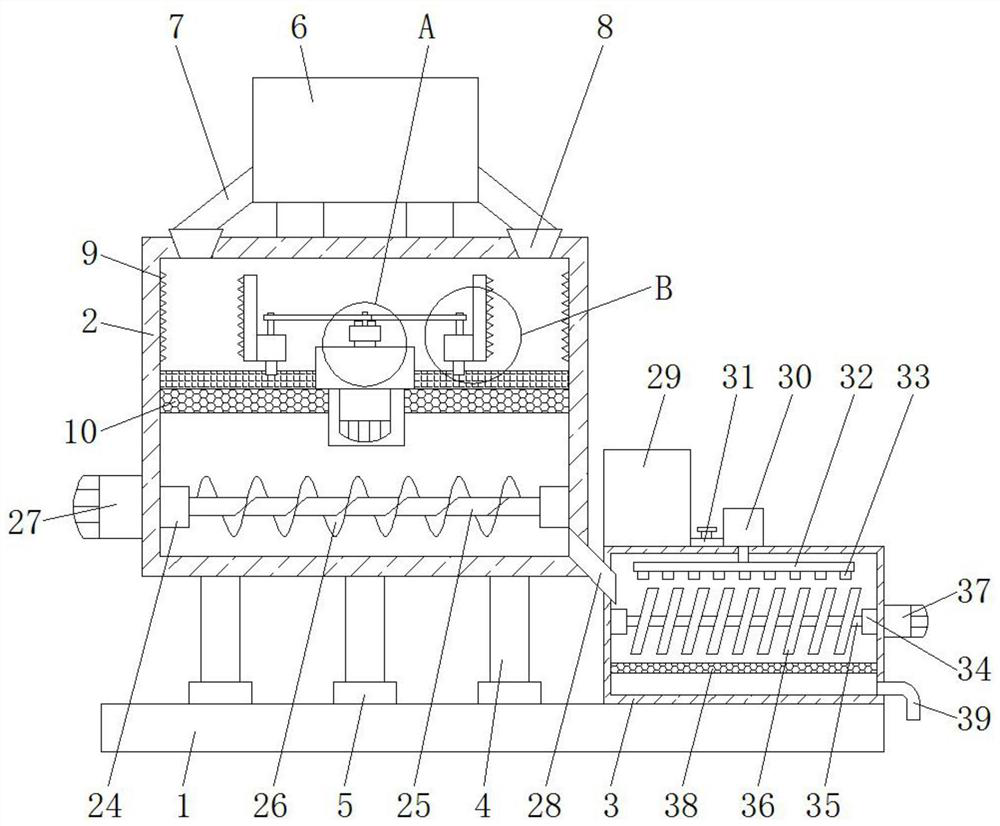

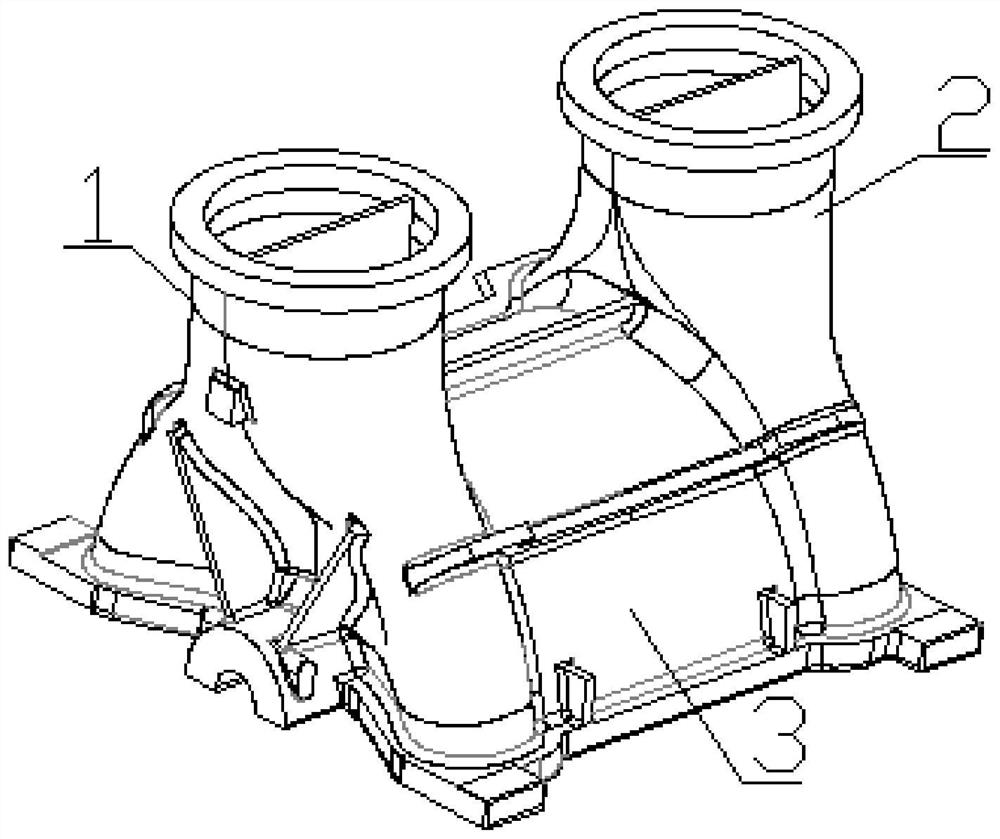

Novel sand mold recycling reprocessing device

InactiveCN111957881AReduce energy consumptionReduce resistanceMould handling/dressing devicesCleaning using liquidsElectric machineryProcess engineering

The invention discloses a novel sand mold recycling reprocessing device comprising a base, a smashing box and a cleaning box. Props are fixedly installed at the bottom of the smashing box. A base plate is fixedly installed at the bottoms of the props and is fixed to the top of the base. The cleaning box is located on the right side of the top of the base. A material box is fixedly installed at thetop of the smashing box through two symmetrical racks. The left and right sides of the material box are each provided with a discharge pipe. The left and right sides of the smashing box are providedwith feed hoppers. First smashing teeth are arranged on the upper portions of the inner walls of the left and right sides of the smashing box, and a filter plate is fixedly installed between the middle inner walls of the smashing box. A motor box is fixedly embedded in the middle of the filter plate. A positive and negative motor and a fixed block are fixedly installed in the motor box and at thetop of the motor box correspondingly. A rotary shaft is fixedly installed at the output end of the positive and negative motor. Two symmetrical sliding rails are fixedly installed on each of the leftand right sides of the fixed block, and the ends, away from the fixed block, of the sliding rails are fixedly connected with the inner wall of the smashing box. According to the novel sand mold recycling reprocessing device, washing is conducted with hot water after smashing, and quality of molding sand is improved.

Owner:安徽宜安精密机械零部件有限公司

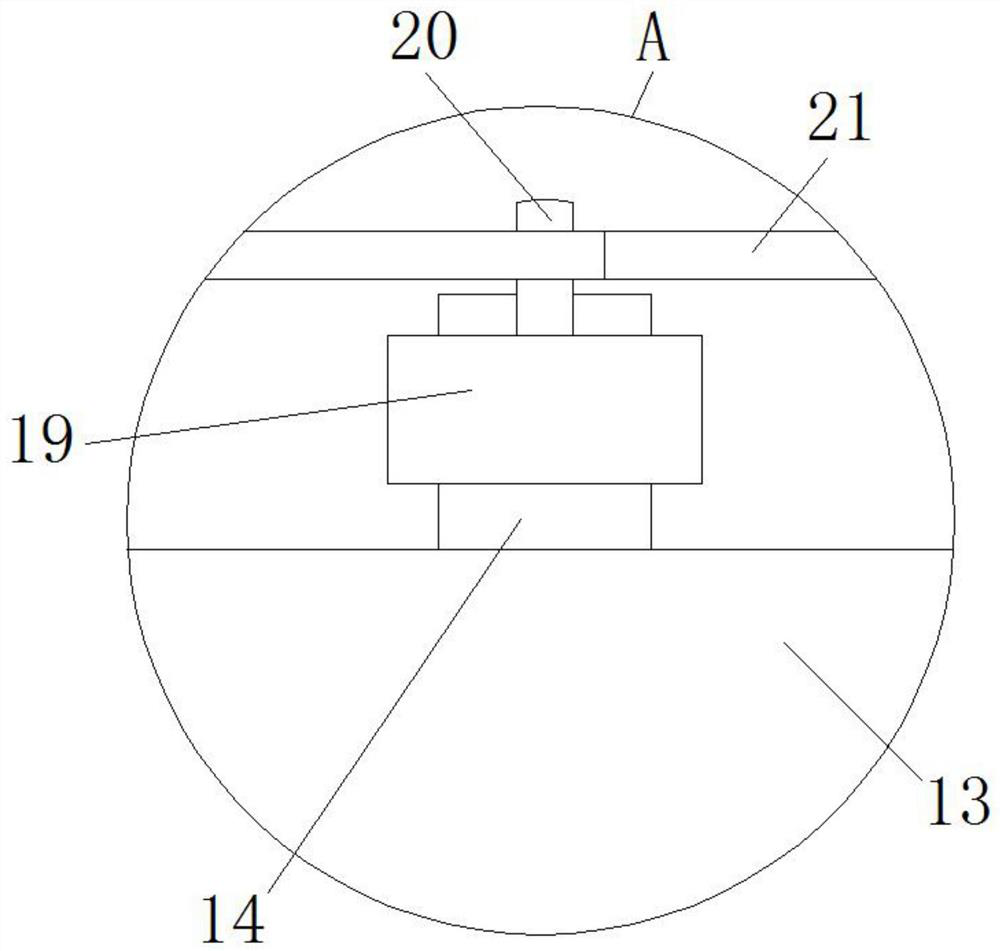

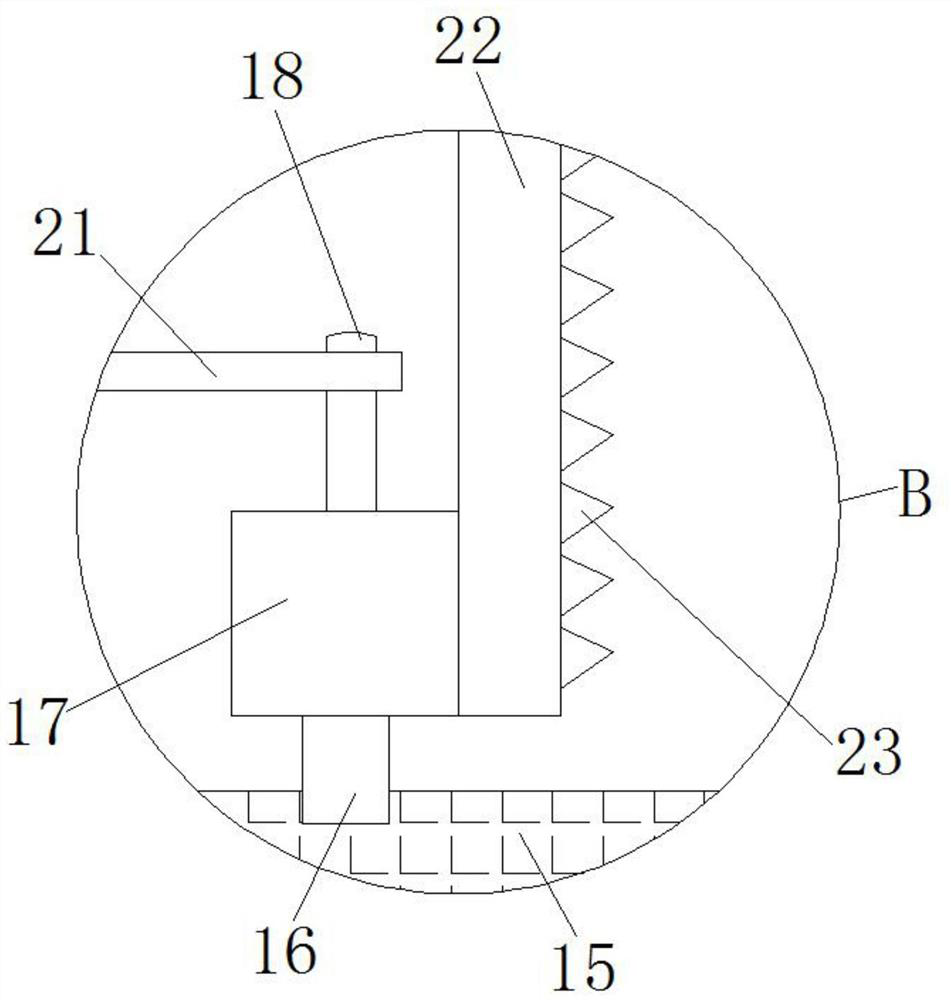

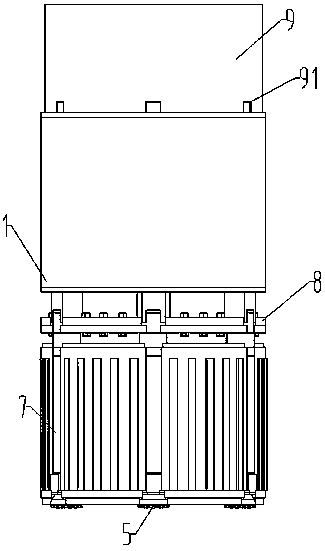

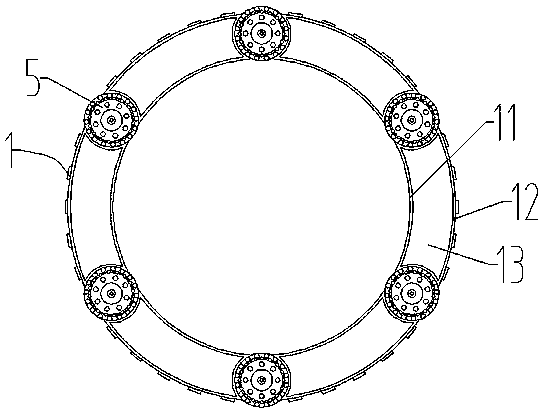

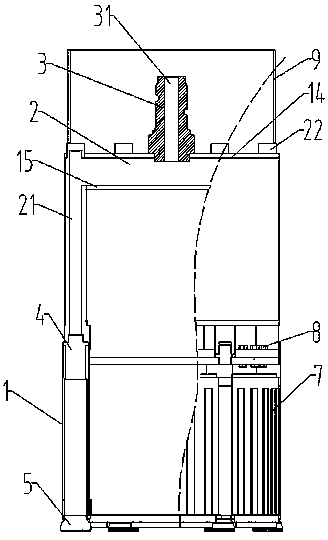

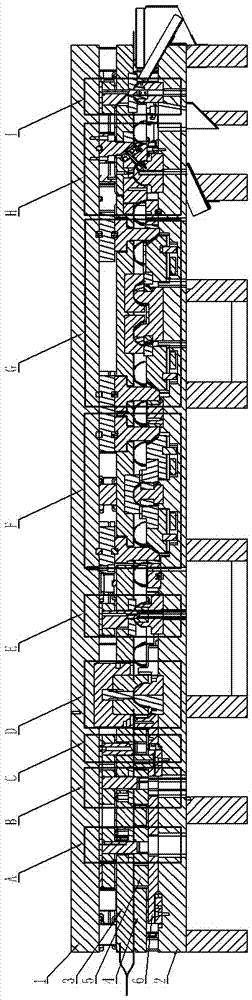

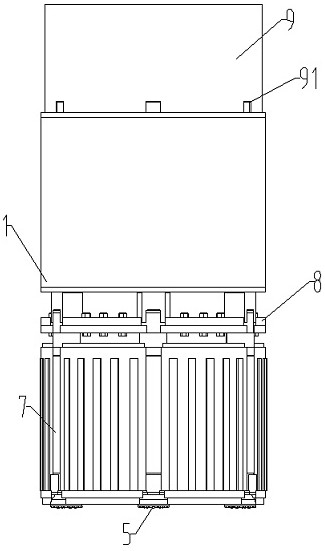

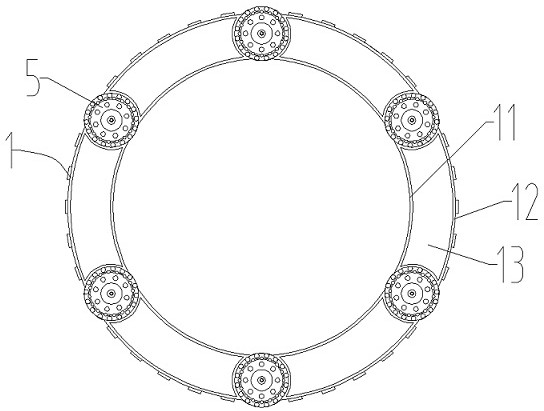

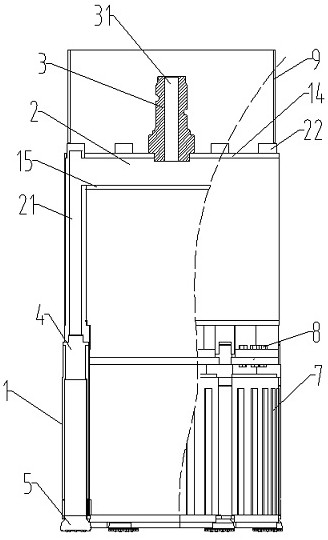

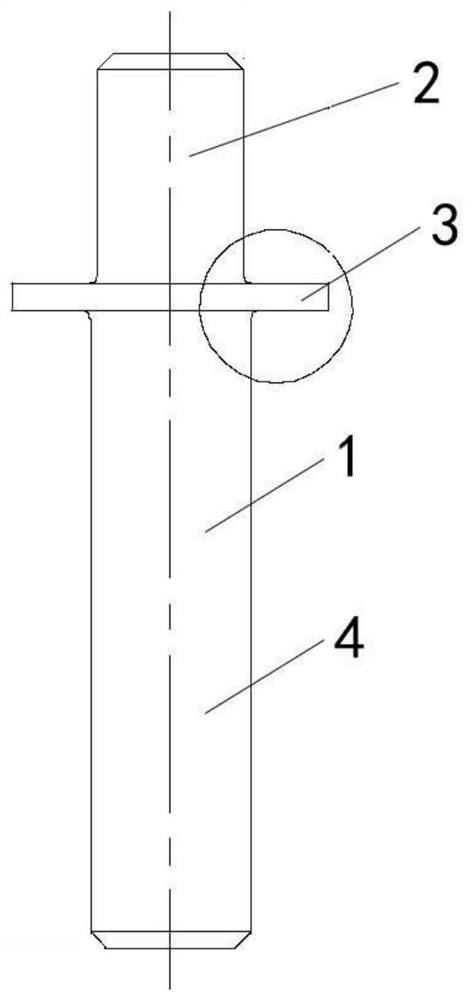

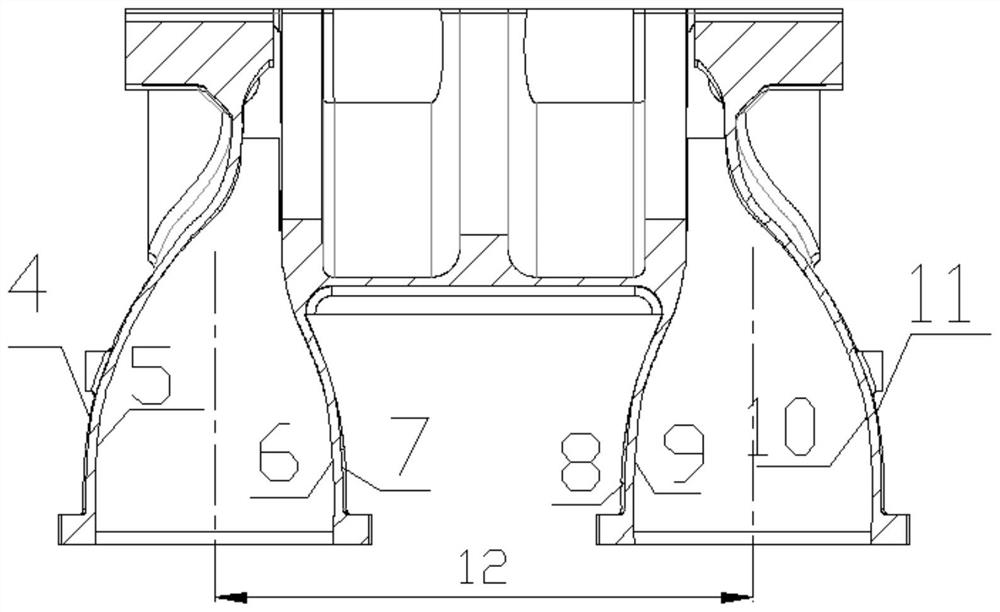

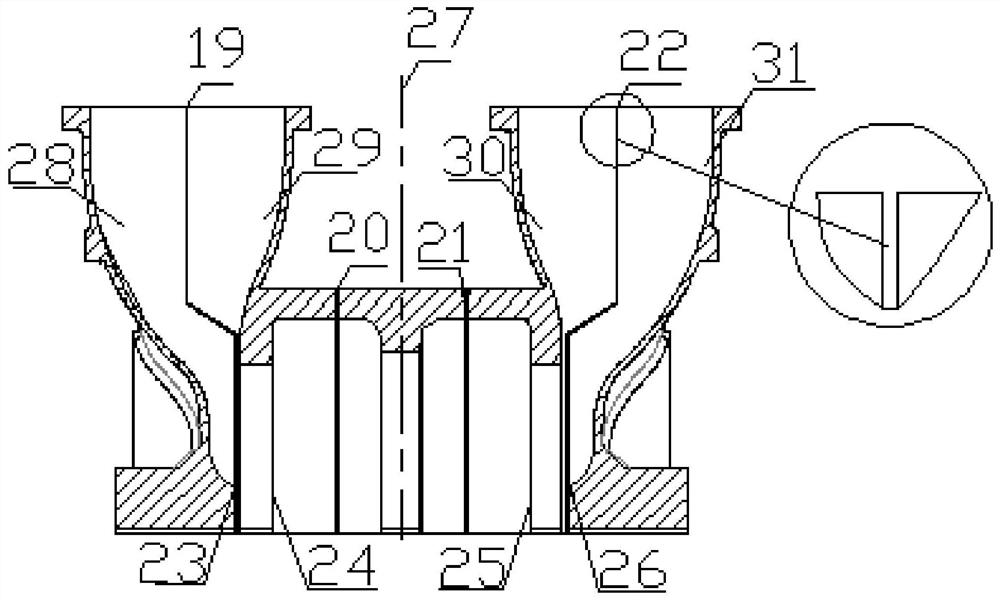

Annular cluster-type down-hole hammer

The invention discloses an annular cluster-type down-hole hammer. The annular cluster-type down-hole hammer comprises a down-hole hammer body; a cylindrical cavity is formed in the down-hole hammer body; a plurality of crushing hammer heads are arranged on the lower end surface of the down-hole hammer body; an impactor hammer for driving the crushing hammer heads to impact a rock layer is arrangedin the down-hole hammer body; and a storage device for collecting and storing crushed stone powder is arranged on the down-hole hammer body. The rock layer is crushed by using an impacting and crushing principle of the impactor hammer, so that the operation efficiency can be improved, and the energy consumption is reduced; and the crushing of a rock layer with a large-diameter pile hole can be realized, the overall work is pollution-free, slag is discharged directly with high-pressure exhaust gas discharged by the impactor hammer, the vibration of the hammer body is small, a drilling rig device and a hole wall are not damaged, and the hole forming quality is high.

