Manufacture method of automobile coating product protection cover

A technology of product protection and manufacturing method, which is applied in the field of manufacture of protective covers for vehicle coating products, can solve the problems of energy consumption and waste, unfavorable reuse, packaging costs, etc., so as to reduce the rework rate, save packaging materials, and save packaging costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

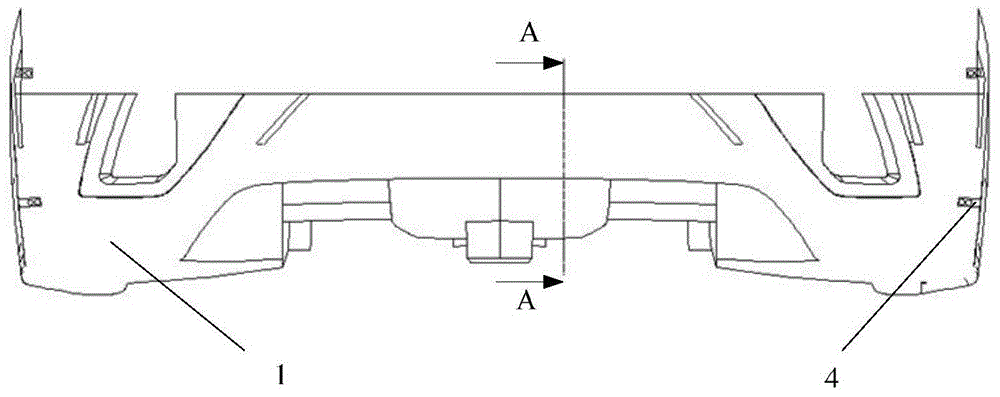

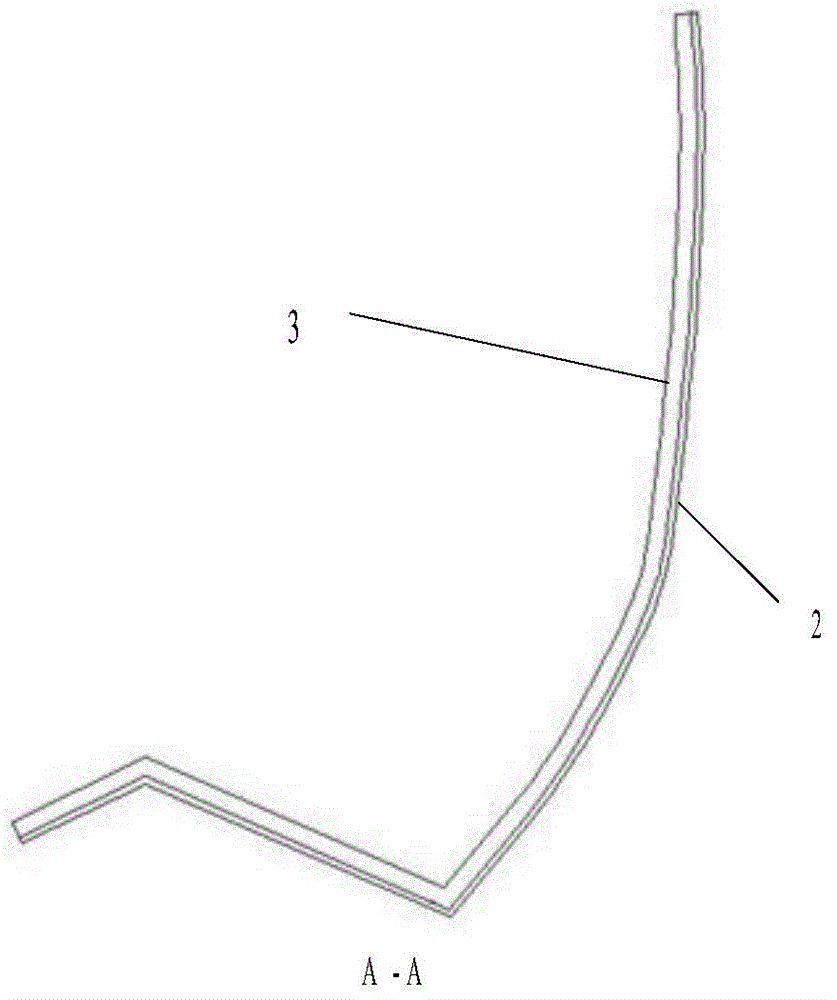

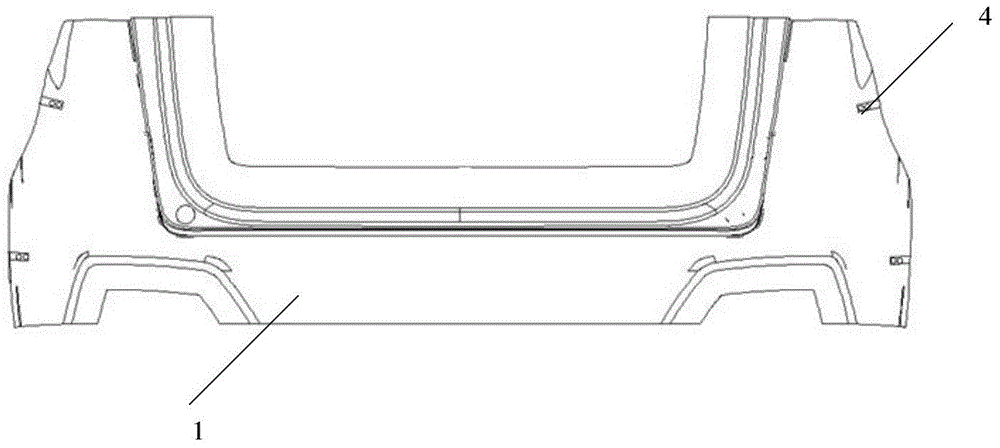

[0026] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

[0027] In the process of processing, the present invention adopts a plastic-absorbing production process, adopts a plastic-absorbing mold, and the material of the mold is epoxy resin. After the flat plastic sheet is heated and softened by the temperature control box, it is adsorbed on the surface of the mold by vacuum, and formed after cooling, as follows:

[0028] Step 1, select the vehicle coating product protective cover sheet, including two layers: the outer layer is a PP material layer, and the inner layer is a PE material layer;

[0029] Step 2: Use a blister mold, the mold material is epoxy resin, install the vehicle coating product protection cover sheet on the mold, preheat the temperature control box for the installation mold, and then use pliers and angle irons to protect the vehicle coating product Cover sheets are properly cl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com