Slag system for heat treatment of desulfurization wastewater

A desulfurization wastewater and slag storage technology, which is applied in water/sewage treatment, water/sludge/sewage treatment, mixed material pretreatment, etc., can solve the problems that the residue treatment cannot reach a unified standard and the size of the residue is different

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

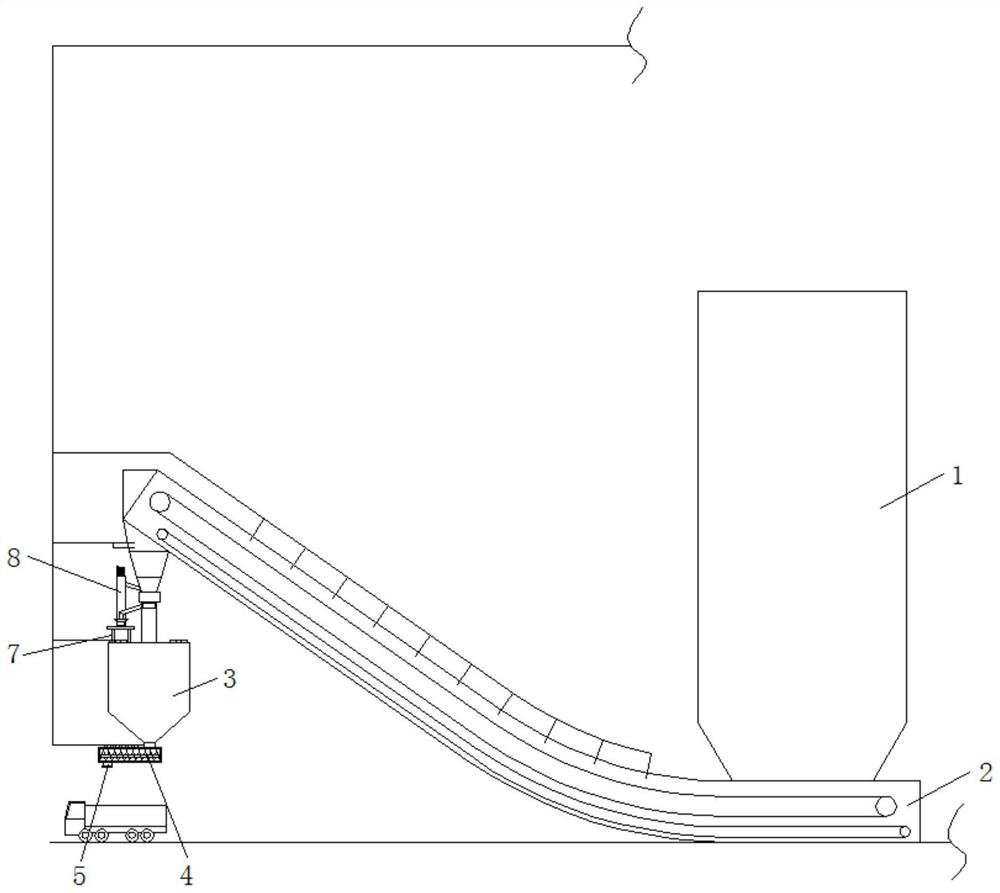

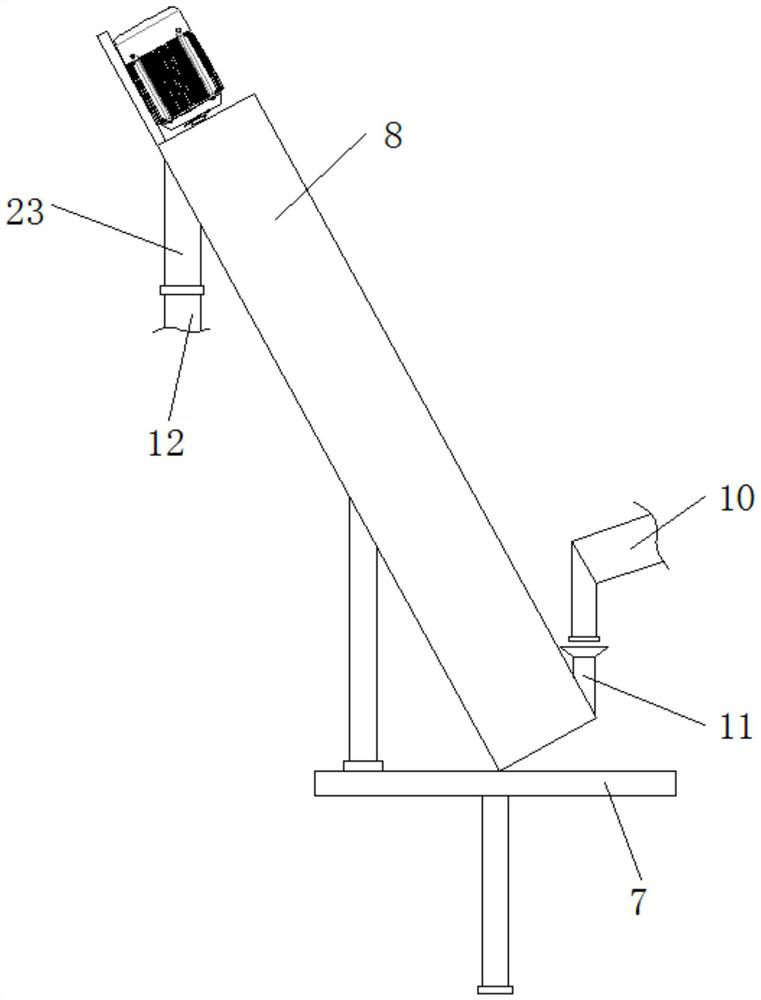

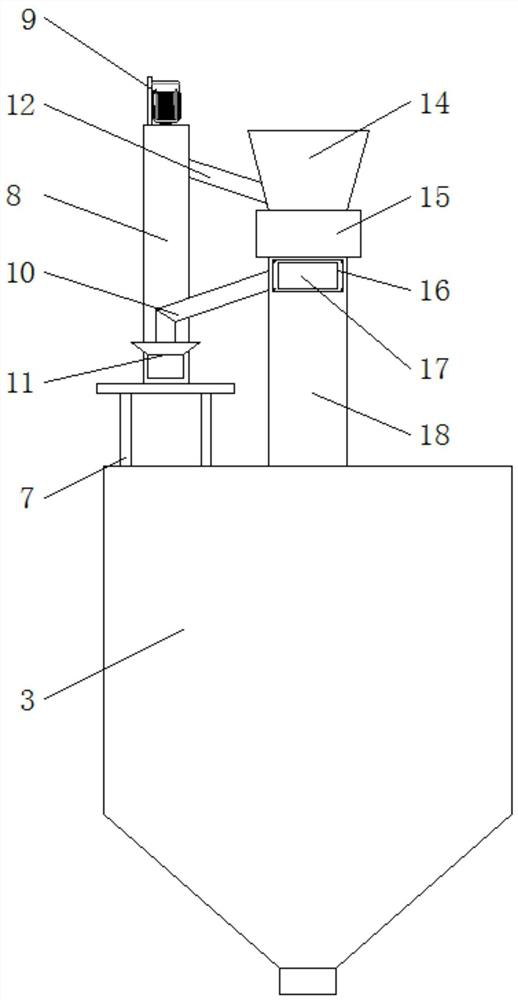

[0024] refer to Figure 1 to Figure 6 An embodiment of a slag system used for heat treatment of desulfurization wastewater in the present invention will be further described.

[0025] A slag system for heat treatment of desulfurization wastewater, see figure 1 and 3 , including a boiler 1, the bottom of the boiler 1 is connected to a slag crusher 15 through a first transmission mechanism, the bottom of the slag crusher 15 is connected to a slag storage bin 3 through a first connecting pipe 18, and a discharge outlet is provided below the slag storage bin 3 The inner cavity of the first connecting pipe 18 is provided with a filter component for filtering the residue, and the side of the first connecting pipe 18 is provided with a second transmission mechanism for transporting the residue above the filter component to the top of the slag crusher 15 . The residue is inside the boiler 1, and the residue inside the boiler 1 is transported to the inside of the slag crusher 15 thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com