Owner:新泰玖翊工程机械有限公司

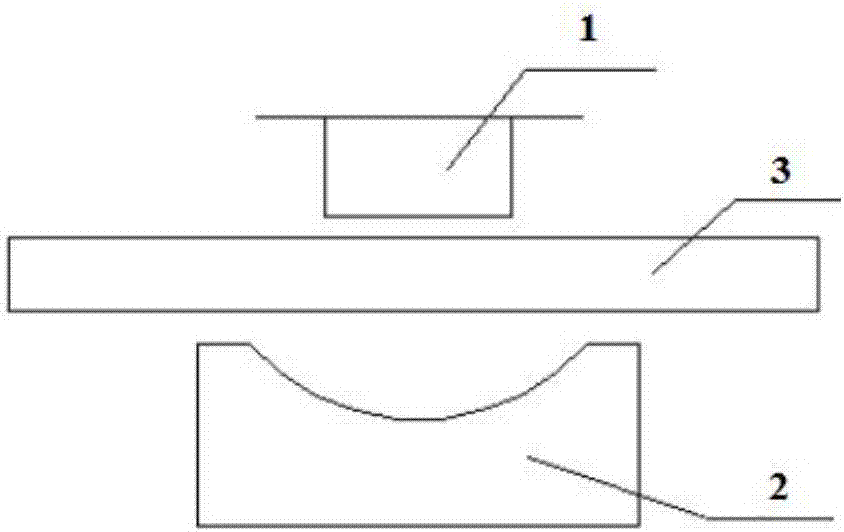

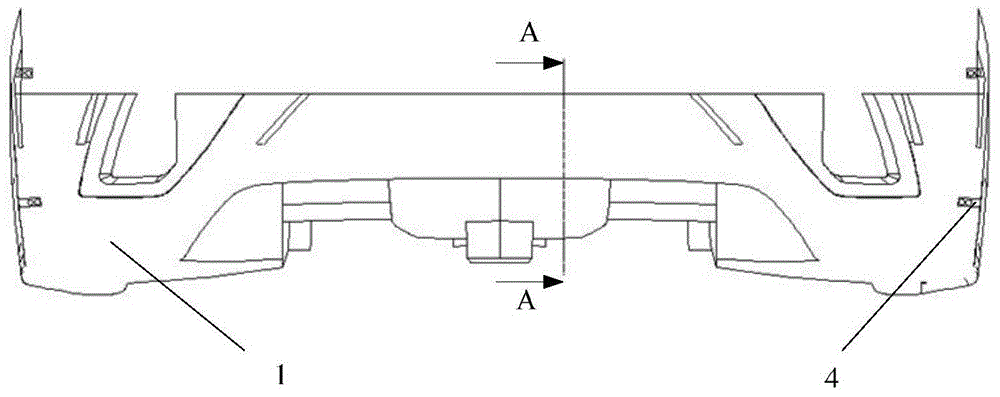

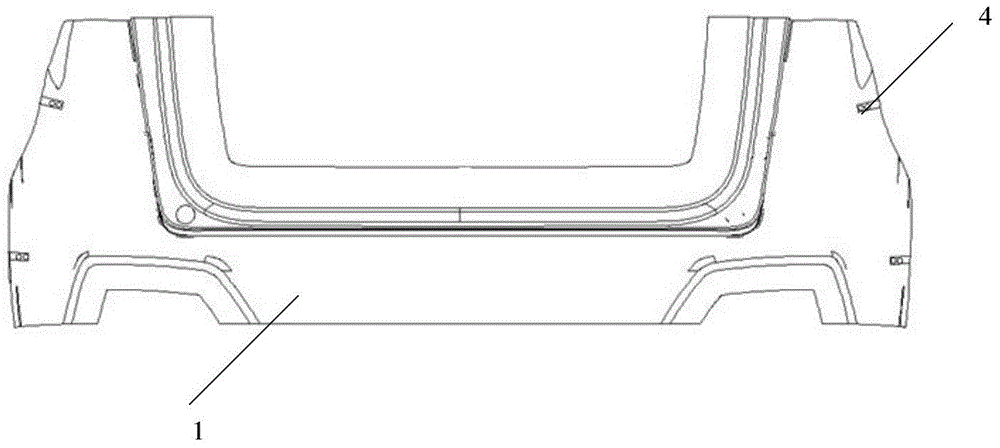

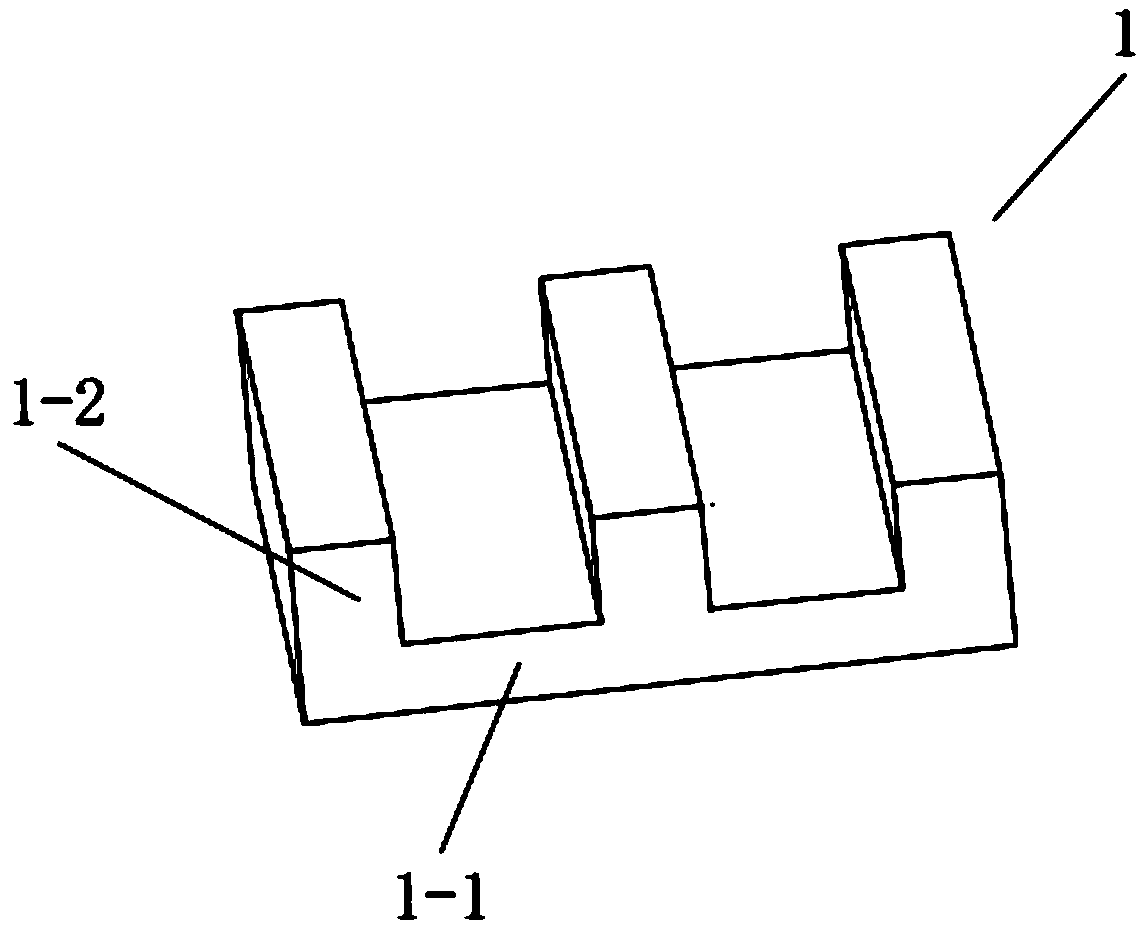

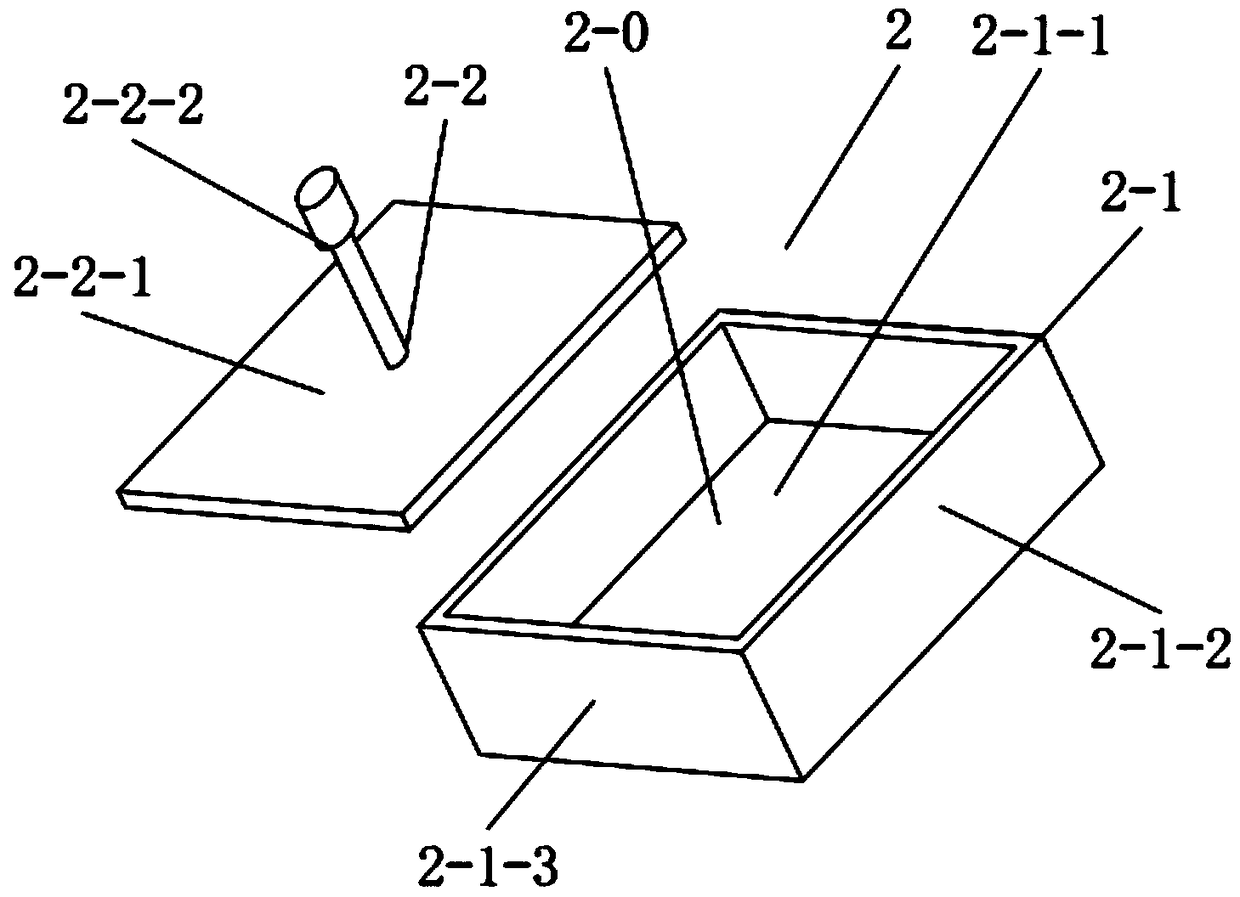

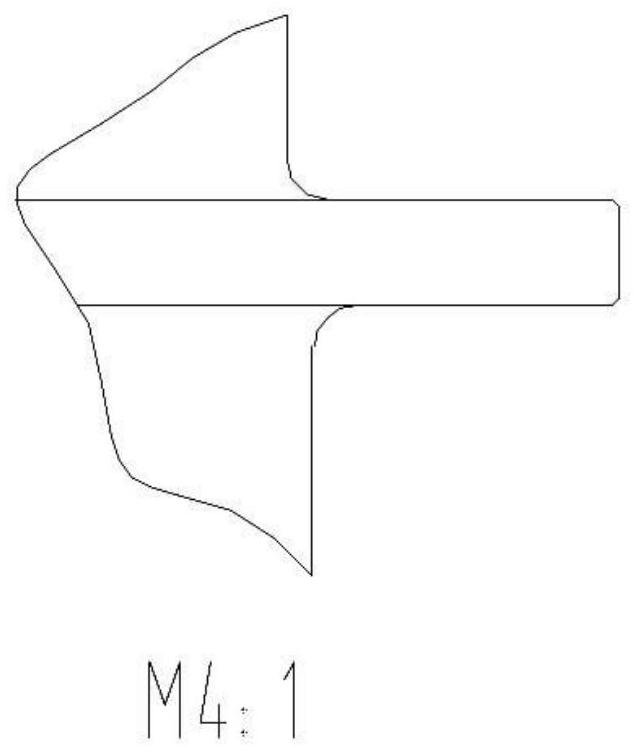

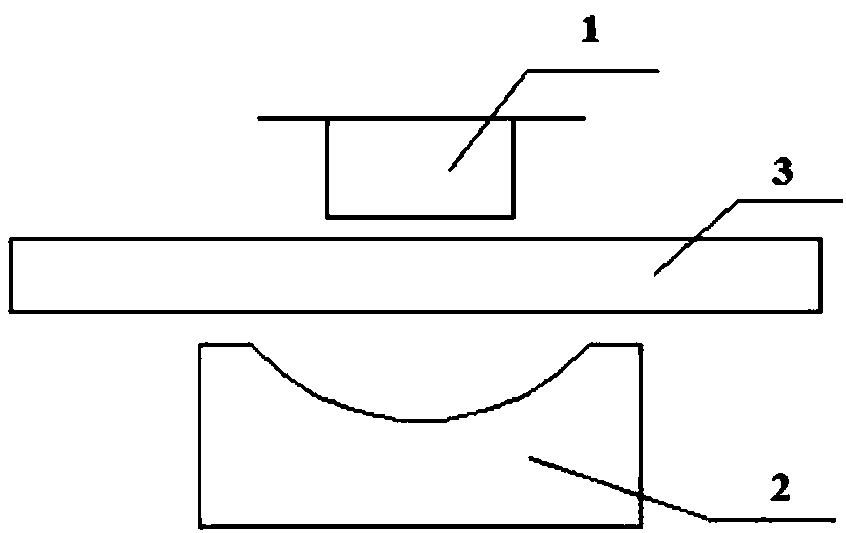

Machining mold of seat slide rail bracket

ActiveCN107470460AThe size meets the requirementsMeet the requirements of the positionShaping toolsEngineeringMechanical engineering

The invention provides a machining mold of a seat slide rail bracket capable of solving the technical problem that a traditional mold cannot guarantee the bracket size and the hole position degree. The machining mold comprises a shaping device; and the shaping device comprises a main body shaping mechanism for shaping a main body of a bracket. The machining mold is characterized in that the shaping device further comprises a side shaping mechanism for inwards shaping the side part of the bracket.

Owner:WUXI WEITANG IND TECH CO LTD

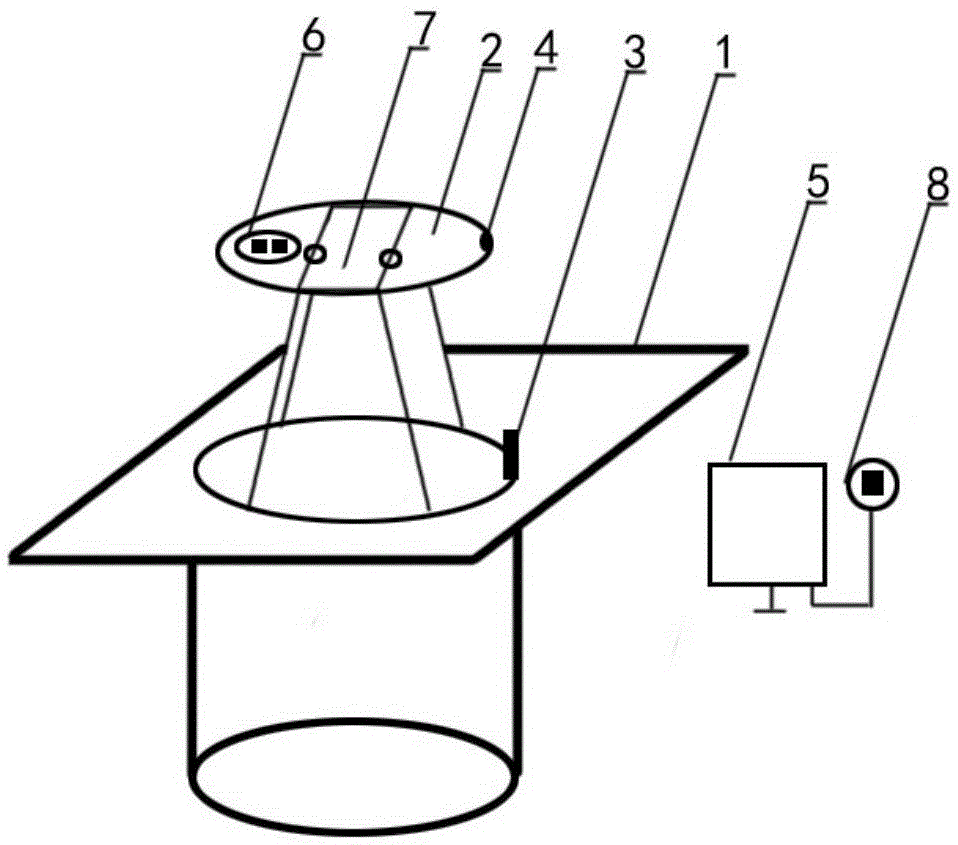

Combustible and explosive defense module for charging of intermediate frequency furnace

InactiveCN105605935AThe temperature meets the regulationsHumidity meets regulationsFurnace safety devicesControl devices for furnacesCombustionIntermediate frequency

The invention relates to a combustible and explosive defense module for charging of an intermediate frequency furnace. The combustible and explosive defense module comprises a body (1), wherein a feeding transition region (2), a liquid detection module (3), a telecommunication module (4) and a management module (5) are arranged on the body (1); during running, the liquid detection module (3) detects whether the body (1) at an initial state has combustible and explosive goods or not, materials added at a later stage enter the body (1) through the feeding transition region (2), and induced condition is transmitted to the management module (5) for processing through the telecommunication module (4); a humiture induction module (6) is arranged on the feeding transition region (2), so as to induce humidity and temperature value conditions of the materials added at the later stage; a volume adjusting module (7) is connected onto the feeding transition region (2), so as to control the volume of the added materials; a prompting module (8) is arranged on the management module (5). Through controlling the materials added at the later stage so as to guarantee that the temperature, humidity and size of the materials are in accordance with provisions, circumstances such as combustion and explosion are avoided.

Owner:ANQING HONGYU IND PROD DESIGN

Manufacturing technique of shrink-resistant quilt in washing

The invention discloses a manufacturing technique of shrink-resistant quilt in washing. The manufacturing technique comprises the following steps: 1) choosing a washing craft as required and measuring quilting shrinkage of shell fabric and filler, washing shrinkage and fluffy rate after washing according to the washing craft; 2) measuring and calculating the size of materials before washing according to the measurement result of the step 1), and tailoring for reserve; 3) combining the shell fabric with the filler in operation, adopting a well-distributed method to make the shell fabric and the filler correspond evenly, and then sewing into a product; 4) washing the quilt which is made, drying and then gaining the shrink-resistant quilt in washing with standard size. The manufacturing technique of shrink-resistant quilt in washing has the advantages of being capable of solving a problem that the ordinary quilt can not be washed and being reasonable in the craftsmanship of quilts. The quilts after the manufacturing technique of shrink-resistant quilt in washing can be washed and has a good planeness after being washed. Besides, the size of the quilt meets the requirement. The quilts are equipped with better wearability by adopting different washing crafts in the washing process.

