Position error measurement head of hole axis

A position and probe technology, applied in the direction of measuring devices, using fluid devices, instruments, etc., can solve the problems of complex probe structure, poor accuracy, inconvenient operation, etc., and achieve the effect of accurate measurement, simple structure, and convenient adjustment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

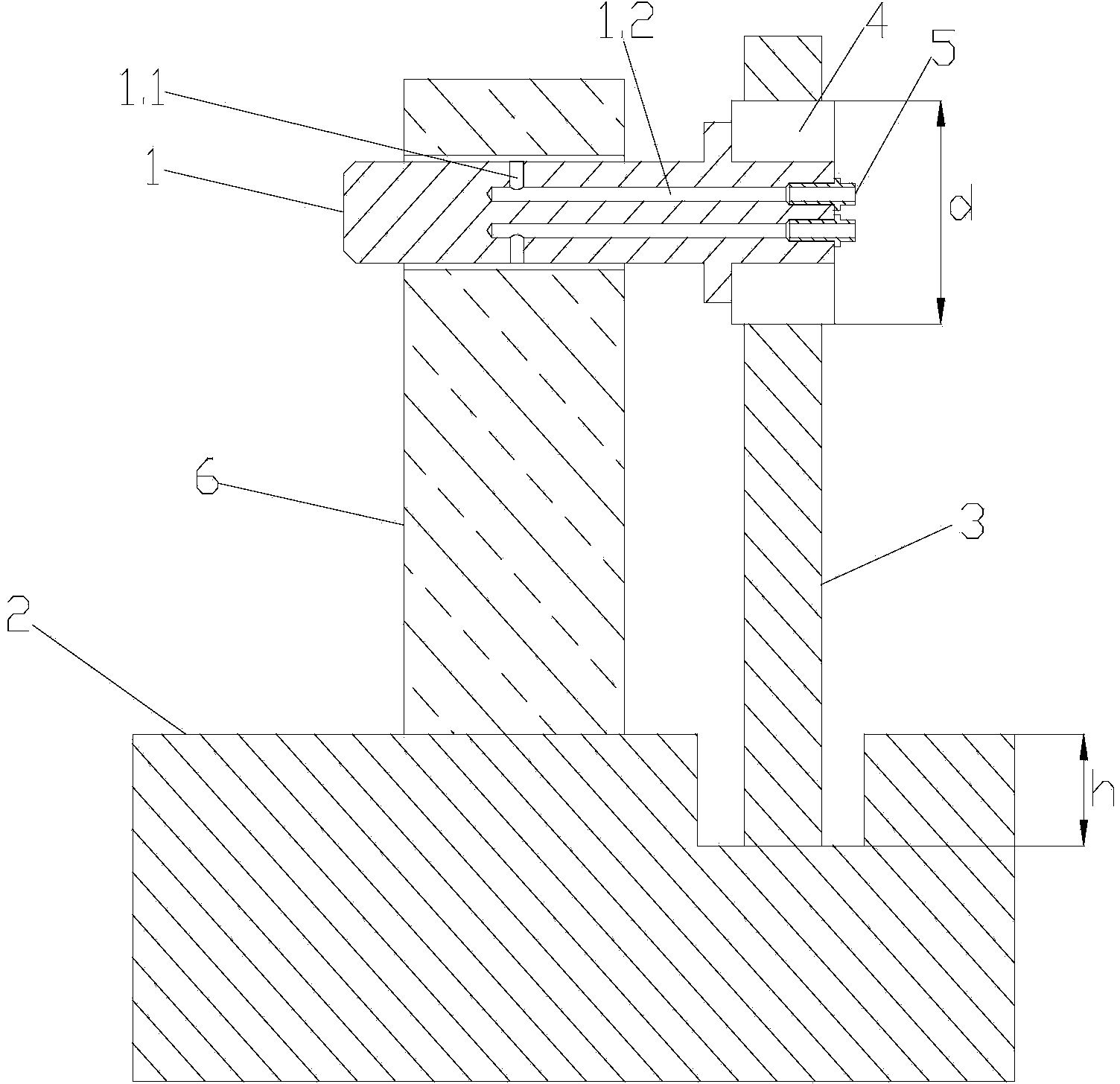

[0012] like figure 1 The shown hole axis position error measuring head includes a cylindrical measuring head body 1 and a horizontal worktable 2. The same axial section of the measuring head body 1 is provided with two sets of one-way nozzles 1.1 symmetrical about its axis. The nozzles 1.1 The direction is opposite, and the probe body 1 is also provided with an air channel 1.2 corresponding to the nozzle 1.1. The air channel 1.2 is located at the rear end of the probe body 1 and is also provided with an air inlet joint 5. The air components are connected, and the two sets of nozzles 1.1 correspond to the two tubes of pneumatic measuring instruments, the horizontal workbench 2 is provided with a column 3, and the column 3 is provided with a height-adjustable block 4, the horizontal workbench 2 at the column 3, and the measuring head The body 1 is fixed on the height adjustment block 4, and in order to make the measurement accurate, the axial section of the probe body 1 where th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com