A double-acting pneumatic switch

A technology of double-acting air-operated switch and drive seat, which is applied in the directions of engine components, valve details, valve operation/release devices, etc., can solve the problems of high maintenance cost, complicated wiring, and inability to apply safety requirements, and achieves simple structure, The effect of easy operation and use, strong practicability and marketing value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

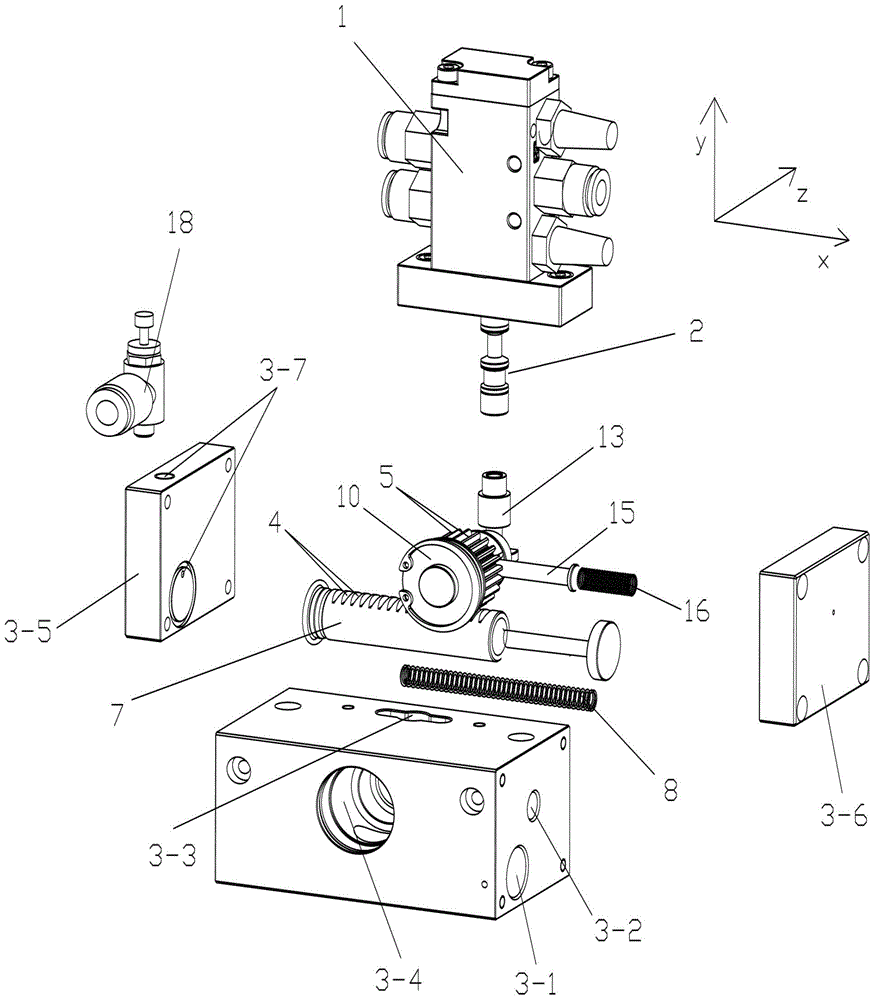

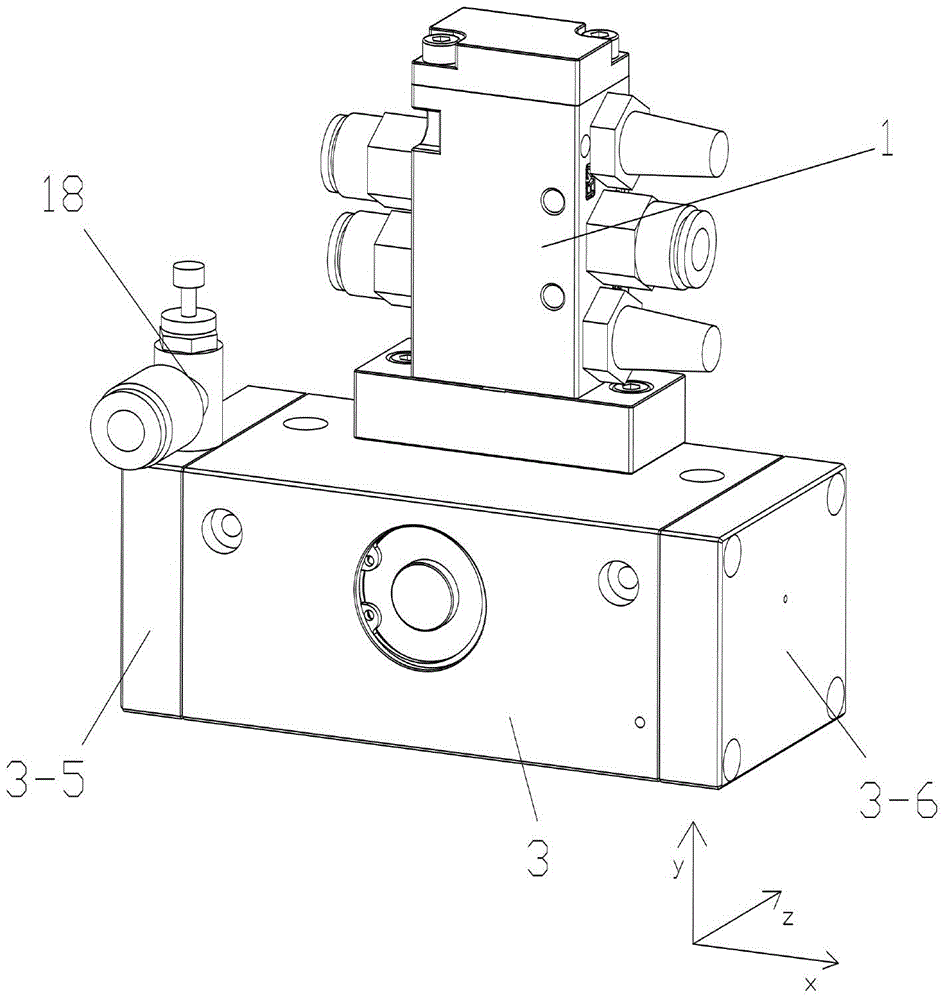

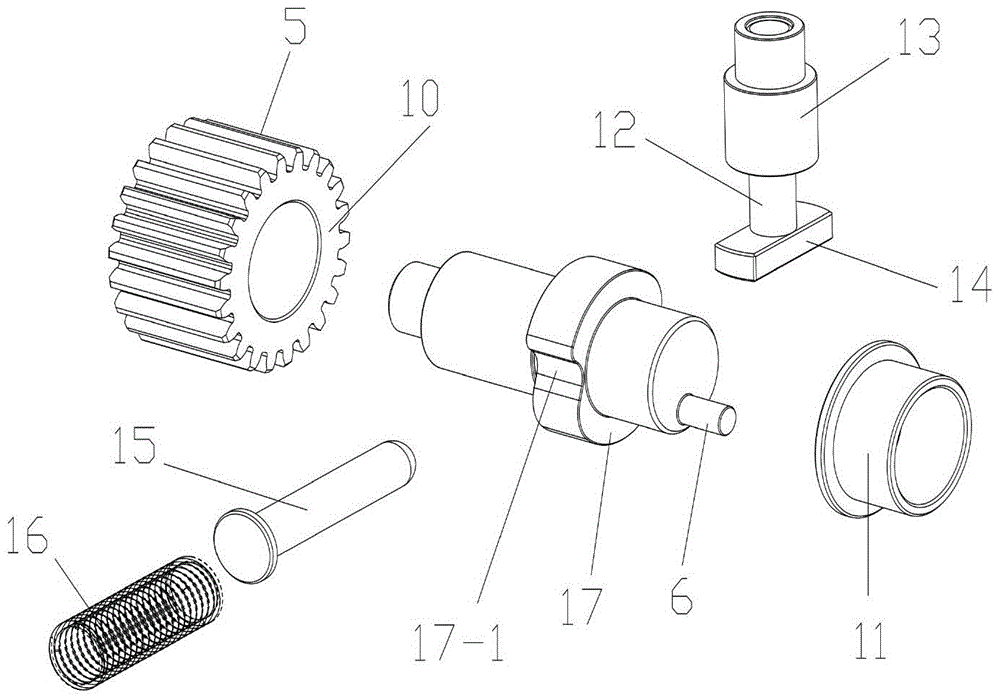

[0027] Such as Figure 1 to Figure 6 As shown, a double-acting pneumatic switch provided by this embodiment includes a valve body 1, and a valve core 2 for realizing the opening or closing of the valve body is arranged in the valve body 1, and it also includes a driving seat 3. 3 is provided with a piston group used as a power source, a guide wheel group as an intermediate transmission link, and a drive rod group used to drive the valve core 2 to move; wherein, the piston group is arranged in the X direction relative to the drive seat 3, and the guide wheel group Relative to the driving seat 3, it is arranged in the Z direction, and the driving rod group is arranged in the Y direction relative to the driving seat 3; at the same time, several tooth g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com