Owner:VIOLET HOME TEXTILE TECH

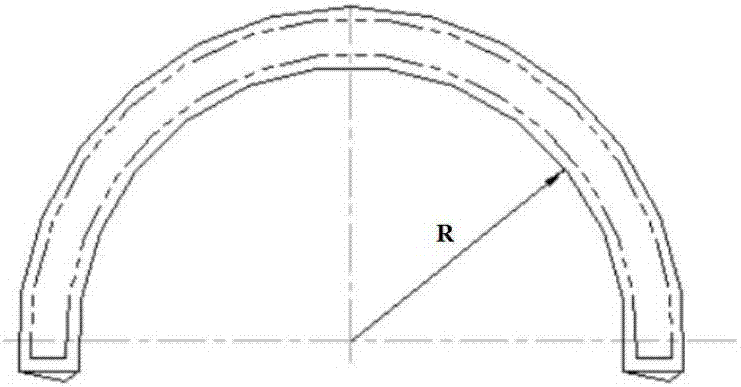

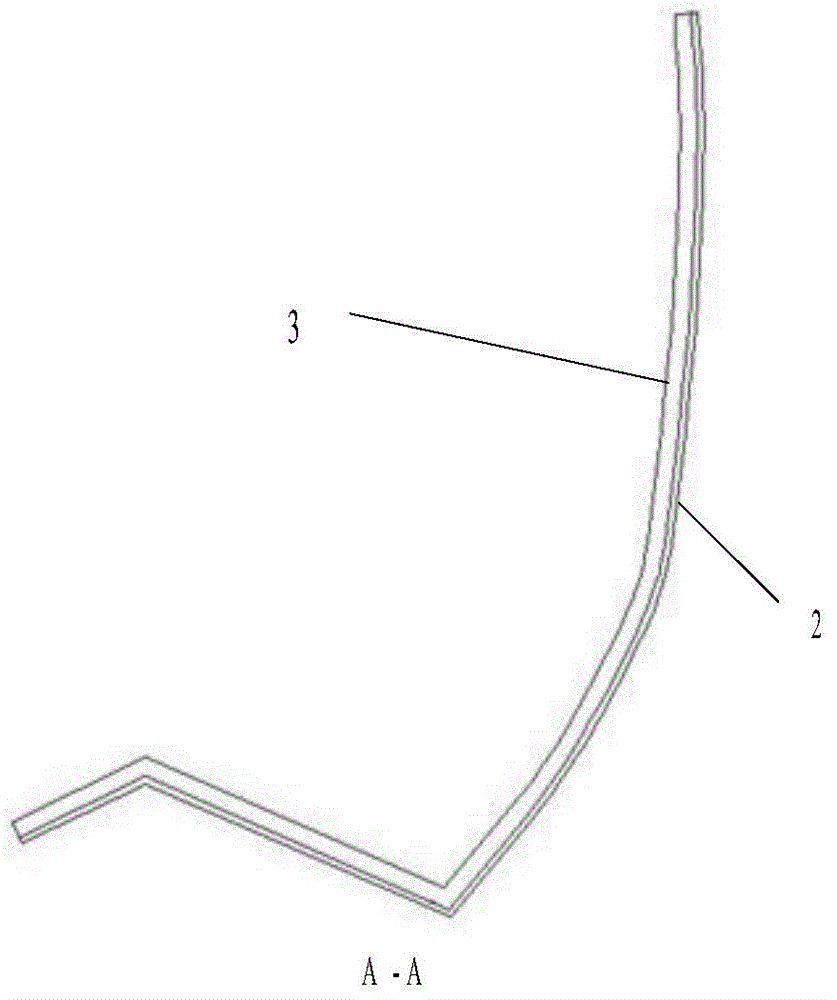

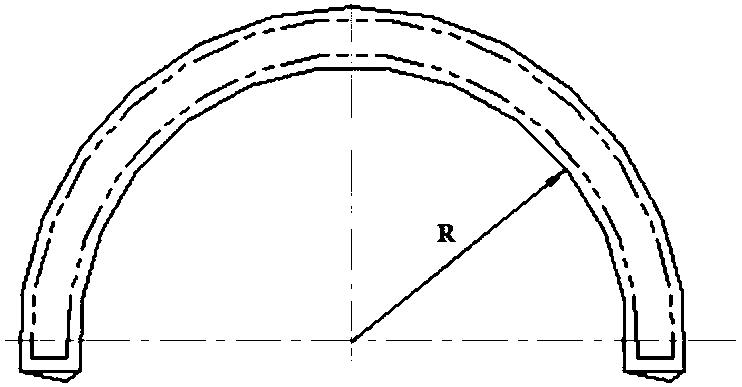

Free forging method for oversized overweight forging through 3-ton free forging hammer

ActiveCN106862446AGuaranteed sizeThe size meets the requirementsForging hammersOverweightProcess requirements

The invention provides a free forging method for an oversized overweight forging through a 3-ton free forging hammer and relates to a forging method for an oversized overweight forging. The free forging method aims at solving the problems that the radian of a forging cannot meet the process requirements fundamentally during existing forging production through a 3-ton free forging hammer; when bent to a certain angle, the forging is clamped on an equipment bumper, and bending cannot be conducted; and deformation is hard to control. The free forging method comprises the steps that 1, a forging drawing is drawn, and the size of a blank is calculated; 2, drawing-out is conducted, and a long-strip forging is obtained; 3, large-angle bending forming is conducted, and a semi-ring rough forging is obtained; 4, small-angle bending forming is conducted, and a rough forging is obtained; and 5, forging trimming is conducted, so that the partition plate body forging is obtained. The free forging method has the advantage that the qualified rate of the forging is 100% and is mainly used for forging the oversized overweight forging through the 3-ton free forging hammer.

