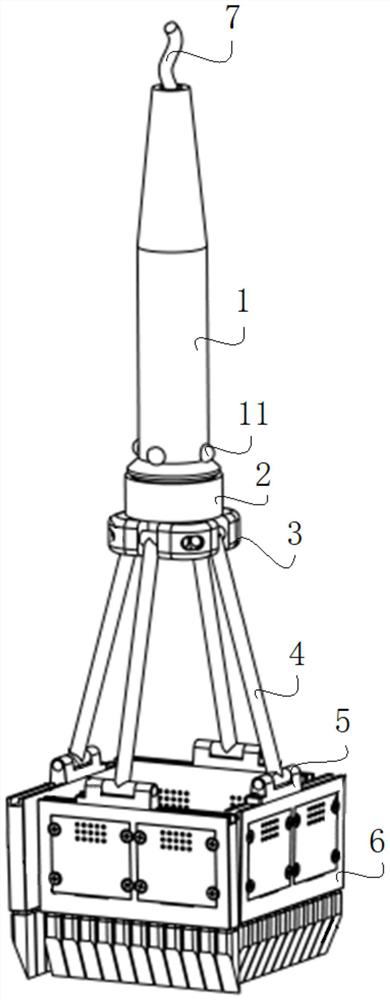

Special electric soldering iron device for disassembling electronic components

A technology of electronic components and electric soldering irons, which is applied in the direction of soldering irons, soldering positions, metal processing equipment, etc., can solve problems such as troublesome disassembly, affecting circuit reliability, and damaging solder pads of electronic components, so as to achieve easy identification and improve eye-catching , the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

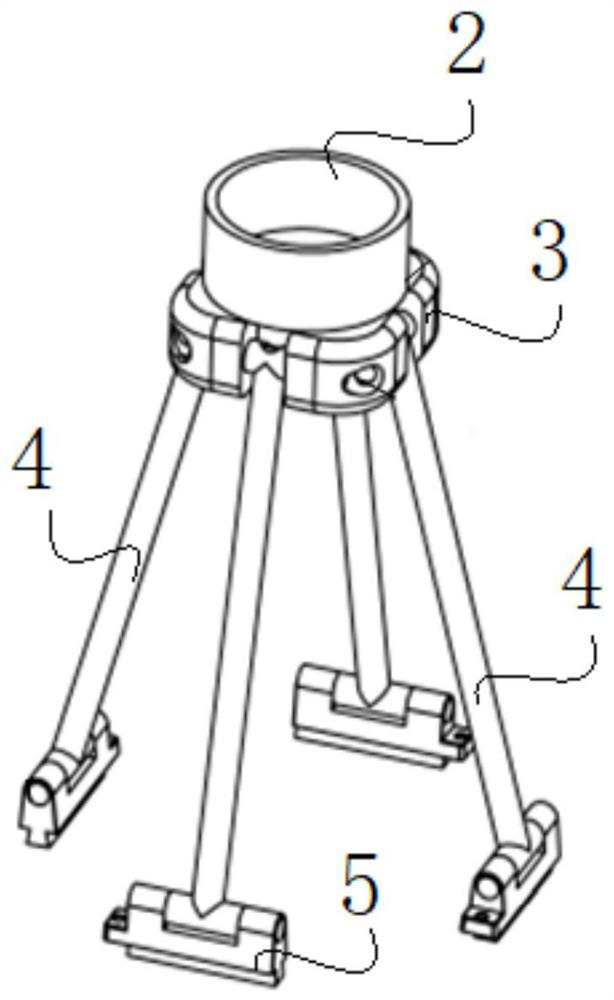

[0065] Such as Figure 9 As shown, to remove the electronic components 8 to be disassembled, only one of the four sets of heating unit assemblies 6 can be used. Only keep the group of heating unit components 6 without lifting them up, and adjust the number of soldering iron tips 61 on the group of heating unit components 6 to suit the overall size of the 8 pins of the electronic components to be disassembled. Power on the device, keep the power switches corresponding to the remaining three groups of heating unit components 6 off, turn on the power switch of the selected heating unit component 6, and disassemble the electronic components 8 to be disassembled after the temperature rises to the required temperature.

[0066] Finally, as time goes by, after the present invention is used, ensure that the four power switches are in the off state, unplug the plug, and after the electric soldering iron device cools down, it is cleaned up, and finally it is put into the storage room fo...

