work machinery

A technology of operating machinery and engines, which is applied in earth movers/excavators, construction, etc., and can solve problems such as difficult maintenance operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

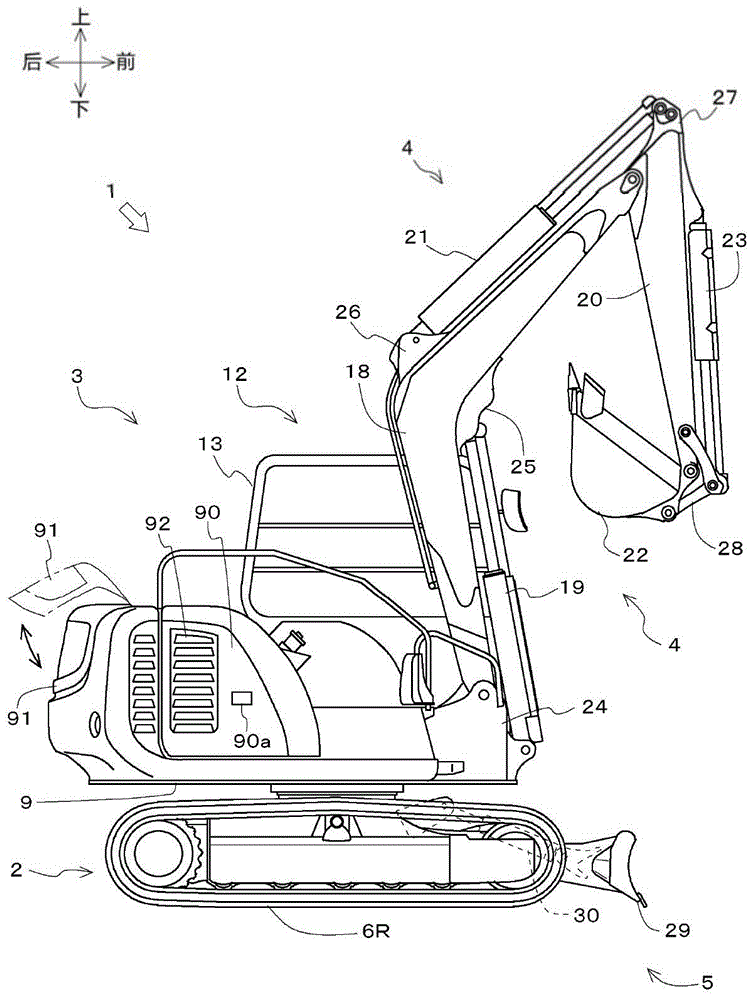

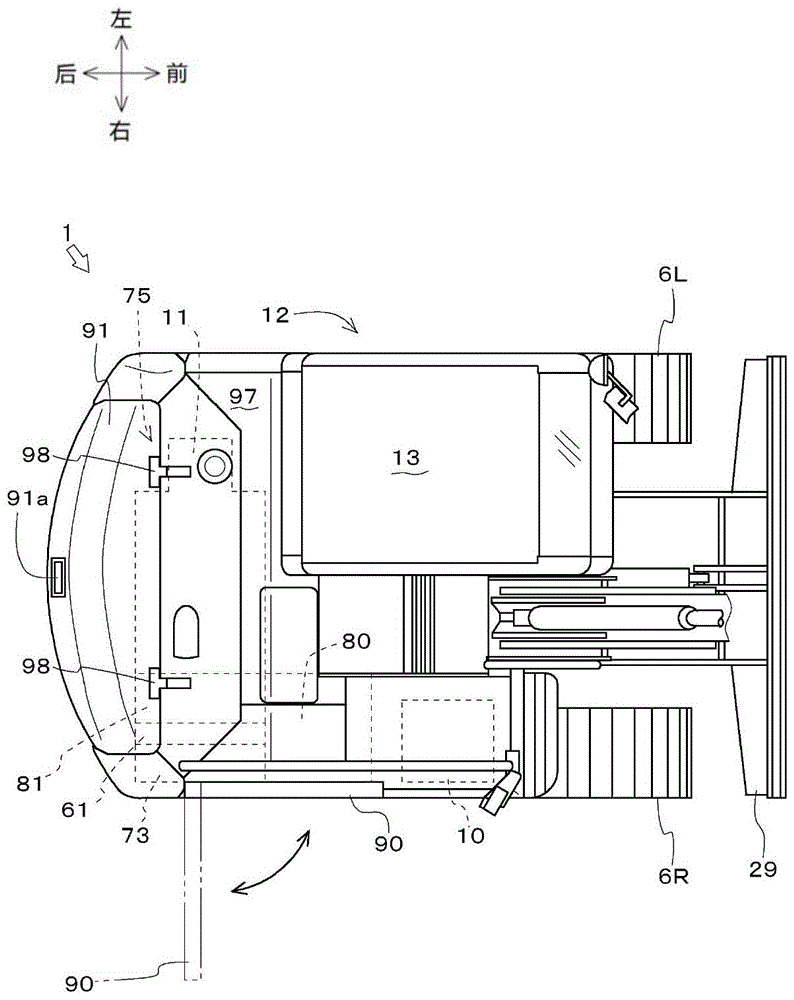

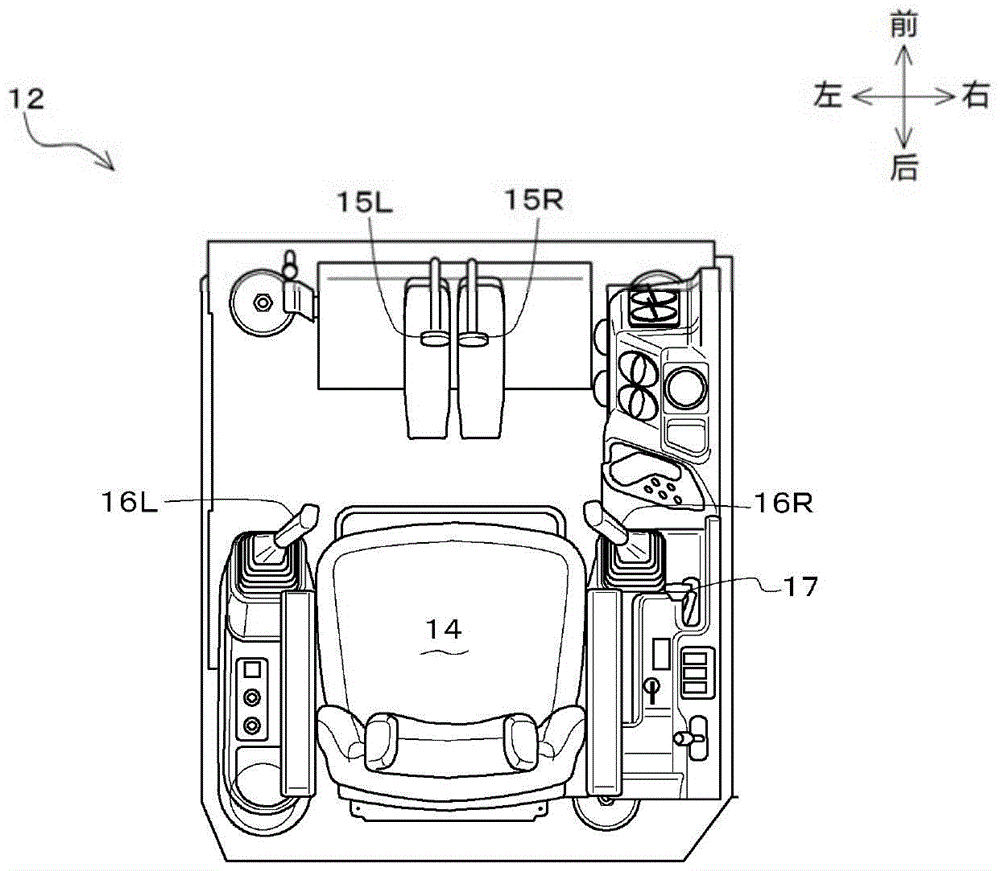

[0032] Hereinafter, the work machine (backhoe 1) will be described with reference to the drawings.

[0033] like figure 1 as well as figure 2 As shown, the backhoe 1 is a rotary working machine. The backhoe excavator 1 includes: a crawler-type traveling device 2; a body 3, which is arranged in the center of the upper part of the crawler-type traveling device 2, and is mounted on the crawler-type traveling device 2 so as to be rotatable left and right; an operating device 4 (boom 18, boom Oil cylinder 19, stick 20, stick cylinder 21, bucket 22, and bucket cylinder 23), are installed on the front part of body 3; bulldozing device 5 (dozer blade 29 and bulldozer cylinder 30), are installed on The front and rear sides of the crawler-type traveling device 2 ; and the control valve device 10 .

[0034] The crawler-type traveling device 2 includes: crawler-type traveling units 6L, 6R arranged as a pair of left and right; and hydraulic actuators (traveling motors) for driving the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com