Owner:HARBIN TURBINE +1

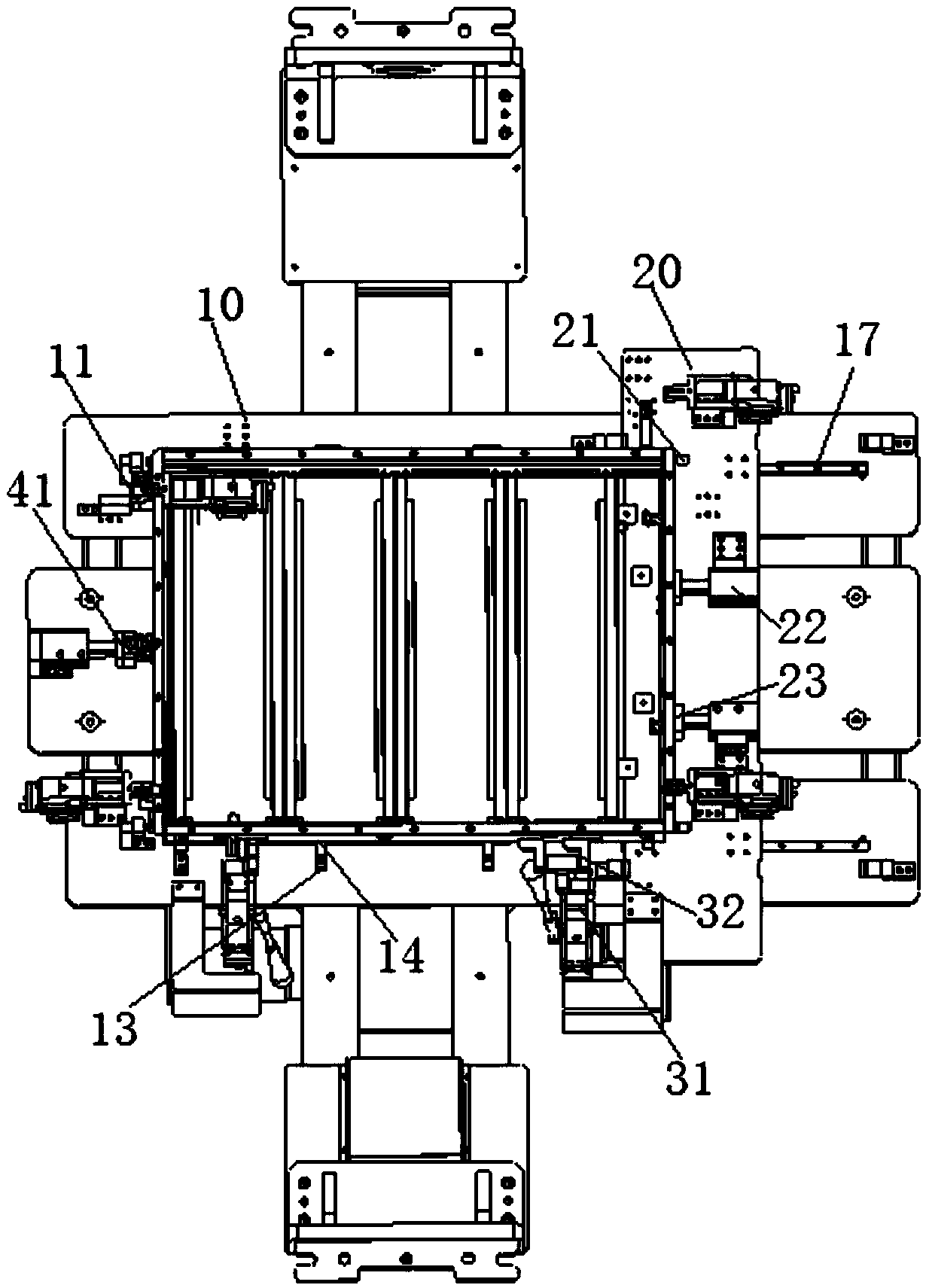

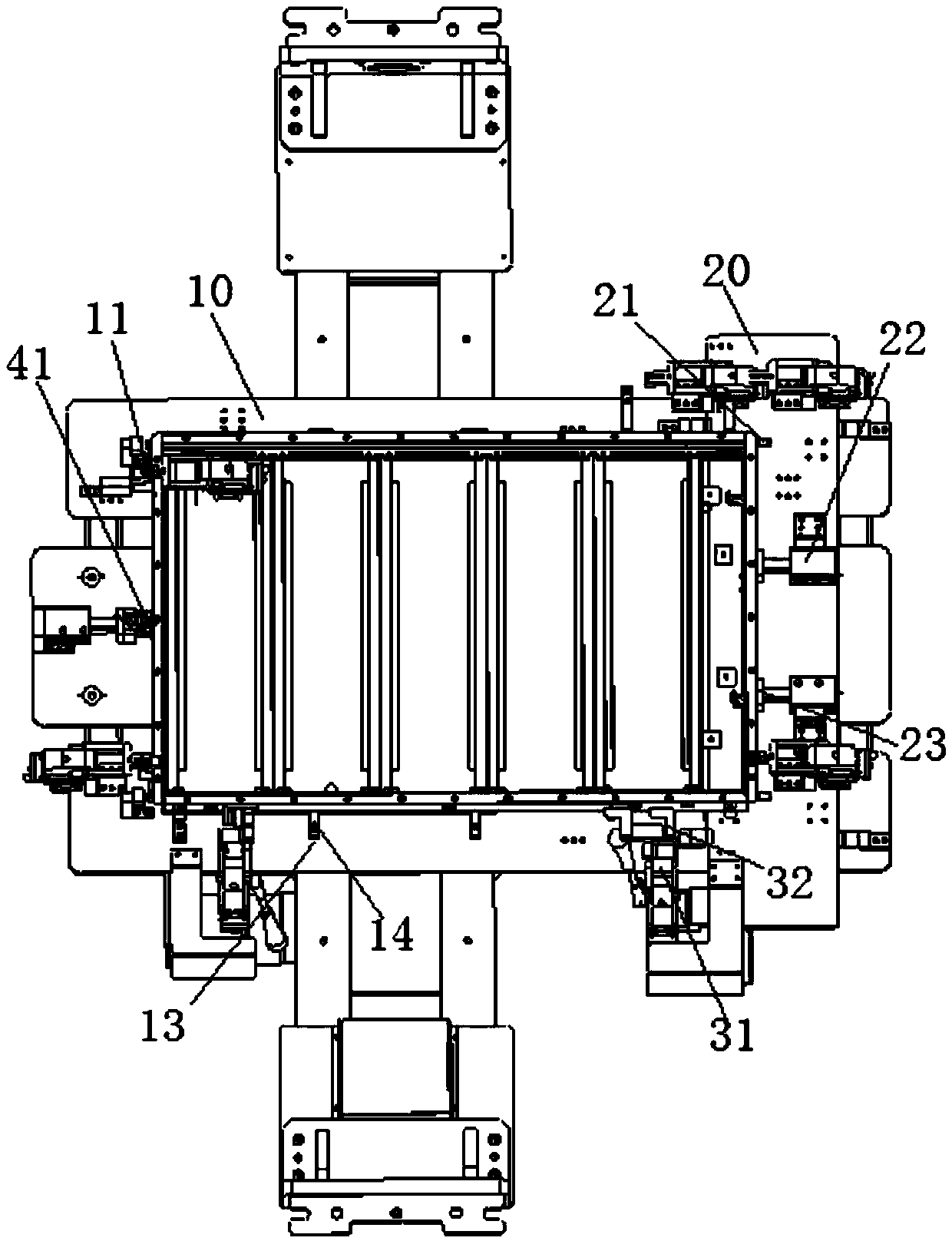

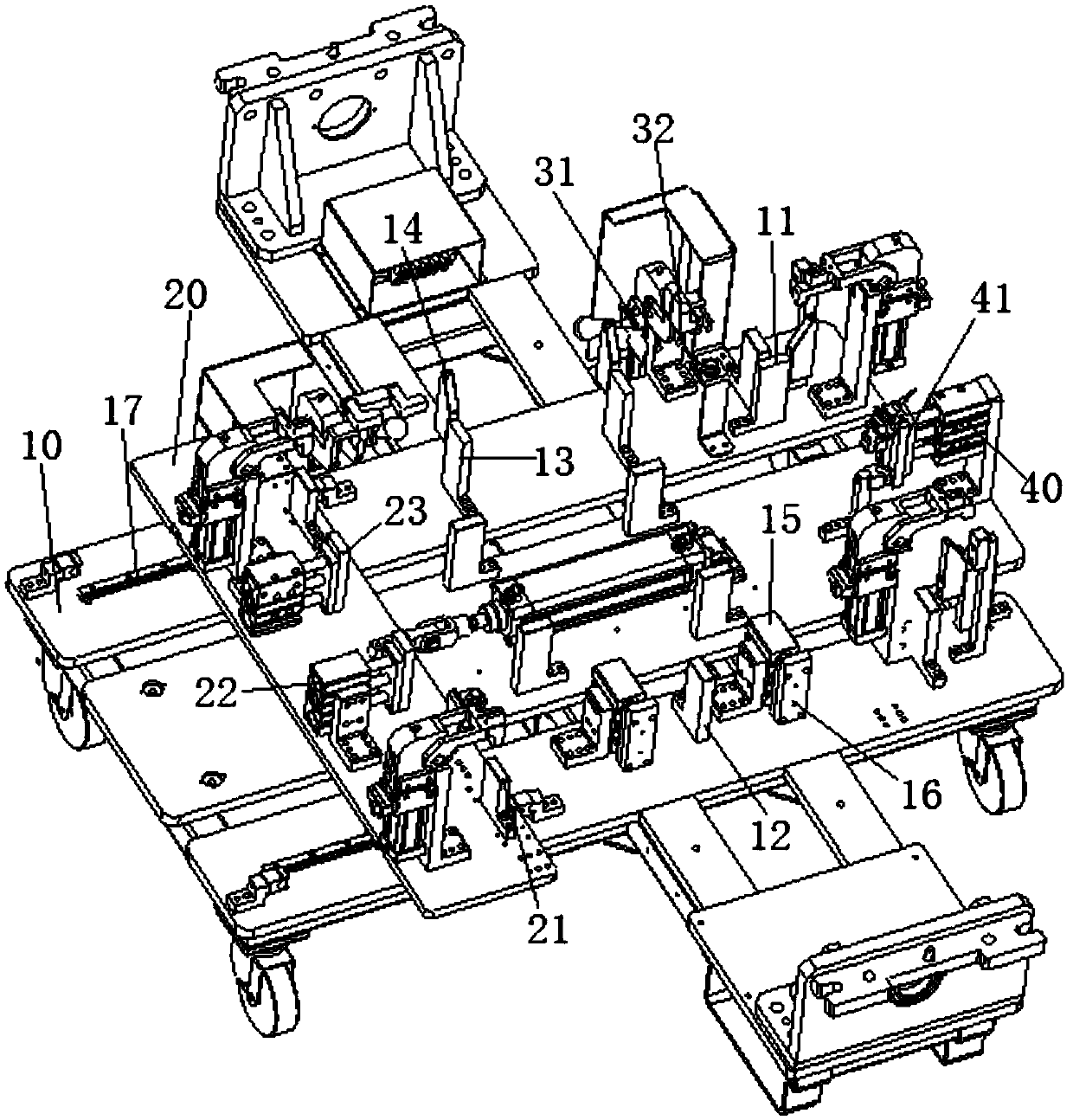

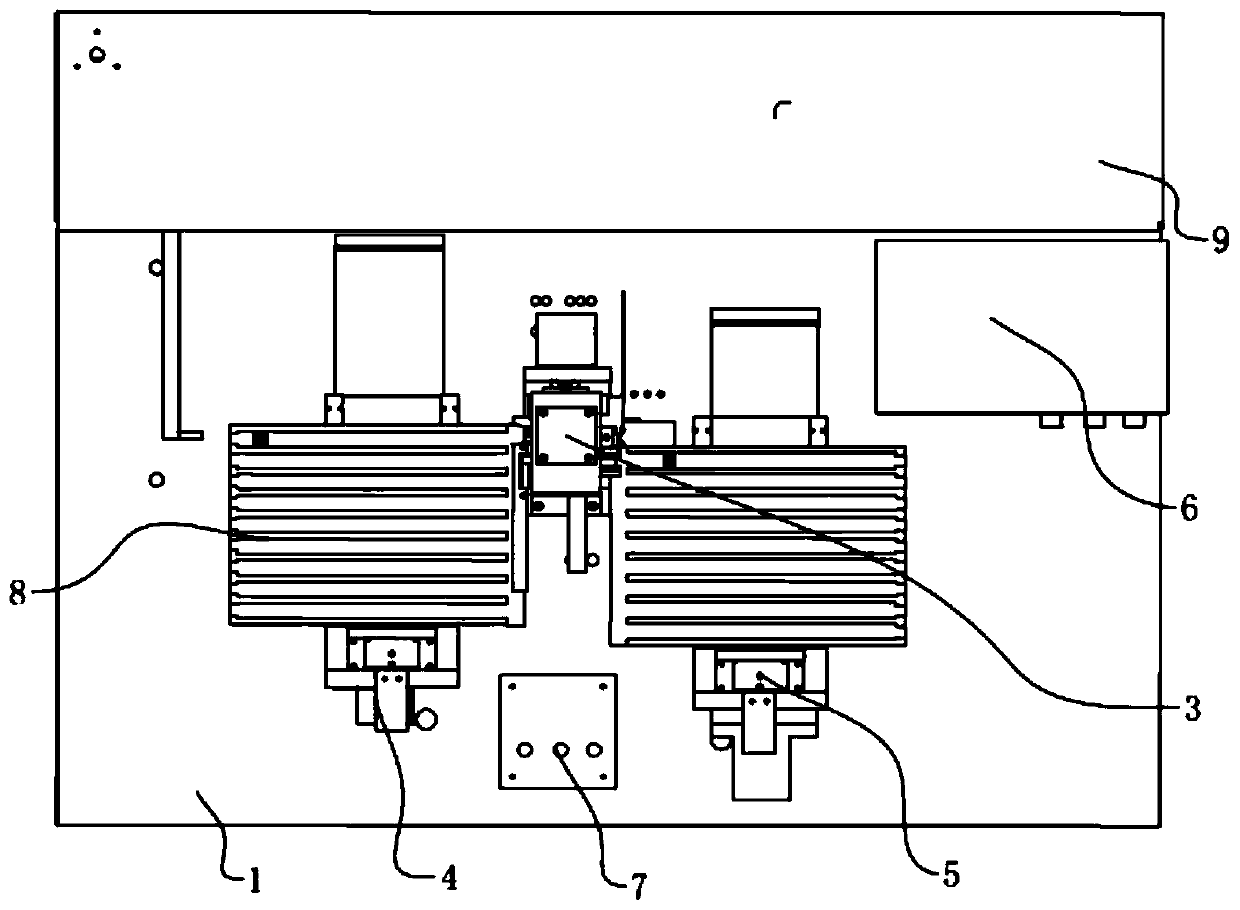

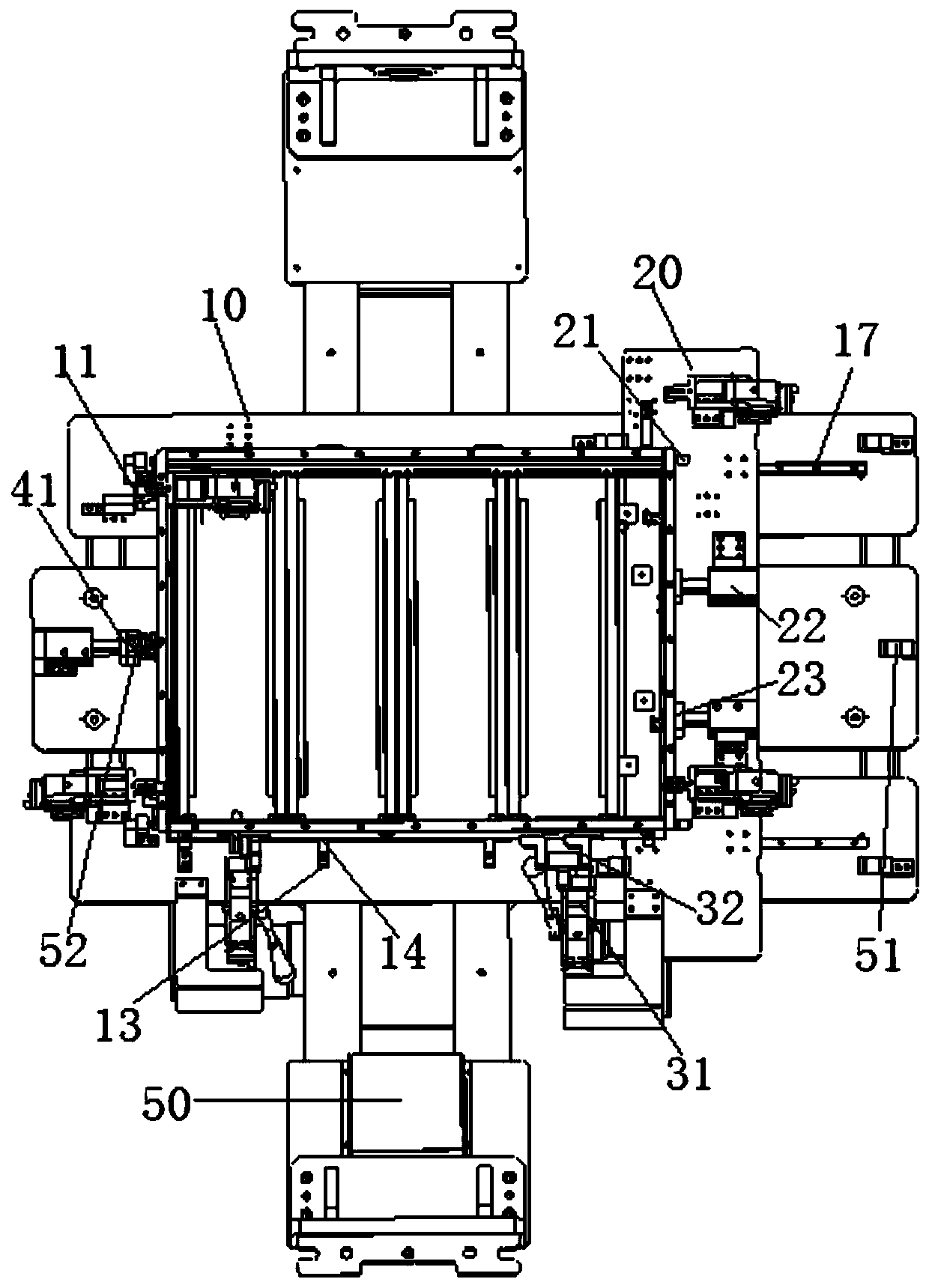

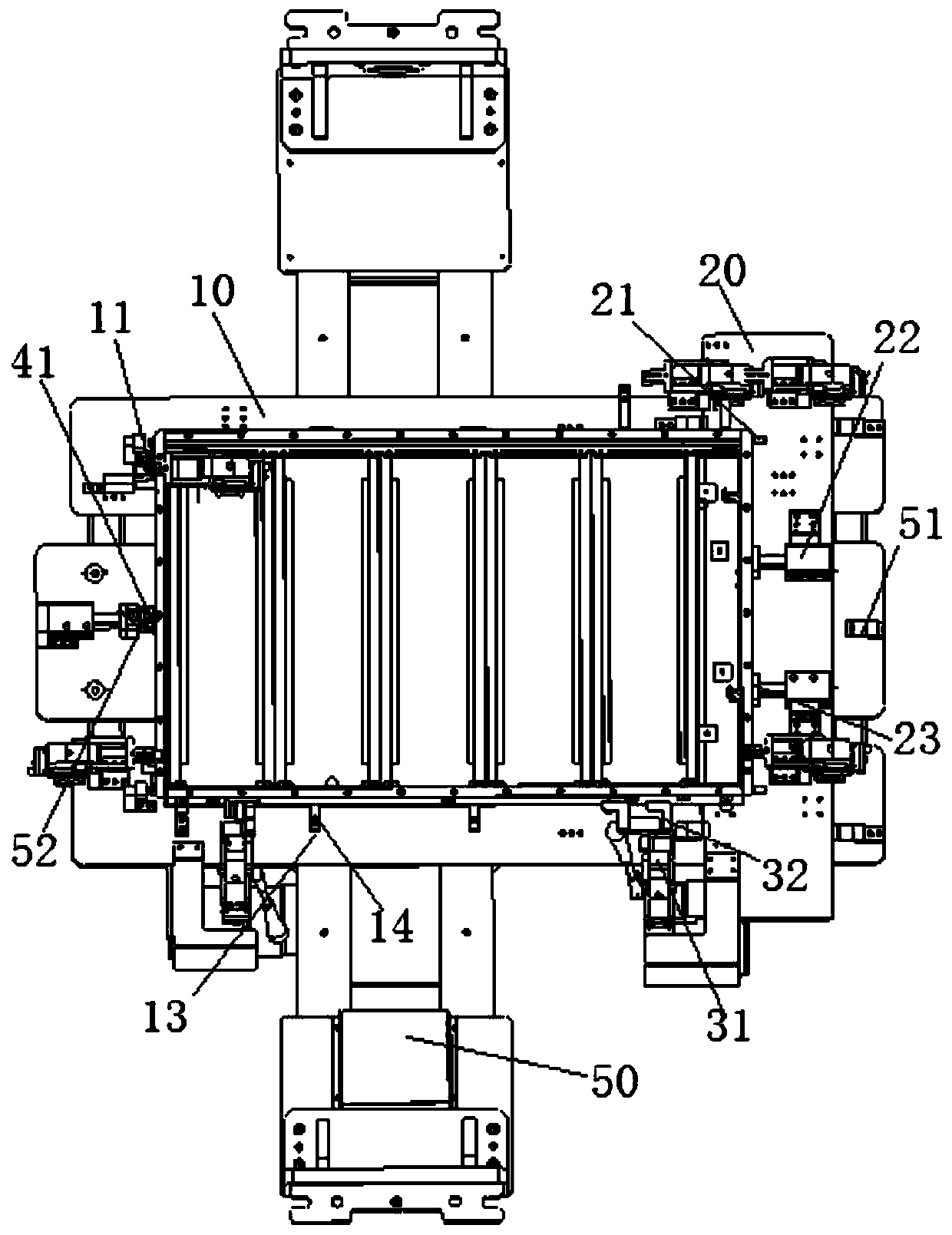

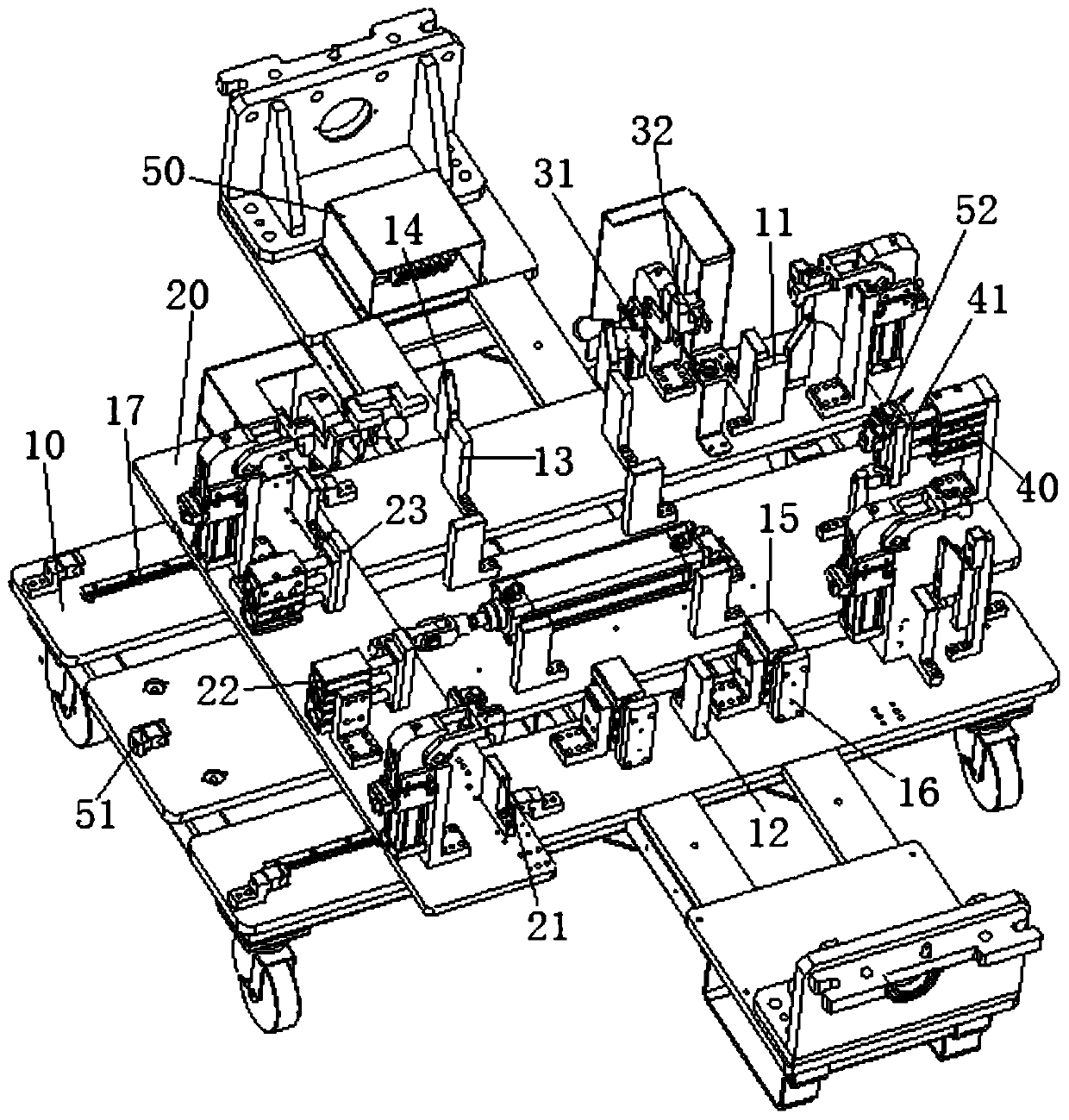

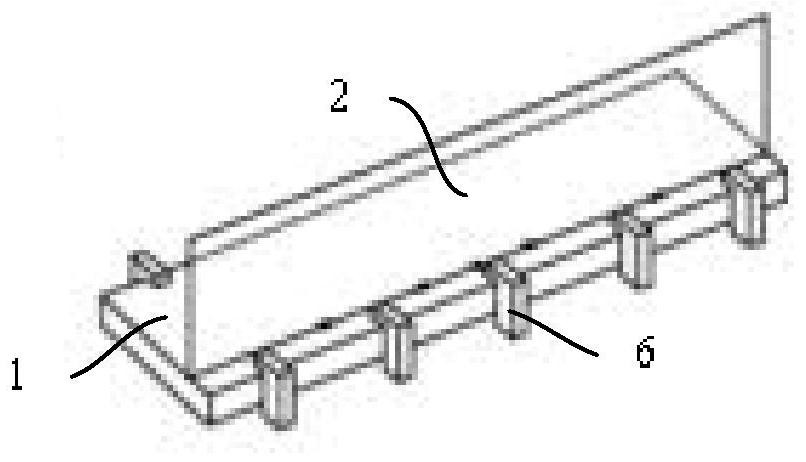

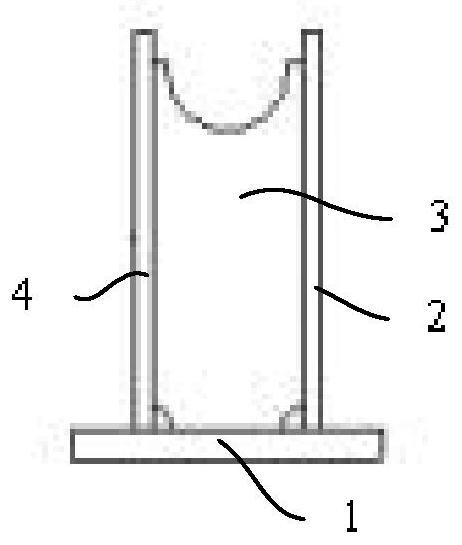

Flexible welding jig of automobile battery tray

PendingCN109676308AThe size meets the requirementsImprove welding qualityWelding/cutting auxillary devicesAuxillary welding devicesAutomotive batteryEngineering

The invention discloses a flexible welding jig of an automobile battery tray. The flexible welding jig comprises a jig base, a broadside bushing support I, a flank bushing support II, an end bushing support I and an end bushing support II, wherein the flank broadside support I and the broadside bushing support II are used for respectively supporting two sides in the length direction of a battery tray to be welded; the end bushing support I and the end bushing support II are used for respectively supporting two ends in the length direction of the battery tray to be welded; a switching sliding rail is arranged on the jig base; a switching sliding seat is arranged on the switching sliding rail; the end bushing support I is arranged on the switching sliding seat; and the end bushing support IIis arranged on the jig base. Through the adoption of the flexible welding jig of the automobile battery tray disclosed by the invention, the welding jig can be used for welding and processing batterytrays of various specifications and various dimensions.

Owner:珠海市福尼斯焊接技术有限公司

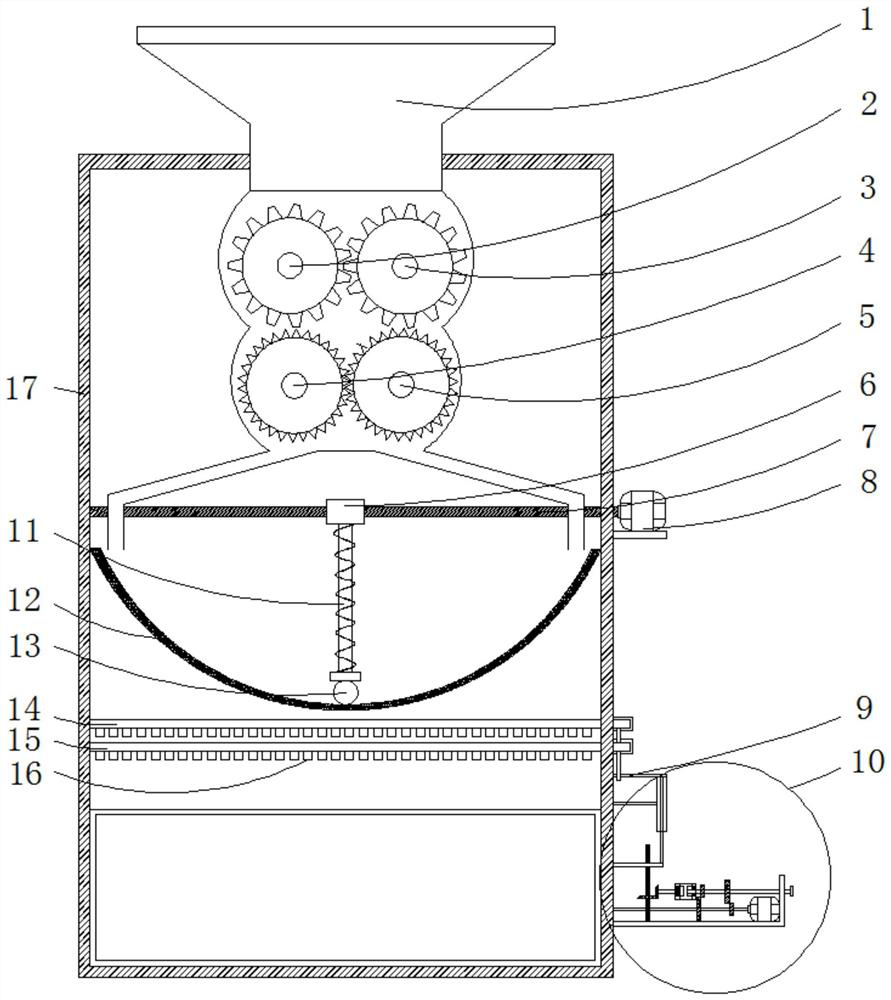

Grinding device for producing nanometer material

InactiveCN111992288ASave manpower and material resourcesEnergy savingMagnetic separationGrain treatmentsPhysicsGrinding

The invention provides a grinding device for producing a nanometer material, and relates to the field of grinding devices. The grinding device comprises a feeding port and a device body. A first motoris arranged on one side of the device body through a baffle, and an output shaft of the first motor is fixedly connected with a first threaded rod. One end of the first threaded rod penetrates through the device body and extends into the device body. The surface of the first threaded rod is in threaded connection with a threaded block, and the bottom of the threaded block is fixedly connected with a telescopic rod. The bottom of the telescopic rod is fixedly connected with a grinding roll, and a grinding table is fixedly connected between the two sides of the inner wall of the device body. According to the grinding device, by means of the cooperation of the telescopic rod and the grinding roll, production can be completed only when the nanometer material reaches the specified size; and the metal nanometer material and the nonmetallic nanometer material can be separated and collected through the cooperation of a sliding rod and an electromagnet, and manpower and material resources aregreatly saved.

