Method for manufacturing color filter, color filter, and display device

A color filter and reflector technology, applied in the field of display devices and color filters, can solve the problems of uneven edge brightness, color, and poor contrast of display modules, achieve good contrast, uniform edge brightness, and improve exposure effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

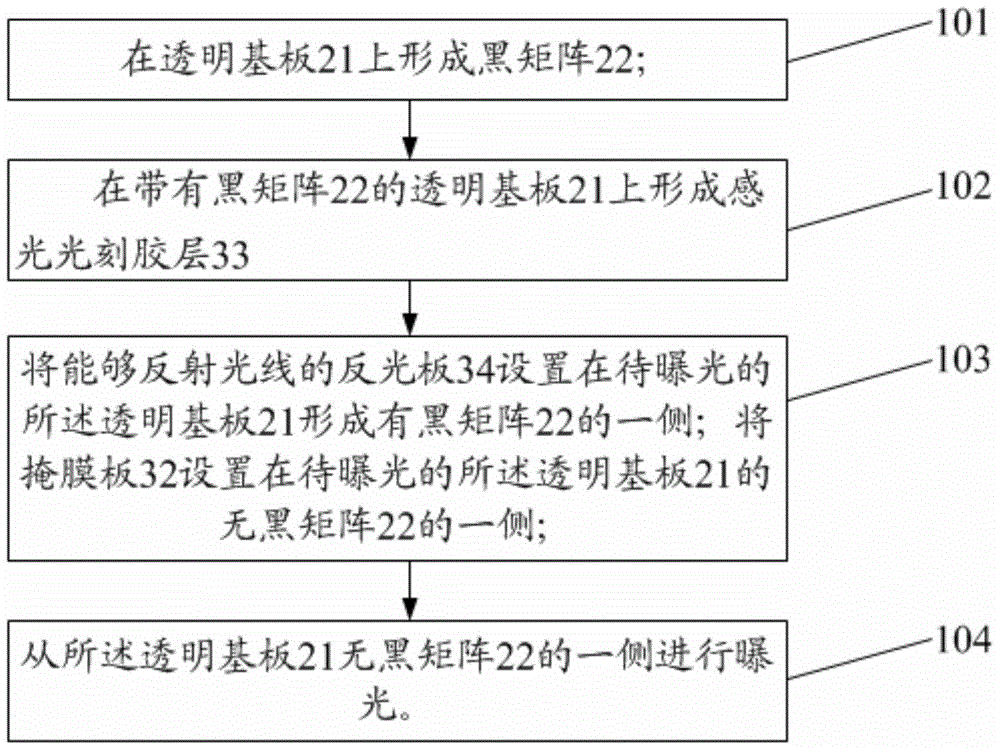

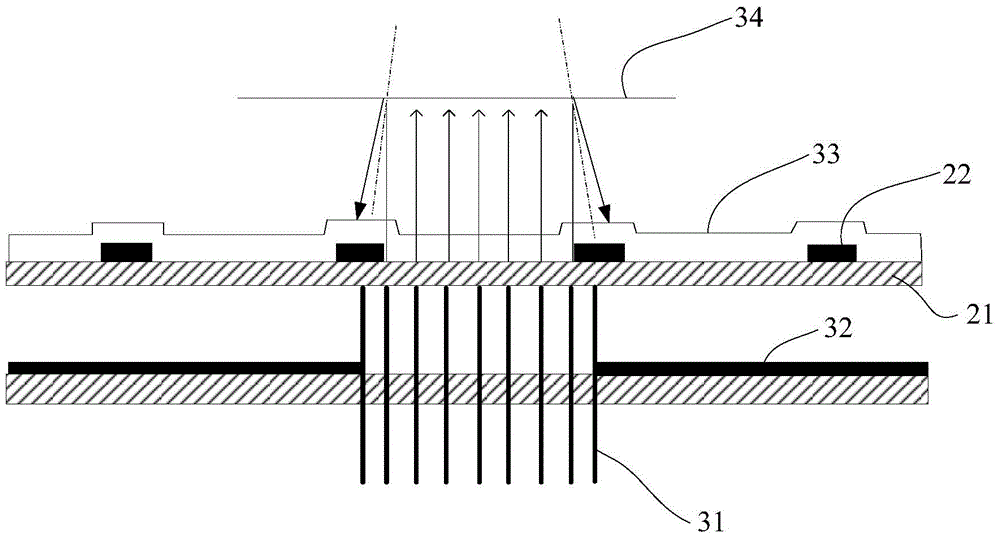

[0028] see figure 1 , figure 2 and image 3 , an embodiment of the present invention provides a method of manufacturing a color filter, the method comprising:

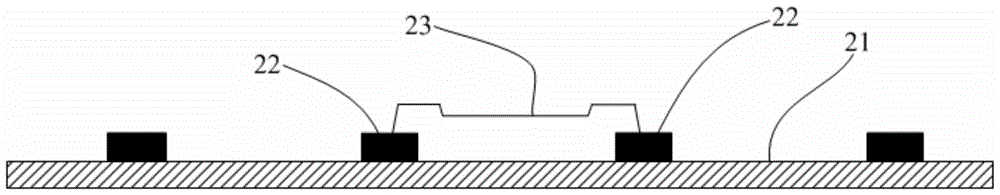

[0029] 101. Forming a black matrix 22 on a transparent substrate 21;

[0030] The black matrix 22 can be formed on the transparent substrate 22 by coating, specifically, there is a certain interval between the black matrix 22;

[0031] 102. Form a photosensitive photoresist layer 33 on the transparent substrate 21 with the black matrix 22;

[0032] Specifically, taking the color-resist layer of a color filter including the three primary colors of red, green and blue as an example, the color-resist materials of the three primary colors of red, green, and blue can be arranged in sequence in each pixel; The transparent substrate 21 of the adhesive layer 33 is pre-baked, and then the cooling ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com