Centering roller ball base surface size measuring device

A measuring device and self-aligning roller technology, applied in the direction of measuring device, mechanical measuring device, using mechanical device, etc., can solve the problems of difficult size, unsuitable size deviation, and high requirements for workers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

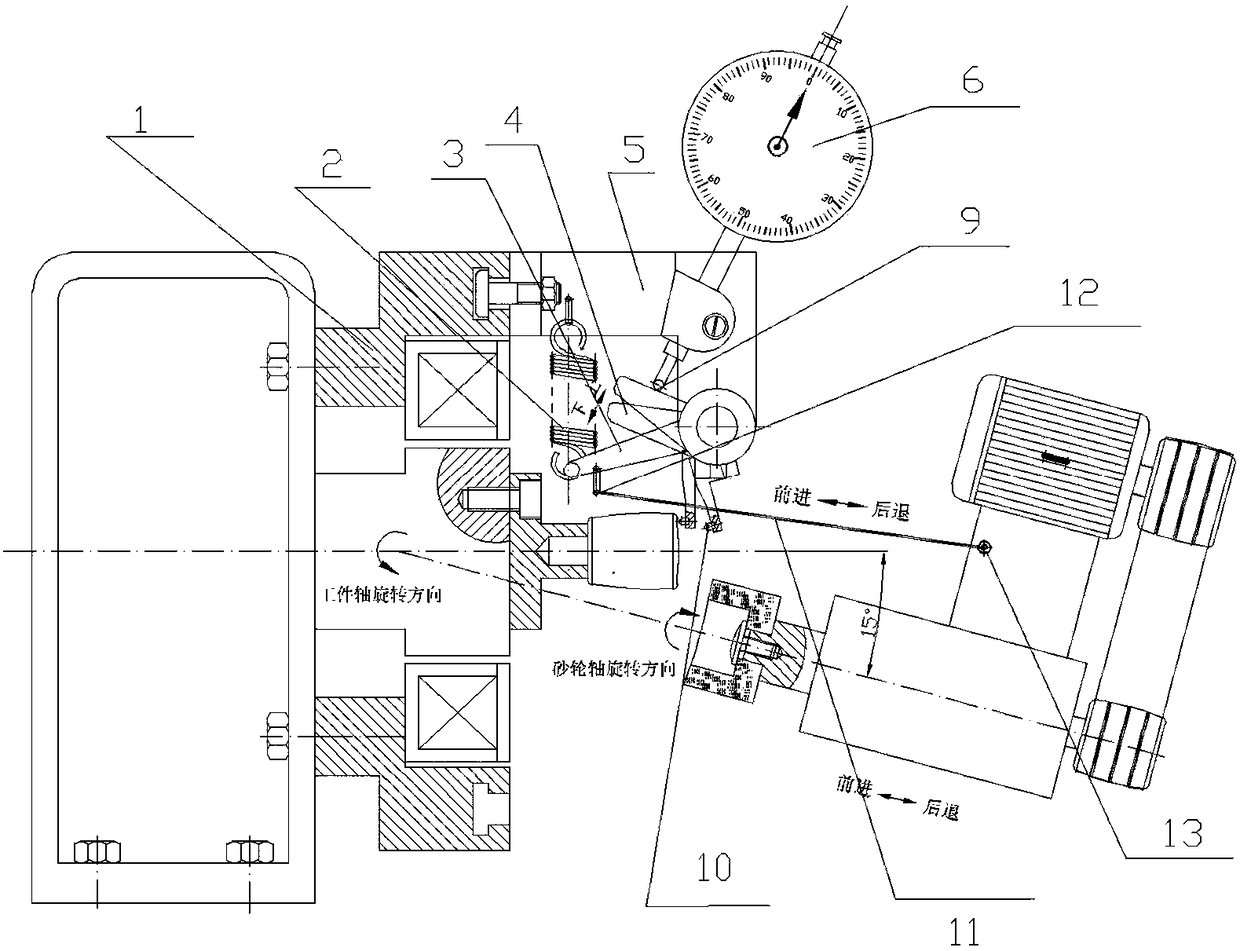

[0012] The present invention is further explained in conjunction with accompanying drawings, as figure 1 As shown in the self-aligning roller ball base surface size measuring device, a card body 1 is arranged above the grinding wheel shaft box, and one end of the card body 1 is fixedly connected with the end of the fixing seat 5 by screws, and the fixing seat 5 is in the shape of " L" type, a dial indicator 6 is fixed at the 90-degree corner position of the fixing seat 5, and a first measuring head 9 is fixed at the lower end of the dial indicator 6, and at the end connecting the fixing seat 5 and the card body 1, a A spring 2, with hooks at both ends of the spring 2, the spring 2 is placed vertically, and the upper end of the spring 2 is fixed on the holder 5 through the hook; the other end of the holder 5 is equipped with a measuring rod 4, a swing rod 3 and A second measuring head 10, the measuring rod 4, the swing rod 3 and one end of the second measuring head 10 are fixed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com