Owner:LINYI UNIVERSITY

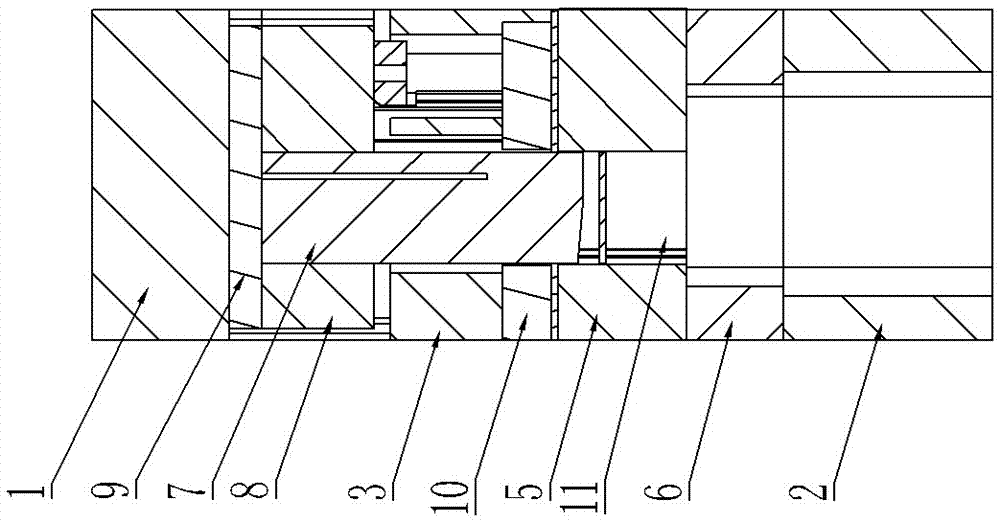

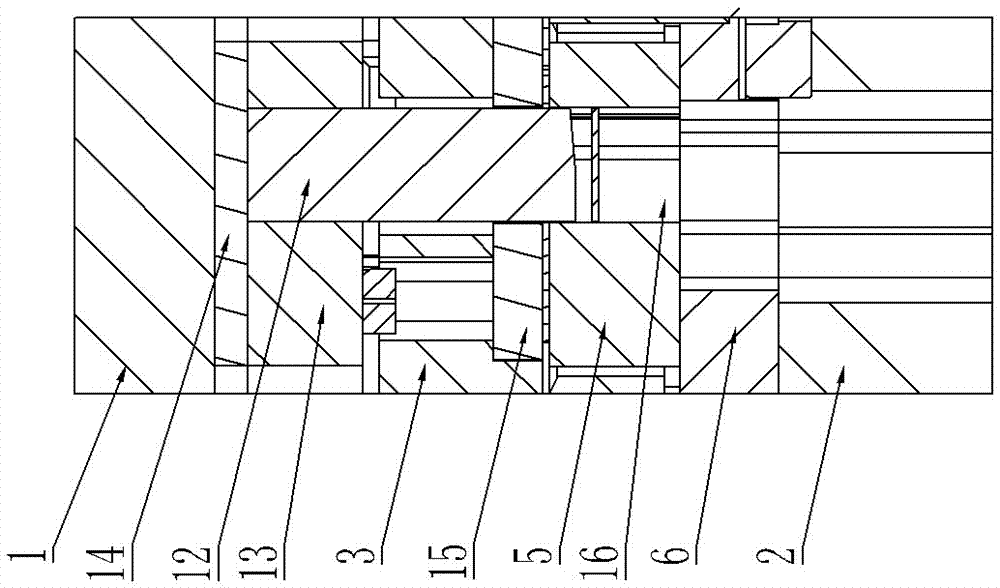

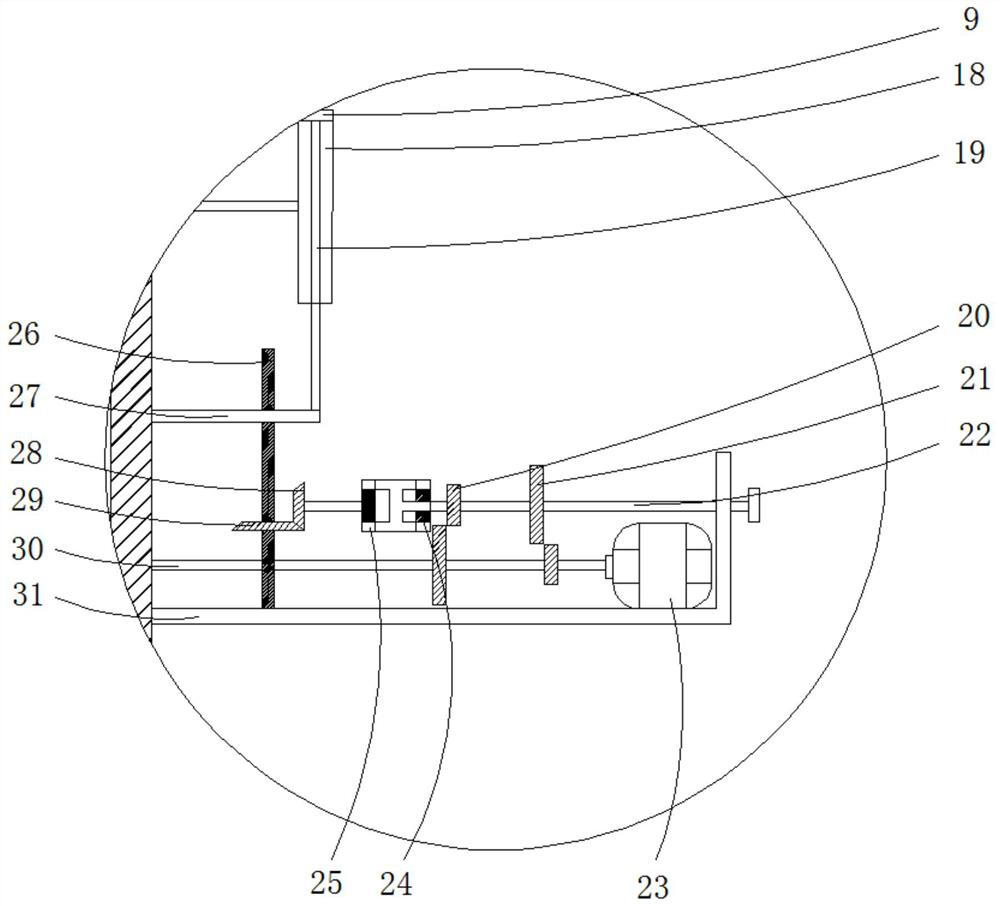

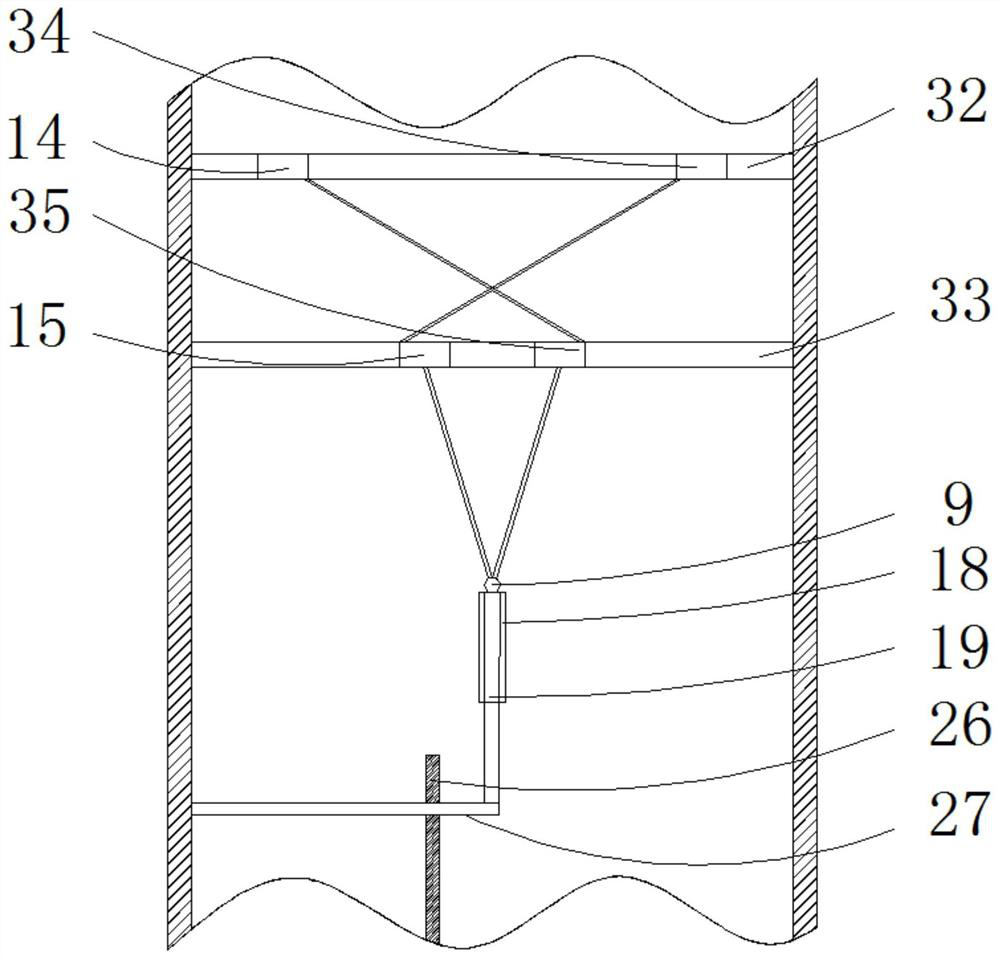

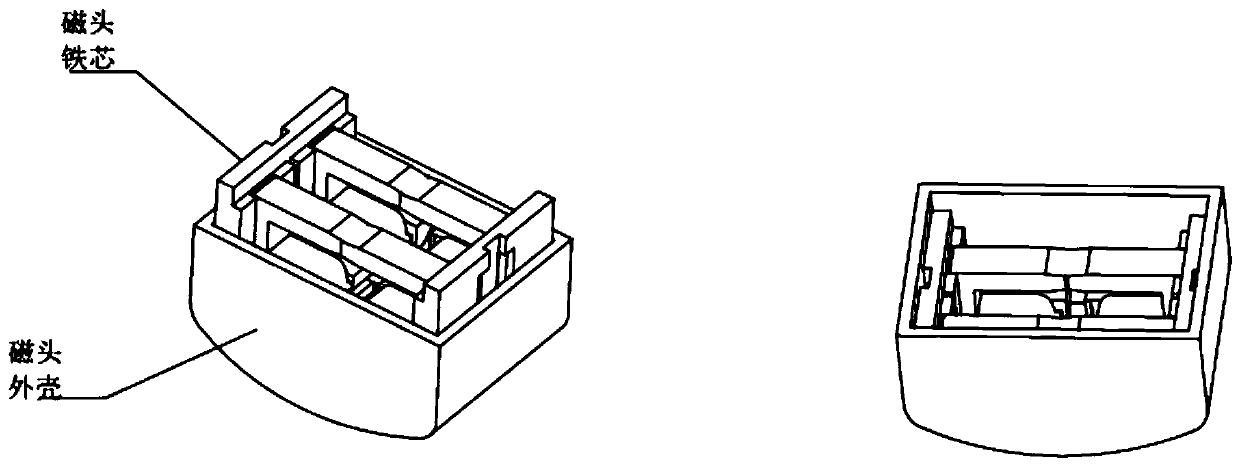

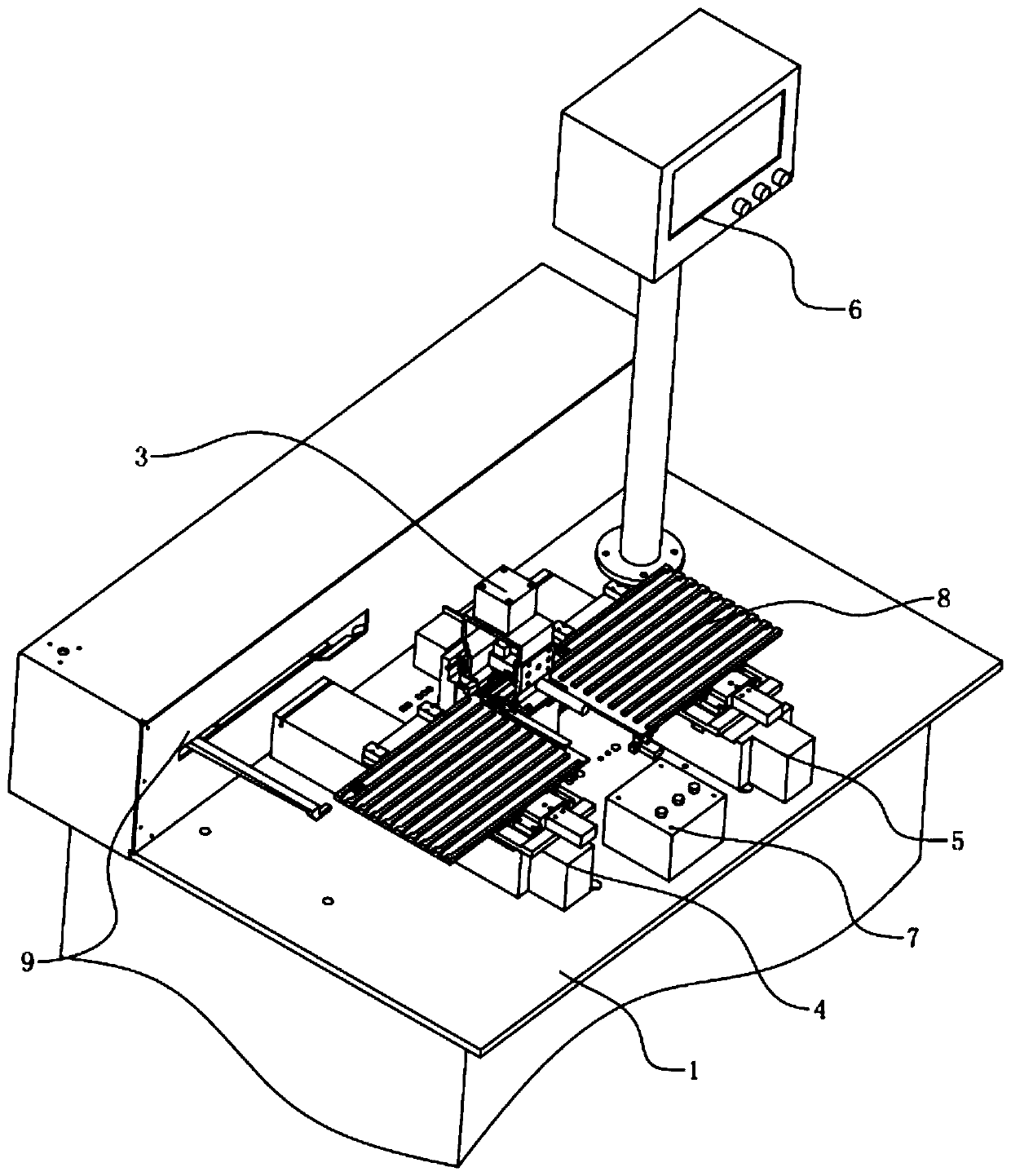

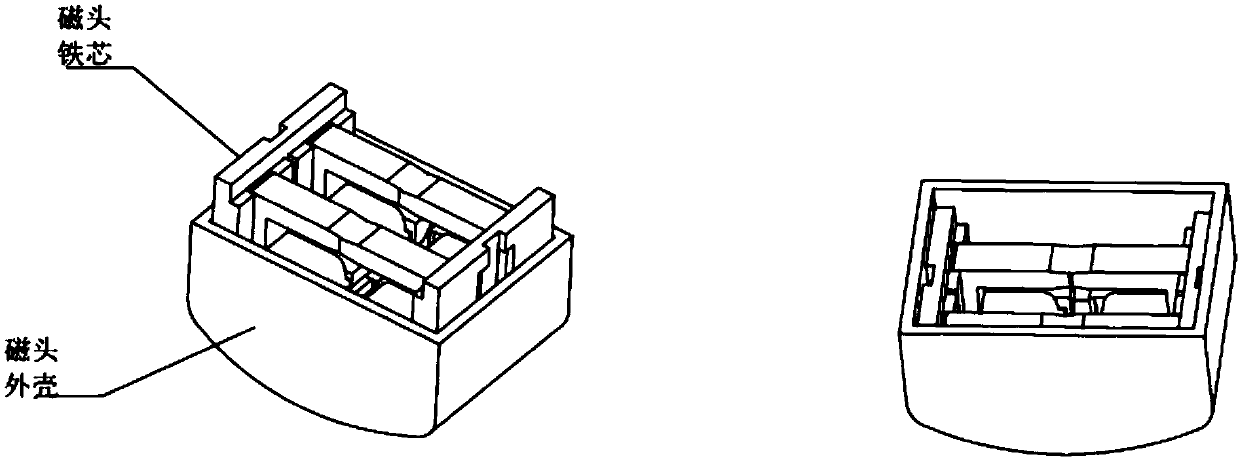

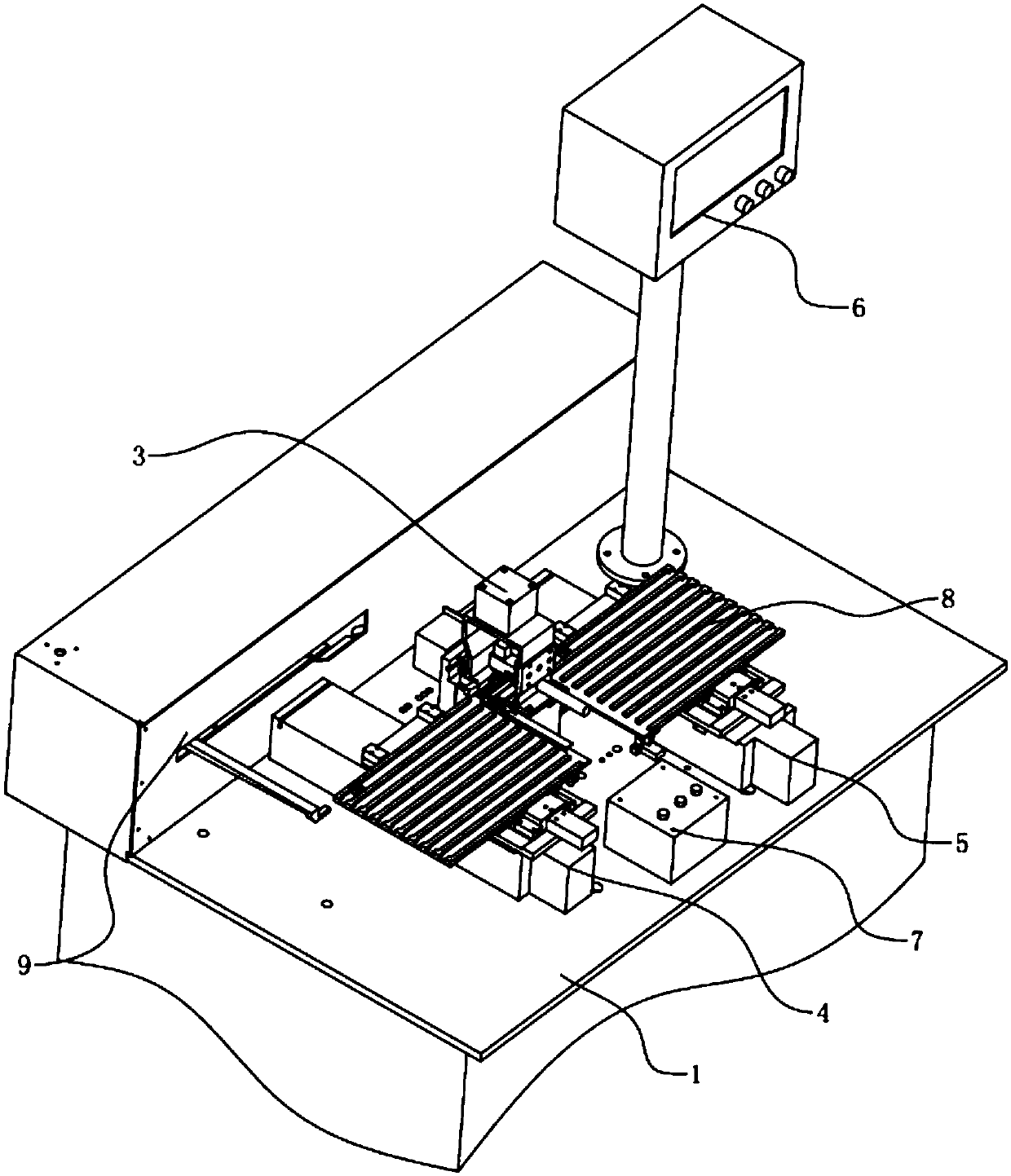

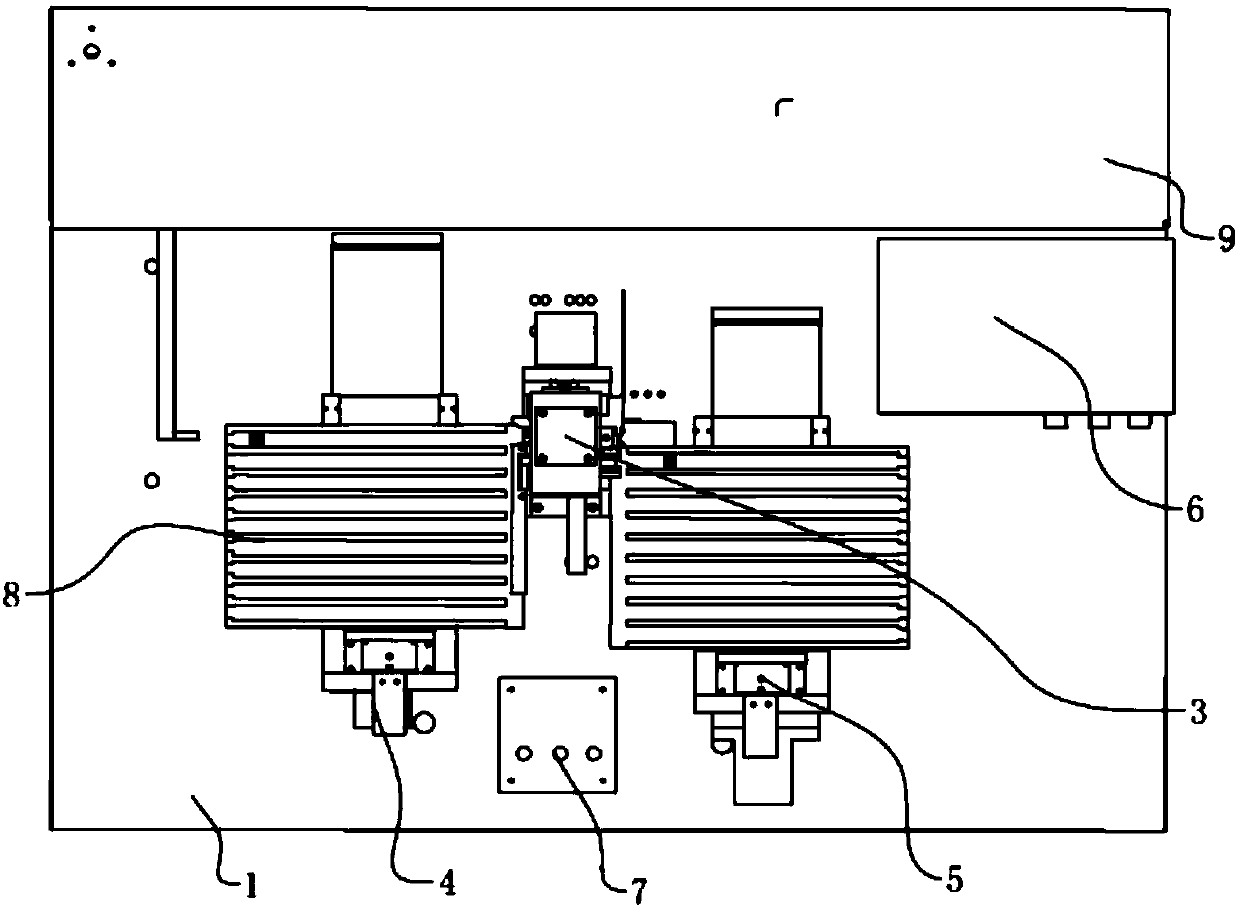

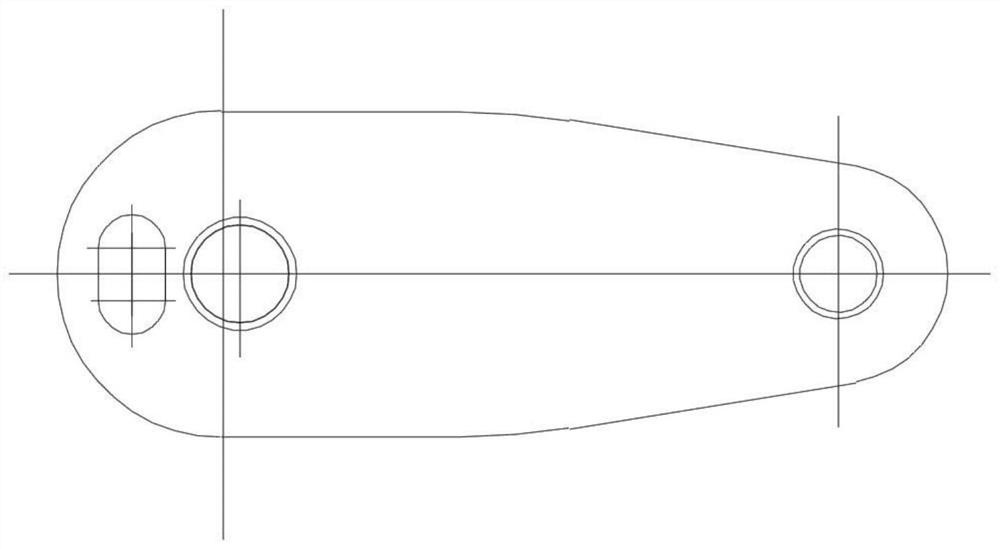

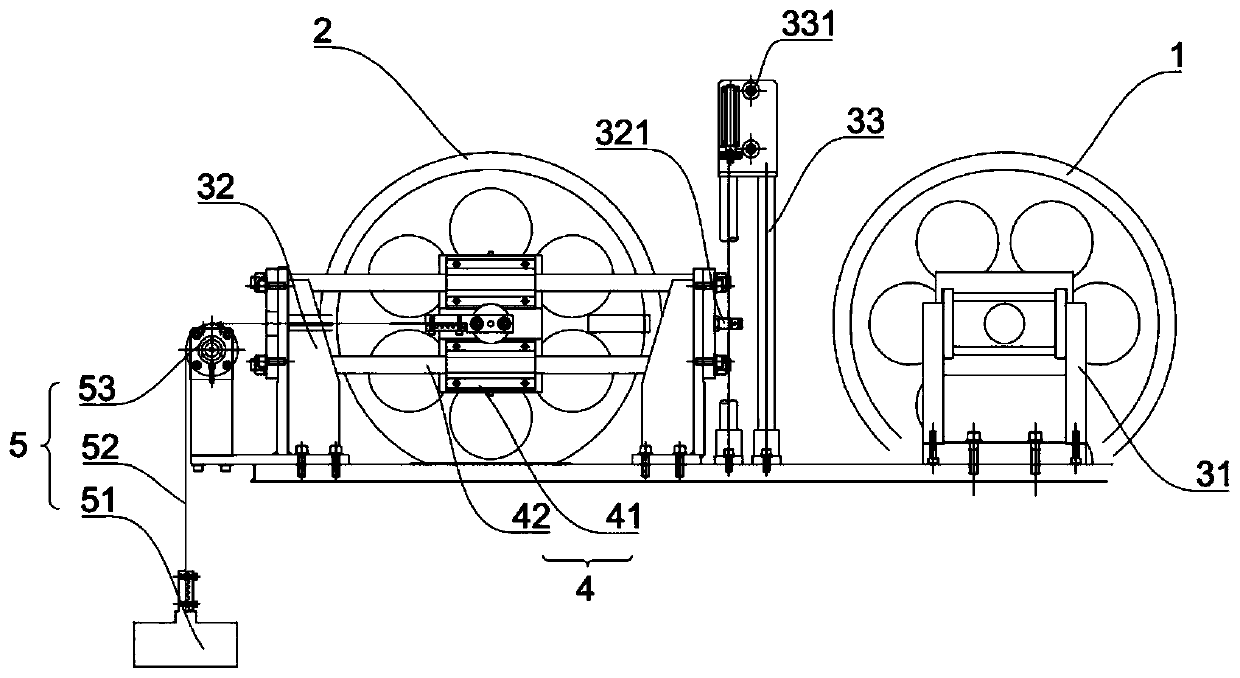

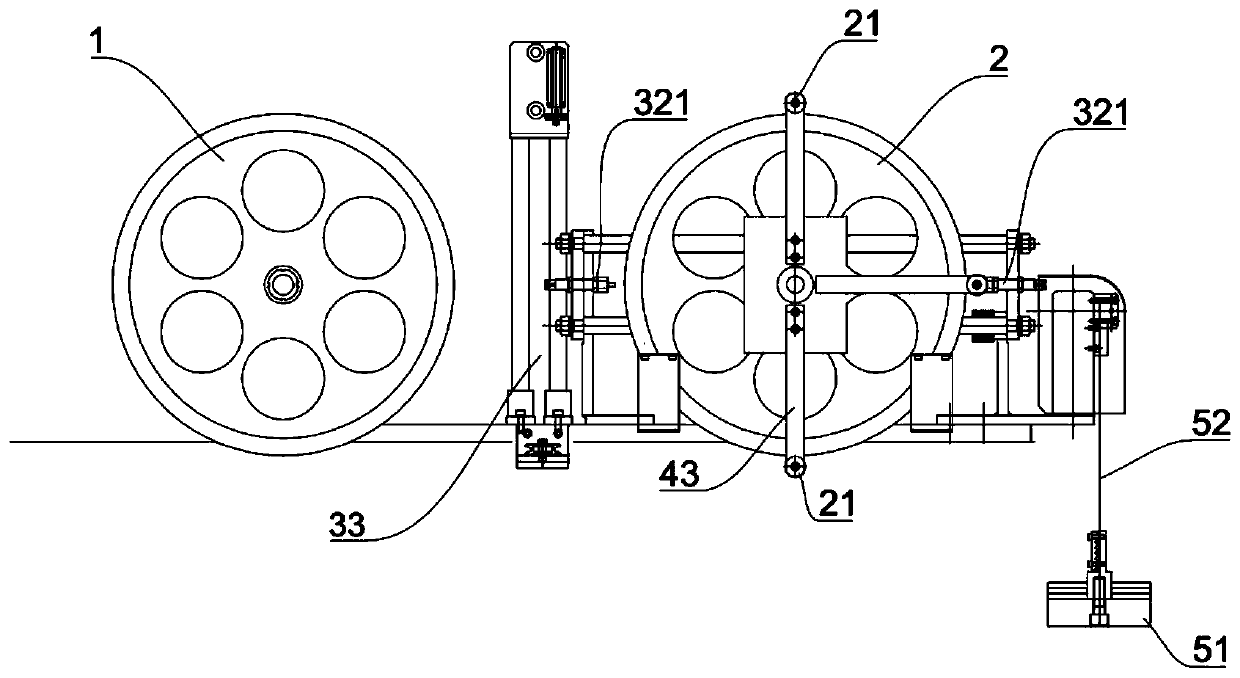

A kind of shaping equipment for magnetic head automatic shell insertion

The invention relates to magnetic head automatic into-shell shaping equipment. The magnetic head automatic into-shell shaping equipment comprises a machine body; the top of the machine body is provided with a feeding moving slide table, an into-shell shaping mechanism, a discharging moving slide table and a touch screen controller, wherein the position, located on the rear sides of the feeding moving slide table, the into-shell shaping mechanism, the discharging moving slide table and the touch screen controller, of the top of the machine body is provided with a feeding pushing mechanism, andthe position, located on the front side of the into-shell shaping mechanism, of the top of the machine body is provided with a control switch; the touch screen controller is connected with the feedingmoving slide table, the into-shell shaping mechanism, the discharging moving slide table and the feeding pushing mechanism; the control switch is connected with the feeding moving slide table and thedischarging moving slide table; and the feeding moving slide table and the discharging moving slide table are both provided with magnetic head turnover plates. According to the magnetic head automatic into-shell shaping equipment, a magnetic head is subjected to automatic feeding positioning and punching and shaped to the specified dimension, and the punching and shaping steps of the magnetic arecompleted on the same jig.

Owner:全南群英达电子有限公司

Automatic detection flexible welding fixture and working method thereof

InactiveCN109865965AThe size meets the requirementsImprove welding qualityWelding/cutting auxillary devicesAuxillary welding devicesLaser rangingEngineering

The invention discloses an automatic detection flexible welding fixture, which includes a fixture base and a welding robot controller. A switching sliding rail is arranged on the fixture base, a switching sliding seat is arranged on the switching sliding rail, a first laser range finder for detecting the position of the switching sliding seat and a second laser range finder for detecting the position of a workpiece are arranged on the fixture base, the first laser range finder and the second laser range finder are arranged at the both ends of the length direction of the switching sliding railcorrespondingly, and the first laser range finder and the second laser range finder are both connected with the welding robot controller through signals. According to the automatic detection flexiblewelding fixture and a working method thereof, one welding fixture can be used for processing battery trays with various specifications and sizes in a welding mode, whether workpiece placement meets the set requirements or not can be automatically detected, and welding robot control programs corresponding to the workpiece length specifications are automatically selected.

Owner:珠海城市职业技术学院

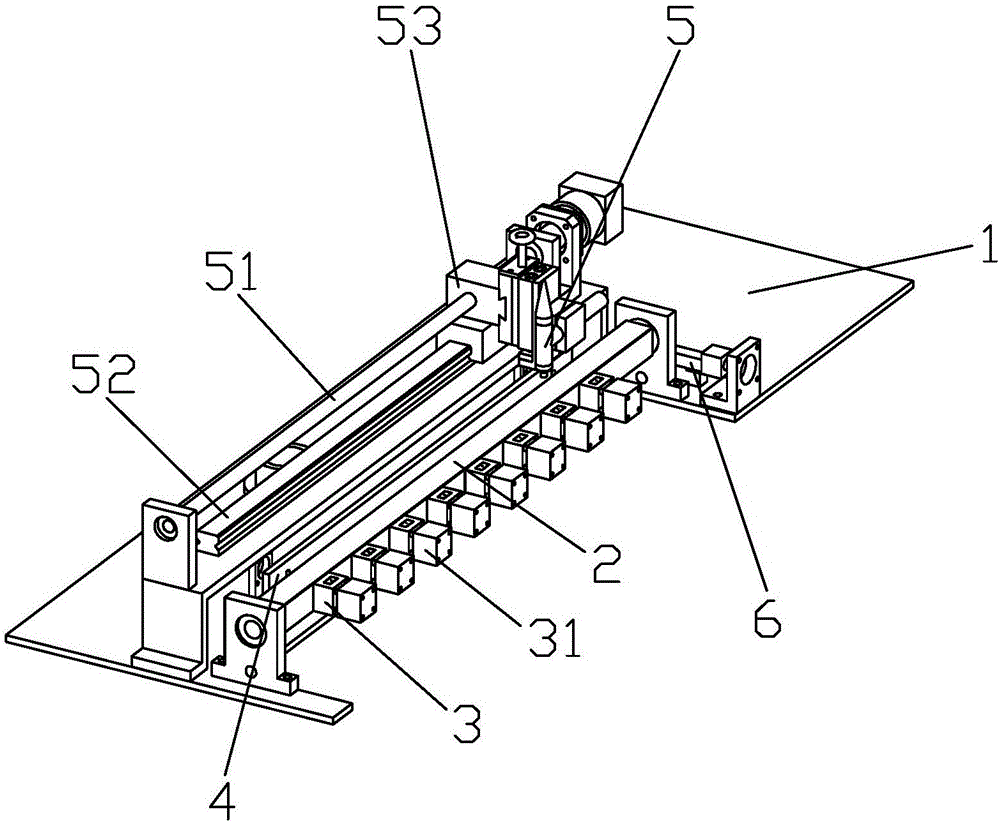

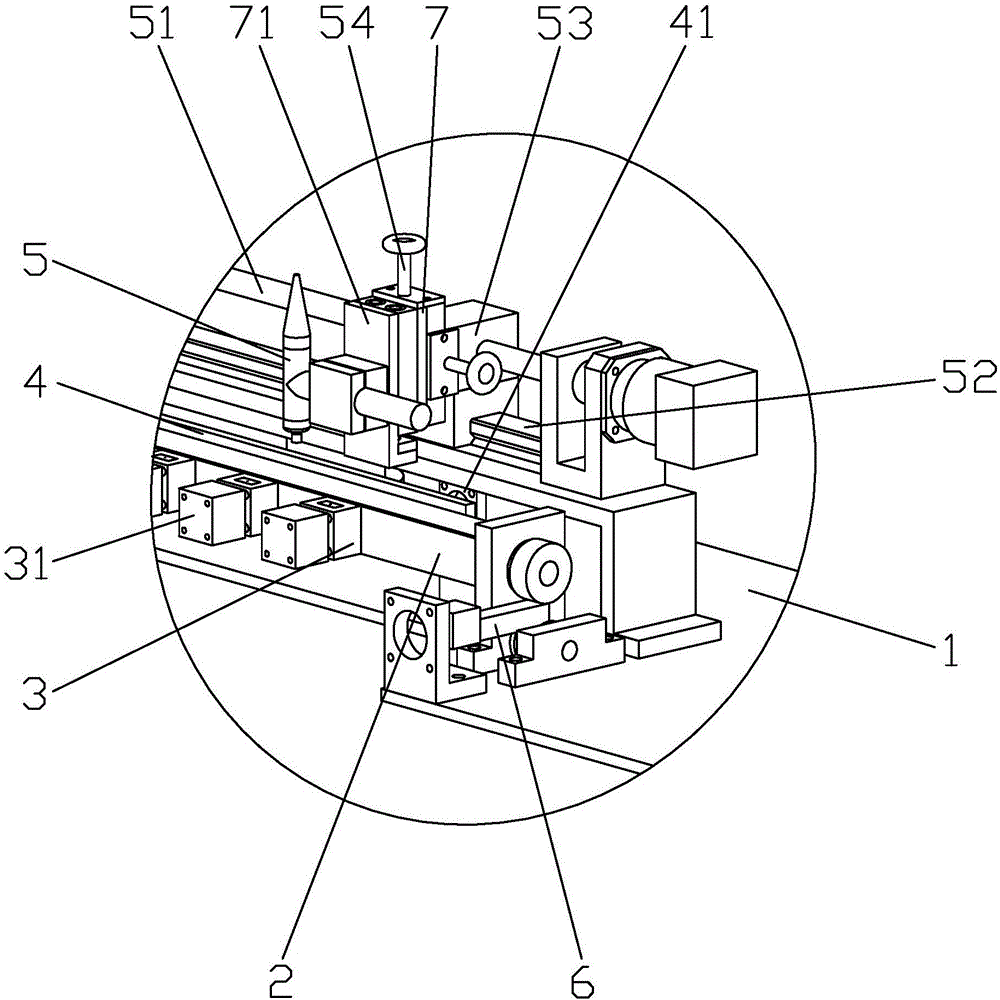

Magnetic head automatic into-shell shaping equipment

The invention relates to magnetic head automatic into-shell shaping equipment. The magnetic head automatic into-shell shaping equipment comprises a machine body; the top of the machine body is provided with a feeding moving slide table, an into-shell shaping mechanism, a discharging moving slide table and a touch screen controller, wherein the position, located on the rear sides of the feeding moving slide table, the into-shell shaping mechanism, the discharging moving slide table and the touch screen controller, of the top of the machine body is provided with a feeding pushing mechanism, andthe position, located on the front side of the into-shell shaping mechanism, of the top of the machine body is provided with a control switch; the touch screen controller is connected with the feedingmoving slide table, the into-shell shaping mechanism, the discharging moving slide table and the feeding pushing mechanism; the control switch is connected with the feeding moving slide table and thedischarging moving slide table; and the feeding moving slide table and the discharging moving slide table are both provided with magnetic head turnover plates. According to the magnetic head automatic into-shell shaping equipment, a magnetic head is subjected to automatic feeding positioning and punching and shaped to the specified dimension, and the punching and shaping steps of the magnetic arecompleted on the same jig.

