Pipe blank forming mold structure of single-wall corrugated pipe

A single-wall corrugated pipe and tube blank forming technology, which is applied to household appliances, tubular objects, and other household appliances, can solve problems such as large fluid resistance and suspended solids deposition, and achieve good elongation, strong compression resistance, and The effect of long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

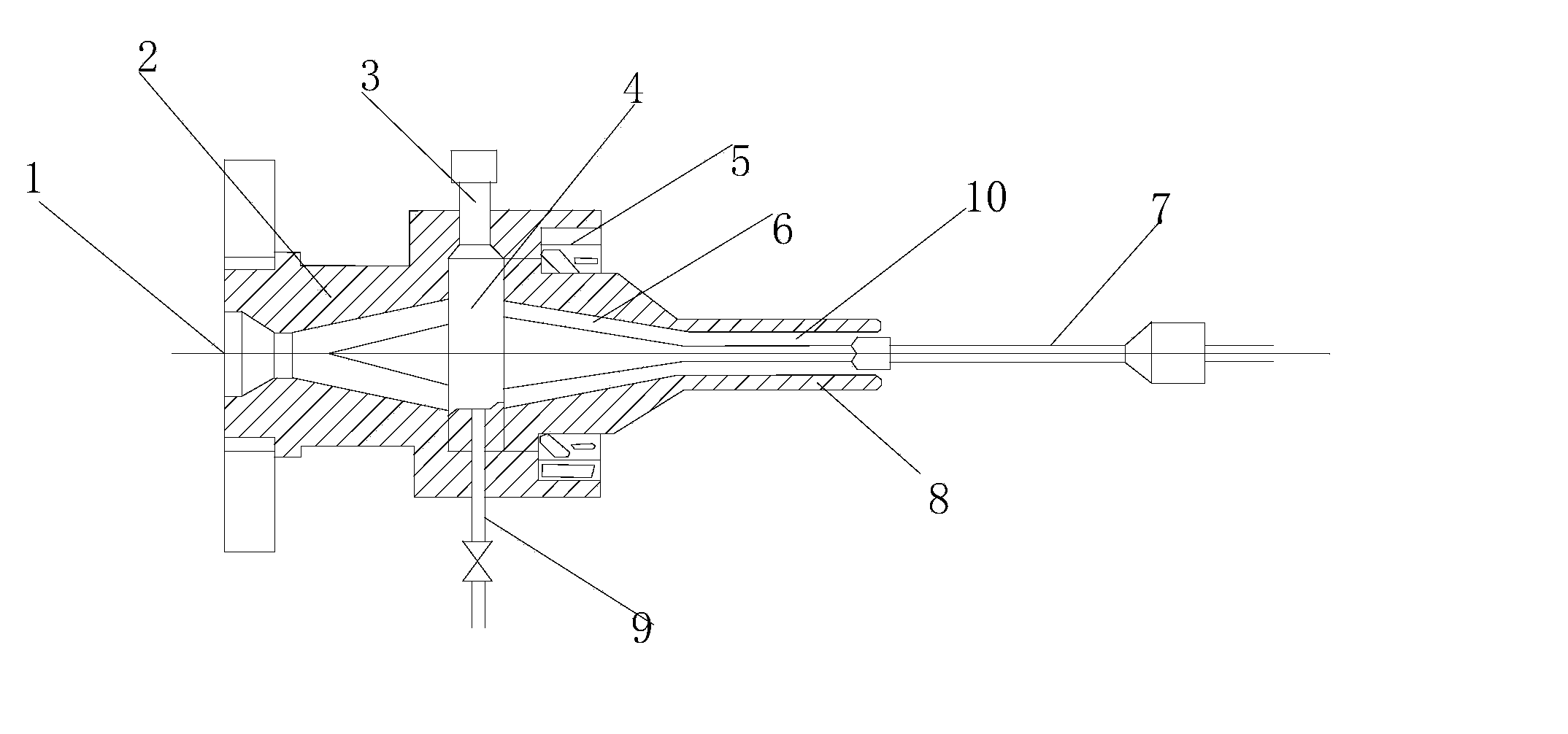

[0008] refer to figure 1 , the pipe blank forming mold structure of single-wall corrugated pipe, including the mold body formed by connecting the plug 2, the die 6 and the mandrel 8, the front end of the plug 2 is fixedly connected with the porous plate 1, and the rear end of the plug 2 is provided with Groove, the die 6 and the plug 2 are connected through the lock nut 5, the junction of the plug 2 and the die 6 is provided with a diversion cone 4, and the top of the diversion cone 4 is provided with Adjusting screw 3, the lower end of the diverter cone 4 is provided with an air inlet pipeline 9 connected with the diverter cone 4 and the mold body, the inlet pipeline 9 is provided with a switch valve, and the center of the mandrel 8 is provided with a through hole 10. An air-blocking rod 7 is arranged in the through hole 10 .

[0009] The adjustment of the wall thickness of the tube blank is to adjust the gap between the mandrel and the die by adjusting the movement of the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com