Processing method of ultra-short slot of circuit board

A processing method and circuit board technology, applied in metal processing, printed circuit, printed circuit manufacturing, etc., can solve problems such as slot knife offset, slot knife force unevenness, ultra-short slot deformation, etc., to avoid slot holes Deformation and the effect of improving machining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The features of the present invention and other relevant features are described in further detail below through the embodiments, so as to facilitate the understanding of those skilled in the art:

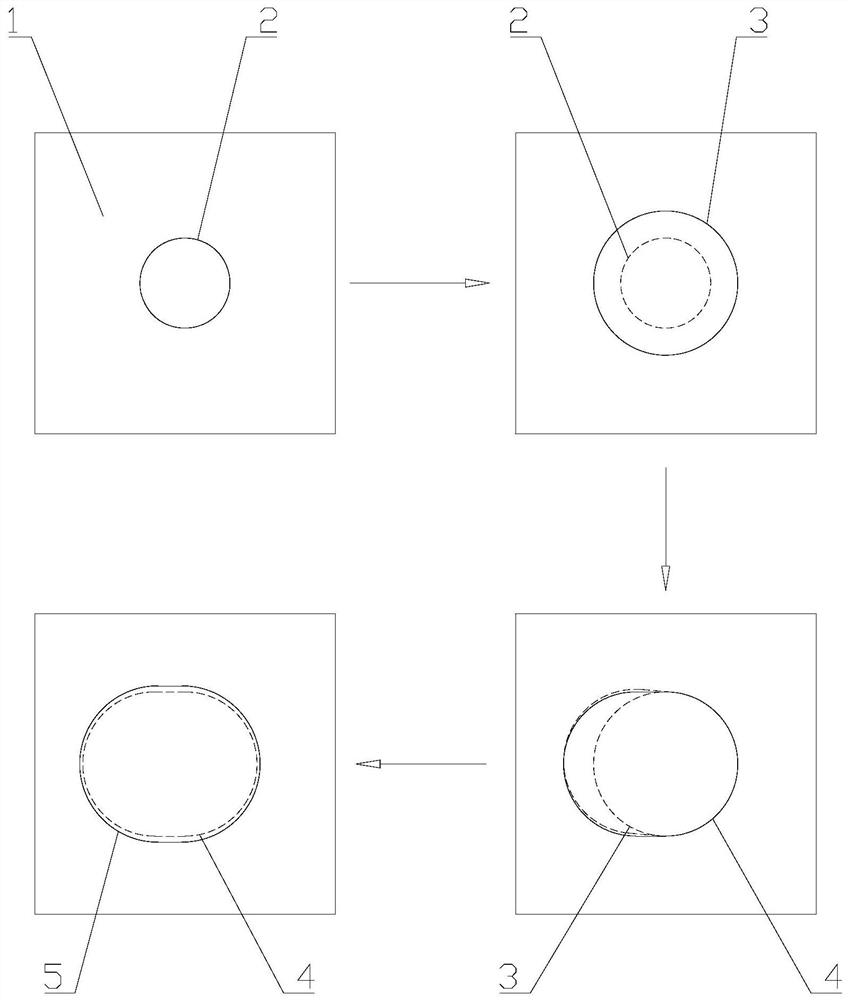

[0020] Such as figure 1 Shown, a kind of processing method of the ultra-short slot hole of circuit board, comprises the following steps:

[0021] Step 1: Use a pre-drilling knife to drill the lower hole 2 on the circuit board 1;

[0022] Step 2: use the end mill to align the center of the lower hole 2 and feed downward, and mill to form the first circular hole 3;

[0023] Step 3: use the end mill to carry out rough machining and milling with the center of the first round hole 3 as the starting point and feed outward along a straight line to form the second slot hole 4;

[0024] Step 4: Use a keyway milling cutter to finish and trim the edge of the second slot 4 to finally form the third slot 5 .

[0025] As mentioned above, the processing method of this case first uses the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com