Owner:全南群英达电子有限公司

Preparation method for AuSn20 alloy brazing filler metal used for packaging integrated circuit and usage thereof

ActiveCN102114584BUniform compositionSize fitsWelding/cutting media/materialsSoldering mediaAlloyNitrogen gas

The invention relates to a preparation method for an AuSn20 alloy brazing filler metal used for packaging an integrated circuit, which comprises the following steps: preparing gold and tin in proportions; placing the gold and tin into a casting furnace; sealing the furnace and vacuumizing the furnace; rising the temperature till the gold and tin are completely melted, controlling the temperature of the melt at 500-600 DEG C, refining for the purpose of alloying the gold and tin and degassing, and pouring the alloy in a graphite mould; placing an acquired AuSn20 alloy bar into a quartz tube and heating; sealing the furnace and vacuumizing till the pressure is 4-6Pa; rising the temperature and controlling the temperature rising; after melting the alloy bar, controlling the temperature of the melt to be 500-600 DEG C, and refining for 2-3 minutes; performing the melt-spinning process by using a vacuum quenching melt-spinning machine, controlling the temperature of the melt within 500-600 DEG C in the melt-spinning process, and introducing high-pressure nitrogen from an upper port of the quartz tube, wherein the nitrogen pressure is 10-15Pa; and spraying the alloy melt onto a speedily rotating metal wheel of the vacuum quenching melt-spinning machine from a bottom hole on the quartz tube, thereby acquiring a belt material. The belt material can be milled into a foil belt material or be punched into a slice or annular deeply processed product in the corresponding specification. By using the method, the product having excellent integrated circuit property can be prepared.

Owner:BEIJING INST OF NONFERROUS METALS & RARE EARTH

Manufacture method of automobile coating product protection cover

InactiveCN104441589AAvoid bumping and scratchingProduct surface quality controlWrinkle skinTemperature control

Owner:江苏天诚车饰科技有限公司

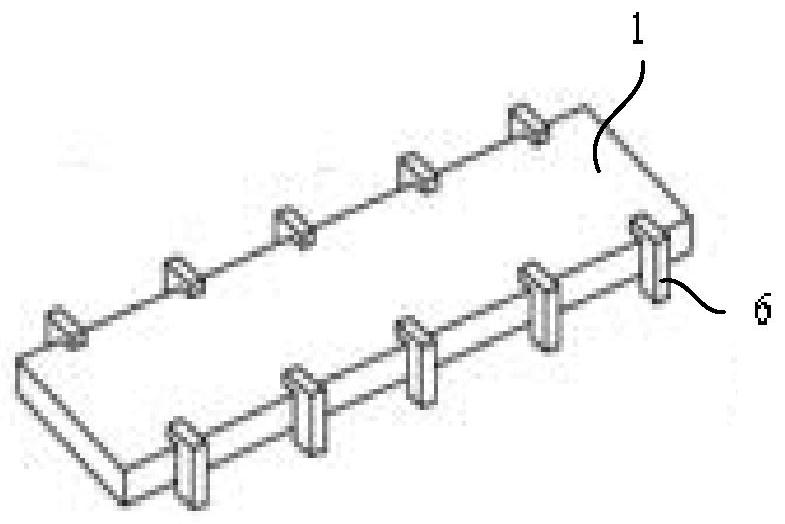

Pallet as well as molds and production method thereof

ActiveCN109279141AThe size meets the requirementsAccurate settingBio-packagingCane mechanical workingEngineeringUltimate tensile strength

The invention discloses a pallet as well as a production method and molds thereof. The pallet comprises a supporting plate and supporting legs, wherein the supporting legs are located below the supporting plate, the supporting plate is formed by pressing and bonding bamboo bundles and glue, the supporting legs are formed by pressing and bonding the bamboo bundles and the glue, and the supporting legs and the supporting plate are pressed into a whole. The molds of the pallet comprise the supporting plate mold and the pallet mold, the supporting plate mold comprises a supporting plate mold mainbody and a supporting plate pressurizing part, the pallet mold comprises a pallet mold main body, a pallet cavity with an opening in the side surface and a pallet pressurization part. The production method of the pallet comprises the following steps that firstly, the bamboo bundles are placed into a first supporting plate cavity to be pressed into the supporting plate, then the supporting plate manufactured by pressing is placed in a second supporting plate cavity of the pallet mold, the bamboo bundles are placed in a supporting leg cavity of the pallet mold, and the pallet mold is used to press the supporting plate and the bamboo bundles into the pallet. According to the pallet as well as the production method and the molds thereof, bamboo is utilized to be processed and integrated into the bamboo pallet, so that the pallet has the advantages of being high in strength, high in corrosion resistance, low in cost, light, easy to carry and convenient to carry.

