Diaphragm Control Valve

A technology of control valve and diaphragm type, which is applied in the direction of safety valve, balance valve, valve device, etc., can solve the problems of slow overpressure response speed, slow response speed, large static inertia, etc., and achieve high overpressure sensing sensitivity and manufacturing The effect of low cost and ensuring safe operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

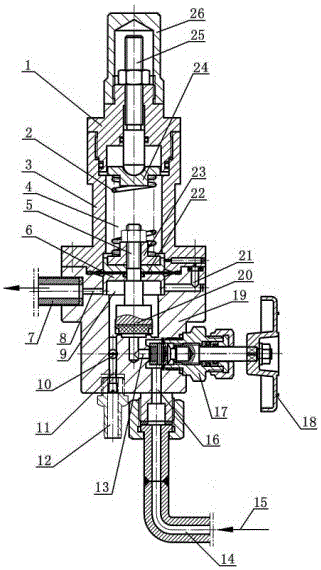

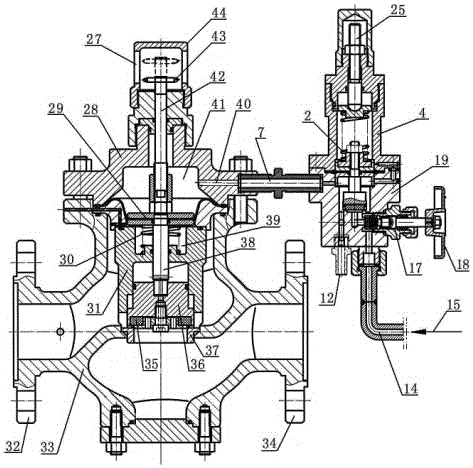

[0015] Embodiments of the present invention are further described below in conjunction with the accompanying drawings:

[0016]A diaphragm control valve proposed by the present invention is mainly composed of a control valve body 19, an air source inlet valve 17 connected and installed on the control valve body 19, a manual reset valve 10, a downstream air source introduction pipe 14, and a pressure guiding air pipe. 7. Valve cylinder 3, upper bonnet 1, bonnet 26, adjusting screw rod 25, pressure regulating spring 2, upper pressing block 24, lower pressing block 23, elastic diaphragm 22, pressing film assembly 6, pressure regulating shaft 5 and connected to The pressure regulating shaft 5 is composed of a valve core 20, the valve cylinder 3 is fixedly connected and installed on the upper end surface of the control valve body 19, and an elastic diaphragm 22 is fixedly installed between the valve cylinder 3 and the control valve body 19 to divide it into an upper membrane cavity ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com