Embolism microsphere based on soluble starch as well as preparation and application of embolism microsphere

A soluble, starch technology, applied in the application, non-active ingredient medical preparations, medical preparations containing active ingredients, etc., can solve the problems of small specific surface area, limited drug loading and encapsulation rate, etc., to achieve the preparation method. Simple, good application prospect, the effect of wide application prospect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

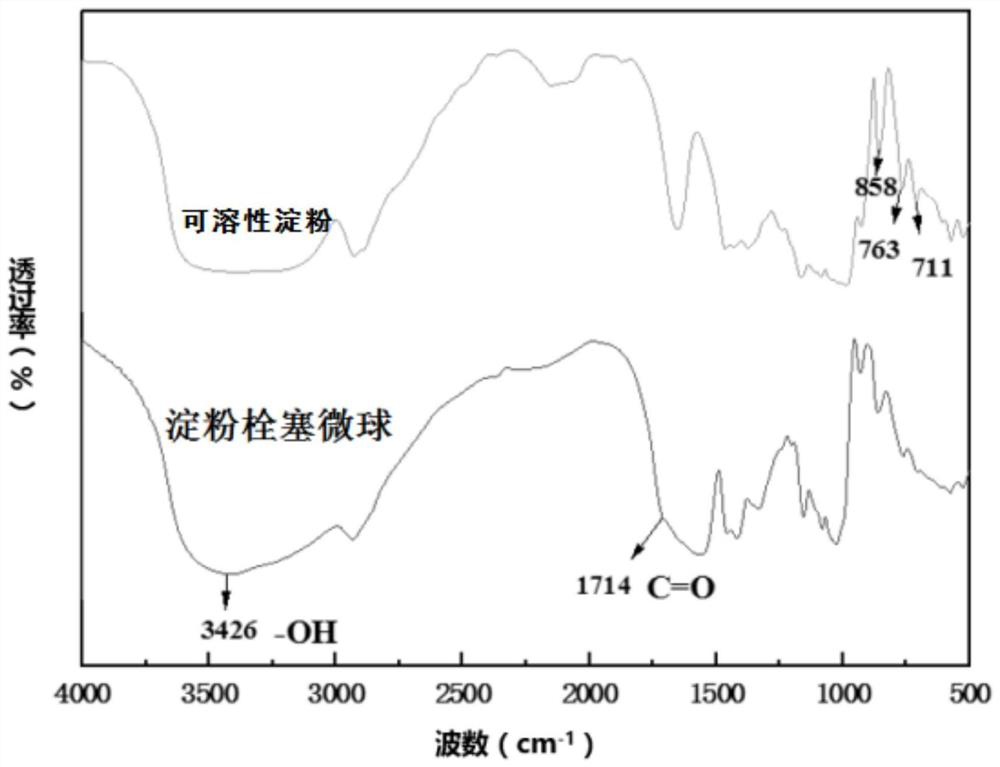

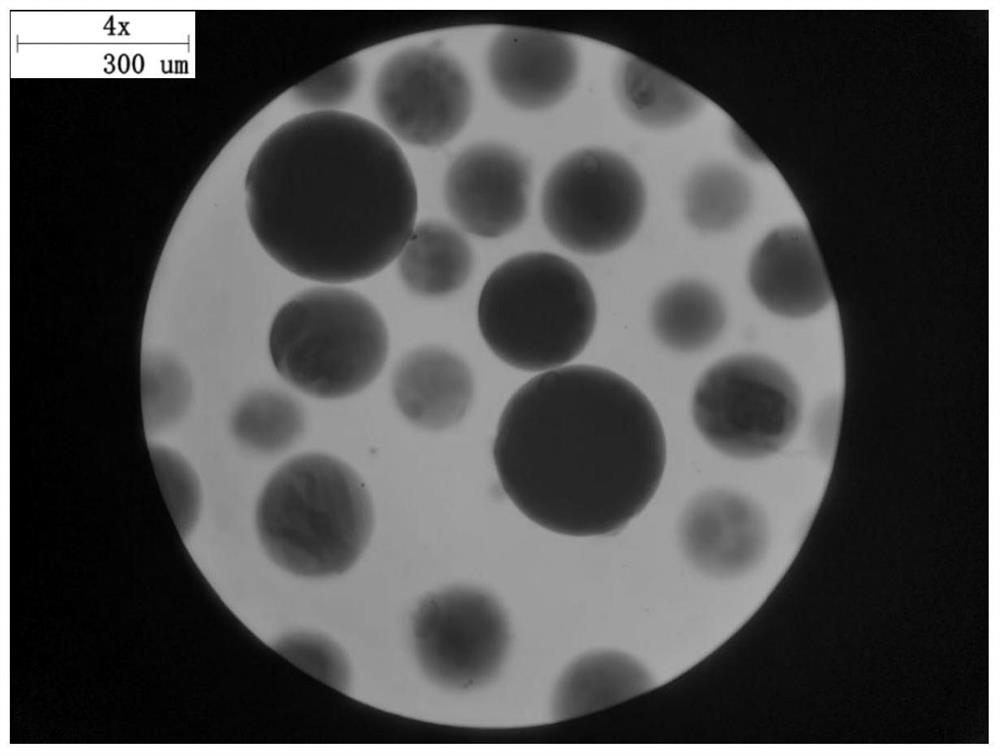

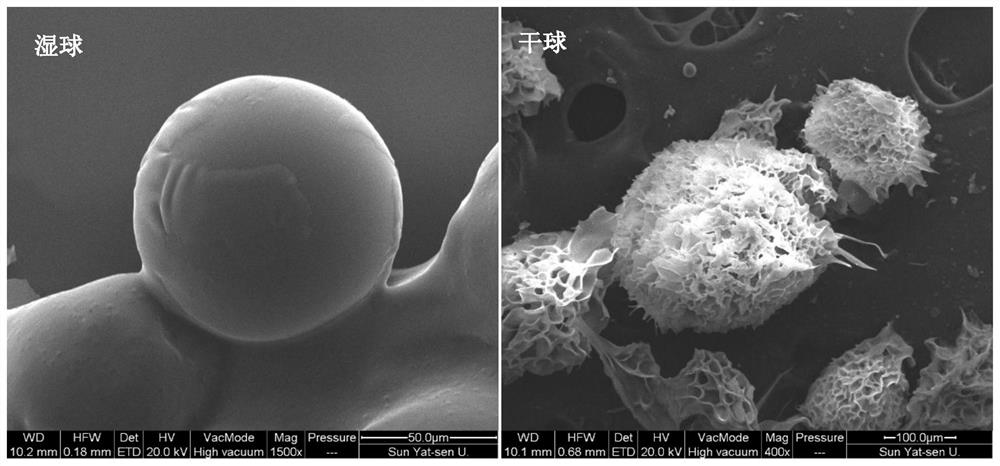

[0048] Embodiment 1 A kind of preparation of embolic microspheres based on soluble starch

[0049] 1. Preparation of embolization microspheres

[0050] S1. Dissolve 2g of soluble tapioca starch in 20mL of water, then add 500 μL of 0.2mol / L sodium hydroxide aqueous solution to mix and dissolve, to obtain a soluble tapioca starch solution;

[0051] S2. Stir and mix acrylic acid, ammonium persulfate, N,N'methylenebisacrylamide with the soluble tapioca starch solution obtained in step S1 to obtain a dispersed phase; (soluble tapioca starch: acrylic acid, ammonium persulfate, N,N' The mass ratio of methacrylamide satisfies 10:10:0.2:0.1);

[0052] S3. After mixing n-hexane and Span 80, heat it to 85°C, and the stirring speed is 300r / min to obtain a continuous phase; (the mass ratio of soluble tapioca starch, n-hexane and Span 80 satisfies 1:15:0.4);

[0053] S4. Add the dispersed phase obtained in step S2 to the continuous phase obtained in step S3, continue heating at 85°C, and st...

Embodiment 2

[0059] Embodiment 2 A kind of preparation of embolic microspheres based on soluble starch

[0060] S1. Dissolve 2 g of soluble potato starch in 20 mL of water, and then add 500 μL of 0.2 mol / L sodium hydroxide aqueous solution to mix and dissolve to obtain a soluble potato starch solution;

