Oscillator for screening superfine powder

A technology of oscillators and powders, which is applied in the fields of filtration, chemical instruments and methods, solid separation, etc., can solve the problems of narrow application range and ineffective improvement of screening accuracy, so as to improve output and service life, and increase flexibility in use The effect of increased resistance and load bearing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

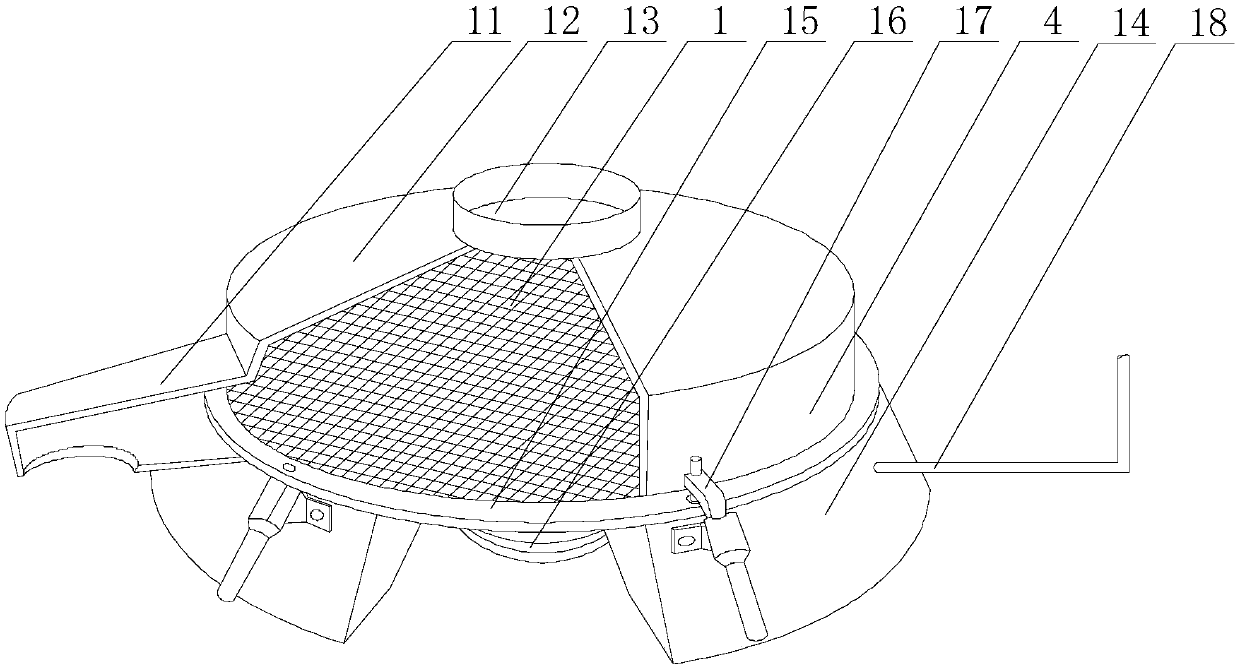

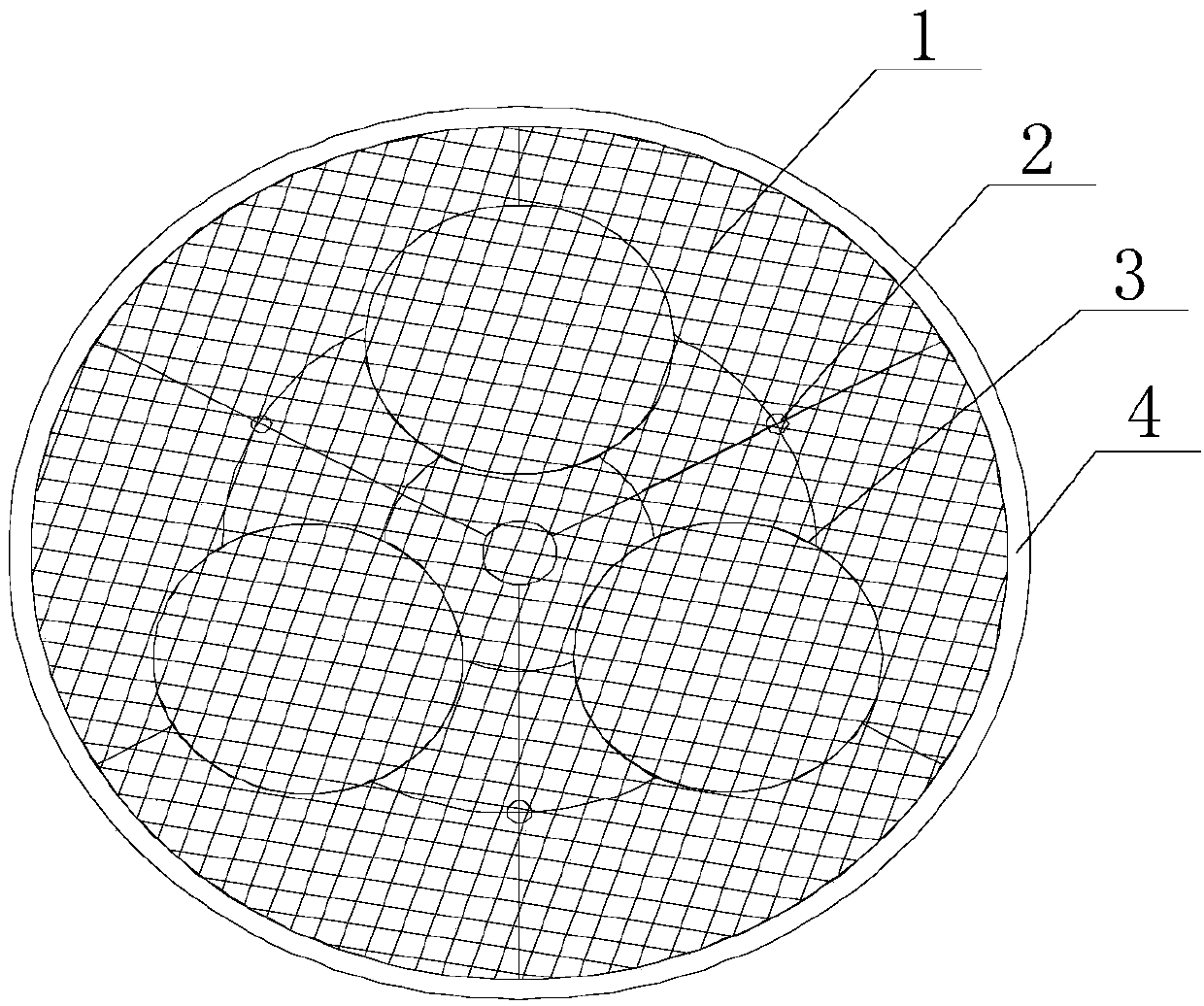

