Automatic detection flexible welding fixture and working method thereof

A welding fixture and automatic detection technology, which is applied in the direction of welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the high requirements: the distance deviation between the lifting lugs should not exceed 0.5mm, the distance between the wire harness bracket and the frame The distance deviation shall not exceed 0.5 mm, and the distance deviation between the wire harness bracket and the ground shall not exceed 0.5 mm to achieve the effect of stable welding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

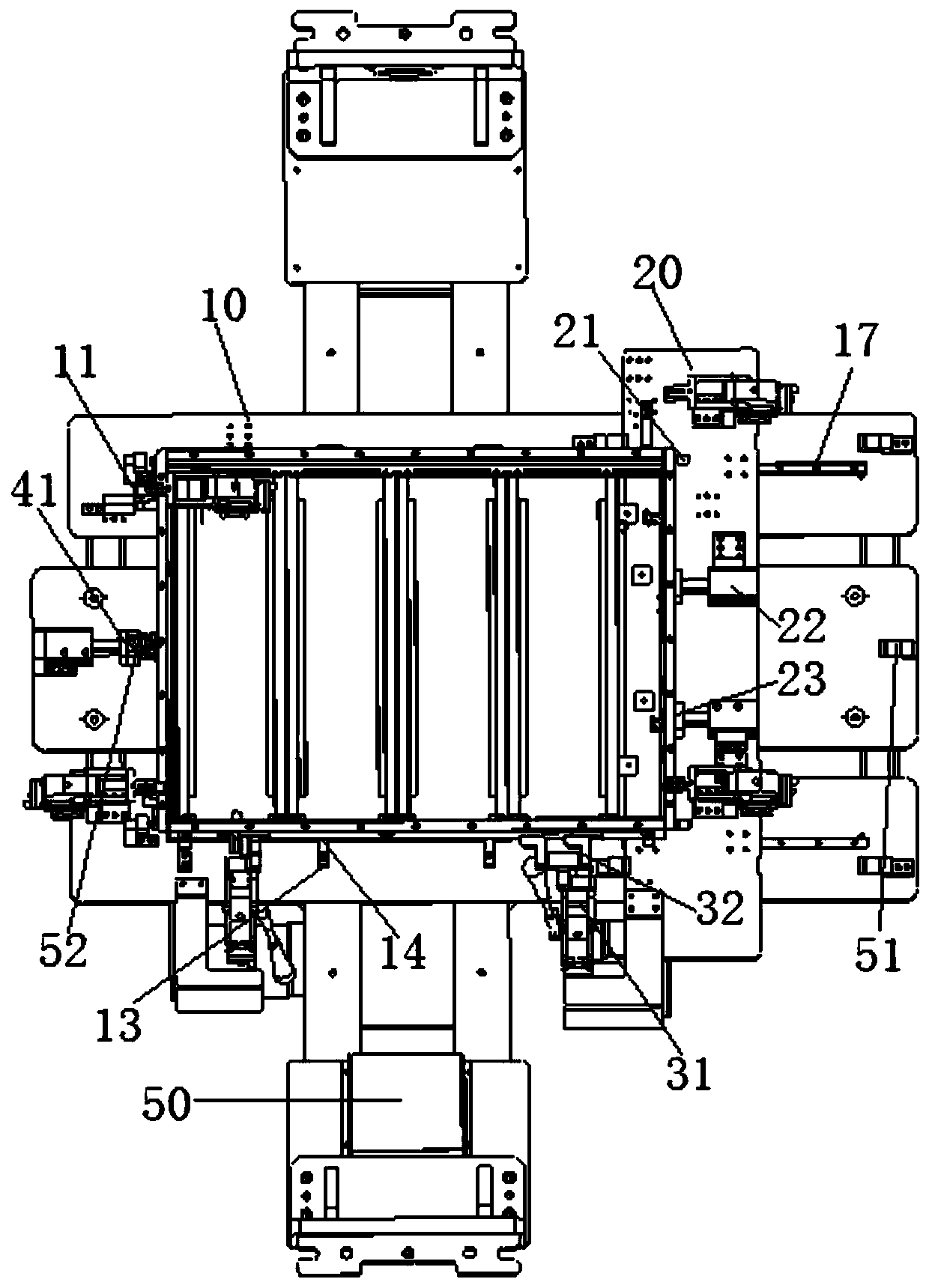

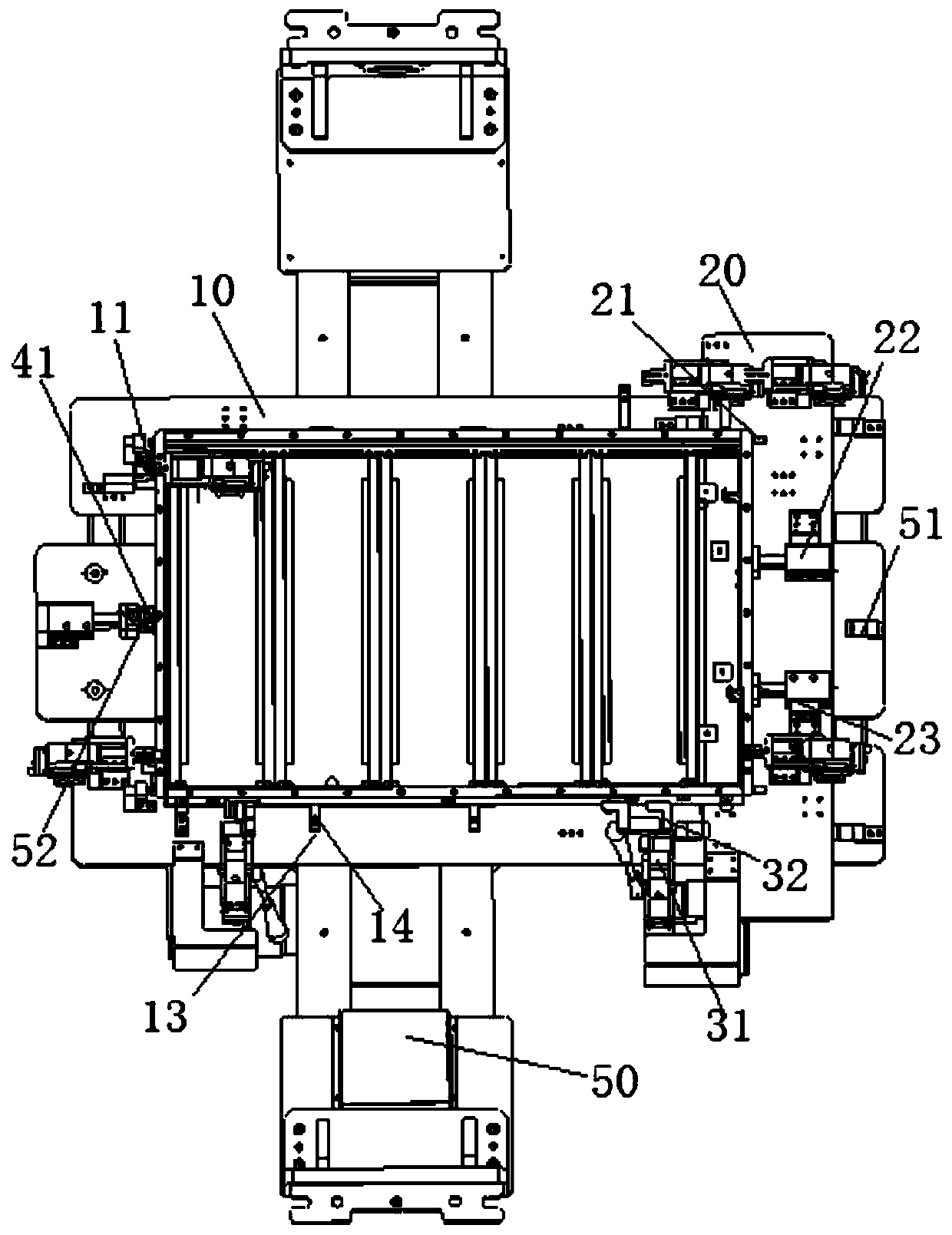

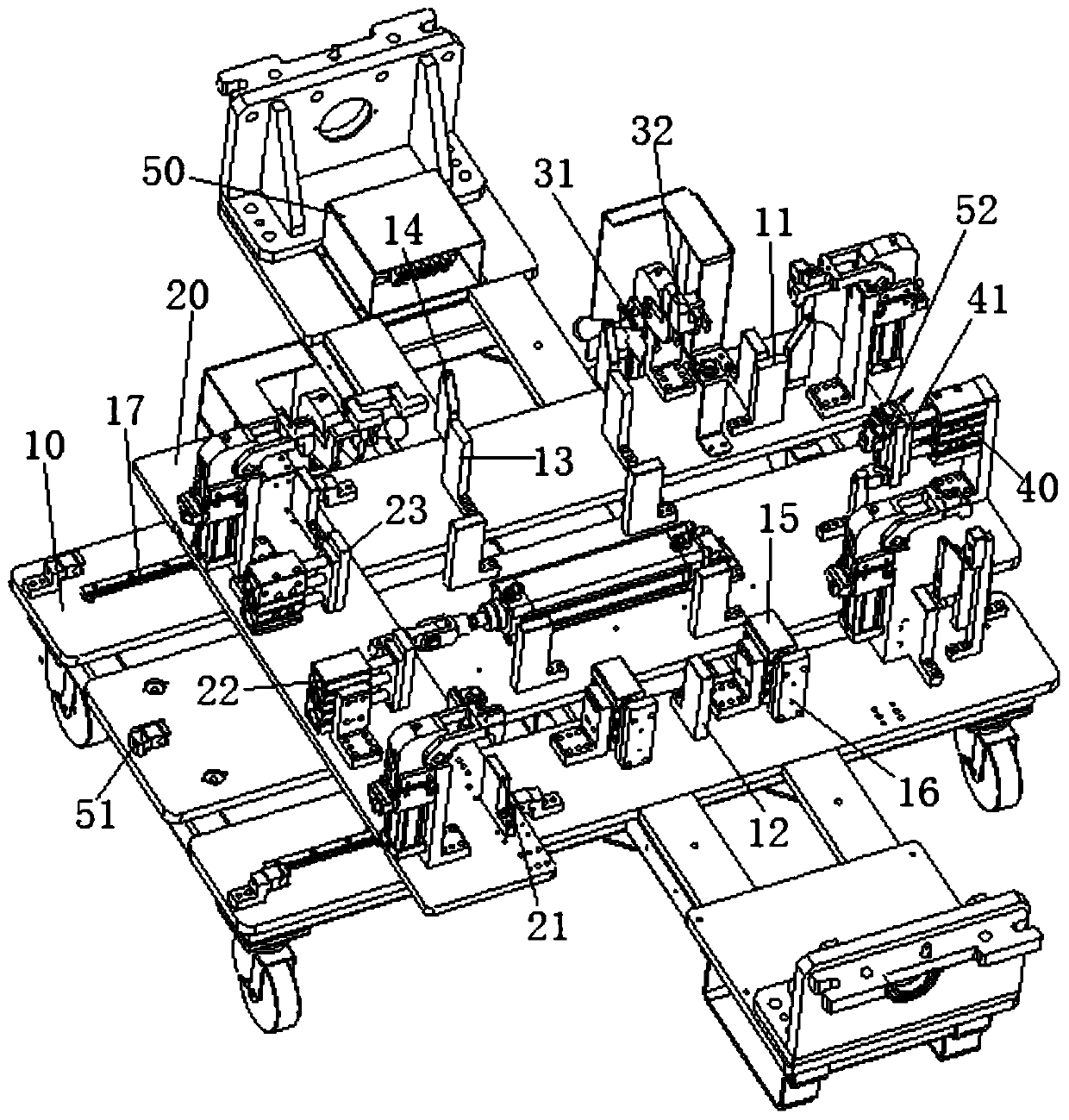

[0025] refer to Figure 1 to Figure 5 , Figure 1 to Figure 5 It is a structural schematic diagram of a specific embodiment of the present invention.

[0026] An automatic detection flexible welding fixture provided in this embodiment is mainly used for welding two or more battery trays with different lengths including lifting lugs, bushings and harness brackets, and the outer frames of different battery trays have the same shape and characteristics , The components such as lifting lugs, bushings and harness brackets on the battery tray are also shared, the difference is only in the length of the tray and the positions of the lifting lugs and bushing holes.

[0027] Such as Figure 1 to Figure 5 As shown, an automatic detection flexible welding fixture and its working method include a fixture base 10 and a welding robot controller 50, the fixture base 10 is provided with a switching slide rail 17, and the switching slide rail 17 is provided with a switching slide seat 20, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com