Production process of smearing type automobile air conditioner compressor piston

A technology of automobile air conditioner and production process, which is applied to the coating, the device for coating liquid on the surface, etc., and can solve the problems of easy foaming of the sprayed coating, weak bonding force, and uneven spraying of the coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

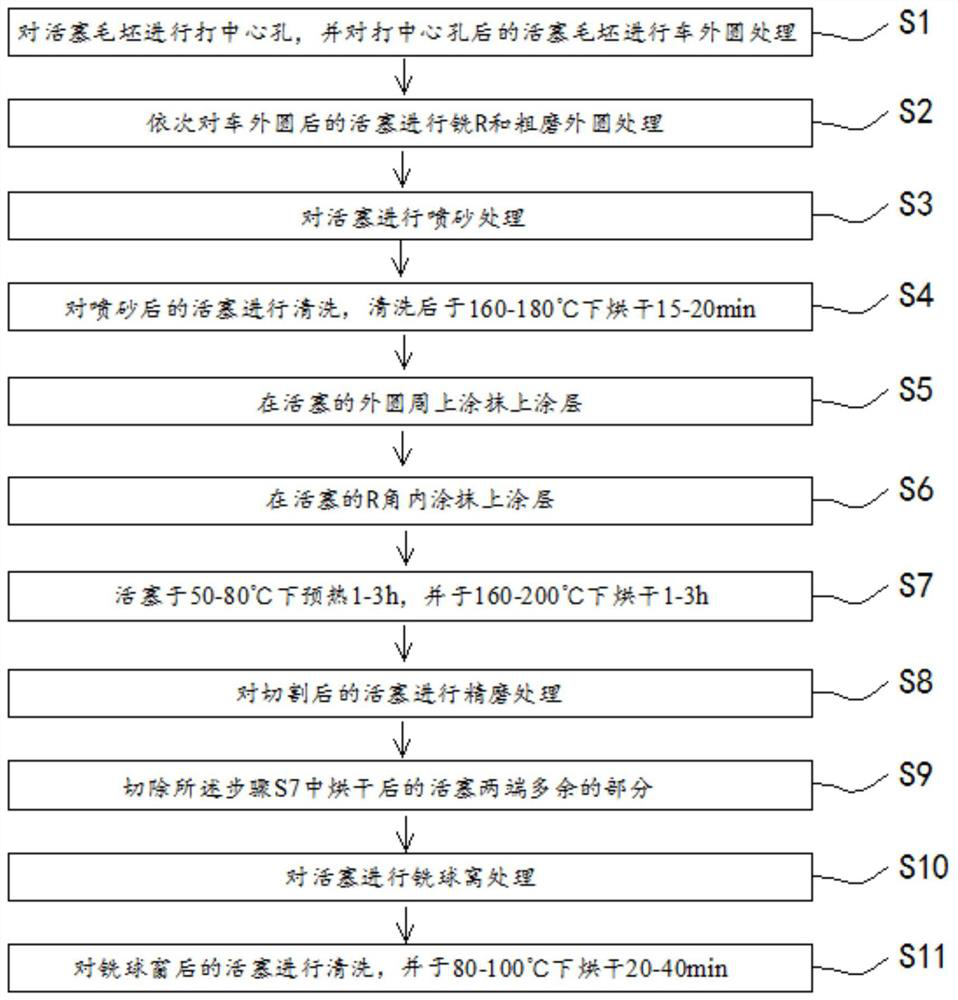

Image

Examples

Embodiment 1

[0036] On the basis of the above-mentioned scheme, in this embodiment, before the step S5, a step S1 is also included: punching a center hole on the piston blank, and performing a turning process on the piston blank after the center hole is punched; in addition, on the piston, The punched center hole is the thimble hole. During the processing, the blank on the surface of the piston can be removed through the above process for subsequent processing to ensure the quality of the piston processing.

[0037] Based on the above method, the specific steps of piston processing in the present embodiment are as follows:

[0038] S1: Punch the center hole on the piston blank, and perform the outer circle processing on the piston blank after the center hole is punched;

[0039] S5: Apply a coating liquid on the outer circumference of the piston to form a coating;

[0040] S6: Apply the coating solution in the R angle of the piston to form a coating.

Embodiment 2

[0044] On the basis of embodiment 1, in this embodiment, step S2 is also included between said step S1 and said step S5: milling R and rough grinding of the outer circle of the piston after turning the outer circle in turn; R means that the R angle is processed by milling at the corresponding position of the piston; the rough grinding outer circle treatment refers to grinding the piston to improve the accuracy of the piston size, thereby improving the qualified rate of the product. During the processing, the piston is further polished through the above process to further ensure the quality of the piston processing.

[0045] The above specific process of milling the R angle is as follows: using a suitable milling cutter to process the piston to process the corresponding R angle.

[0046] Based on the above method, the specific steps of piston processing in the present embodiment are as follows:

[0047] S1: Punch the center hole on the piston blank, and perform the outer circl...

Embodiment 3

[0054] On the basis of the above implementation methods, in this embodiment, a step S3 is further included between the step S1 and the step S5: sandblasting the piston. During the processing, the bonding force between the coating and the piston can be enhanced through the above-mentioned process, so as to prevent the coating from bubbling, prevent the coating from falling off, and ensure the quality of coating processing.

[0055] The above-mentioned sand blasting process refers to the process of cleaning and roughening the surface of the piston by the impact of high-speed sand flow. Compressed air is used as the power to form a high-speed jet beam to spray the spray material (copper ore, quartz sand, corundum, iron sand, Hainan sand) to the surface of the piston to be treated at a high speed, so that the appearance or shape of the outer surface of the piston surface changes. , due to the impact and cutting effect of the abrasive on the surface of the workpiece, the surface of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com