Owner:BEIJING WUZI UNIVERSITY

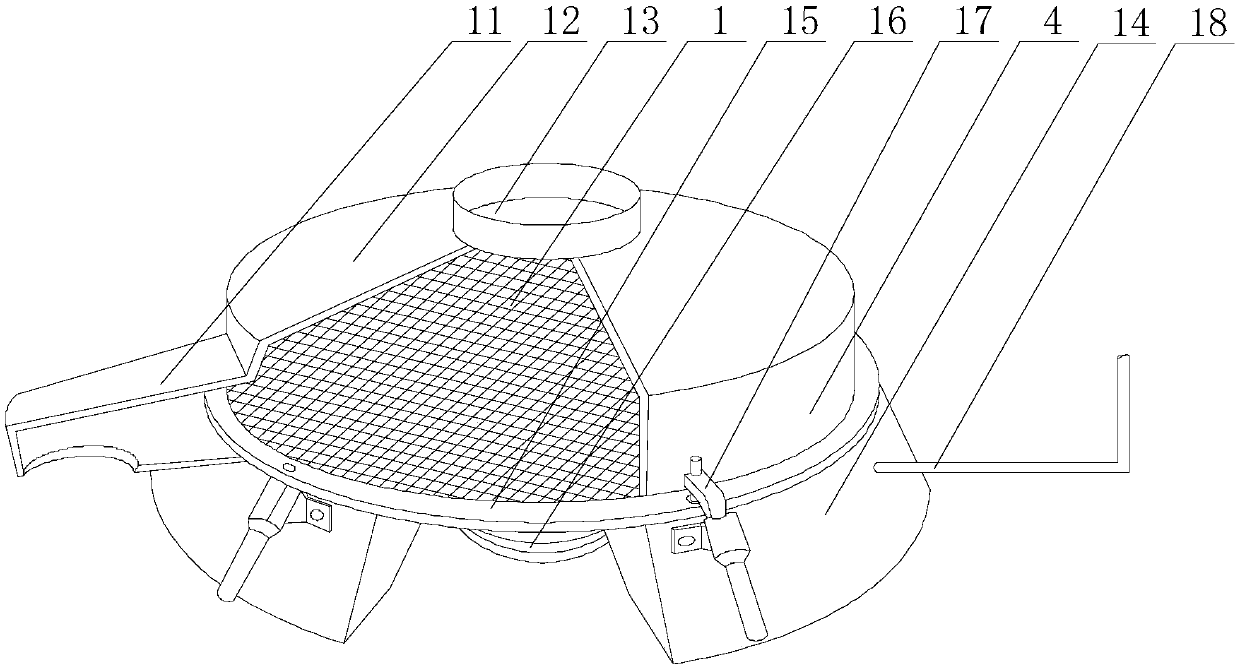

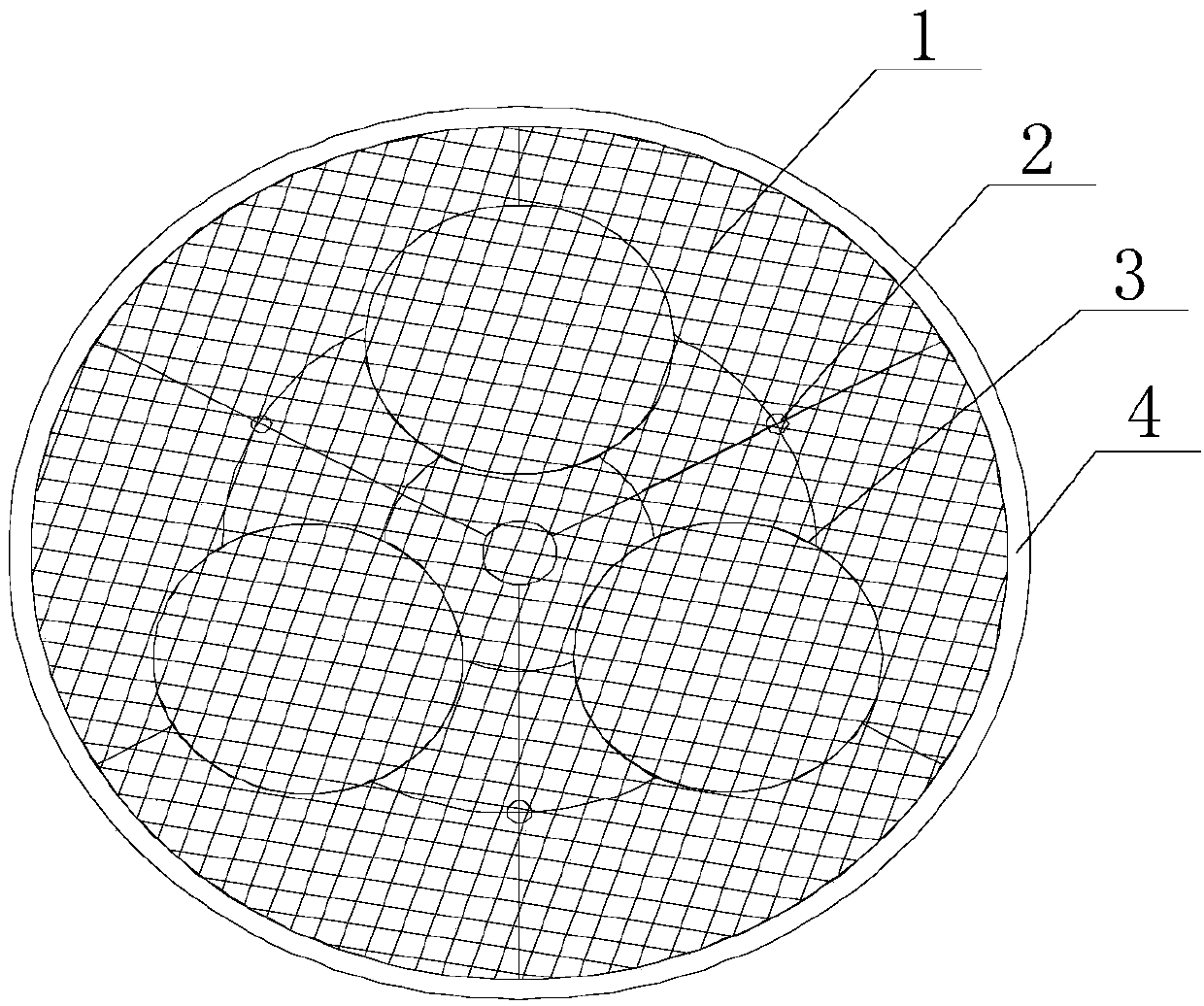

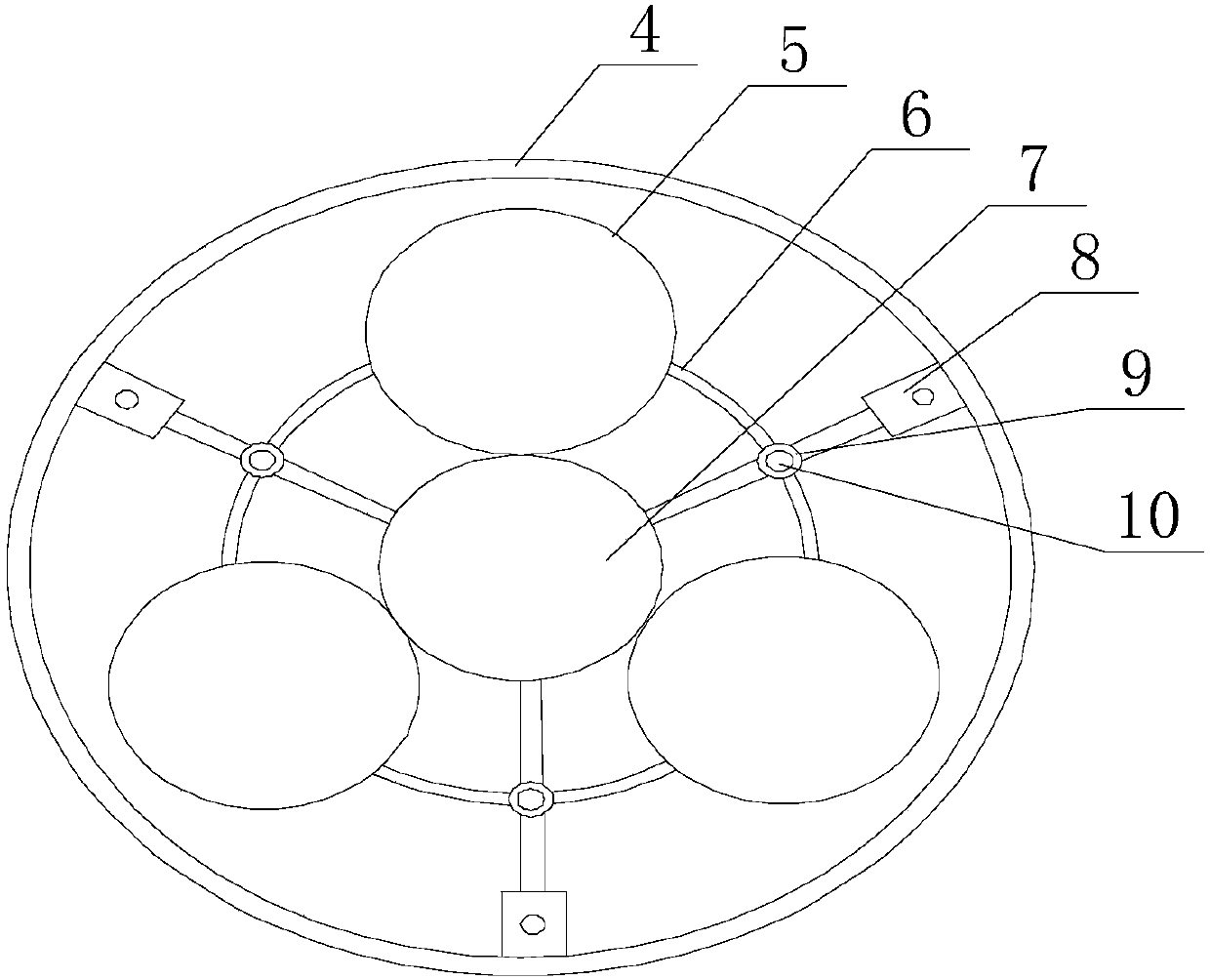

Oscillator for screening superfine powder

InactiveCN107803337AImprove support strengthHeavy loadSievingScreeningResonanceArchitectural engineering

The invention discloses an oscillator for superfine powder screening, which includes a base, a cover plate, a screen frame, and a screen mesh. A groove is formed on the upper end surface of the base, and a flange is provided on the outer wall along the outer circumference of the lower end surface of the screen frame. The flange is connected to the base through a buckle. A secondary discharge pipe is provided on the lower end of the base, and a primary discharge pipe is provided on the side wall of the screen frame. The top cover seals the upper opening of the screen frame. There is a feed pipe, and the skeleton includes a reinforcing ring, three resonance rings and three connecting rods. Two adjacent resonance rings are connected by connecting rods. There are three connecting plates on the inner wall of the lower end of the screen frame. The middle part of the connecting rods It is fixed with the connecting rod, and the connecting rod is connected with the connecting plate through bolts. Under the premise of not affecting the passage of materials, the skeleton under the screen greatly improves the support strength of the screen, increases the bearing capacity of the screen, and can effectively improve the output and service life.

Owner:成都瞬科仪器仪表有限公司

Slag system for heat treatment of desulfurization wastewater

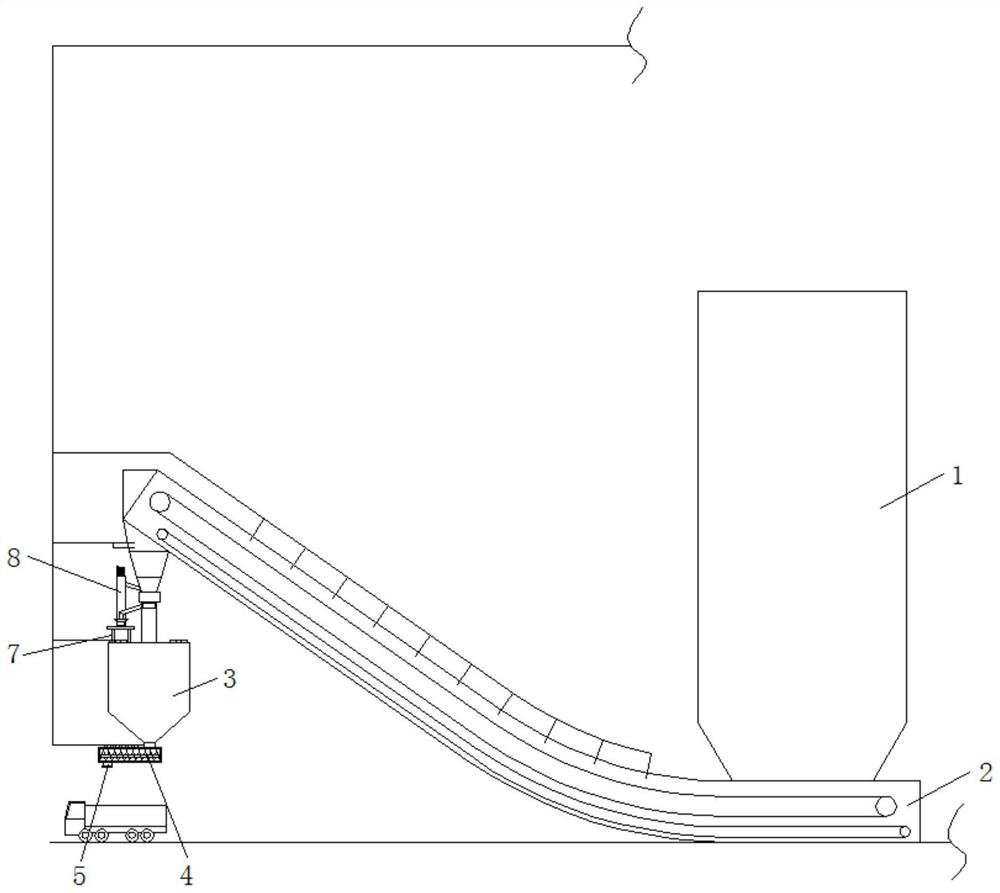

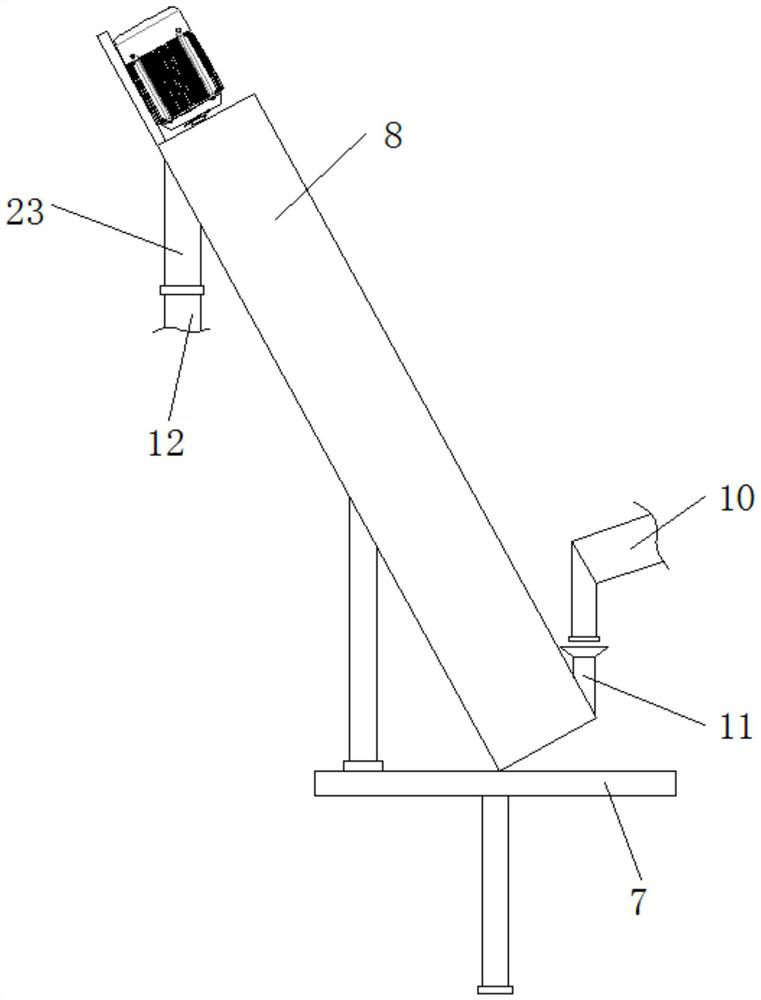

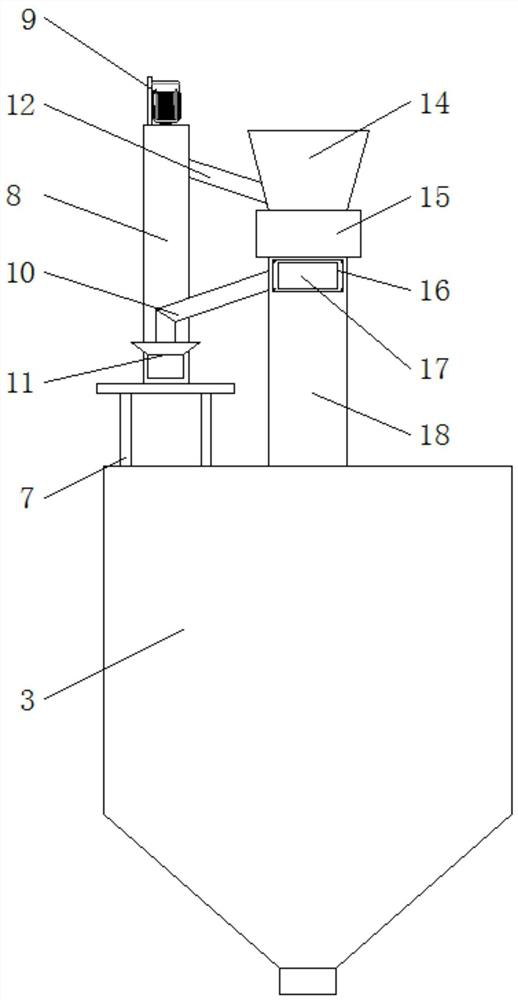

PendingCN112830538AThe size meets the requirementsEasy accessLighting and heating apparatusTransportation and packagingSlagScrew conveyor

The invention discloses a slag system for heat treatment of desulfurization wastewater, and relates to the technical field of desulfurization wastewater treatment. According to the technical scheme, the slag system comprises a boiler, the bottom of the boiler is connected with a slag crusher through a first conveying mechanism, the bottom of the slag crusher is connected with a slag storage bin through a first connecting pipe, a discharging port is formed in the lower portion of the slag storage bin, a filtering component for filtering slags is arranged in an inner cavity of the first connecting pipe, and a second conveying mechanism for conveying the slags located above the filtering component to the position above the slag crusher is arranged on the side face of the first connecting pipe. The system has the effects that a filter screen and a spiral conveyor are arranged, the filter screen is used for filtering crushed slags, the slags conforming to the size enter the slag storage bin through the filter screen and are finally discharged from a discharging pipe, and the slags not conforming to the size are conveyed into the slag crusher again by the spiral conveyor and are crushed again until the sizes of all the slags meet the requirements.

Owner:南京通用电气装备有限公司

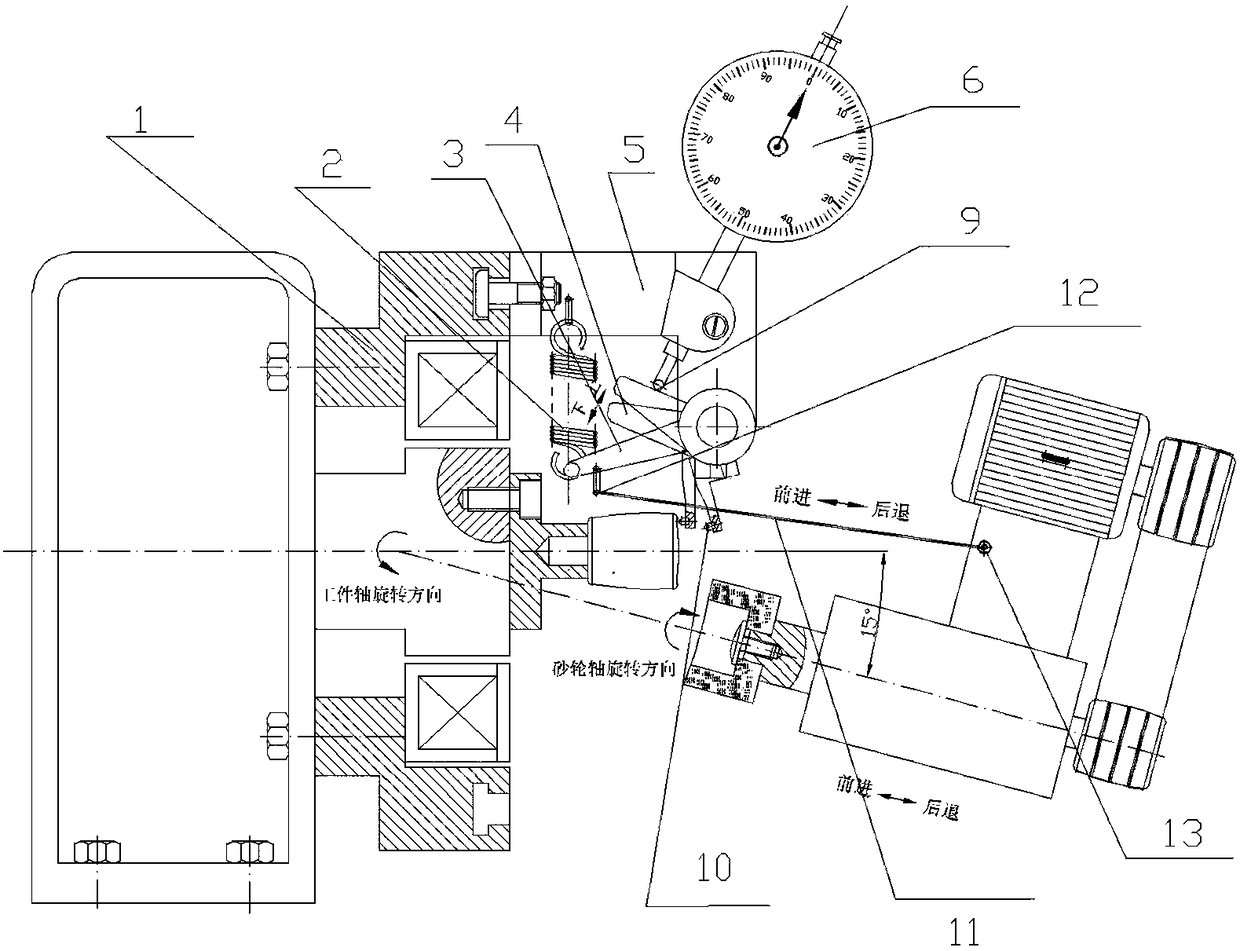

Centering roller ball base surface size measuring device

PendingCN108332634AMaster sizeThe size meets the requirementsMechanical measuring arrangementsEngineeringGrinding wheel

The invention discloses a centering roller ball base surface size measuring device which comprises a fixing base, wherein the fixing base is 'L'-shaped; a dial gage is fixed in the position of the corner of the fixing base; a first measuring head is arranged at the lower end of the dial gage; a second measuring head, a swinging rod and a measuring rod are arranged at one end of the fixing base; aspring is arranged at the other end of the fixing base; the second measuring head, the swinging rod and one end of the measuring rod are fixedly connected into an entity; the entity is in shaft connection with one end of the fixing base; one end of the swinging rod is connected with one end of the spring; a steel wire rope is arranged between the swinging rod and a grinding wheel shaft tank. The first measuring head is in contact with the measuring rod, the second measuring head is in contact with a roller ball base surface, a roller is ground by using a grinding wheel, the second measuring head is moved forwards along with the grinding process, then the position of the measuring rod is also changed, data of the first measuring are displayed through the dial gage along with position changeof the measuring rod, and the grinding size of the grinding wheel upon the roller can be judged by operators according to the data. The device has the most significant beneficial effects that size requirements of a ball base surface can be met at one time.

Owner:瓦房店威远滚动体制造有限公司

An annular cluster type down-the-hole hammer

Owner:新泰玖翊工程机械有限公司

Hot riveting method for TC4 titanium alloy pin

The invention relates to a hot riveting method for a TC4 titanium alloy pin. The hot riveting method is characterized by comprising the following steps: 1, a to-be-riveted plate-shaped part and a to-be-riveted pin are cleaned; 2, the plate-shaped part is installed on a riveting tool and leveled, and the riveting tool is composed of an upper electrode assembly and a lower electrode assembly; 3, the pin is clamped, the heating current, the heating time and the riveting pressure of a projection welding machine are controlled to rivet the plate-shaped part so as to guarantee the size and the appearance of the plate-shaped part and the torque requirement of 4-9 Nm between the pin and the plate-shaped part, then the plate-shaped part is taken down, wherein the riveting pressure ranges from 0.06 Mpa to 0.14 Mpa, the heating time is 0.14 s, and the heating current ranges from 4.0 KA to 4.6 KA; and optionally 4, visual inspection is conducted on the riveted plate-shaped part, and torque test is conducted on the riveted first and last test pieces.

