a lifting device

A lifting device and lifting mechanism technology, applied in the direction of lifting device, fluid pressure actuating device, lifting frame, etc., can solve problems such as prone to failure, limited height, unable to lift large objects, etc., and achieve lifting capacity Strong, guaranteed stability, smooth lifting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below in conjunction with accompanying drawing, the specific embodiment of the present invention is described in further detail:

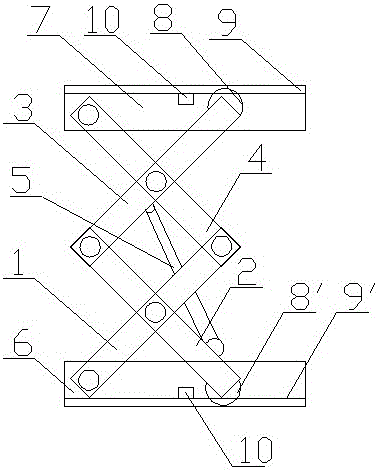

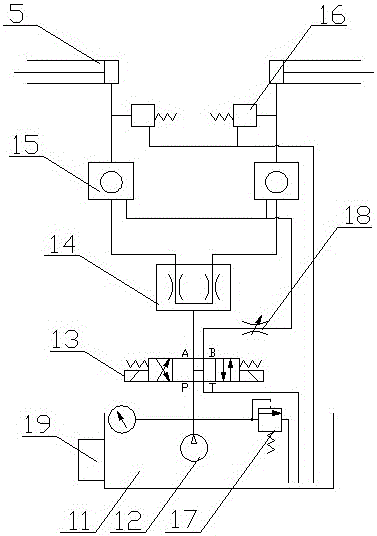

[0022] As shown in the figure: a lifting device, including a lifting mechanism and a hydraulic control system, the lifting mechanism includes two sets of lifting units, the lifting unit includes a lower support plate 6, an upper lifting platform 7 and Four support arms, the support arms are composed of two parallel support rods, and the ends and middle parts of the two support rods are fixedly connected by cross bars; the top surface of the lower support plate 6 is provided with a lower rail 9', The bottom surface of the upper lifting platform 7 is provided with an upper track 9, and the upper track 9 and the lower track 9' are provided with a position switch 10, and the position of the position switch 10 on the track is adjustable; the first support arm 1 and the second support arm 2 are arranged in an X shape, the middle position of the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com