Backlight module and display device with same

A backlight module and display device technology, which is applied in lighting devices, fixed lighting devices, optics, etc., can solve the problems of reduced light uniformity of the backlight module, and achieve the effect of improving the uniformity of light output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

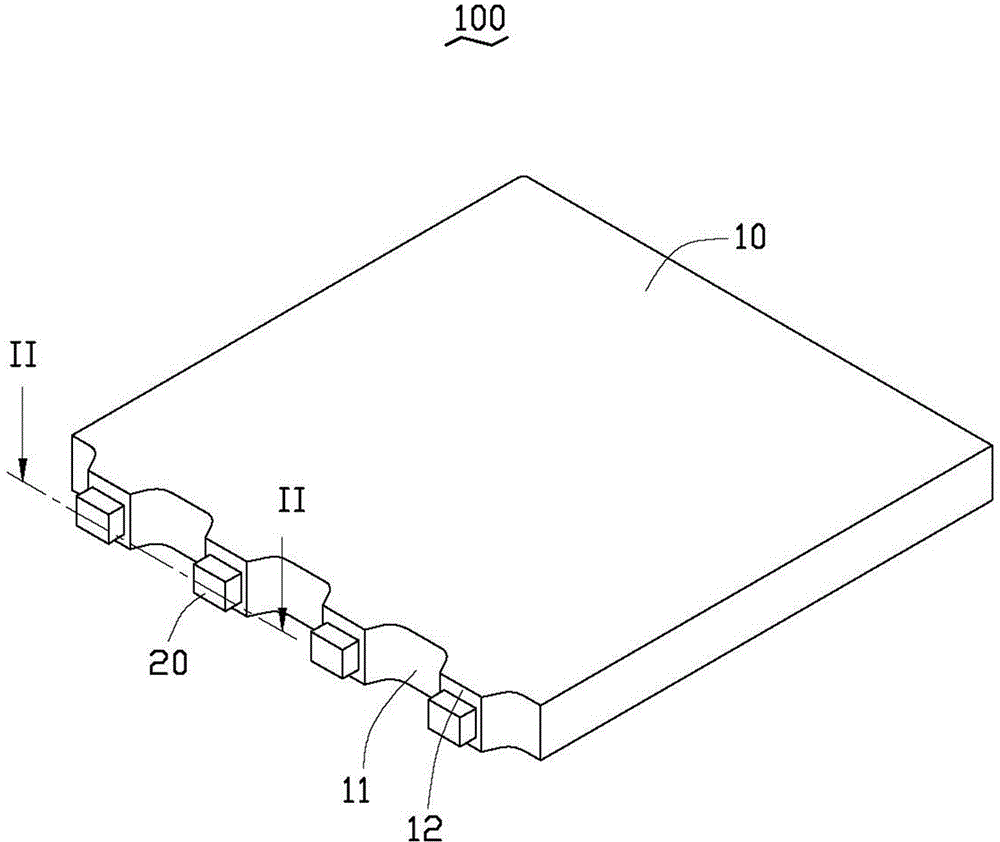

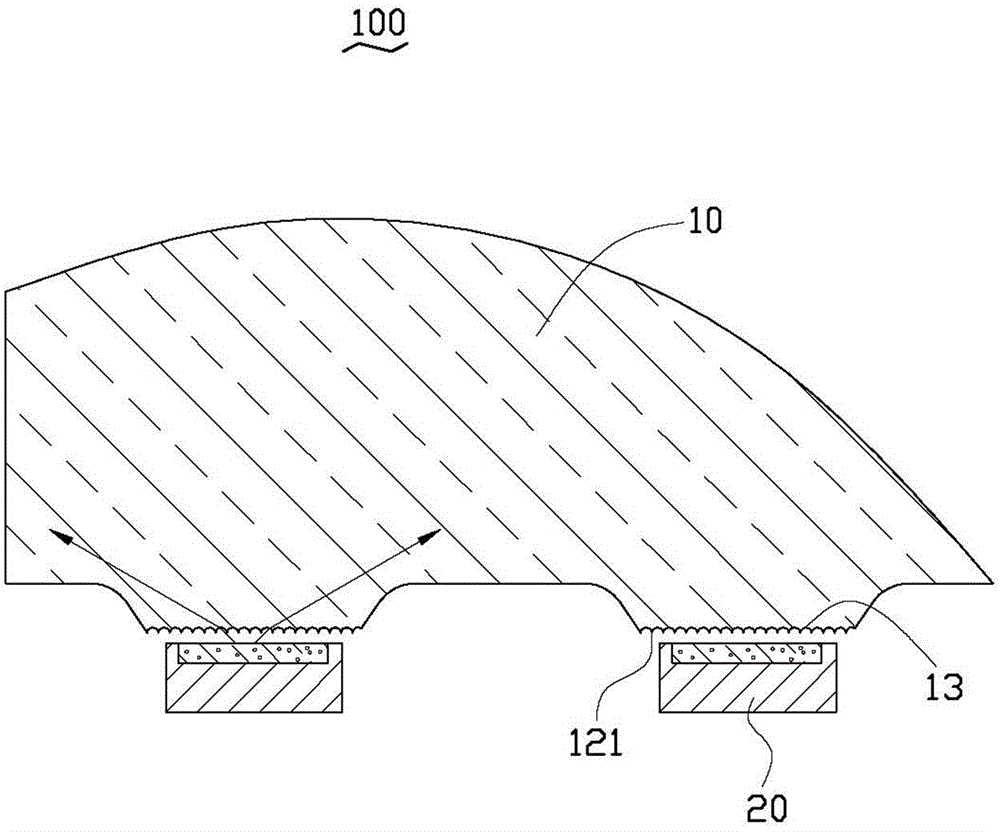

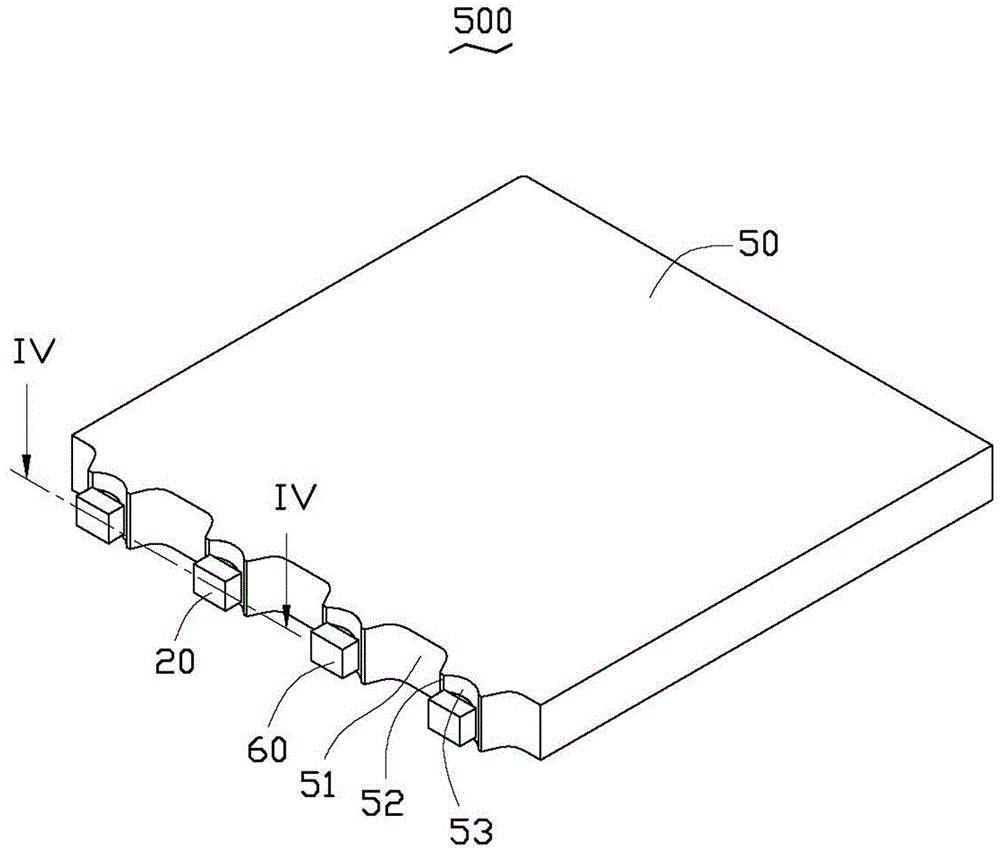

[0015] see figure 1 with figure 2 , the backlight module 100 according to the first embodiment of the present invention is applied to a display device (not shown in the figure), so as to provide a backlight for the display device. The backlight module 100 includes a light guide plate 10 and several point light sources 20 . In the first embodiment, the point light source 20 is a light emitting diode (Light Emitting Diode, LED).

[0016] The light guide plate 10 is substantially in the shape of a cuboid plate, and includes a first surface 11 opposite to the point light source 20 and a plurality of protrusions 12 protruding outward from the first surface 11 . Several protruding parts 12 are arranged at equal intervals, and each protruding part 12 is arranged opposite to one point light source 20 . The protrusion 12 includes a second surface 121 opposite to the point light source 20 . The width of the second surface 121 is larger than the width of the point light source 20 . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com