Owner:北京力威尔航空精密机械有限公司

Processing method of ultra-short slot of circuit board

PendingCN114147807AThe size meets the requirementsAvoid deformationPrinted circuit manufactureMetal working apparatusMilling cutterStructural engineering

The invention discloses a processing method of an ultra-short slotted hole of a circuit board. The processing method comprises the following steps: step 1, drilling a lower cutter hole on the circuit board by using a pre-drilling cutter; secondly, an end mill is used for aligning the center of the lower cutter hole to conduct downward feeding, and a first round hole is formed through milling; thirdly, an end mill is used for conducting rough machining and milling by conducting outward feeding along a straight line with the center of the first round hole as the starting point, and a second slotted hole is formed; and fourthly, the key groove milling cutter is used for conducting finish machining and trimming on the edge of the second groove hole, and finally a third groove hole is formed.

Owner:广东依顿电子科技股份有限公司

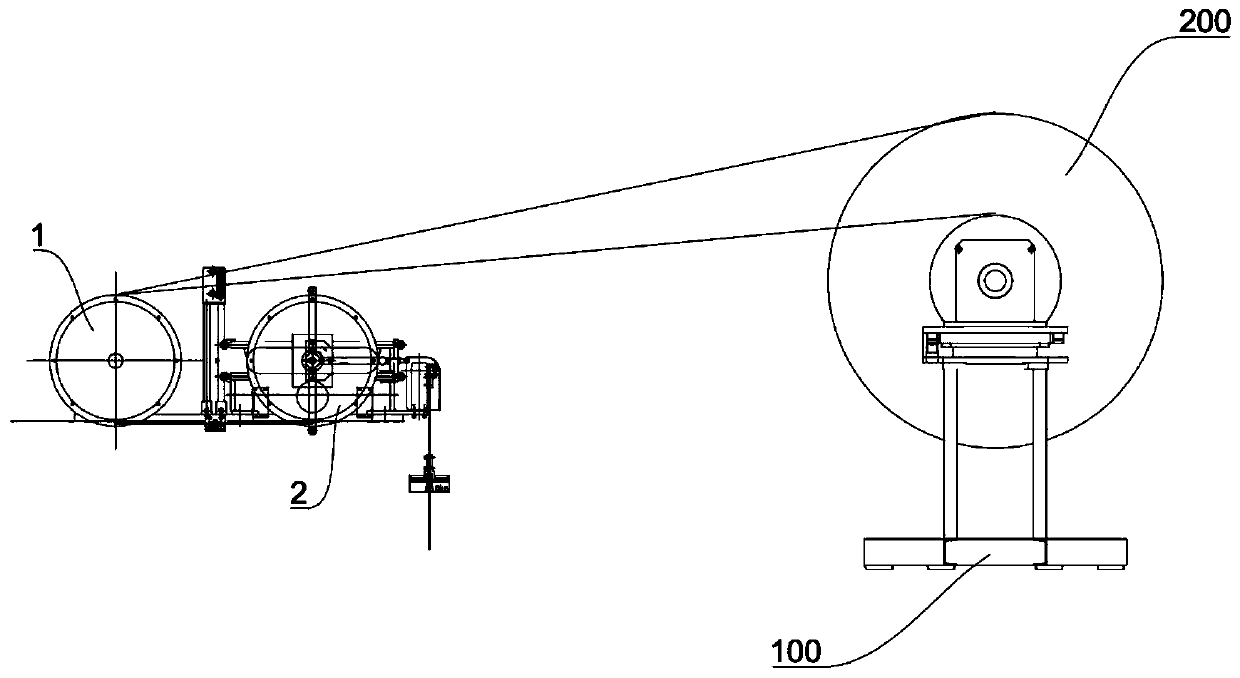

Straightening mechanism and flat pipe cutting device

PendingCN109807200AThe size meets the requirementsTension balanceTube shearing machinesShearing machine accessoriesEngineeringMechanical engineering

The invention relates to the technical field of aluminum flat pipe production equipment and discloses a straightening mechanism and a flat pipe cutting device. The straightening mechanism comprises afirst rolling wheel, a second rolling wheel and a detecting assembly, wherein the first rolling wheel is rotationally connected to a first support; the second rolling wheel is rotationally connected to a supporting assembly, and the supporting assembly is connected to a second support in a sliding manner; and the detecting assembly comprises a balancing weight, a tooth belt and an encoder, one endof the tooth belt is connected with the supporting assembly, and the other end of the tooth belt winds around the encoder to be connected with the balancing weight. The straightening mechanism is arranged between an uncoiler and a cut-off machine, a flat pipe is conveyed through the first rolling wheel and the second rolling wheel, the flat pipe is pulled to be straight after passing through thefirst rolling wheel and the second rolling wheel, and the size of the cut flat pipe meets the requirement. The tension change on the second rolling wheel is detected through the detecting mechanism, when the diameter of a material roll on the uncoiler is reduced, by adjusting the rotation speed of the uncoiler and the cut-off machine, the tension of the flat pipe is kept balanced, and stable feeding is achieved.

Owner:SHANGHAI HEKE EQUIP MFG

Production process of washing non-shrinking quilt

ActiveCN103082761BSolve the problem of not being able to wash with waterReasonable preparation processBed-coversEngineeringBlanket

The invention discloses a manufacturing technique of shrink-resistant quilt in washing. The manufacturing technique comprises the following steps: 1) choosing a washing craft as required and measuring quilting shrinkage of shell fabric and filler, washing shrinkage and fluffy rate after washing according to the washing craft; 2) measuring and calculating the size of materials before washing according to the measurement result of the step 1), and tailoring for reserve; 3) combining the shell fabric with the filler in operation, adopting a well-distributed method to make the shell fabric and the filler correspond evenly, and then sewing into a product; 4) washing the quilt which is made, drying and then gaining the shrink-resistant quilt in washing with standard size. The manufacturing technique of shrink-resistant quilt in washing has the advantages of being capable of solving a problem that the ordinary quilt can not be washed and being reasonable in the craftsmanship of quilts. The quilts after the manufacturing technique of shrink-resistant quilt in washing can be washed and has a good planeness after being washed. Besides, the size of the quilt meets the requirement. The quilts are equipped with better wearability by adopting different washing crafts in the washing process.

Owner:VIOLET HOME TEXTILE TECH

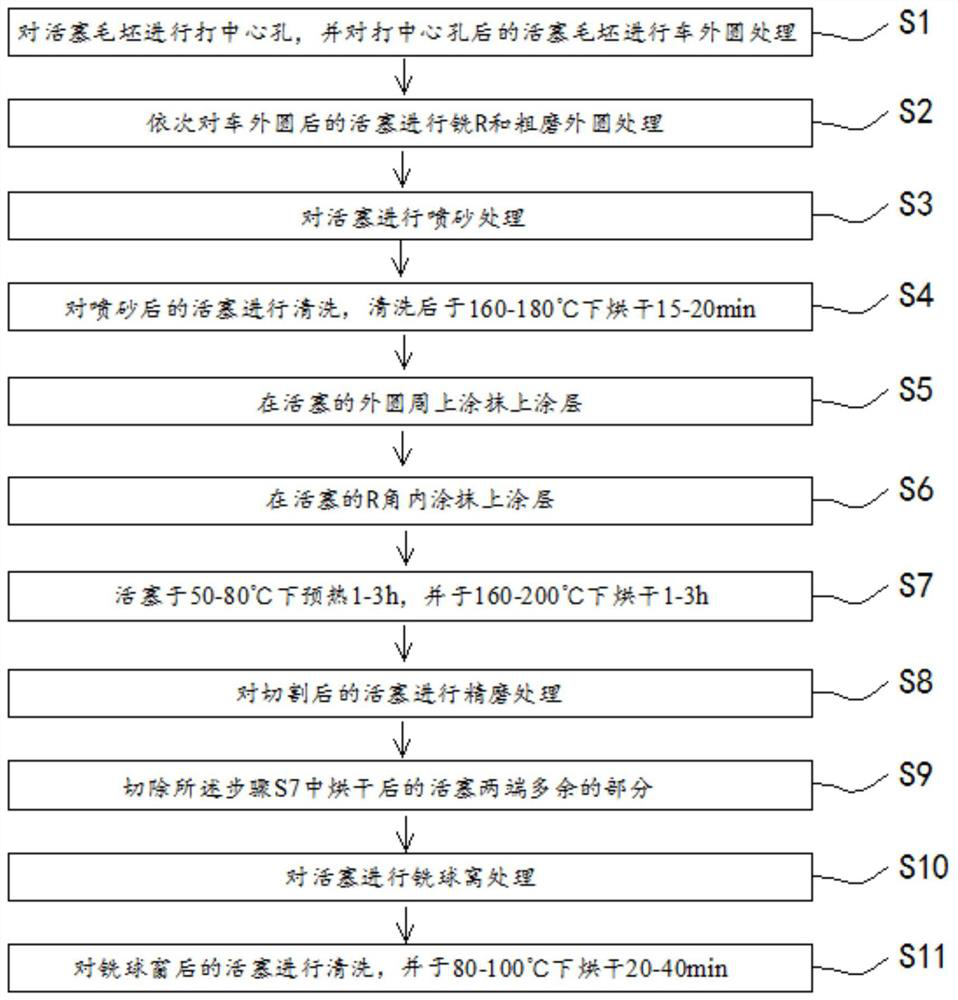

Production process of smearing type automobile air conditioner compressor piston

PendingCN113635003AQuality assuranceImprove bindingLiquid surface applicatorsCoatingsSand blastingWear resistance

Owner:陈仁春

Drill floor BOP hanging beam assembling method

PendingCN113953768AThe size meets the requirementsReduce widthClassical mechanicsStructural engineering

The invention relates to the technical field of ships, in particular to a drill floor BOP hanging beam assembling method. The drill floor BOP hanging beam assembling method comprises the following steps of modeling, material feeding and assembling, wherein the modeling step comprises the step that during structural modeling, shrinkage amounts of preset sizes are added to a first panel, a second panel, a first web plate and a second web plate in the length direction; the material feeding step comprises the steps that in the material feeding process, the straightness of the first panel, the straightness of the second panel, the straightness of the first web plate and the straightness of the second web plate are checked and corrected; in the assembling process, an even number of welders are adopted for left-right symmetrical welding; in the assembling process and after assembling is completed, straightness, flatness, perpendicularity and the like are detected; and correction is conducted in time when out-of-tolerance is found. Therefore, according to the drill floor BOP hanging beam assembling method, errors are eliminated from the aspects of design, material feeding, assembly and the like, and then the precision requirements such as the size, the straightness and the levelness of the hanging beam are guaranteed, reworking operation caused by insufficient precision is avoided, and therefore, a large amount of working hours and energy consumption are saved, and the operation efficiency is improved.

Owner:SHANGHAI WAIGAOQIAO SHIP BUILDING CO LTD

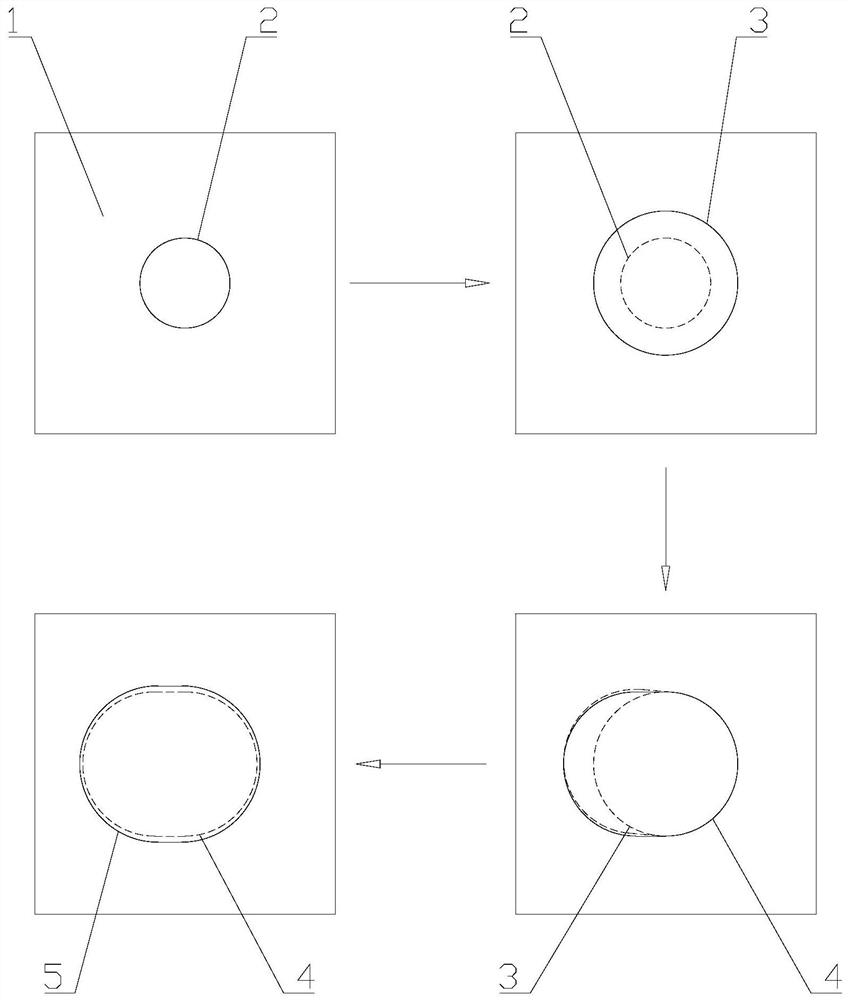

Automatic lens fusing equipment for medical stainless steel wire

ActiveCN106735978AGuaranteed assembly effectThe size meets the requirementsWorkpiece edge portionsWelding apparatusEngineeringStainless steel wire

The invention discloses automatic lens fusing equipment for a medical stainless steel wire. The automatic lens fusing equipment is characterized in that a machine base and a rotating part arranged on the machine base are included, the rotating part is provided with clamping dies, an aligning part is arranged behind the rotating part, and a fusing electrode is arranged above the rotating part. According to the equipment, for the technical requirements of a gastroscope tube, an operator can precisely position the installing position of a stainless steel wire rope to be machined conveniently through the aligning part, an installing ball is automatically fused through the fusing electrode, it is guaranteed that the size of the installing ball obtained through fusing meets the requirement while the machining efficiency is improved, and then the gastroscope assembling effect is guaranteed.

Owner:FOSHAN HAOBANG MACHINERY CO LTD

A method for size control of large thin-walled cylinder castings

ActiveCN112157225BHigh yieldReduce free shrinkageFoundry mouldsFoundry coresEngineeringCylinder block

The casting technology for steel castings of the present invention particularly relates to a method for controlling the size of large thin-walled cylinder castings. The method includes the steps of: taking the centerline of the cylinder body of the large thin-walled cylinder castings as a reference line for parting; Preset shrinkage seams between the exhaust pipe of the profiled surface and the cylinder block; preset shrinkage seams on the left and right parted cylinders respectively; preset process corrections on the inner side of the pipe wall of the exhaust pipe; respectively on the left and right sides The preset process correction amount on the side wall of the gantry; 3D hollow sand cores are set in the sand molds of the exhaust pipes on the left and right sides respectively. The invention overcomes the problem of unqualified casting size caused by the traditional production process, and solves the problem of free shrinkage of the pipe wall by using the method of size shrinkage joints; the 3D hollow sand box is placed in the sand core, so as to improve the receding property of the sand core and ensure the smoothness of the pipe wall. Free shrinkage; effective casting solves the problem that the center of the tube wall becomes longer in the shrinking length direction; and solves the problem of the design sticking amount of the tube wall in the length direction.

Owner:KOCEL STEEL

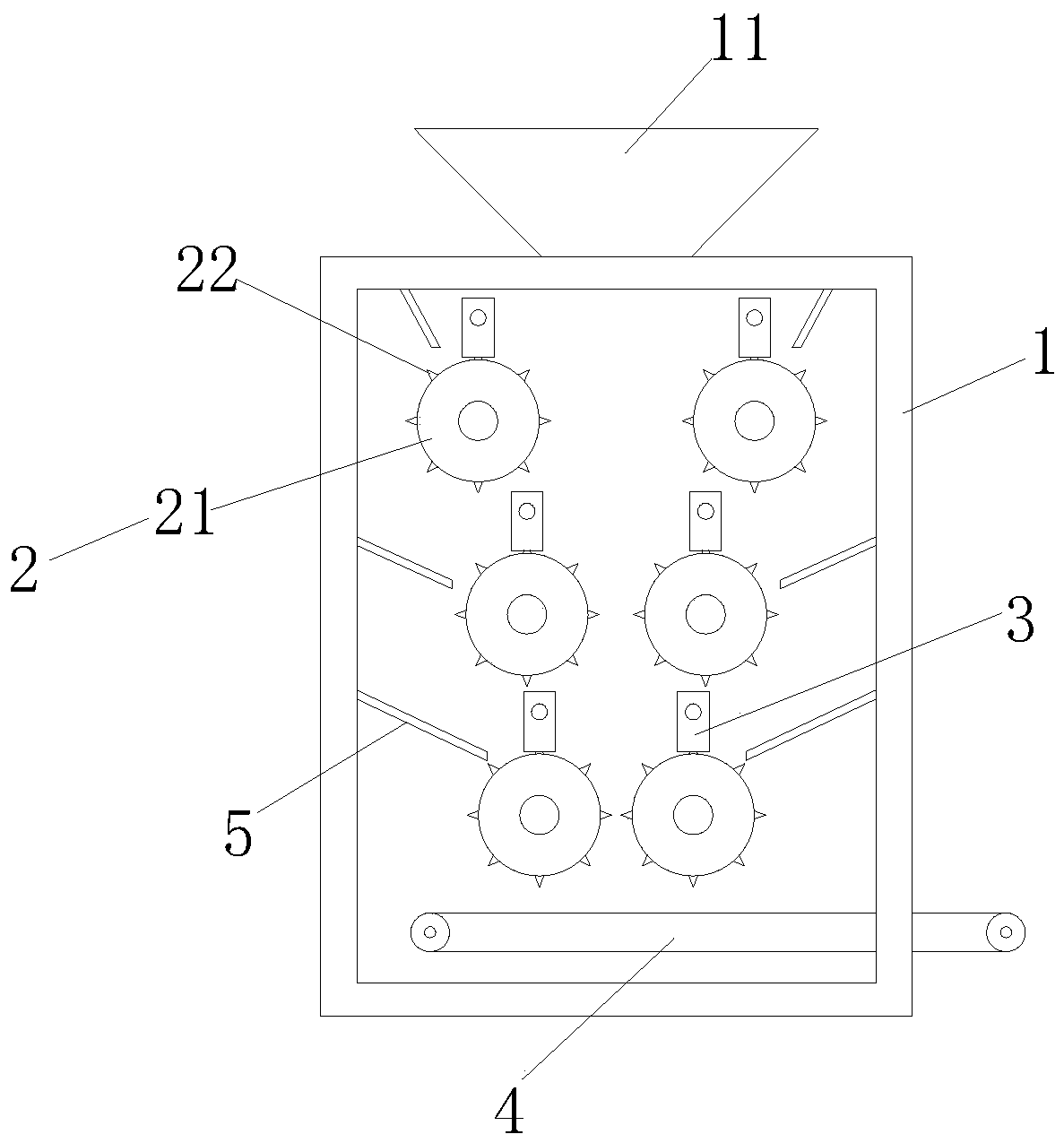

Rare earth alloy material breaking device with polishing mechanism

PendingCN110694728AImprove crushing efficiencyReduce labor intensityOther manufacturing equipments/toolsGrinding machinesPolishingAlloy

The invention discloses a rare earth alloy material breaking device with a polishing mechanism. The rare earth alloy material breaking device comprises a box, a breaking mechanism and the polishing mechanism, and the breaking mechanism and the polishing mechanism are arranged in the box. The breaking mechanism comprises a breaking roller. Breaking teeth are arranged on the breaking roller and aredivided into a plurality of sets. The multiple sets of breaking teeth are evenly arranged at intervals in the axial direction of the breaking roller, and meanwhile, the breaking teeth in the each setare arranged evenly at intervals in the circumferential direction of the breaking roller. The polishing mechanism is arranged in the rare earth alloy material breaking device, when polished, the breaking teeth do not need to be taken out, polishing is convenient and high in speed, rare earth breaking efficiency is improved, and labor intensity of workers is lowered.

Owner:ANHUI BAO TOU STEEL RARE EARTH PERMANENT MAGNETICALLOY IND

The free forging method of realizing super large and super heavy forgings by using 3 tons free forging hammer

ActiveCN106862446BGuaranteed sizeThe size meets the requirementsForging hammersProcess requirementsRadian

The invention provides a free forging method for an oversized overweight forging through a 3-ton free forging hammer and relates to a forging method for an oversized overweight forging. The free forging method aims at solving the problems that the radian of a forging cannot meet the process requirements fundamentally during existing forging production through a 3-ton free forging hammer; when bent to a certain angle, the forging is clamped on an equipment bumper, and bending cannot be conducted; and deformation is hard to control. The free forging method comprises the steps that 1, a forging drawing is drawn, and the size of a blank is calculated; 2, drawing-out is conducted, and a long-strip forging is obtained; 3, large-angle bending forming is conducted, and a semi-ring rough forging is obtained; 4, small-angle bending forming is conducted, and a rough forging is obtained; and 5, forging trimming is conducted, so that the partition plate body forging is obtained. The free forging method has the advantage that the qualified rate of the forging is 100% and is mainly used for forging the oversized overweight forging through the 3-ton free forging hammer.

Owner:HARBIN TURBINE +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com