Free forging method for oversized overweight forging through 3-ton free forging hammer

A forging, free technology, used in forging/pressing/hammer devices, hammers, manufacturing tools, etc., can solve the problems of forgings radian cannot meet process requirements, bending cannot be performed, and deformation is not easy to control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

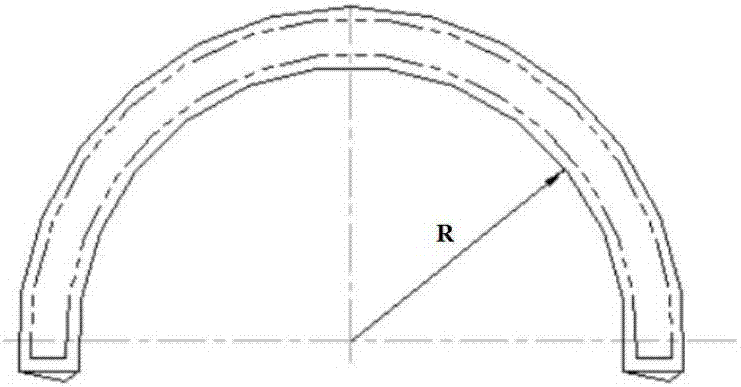

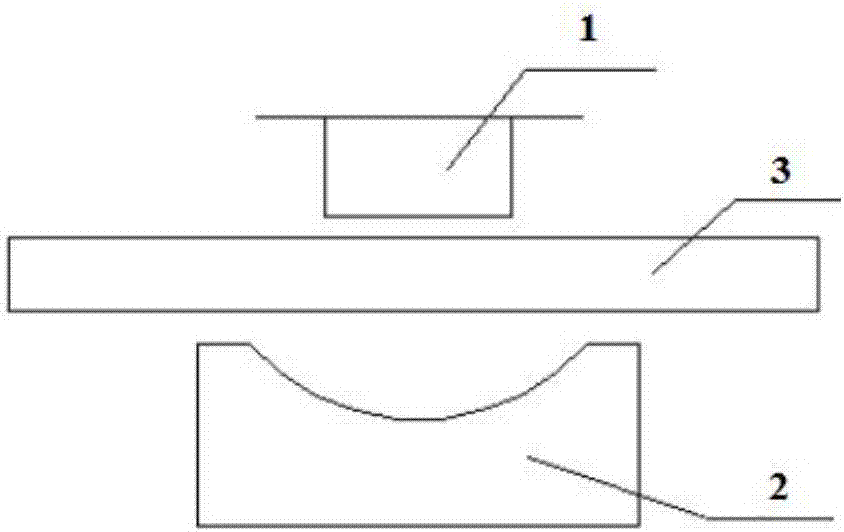

[0024] Specific implementation mode one: combine Figure 1 to Figure 7 , the present embodiment utilizes 3 tons of free forging hammers to realize the free forging method of super large and super heavy forgings, which is specifically completed according to the following steps:

[0025] 1. Draw the forging diagram and calculate the blank size:

[0026] According to the relevant requirements of the national standard GBT 21470-2008, draw the forging diagram of the partition body to obtain the forging diagram of the partition body. The radius of the forging of the partition body in the forging diagram of the partition body is R, and the thickness is H. Calculate blank size from forging diagram and actual deformation steps;

[0027] 2. Elongation: Prepare the round billet according to the billet size calculated in step 1, put the round billet into the furnace, and heat it to the initial forging temperature of 1200 ° C, and draw the round billet into a long strip at the forging tem...

specific Embodiment approach 2

[0037] Specific implementation mode two: combination Figure 1 to Figure 7 , The differences between this embodiment and the first embodiment are: the radius of the partition body forging in step one is R, R=700mm-800mm, and the thickness is H, H=230mm-250mm. Others are the same as the first embodiment.

specific Embodiment approach 3

[0038] Specific implementation mode three: combination Figure 1 to Figure 7 The difference between this embodiment and the first or second embodiment is that the mass of the round blank described in the second step is 700kg-850kg. Others are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com