Cutter linking mechanism of bookbinding machine

A linkage mechanism and binding machine technology, applied in binding, metal processing, etc., can solve the problems of affecting the reversing, the blades of the cutting knife are not separated, the reliability and precision are not high, so as to reduce the occupied space, avoid easy failure, The effect of high motion reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

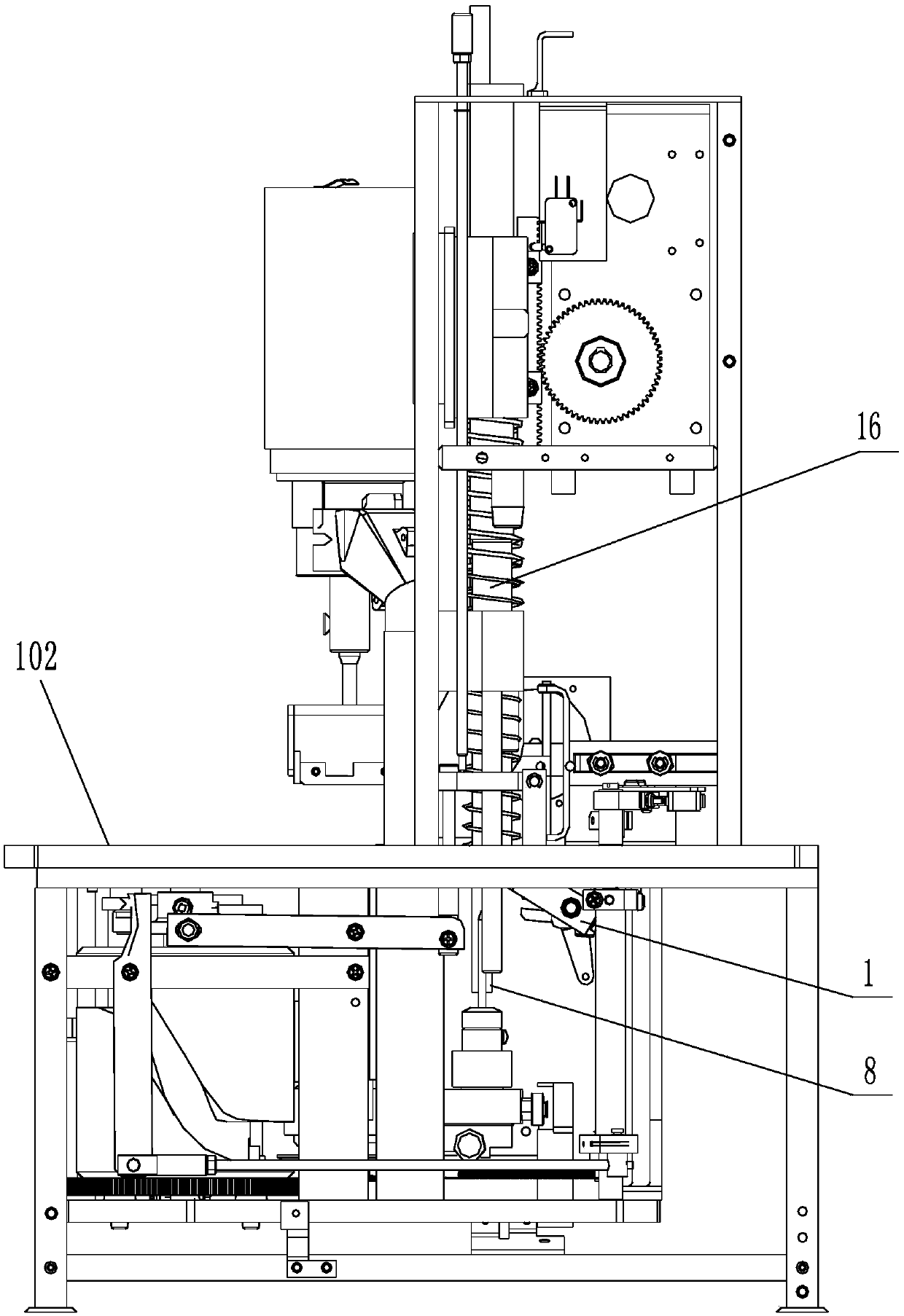

[0035] The binding machine of the present embodiment is as Figure 4 As shown, there are lower pressure riveting thimble 9, cutter assembly 10, lifting motor 11, lifting rack 13, upper pressure riveting mechanism 14, punching mechanism 15, lifting guide column 16, feeding mechanism 17, top plate 101, middle platform plate 