A method for size control of large thin-walled cylinder castings

A technology of size control and casting, applied in the field of steel casting, can solve the problem of unqualified casting size, and achieve the effects of cycle saving, improving concessions, and saving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

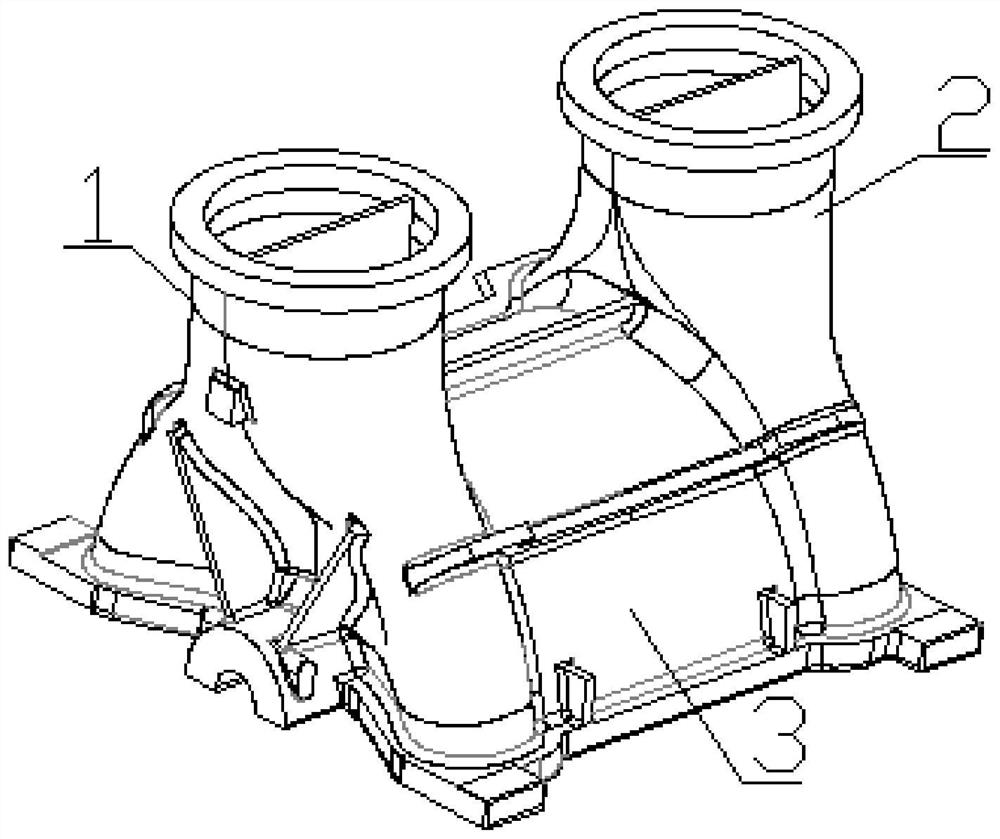

[0030] Taking the oil cylinder block as an example, the oil cylinder block, such as figure 1 , The oil cylinder block consists of three parts: exhaust pipe 1, exhaust pipe 2, and cylinder block 3. The wall thickness of exhaust pipe 1 and exhaust pipe 2 is only 50mm, and the height of the pipe wall can reach 2840mm. 5500mm, width 3991mm; the wall thickness of cylinder block 3 is only 50mm, which has the characteristics of thin wall and super long structure.