[0061] S2. methacrylic acid, sodium persulfate, sodium trimetaphosphate are stirred and mixed with step S1 gained soluble potato starch solution, obtain dispersed phase; (the mass ratio of soluble potato starch, methacrylic acid, sodium persulfate and sodium trimetaphosphate is 10:5:0.3:0.2);

[0062] S3. After mixing the liquid paraffin and Span 60, heat it to 85°C, and the stirring speed is 300r / min to obtain a continuous phase; (the mass ratio of soluble potato starch, liquid paraffin and Span 60 satisfies 1:20:0.5);

[0063] S4. Add the dispersed phase obtained in step S2 to the continuous phase obtained in step S3, continue heating at 85°C, and stir at a speed of 300r / min. After 1h, ...

Embodiment 3

[0064] Example 3 A preparation method of embolic microspheres based on soluble starch

[0065] S1. Dissolve 2g of soluble cornstarch in 20mL of water, then add 500μL of 0.2mol / L sodium hydroxide aqueous solution to mix and dissolve to obtain a soluble cornstarch solution;

[0066] S2. acrylic acid, potassium persulfate, sodium trimetaphosphate are mixed with step S1 gained soluble cornstarch solution to obtain a dispersed phase; (the mass ratio of soluble cornstarch, acrylic acid, potassium persulfate and sodium trimetaphosphate is 10:10 :0.1:0.1);

[0067] S3. After mixing kerosene and Span 80, heat to 90°C, and the stirring speed is 200r / min to obtain a continuous phase; (the mass ratio of soluble cornstarch, kerosene and Span 80 satisfies 1:10:0.02);

[0068] S4. Add the dispersed phase obtained in step S2 to the continuous phase obtained in step S3, continue heating at 85°C, and stir at a speed of 300r / min. After 1h, let stand to separate and wash the remaining oil on the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com