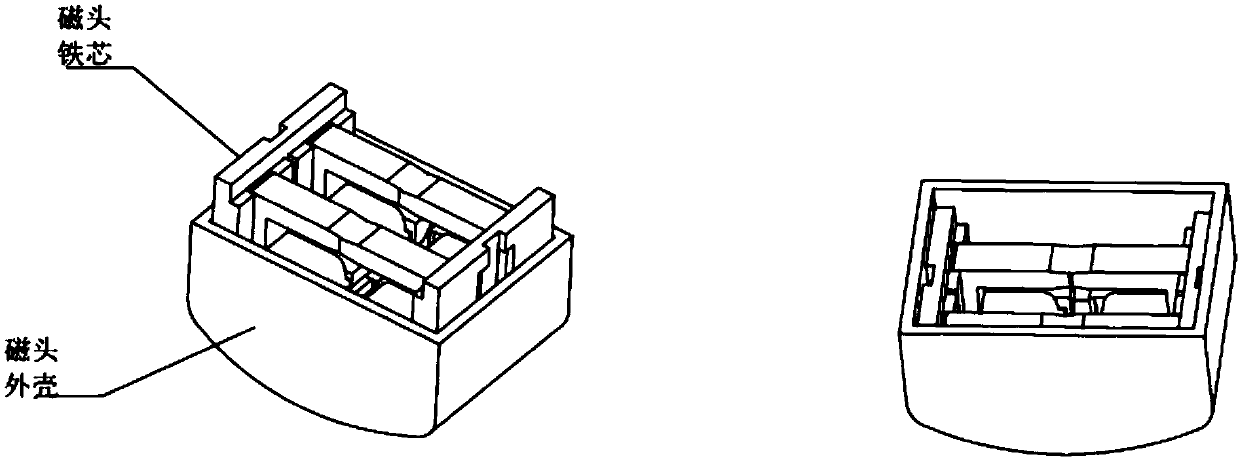

Magnetic head automatic into-shell shaping equipment

A magnetic head and equipment technology, applied in metal processing equipment, metal processing, manufacturing tools, etc., can solve the problems of easy punching of the fixture, causing injuries, poor product consistency, and high failure rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

