High-voltage grounding isolation switch and isolation method

A technology for grounding isolating switches and high-voltage isolating switches, which is applied in the direction of grounding switches, electric switches, and high-voltage air circuit breakers. No contact resistance, good safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings.

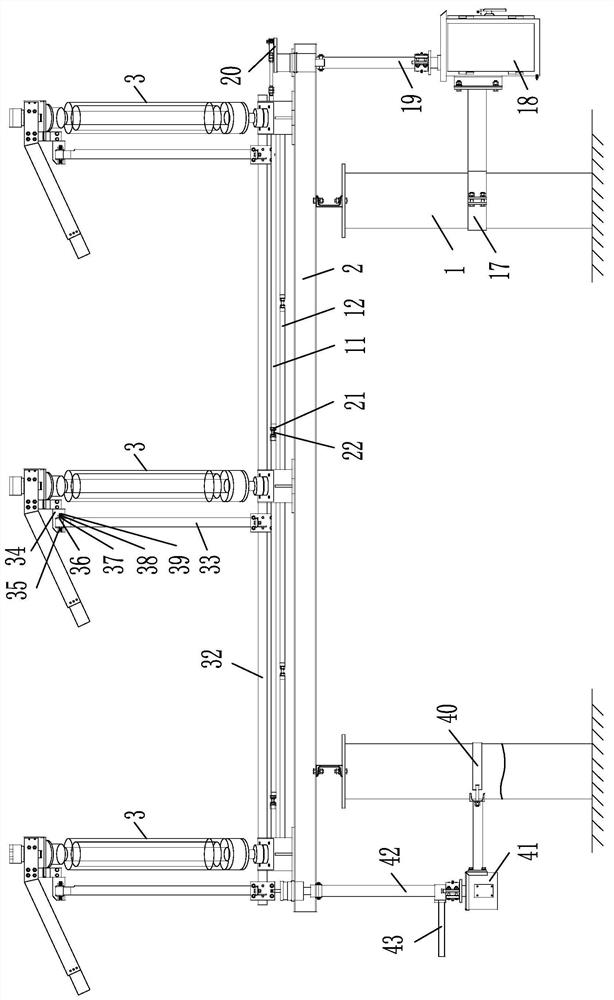

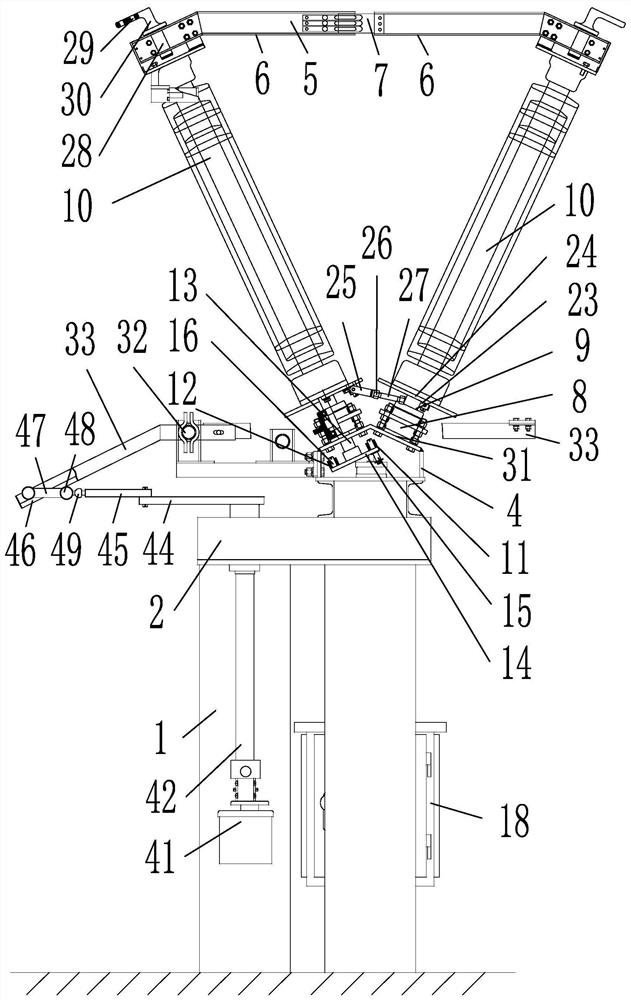

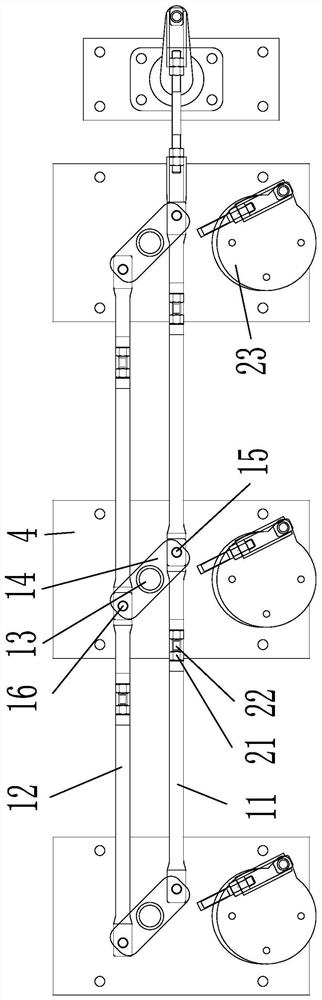

[0022] as attached figure 1 , attached figure 2 , attached image 3 , attached Figure 4 Shown: a high-voltage grounding isolating switch, including: a frame 2 with a plurality of pillars 1, three main knife devices 3 arranged horizontally, a main knife driving device, and a ground knife device. The main knife device 3 includes: mounted on The transmission seat 4 on the frame 2, two main knife assemblies arranged in front and back, two side ends are provided with grooves 5 and correspond to the two main knife assemblies one by one, and the thickness is adapted to the width of the grooves 5 Conductive block 7, knife bar linkage device; main knife assembly includes: bearing seat 8 mounted on the transmission seat 4, the lower end is provided with the insulating column 10 of the installation shaft 9 pivotally connected with the bearing seat 8 through the bearing; two ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com