Shaft brake trundle

A technology of caster and shaft brake, which is applied in the field of shaft brake casters to achieve better braking effect and ideal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below with reference to the drawings and embodiments.

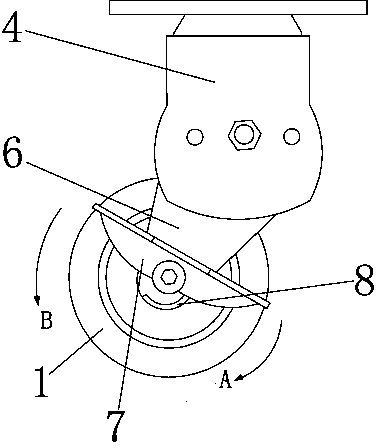

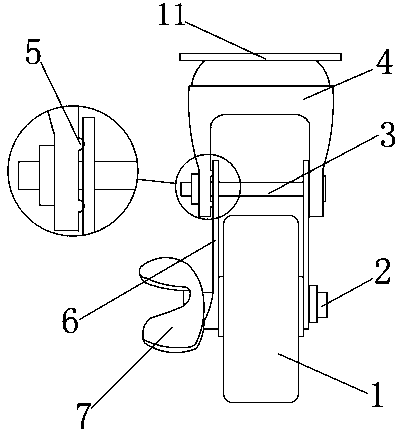

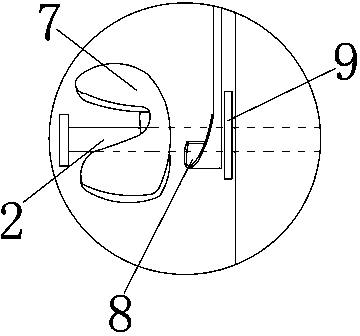

[0014] As shown in Figures 1, 2, 3 and 4: The present invention includes a mounting plate 11, a roller 1 and a roller bracket. The roller bracket includes two side plates 6 and a mounting bracket 4. The two side plates 6 are mounted on the axle 2 On both sides of the roller 1, there is a brake pedal 7 on the outside of the side plate 6. The contact surface of the side plate 6 with the brake pedal 7 is provided with a stop shoulder 8 integrated with the side plate 4, and the upper end of the side plate 6 is fixed by bolts 3. A mounting bracket 4 is connected. The mounting bracket 4 is provided with a circular protrusion 5 on the contact surface with the side plate 6, and the side plate 6 is correspondingly provided with a circular groove 10. The stop shoulder 8 has a gradually decreasing slope structure from the highest point to the lowest point. A friction plate 9 is p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com