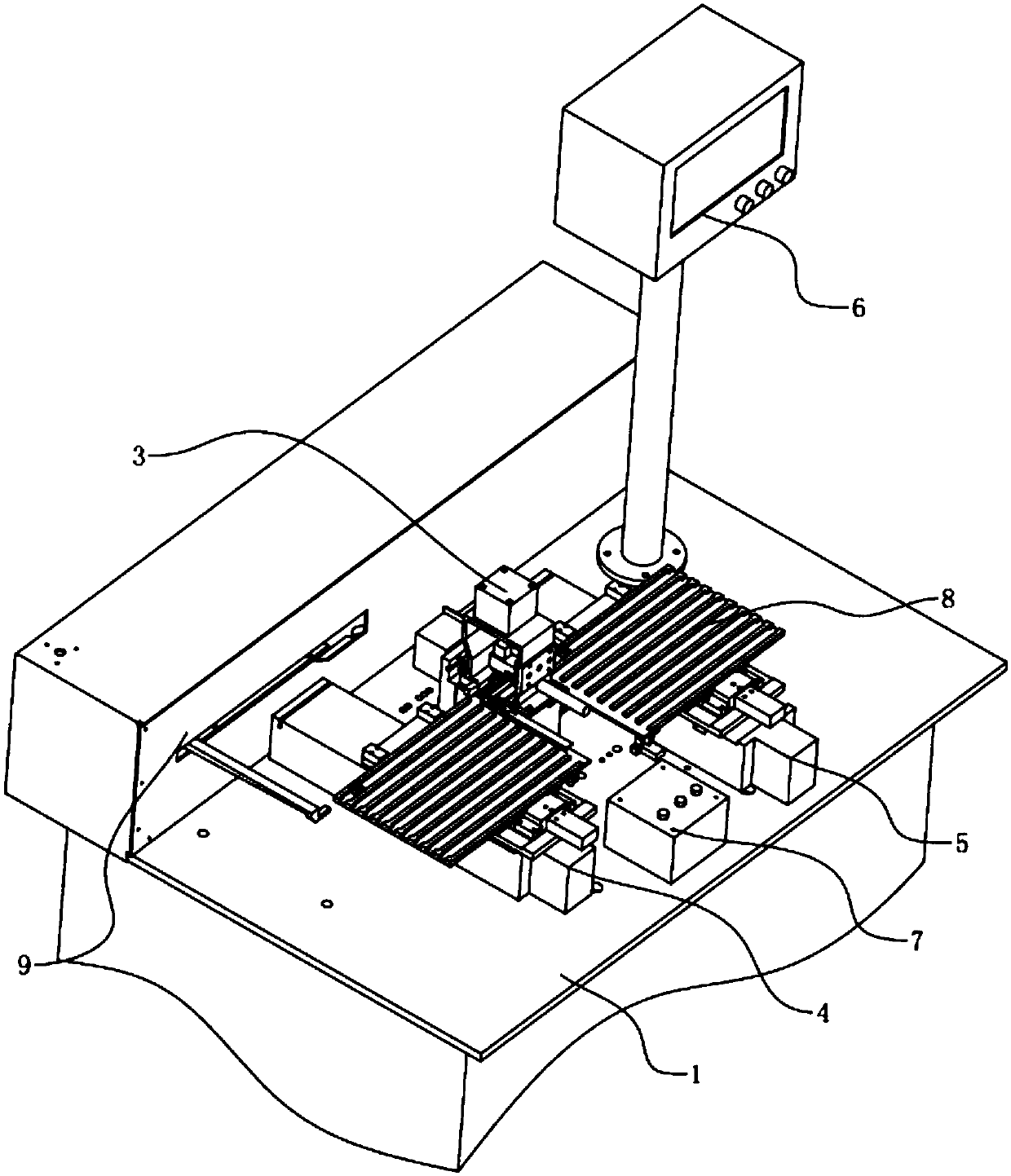

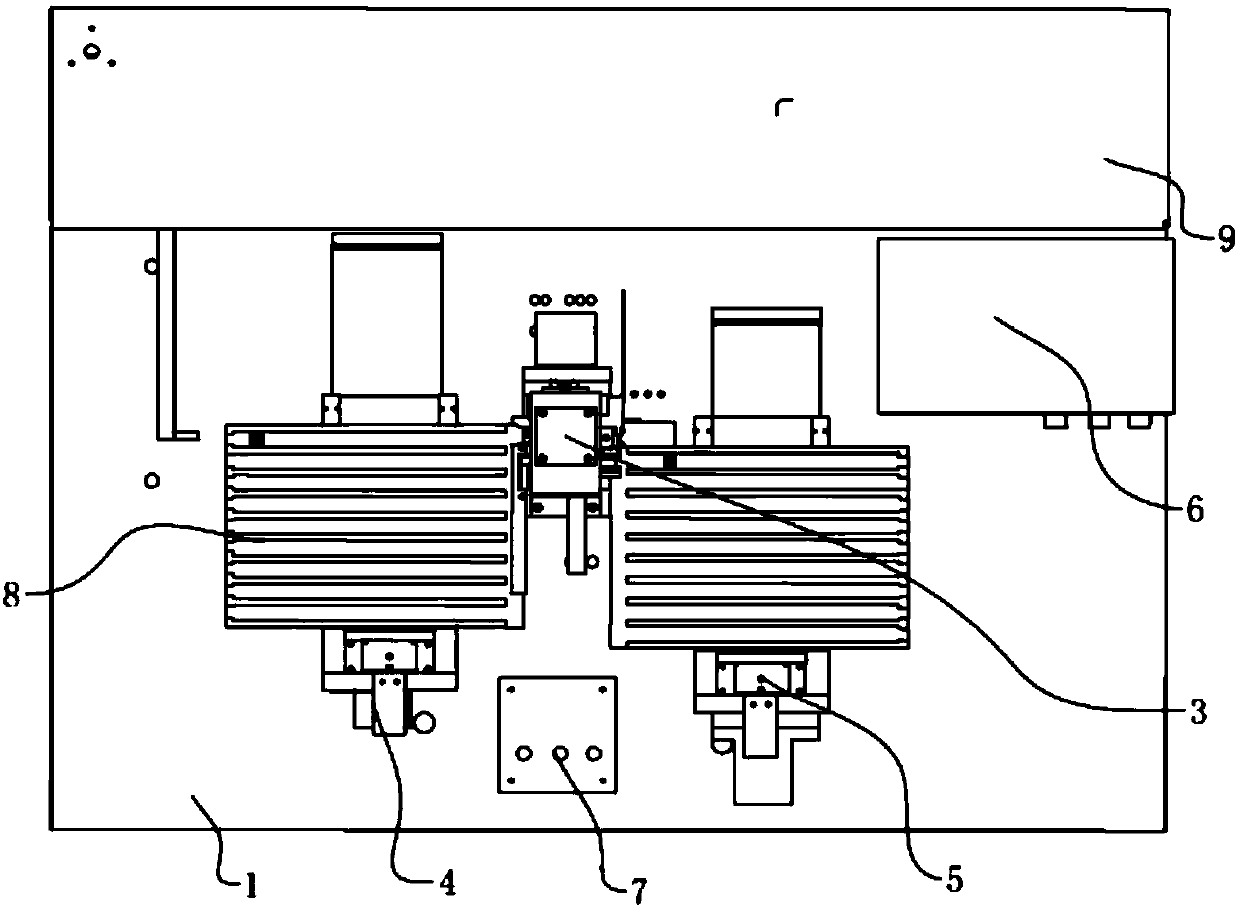

[0046]The technical solutions of the present invention will be further specifically described below through the embodiments and in conjunction with the accompanying drawings.

[0047] What needs to be explained in this embodiment is: since in this embodiment, both the feeding mobile slide 4 and the discharging mobile slide 5 contain components with the same structure and function, but in order to effectively distinguish them for a better understanding of the present invention Structure, in this embodiment, the writing in the feeding mobile slide table 4 is: slide table main body a41, servo motor a42, moving platform a43, positioning block a44, clamping cylinder a45, top plate a46; It is written as: sliding table main body b51, servo motor b52, moving platform b53, positioning block b54, clamping cylinder b55, and top plate b56.

[0048] In this embodiment, since the structure between the feeding moving slide 4 and the discharging moving sliding table 5 is the same, only the st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com