A wind blade maintenance platform

A technology for wind blades and maintenance platforms, which is applied in the direction of construction, industrial buildings, housing structure support, etc., can solve the problems of complex structure, small movable range and danger of the clamping device, so as to keep the blades still, have a large movable range, The effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

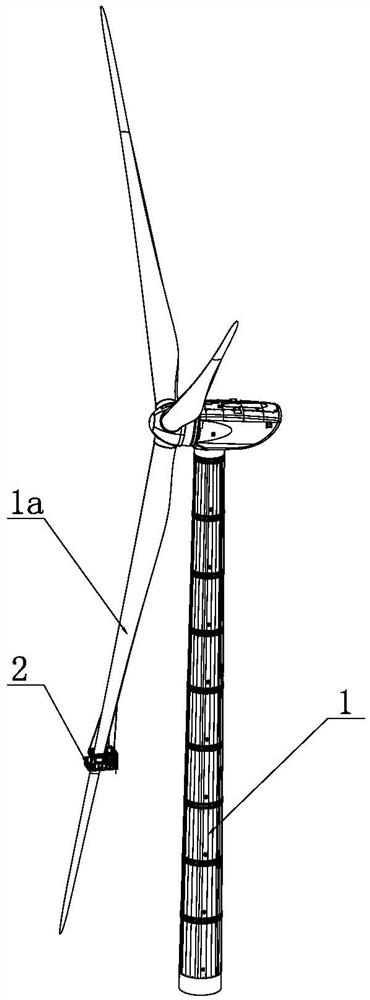

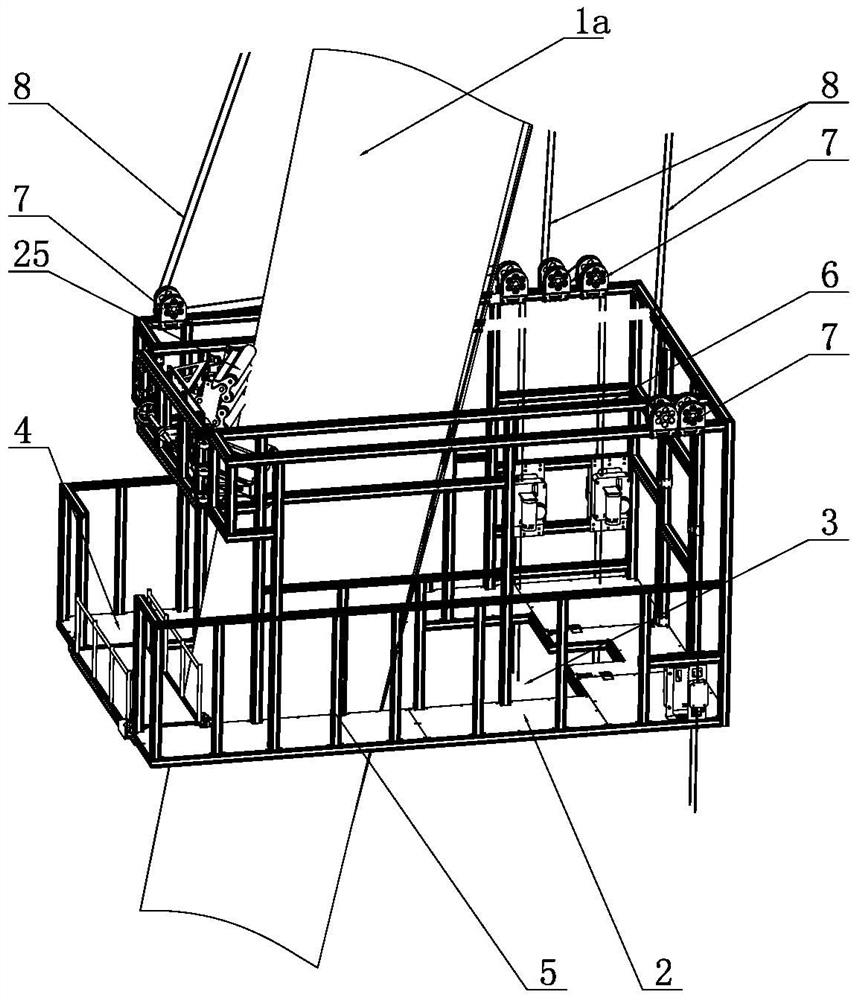

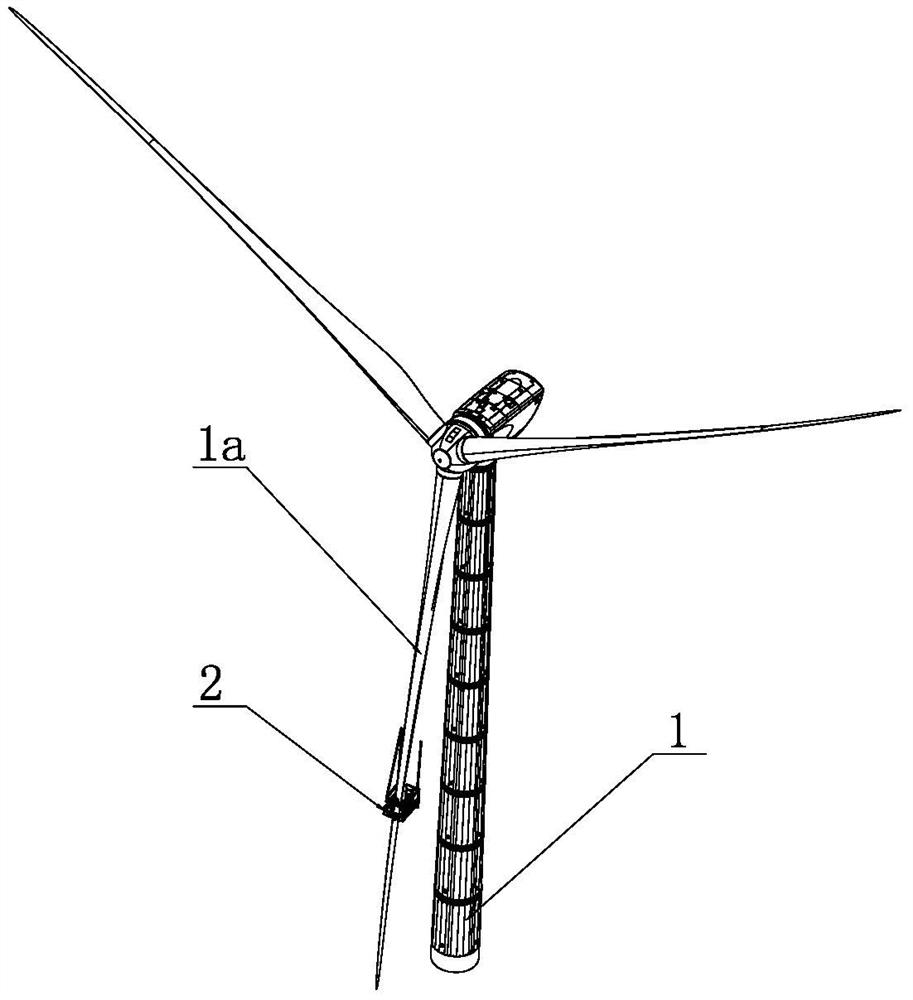

[0032] like Figure 1-15 As shown, it is a wind blade maintenance platform, including a lifting platform 2 corresponding to the wind blade 1a, the wind blade 1a is rotatably installed on the wind generator 1, and the lifting platform 2 is provided with a space for the wind blade 1a to pass through. The lifting tank 3 passed through, the lifting platform 2 is located around the lifting tank 3 to form a maintenance activity area 4, the surrounding edges of the lifting platform 2 are provided with an outer fence 5, and a mounting frame 6 is fixed above the lifting platform 2 through the support mechanism. The frame 6 is provided with at least three groups of pulley guide mechanisms 7, and the outer fence 5 is provided with a number of lifting motors 9 corresponding to each group of pulley guide mechanisms 7. The motor 9 is correspondingly provided with a number of wire ropes 8, the upper end of each wire rope 8 is fixed with the top of the wind turbine 1, the wire ropes 8 are gui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com