Hot riveting method for TC4 titanium alloy pin

A hot riveting and titanium alloy technology, which is applied in the field of hot riveting of titanium alloy pins, can solve problems such as increasing the weight of the engine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

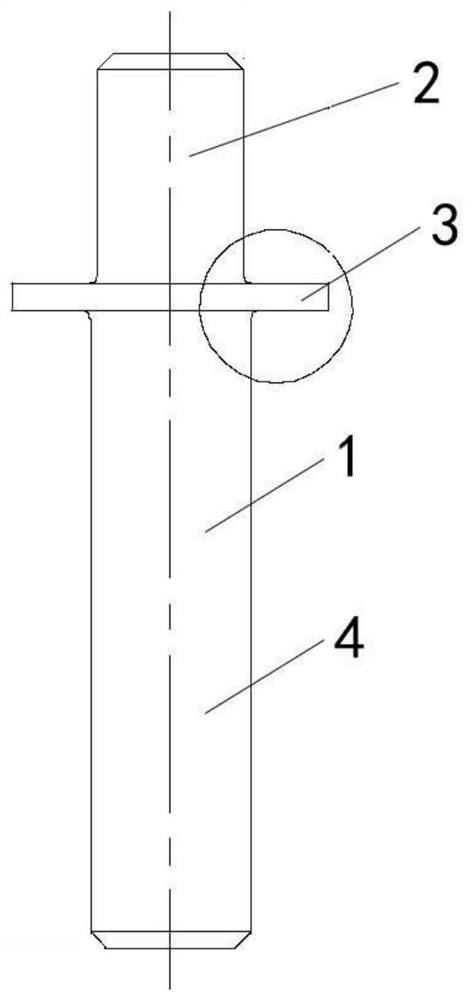

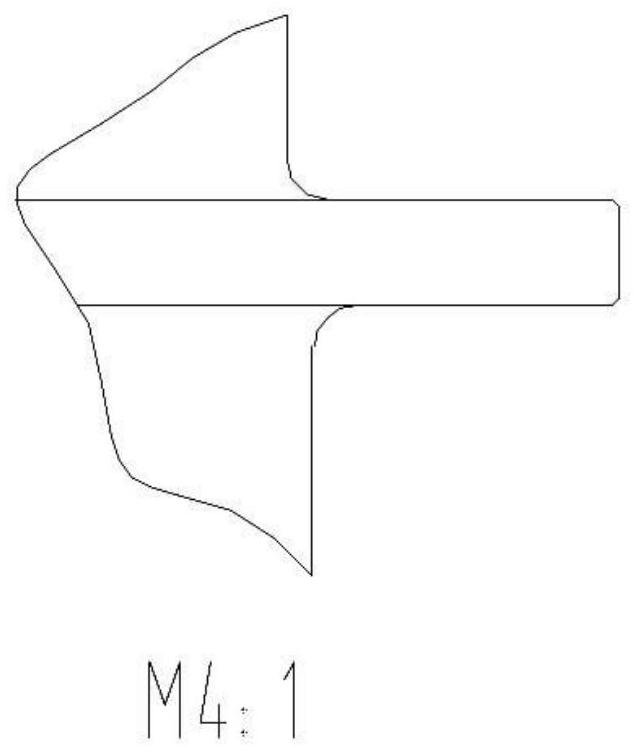

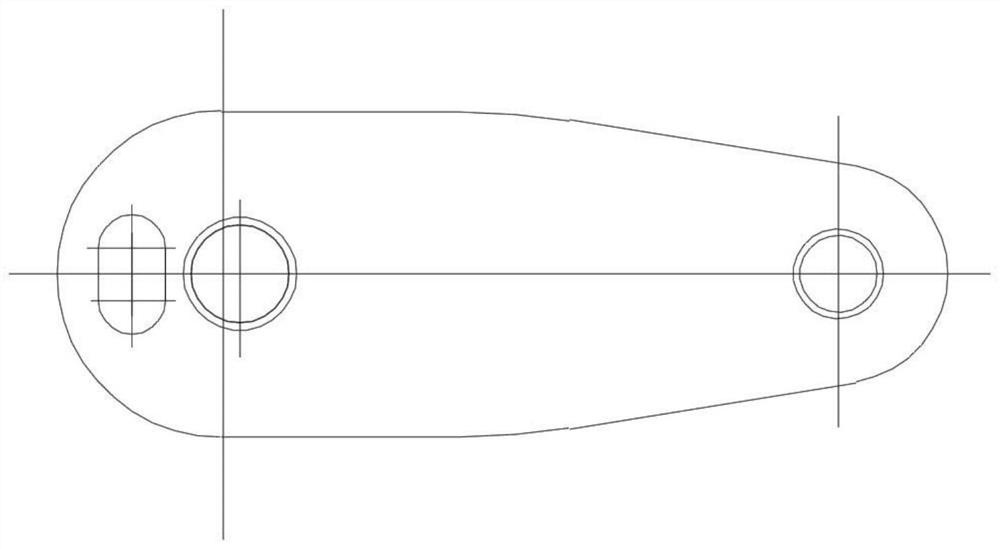

[0024] Hereinafter, specific embodiments of the present invention will be described in detail with reference to the accompanying drawings.

[0025] It can be understood that the numerical values mentioned in the present invention may have errors, and they can be varied within an appropriate range.

[0026] According to a specific embodiment of the present invention, the thermal riveting method of TC4 titanium alloy pins comprises the following steps: the first step: cleaning the plate-shaped parts to be riveted (or the parts to be riveted including the plate-shaped parts) and the pins to be riveted; Step 2: Install the plate-shaped part on the riveting tool and adjust the plate-shaped part. The riveting tool is composed of an upper electrode assembly and a lower electrode assembly; Step 3: Use the lower electrode clamping device to clamp the pin , control the heating current, heating time, and riveting pressure of the projection welding machine to rivet the parts, loosen the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com