Steel Strip Longitudinal Roller Shearing Machine

A steel strip and roller shearing technology, applied in shearing machine equipment, shearing devices, accessories of shearing machines, etc., can solve the problems of low cutting work efficiency and unguaranteed quality, and achieve high cutting efficiency and good quality. , the effect of high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings.

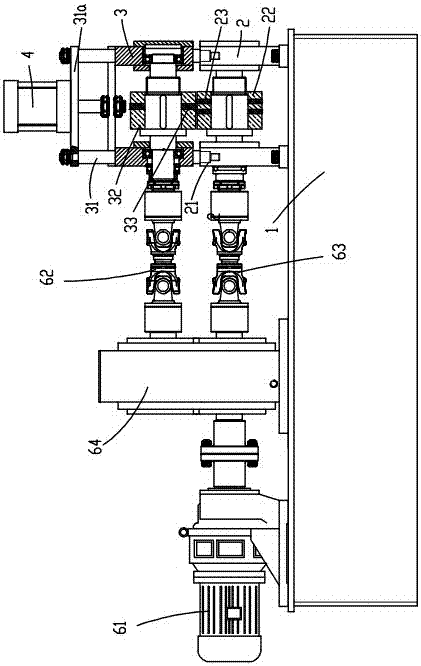

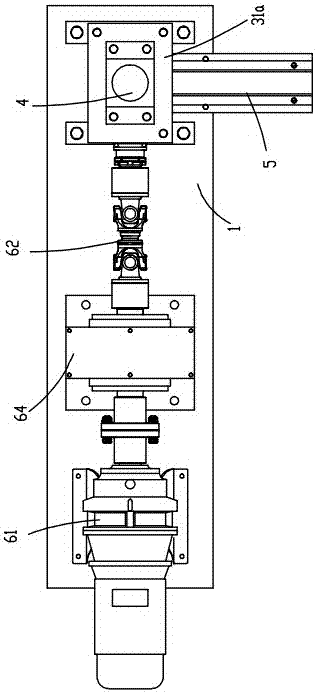

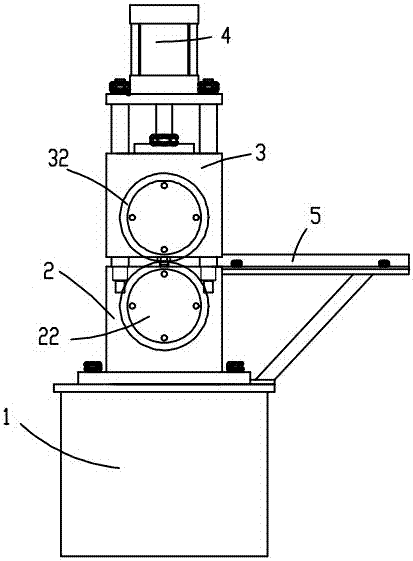

[0022] Figure 1 to Figure 3 Shown is the structural representation of the present invention.

[0023] The reference signs are: machine base 1, roller shear fixed seat 2, fixed groove 21, lower roller 22, lower scissors 23, roller shear movable seat 3, connecting column 31, limit plate 31a, upper roller 32, Upper scissors 33, cylinder 4, feeding guide rail 5, cycloidal reduction motor 61, movable seat universal rotating shaft 62, fixed seat universal rotating shaft 63, power distribution box 64.

[0024] Such as Figure 1 to Figure 3 As shown, the steel slab longitudinal roller shearing machine of the present invention includes a machine base 1, wherein: the machine base 1 is fixed with a roller shear fixing seat 2 and a cycloid deceleration device 6, and the upper part of the roller shear fixing seat 2 is provided with several fixing grooves...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com