Humanoid robot palm structure

A humanoid robot and palm technology, applied in the field of robotics, can solve the problems of long and thick palms

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

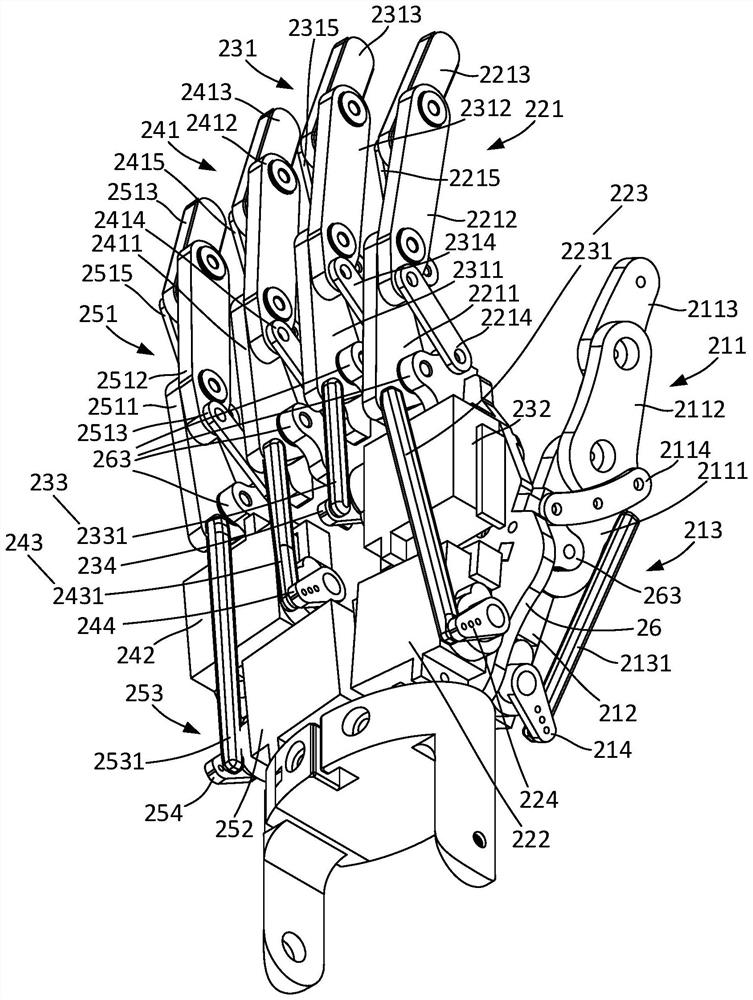

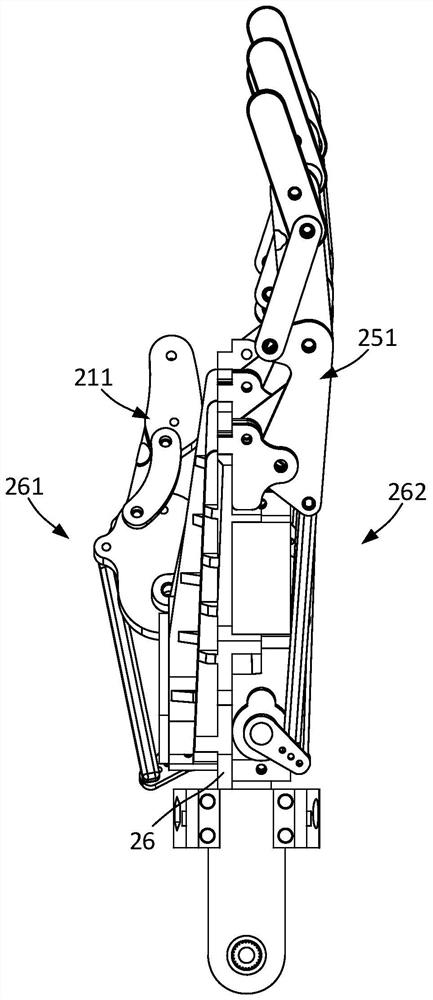

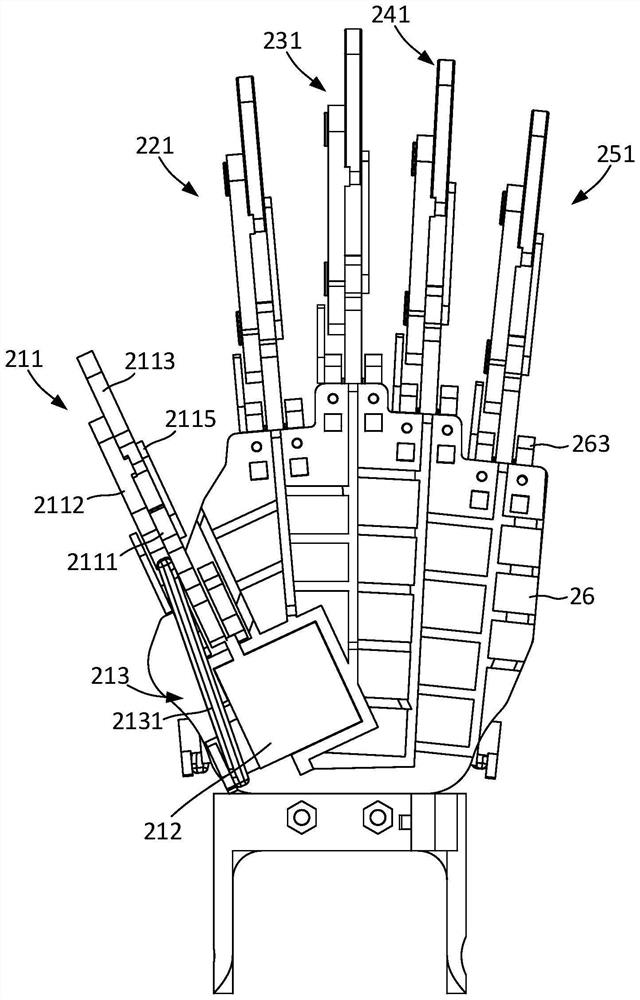

[0049] The present invention will be further described below with reference to the accompanying drawings and specific embodiments.

[0050] see figure 1 The present invention provides a humanoid robot palm structure, which is used to solve the problem that the existing steering gear cooperates with the connecting rod to drive the fingers to stretch and bend. Because of the arrangement that is perpendicular to the palm and parallel to the fingers, the thickness of the palm is higher than normal. The human palm is thicker, looks fatter, and is not in harmony with the humanoid robot arm; it is also used to solve the palm drive structure of the motor with the connecting rod, because the output direction of the motor is parallel to the direction of the fingers, and the fingers form a With different angles of opening, the motor distribution is also adjusted in direction, which leads to the problem of larger palm size. The palm structure of the present invention reasonably arranges ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com