Means for securing jaw plates in a jaw crusher

A technology of jaw crusher and fastening device, which is applied in the direction of grain processing, etc., can solve the problems of crushing, being trapped in the exposed orifice of the through hole on the surface of the clamping rod or the jaw template, and achieving improved wear resistance performance, extended accessibility, improved fastening/clamping ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

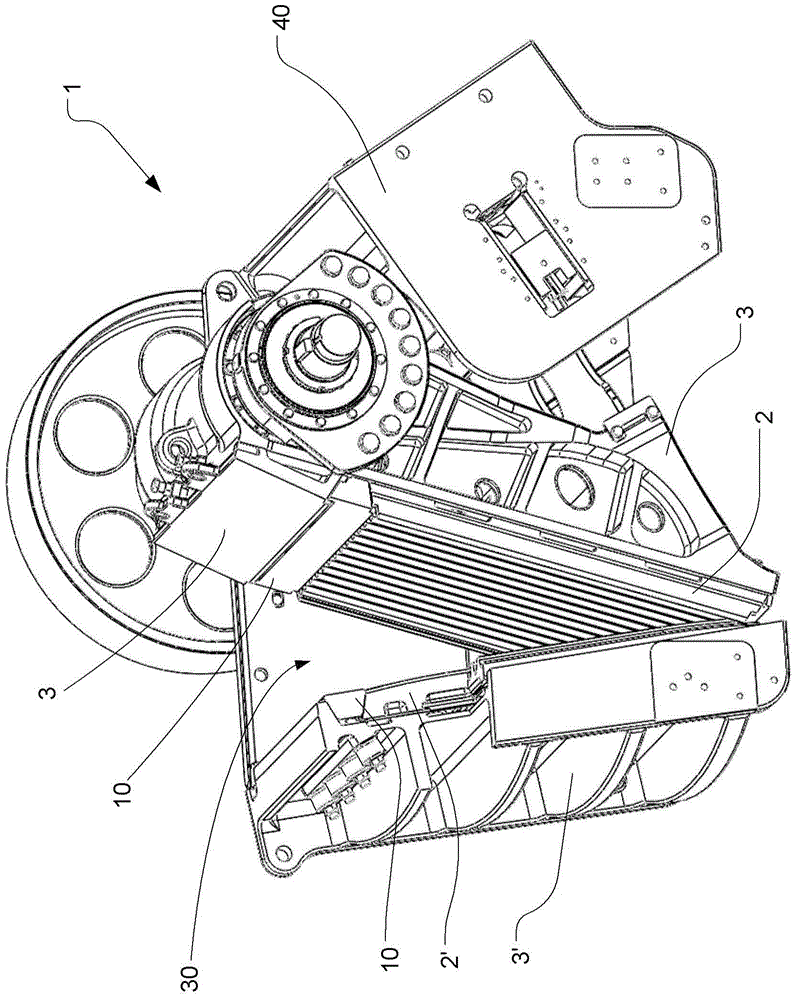

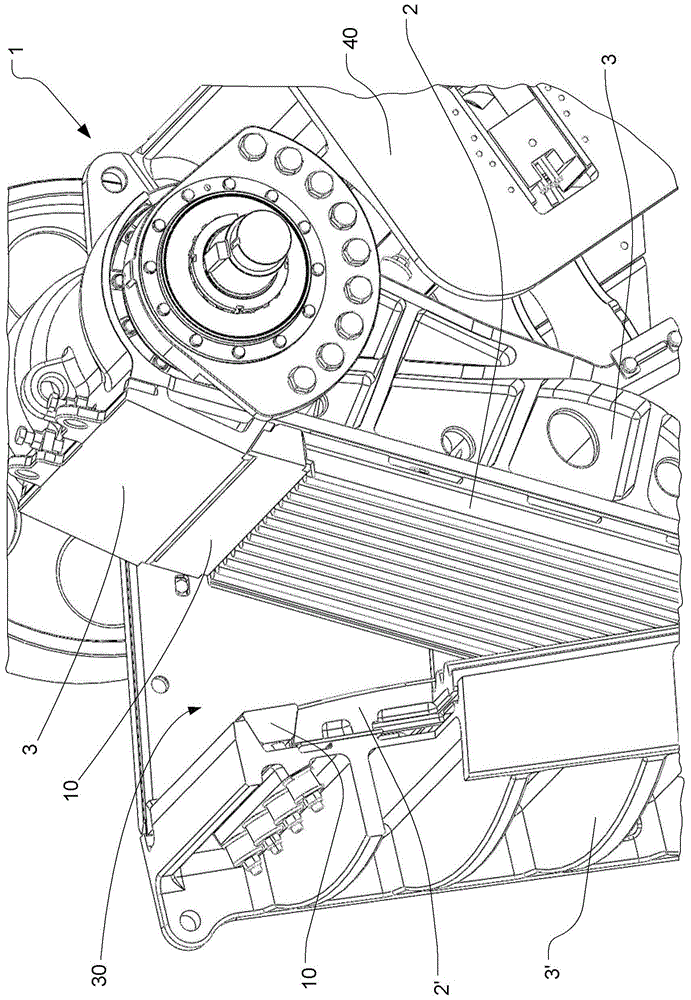

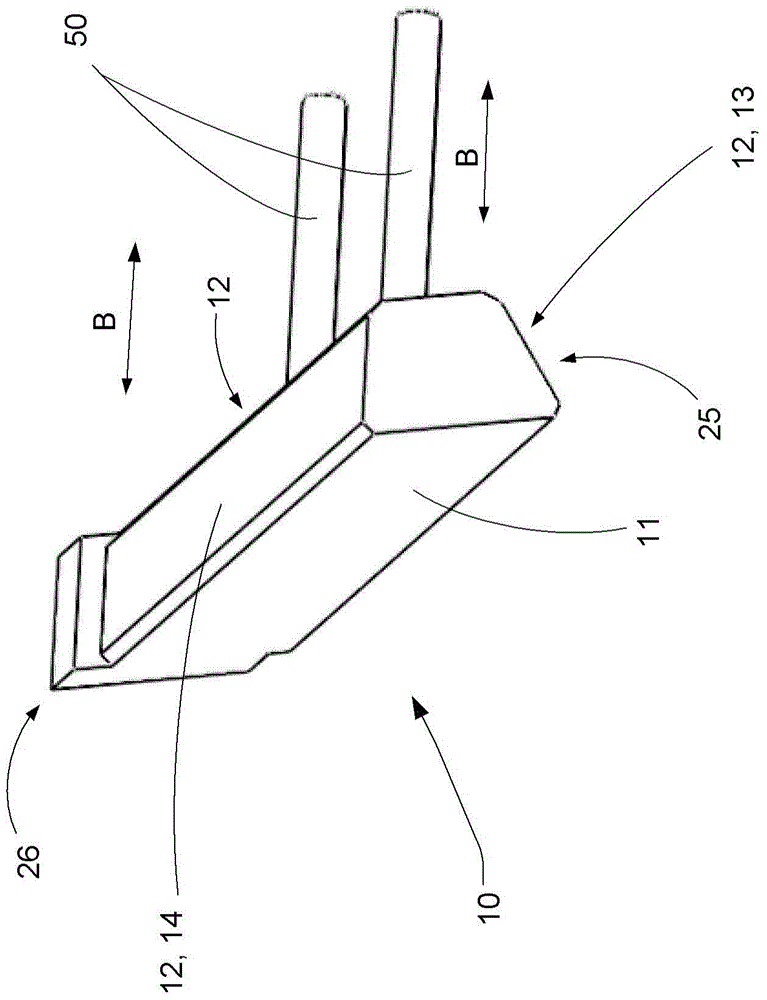

[0037] exist Figures 1 to 2 A jaw crusher 1 is shown in . The jaw crusher comprises jaws 2, 2' and a movable jaw 3 and a fixed jaw 3', each jaw being provided with at least one jaw 2, 2'. If the jaw is divided into more than one part like an elongated or widened jaw part or jaw part, the jaw is held firmly against each A jaw 3, 3'. Such an elongated jaw part 10 does not necessarily have the function of a clamping rod, but can of course have this function or be used in combination with at least one clamping rod 10 . Such an elongated jaw plate 10 may have the same height as the adjacent jaw plate or another height, eg a smaller height measured in the vertical or feed direction of the crusher. Each jaw 3, 3' or jaw plate 2, 2' comprises an upper surface 4 inclined to define a wedge-shaped surface on which the jaw member / clamping rod 10 is wedged to securely clamp the jaw in the appropriate location in the crusher (see figure 1 , 2 and 9). Each jaw 3, 3' or jaw plate 2, 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com