Spring press fitting component and spring device using same

A spring press-fitting and spring device technology, applied in the direction of springs/shock absorbers, coil springs, mechanical equipment, etc., can solve problems such as easy loosening of springs, and achieve the effect of solving easy loosening.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

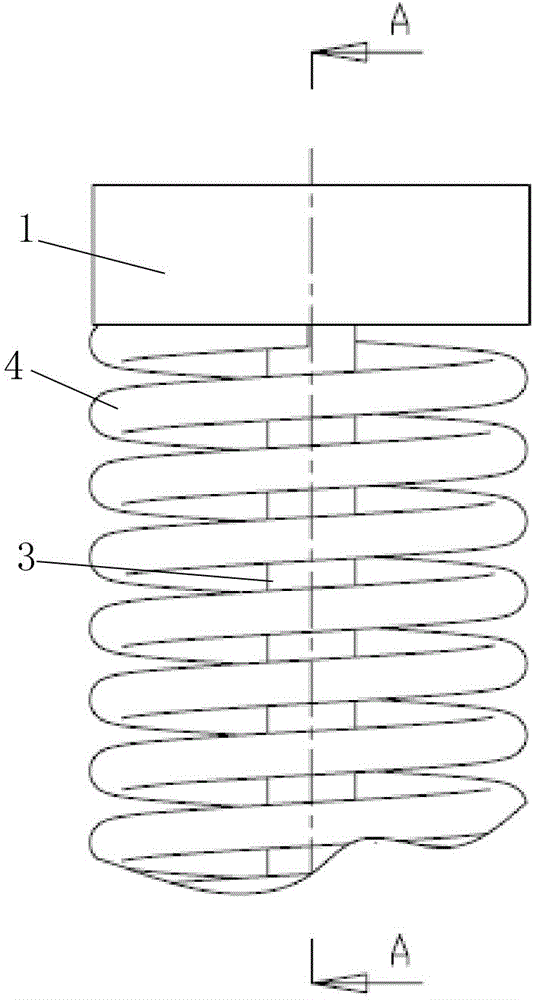

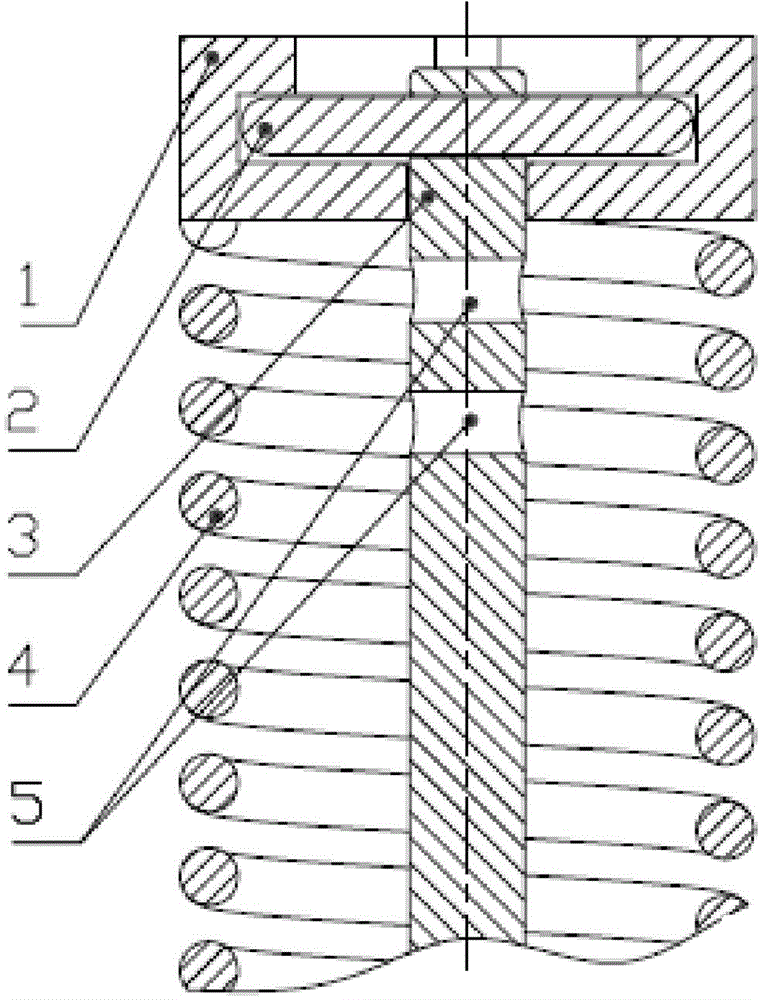

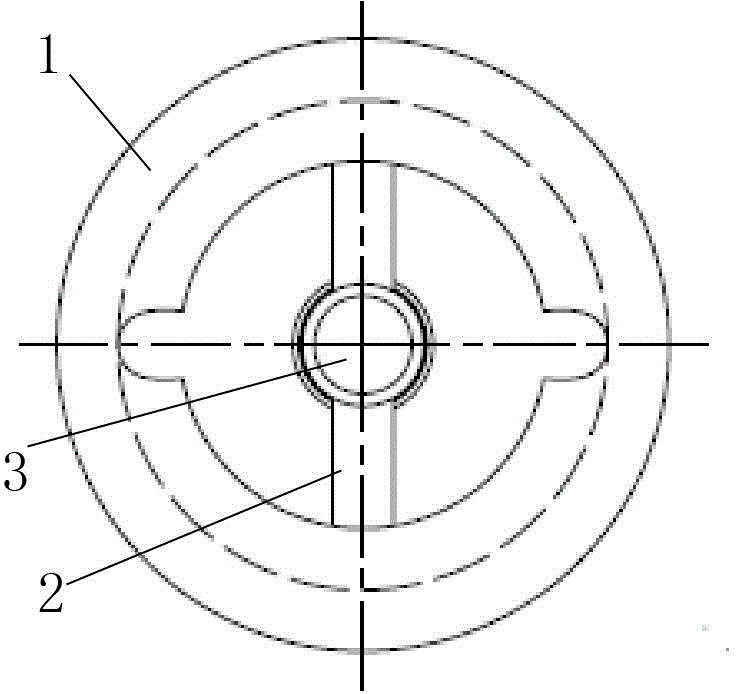

[0022] The embodiment of spring device among the present invention: as Figure 1 to Figure 5 As shown, the spring device is mainly composed of a spring body 4 and a press-fit assembly, wherein the spring body 4 is a cylindrical coil spring, and the press-fit assembly is composed of a positioning member, a stopper and a spring pressing plate 1 . The positioning part is a spring rod 3 coaxially installed in the inner hole of the spring body 4, and the spring rod 3 is provided with a row of positioning pin holes 5 arranged at intervals along the axial direction. The radially extending perforation, and the positioning pin hole 5 is formed on the spring rod 3 for the stopper to move axially along the positioning member, and after the stopper moves in place, the limiter is axially limited and assembled in the positioning position. The adjustment structure on the component. The positioning part is the fixed pin shaft 2 that is installed in the positioning pin hole 5 along the radial...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com