Annular cluster-type down-hole hammer

A down-the-hole hammer and cluster technology, which is applied to drilling equipment, earthwork drilling, and driving devices for drilling in boreholes. Efficiency, improved working efficiency, and high hole quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

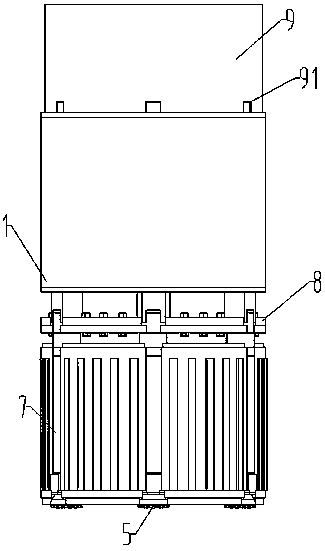

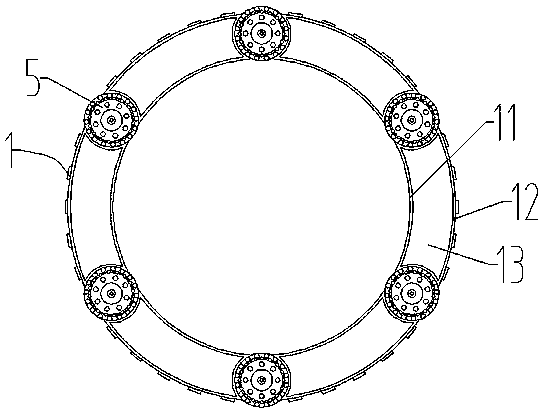

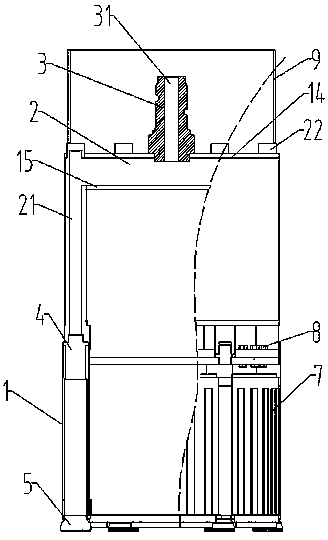

[0036] Example: see Figure 1-6 , an annular cluster type down-the-hole hammer, comprising a down-the-hole hammer body 1, a cylindrical cavity is arranged in the down-the-hole hammer body 1, and a plurality of crushing holes are sequentially arranged in a ring on the lower end surface of the down-the-hole hammer body 1 The hammer head 5, the hammer body 1 is provided with an impact hammer 4 for driving the hammer head 5 to impact the rock formation, and the hammer body 1 is provided with a storage device for collecting and storing crushed stone powder.

[0037] The down-the-hole hammer body 1 includes an inner cylinder 11 and an outer cylinder 12, the inner cylinder 11 is sleeved in the outer cylinder 12, the inner cylinder 11 and the outer cylinder 12 are arranged coaxially, and the diameter of the inner cylinder 11 is smaller than that of the outer cylinder 12, and an installation cavity 13 is formed between the inner cylinder 11 and the outer cylinder 12.

[0038] The impa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com