Novel cleaning mechanical structure

A new type of mechanical structure and technology, applied in road cleaning, cleaning methods, construction, etc., can solve the problems that the cleaning workers are unwilling to use, cannot meet the market demand, and the effect is not very large, and achieves environmental protection, intelligent automation, and low rotational angular velocity. , the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below in conjunction with accompanying drawing, the present invention will be described in further detail:

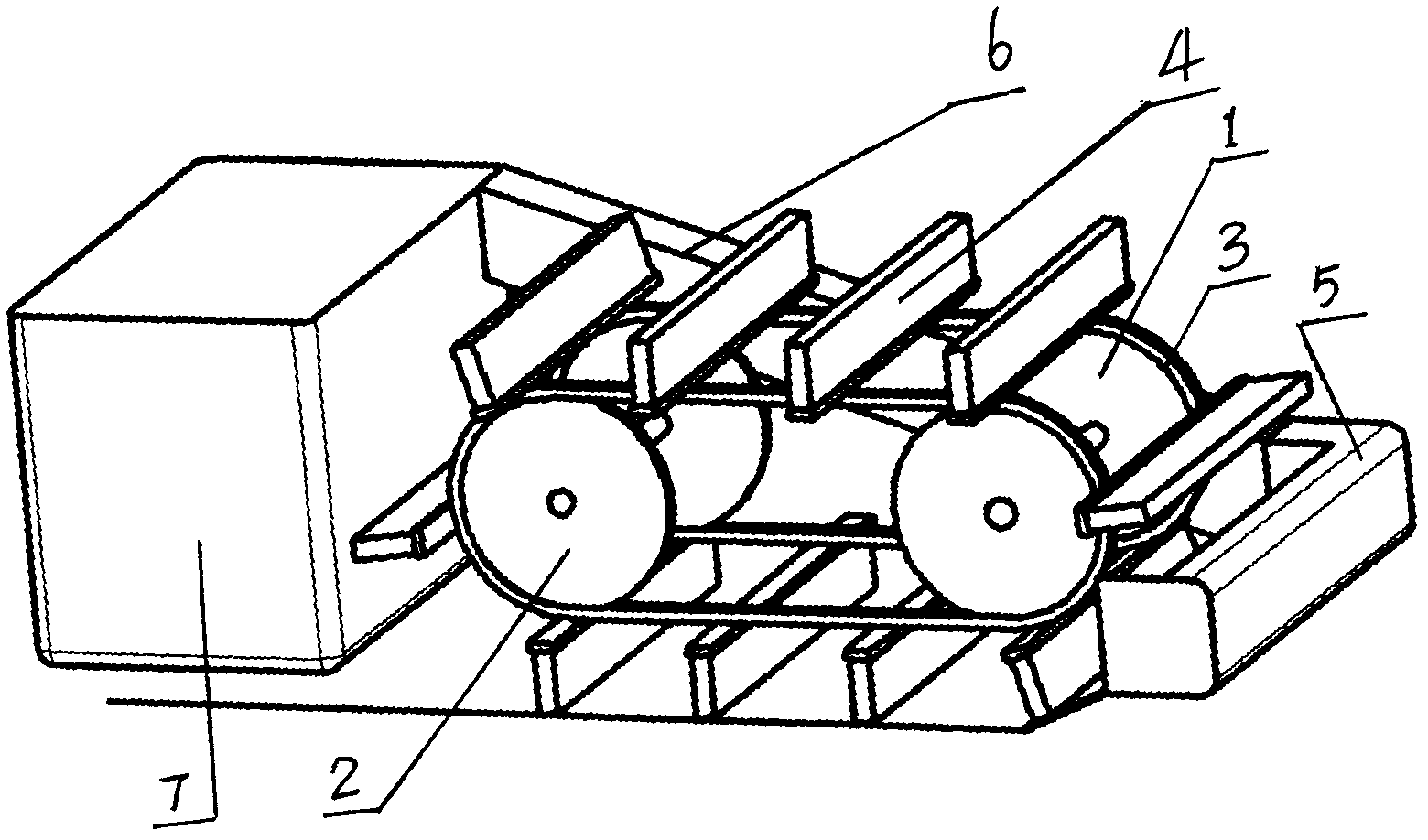

[0014] Such as figure 1 As shown, the technical solution of the embodiment of the present invention is as follows: a new type of cleaning mechanical structure, including a driving wheel 1, a driven wheel 2, a transmission chain 3, a brush 4, a garbage bucket 5, a garbage transmission channel 6, and a garbage bin 7 , it is characterized in that: the driving wheel 9 of the power structure drives the transmission chain 3 and the driven wheel 3 equipped with the brush 4 to rotate; the transmission chain 3 connects the driving wheel 1 and the driven wheel 2 of the power structure; , the other end is communicated with the dustbin 7, and the rubbish reaching the dustbin 5 is sent to the dustbin 7 through the rubbish transmission channel 6.

[0015] Such as figure 1 As shown, the present embodiment drives the transmission chain equipped with the brush and the driven wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com