102 and base plate 103 etc. The output end of the lifting motor 11 is provided with a gear 12 meshed with the lifting rack 13 .

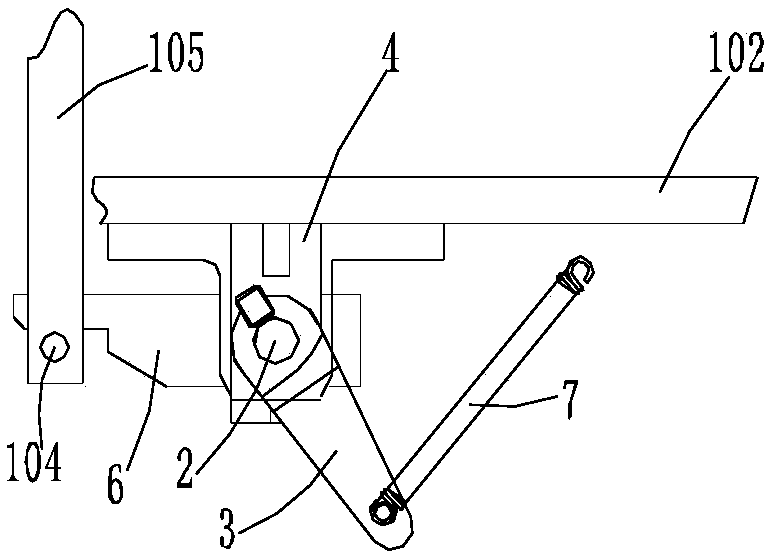

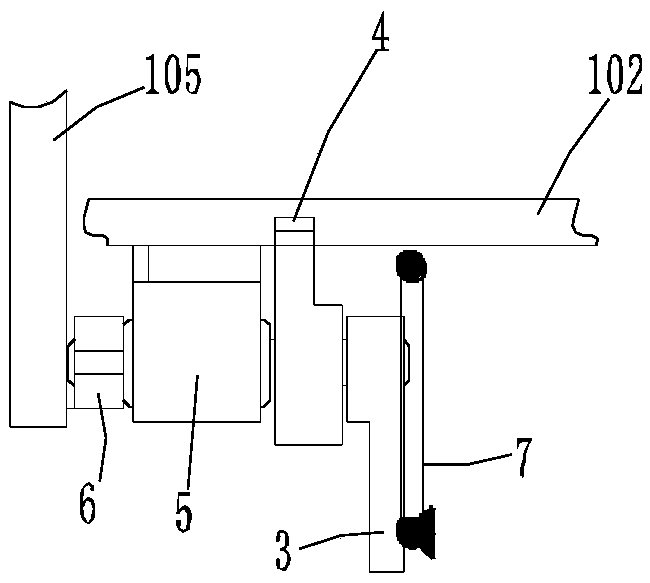

[0036] The cutter linkage mechanism of the binding machine of the present embodiment, such as Figure 4 and Figure 5 As shown, it includes a cutter assembly 10 and a linkage mechanism, and the linkage mechanism includes a lifting rack 13 and a reversing mechanism of the binding machine.

[0037] Such as Figure 6 As shown, the cutter assembly includes a knife rest 19 fixed on the middle platform 102 of the binding machine, a movable blade 18-1 and a stopper 18-2 fixed on the knife rest 19, and the knife edge 18-1 and the stopp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com