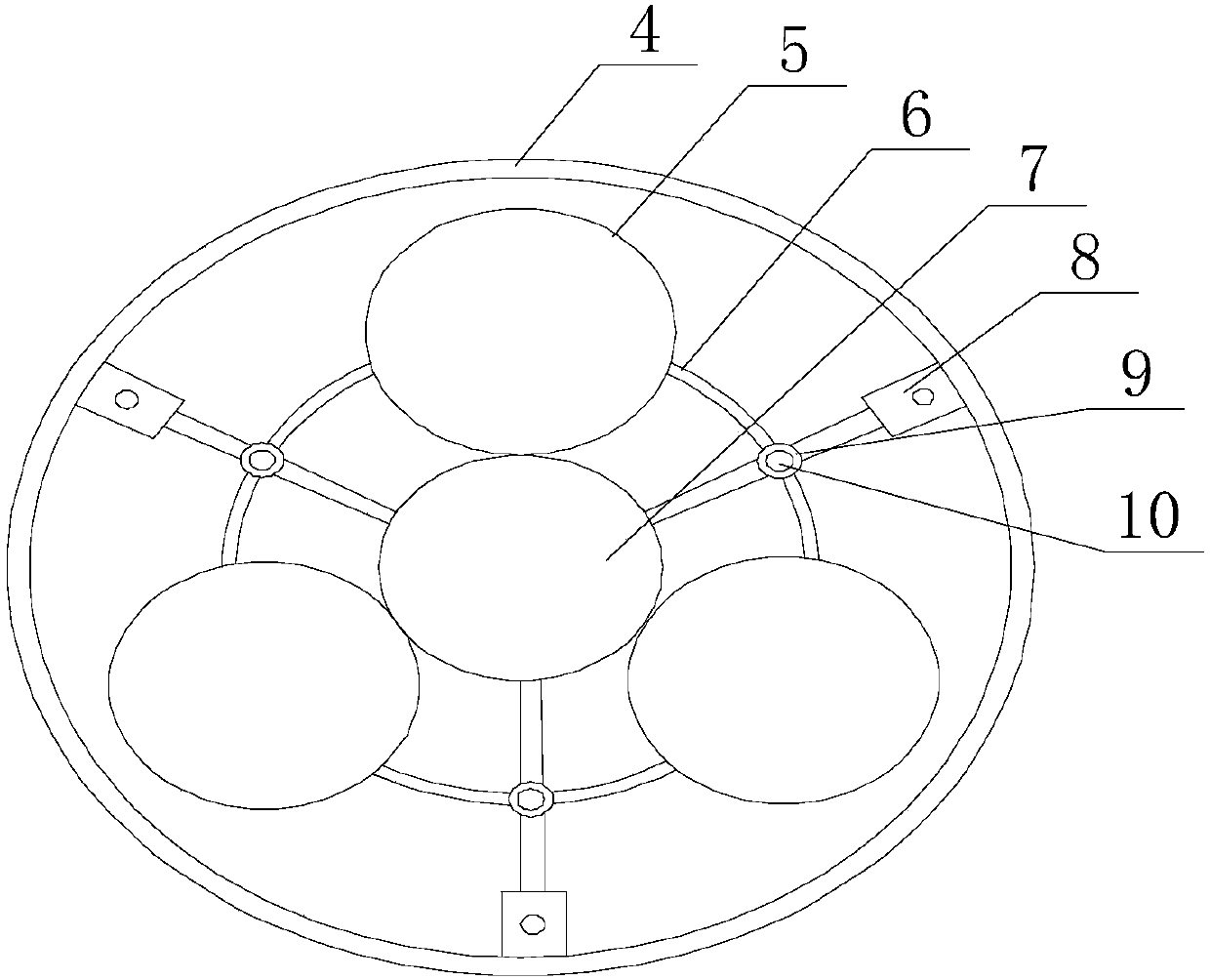

[0021] like Figure 1~3 As shown, this embodiment includes a base 14, a cover plate 12, a cylindrical screen frame 4 with open ends, a screen 1 arranged inside the screen frame 4 and having a diameter equal to the inner diameter of the screen frame 4, on the base 14 There is a groove on the end face, and a flange is provided on the outer wall along the outer circumference of the lower end face of the screen frame 4. The flange is connected with the base 14 through a buckle 17, and the screen 1 is directly above the groove. And the base 14 lower surface is provided with the secondary discharge pipe 16 that communicates with groove, is provided with primary discharge pipe 11 on the screen frame 4 side walls, and described top cover 12 seals the upper end opening of screen frame 4, and In the middle part of the top cover 12, a feed pipe 13 is provided, and a skeleton 3 placed under the screen 1 is also included. The skeleton 3 includes a reinforcement ring 7, three resonance ring...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com