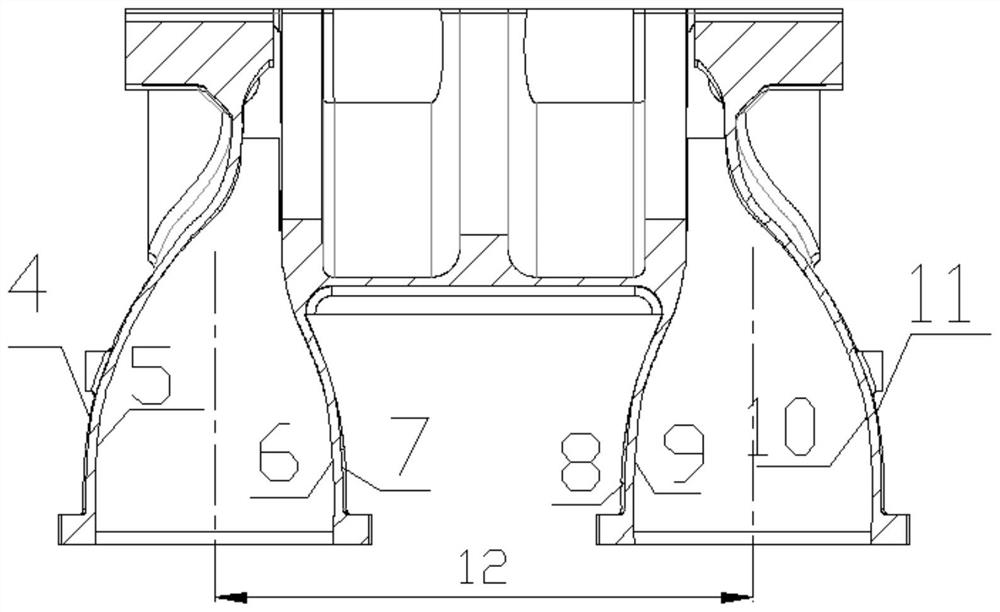

[0031] For large-scale ultra-long and thin-walled cylinder castings, when the casting shrinks, it is hindered by the sand cores inside the exhaust pipe 1 and the exhaust pipe 2 2, which causes the distance 12 between the center of the exhaust pipe wall to become longer. The present invention provides a large-scale The method for controlling the size of thin-walled cylinder castings specifically includes the following steps:

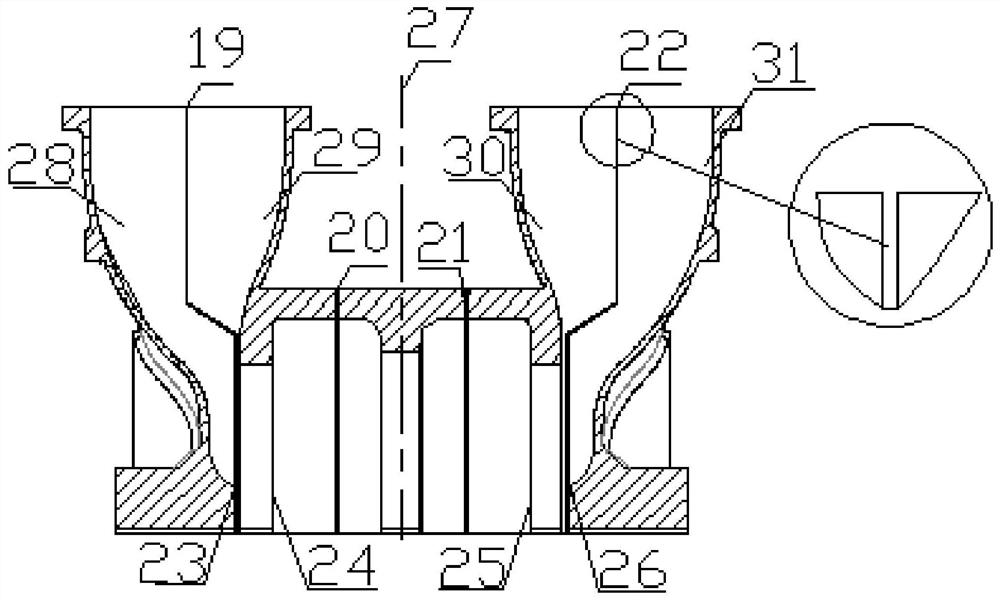

[0032] Taking the cylinder centerline 27 of the cylinder block 3 as the reference line, the cylin...

Embodiment 2

[0041] A 3D hollow sand core 32 is set up, its 3D size is 200*200*200mm, the interior is a hollow structure, and the wall thickness is 15mm. At the same time, in order to solve the problem of core air outlet, 3D hollow sand core air outlet holes 33 are designed on the end face. The diameter of the air outlet 33 of the sand core is 20 mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com