Interchangeable grass guide block lawn mower

A grass guide block and lawn mower technology, which is applied to harvesters, cutters, agricultural machinery and implements, etc., can solve the problems of increasing manufacturing costs, unsatisfactory grass guiding effects of grass guiding structures, and increasing the cost of chassis molds and the difficulty of development. Advanced problems, to achieve the effect of reducing costs and saving mold costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

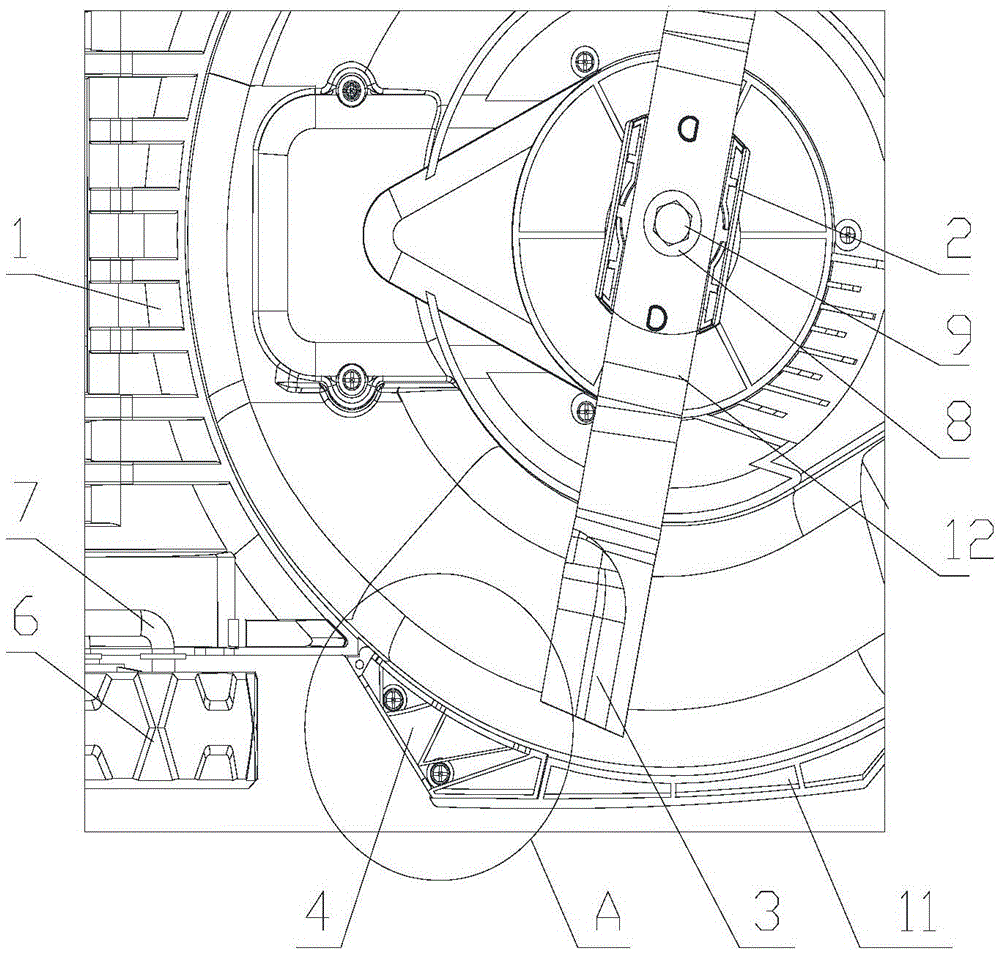

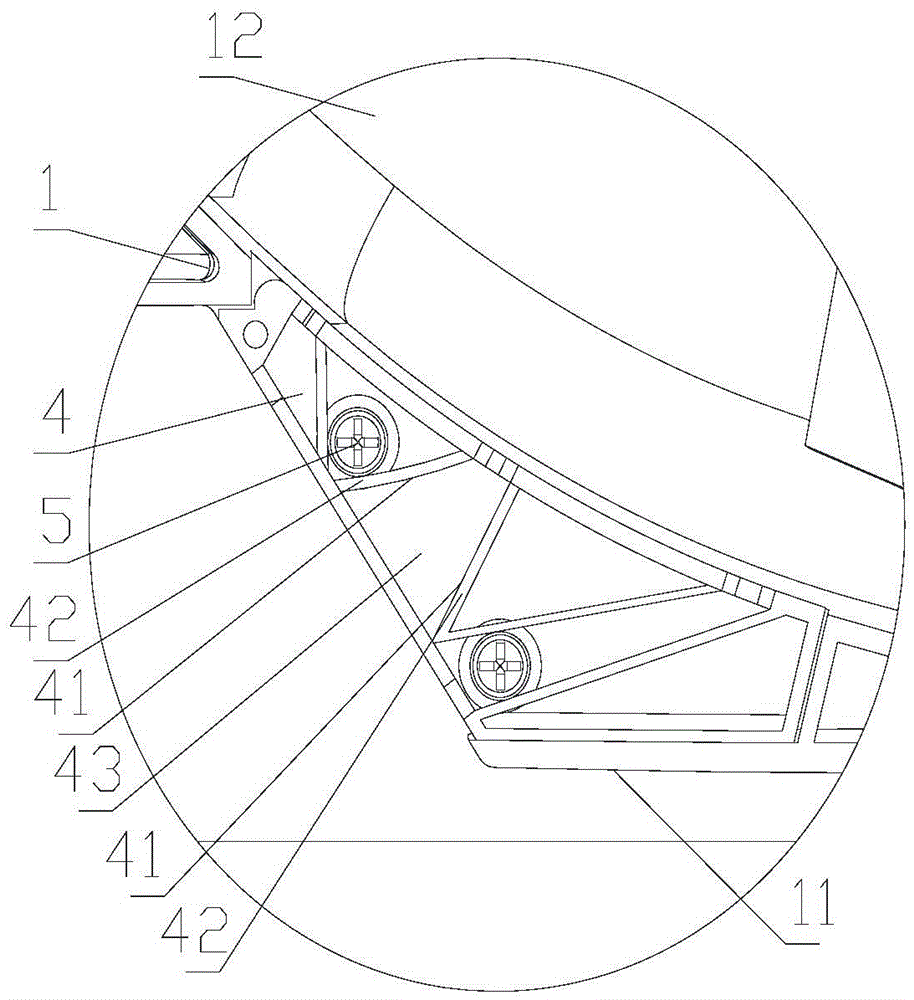

[0017] Such as figure 1 and 2 As shown, the replaceable grass guide block type lawn mower includes a chassis 1 and a blade assembly installed on the bottom surface of the chassis 1. The bottom surface of the chassis 1 can be detachably installed with a grass guide block 4 on the left and right edges, wherein the grass guide block 4 Be fixed on chassis 1 bottom surface by screw 5, be provided with guide grass position on the grass guide block 4, the guide grass position side part has the guide surface 41 that is used to guide the grass guide blade assembly of chassis 1 both sides, guide surface 41 from chassis 1 The outer side extends toward the blade assembly. Wherein, there is an outwardly protruding flange portion 11 on the left and right sides of the chassis 1, and the two grass guide blocks 4 are installed on the outer edge of the bottom surface of the flange portion 11 respectively.

[0018] In this embodiment, the grass guiding parts are several grass guiding ribs 42 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com