Embodiment 2

[0068] Such as Figure 10 As shown, to remove the electronic components 8 to be disassembled, only two groups of the four groups of heating unit assemblies 6 need to be used, that is, two groups of heating unit assemblies 6 facing left and right or two groups of heating unit assemblies 6 facing up and down, so as to use Two sets of heating unit assemblies 6 facing up and down are taken as an example. When in use, the two sets of heating unit assemblies 6 facing left and right are lifted by the corresponding adjustment connecting rod 4, and only the two sets of heating unit assemblies 6 facing up and down are kept. According to the overall size of the pins of the electronic components 8 to be disassembled, adjust the distance between the upper and lower relative two sets of heating unit assemblies 6 and the number of soldering iron tips. The corresponding power switches, the power switches connected to the two groups of heating unit assemblies 6 facing each other on the left an...

Embodiment 3

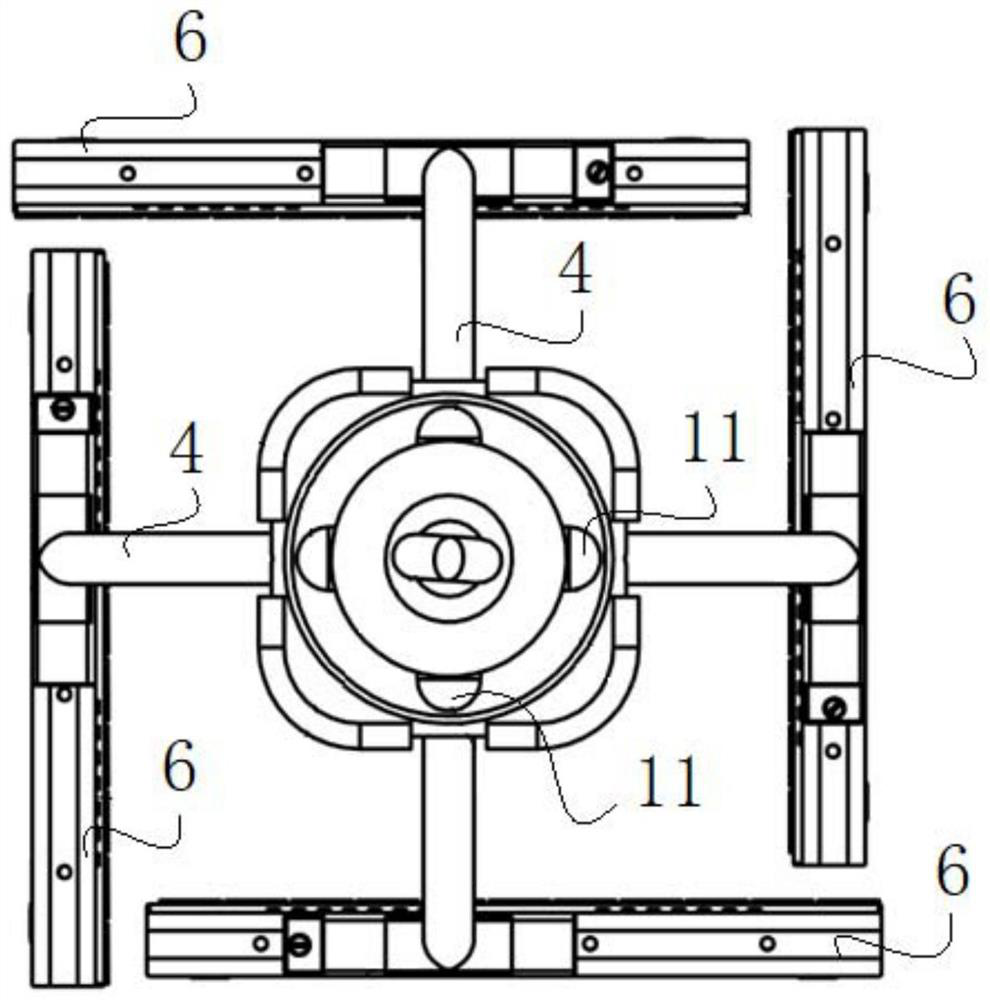

[0071] Such as Figure 11 As shown, removing the electronic components 8 to be disassembled needs to use four sets of heating unit assemblies 6 at the same time. The distance between the group of heating unit components 6 and the two groups of heating unit components 6 facing up and down and the number of soldering iron tips are consistent with the overall size of the 8 pins of the electronic components to be disassembled. After the adjustment and comparison are completed, power on the electric soldering iron device , turn on the power switches corresponding to the four groups of heating unit components 6, and disassemble the electronic components 8 to be disassembled after the temperature rises to the required temperature.

[0072] Finally, as time goes by, after the present invention is used, ensure that the four power switches are in the off state, unplug the plug, and after the electric soldering iron device cools down, it is cleaned up, and finally it is put into the stor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com