Tire vulcanization workshop energy consumption optimization scheduling method based on hybrid genetic algorithm

A hybrid genetic algorithm and tire vulcanization technology, which is applied in the field of optimal scheduling of tire vulcanization workshop energy consumption based on hybrid genetic algorithm, can solve problems such as unfavorable industrial production, complex process, and many parameters of genetic algorithm

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

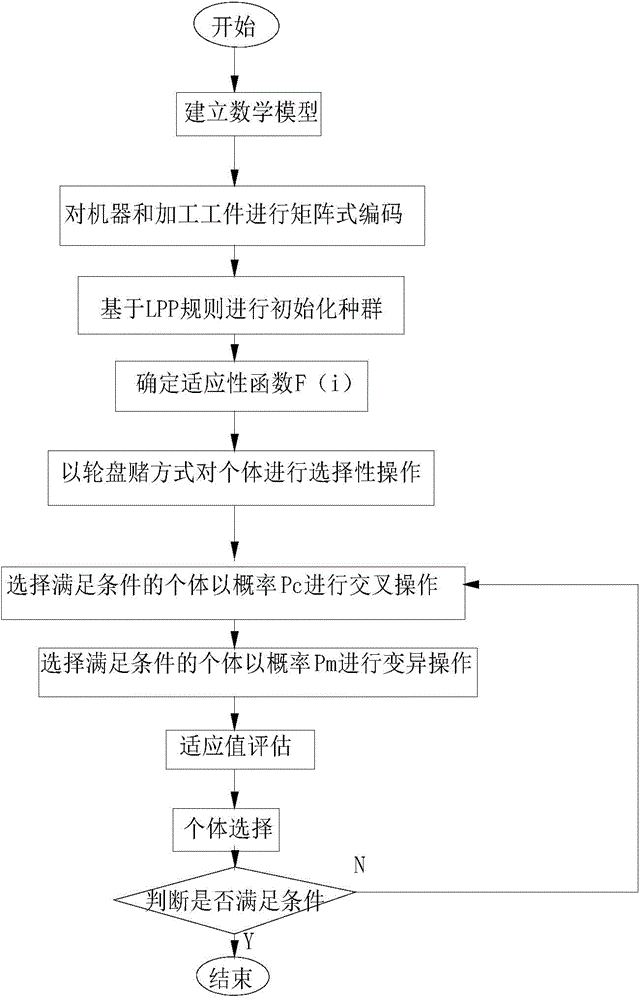

[0075] See attached figure 1 , a step-by-step flow chart of a hybrid genetic algorithm-based method for optimal scheduling of energy consumption in a tire vulcanization workshop, which specifically includes the following steps:

[0076] Step S1: Construct the optimal scheduling model of energy consumption in the tire vulcanization workshop, and determine the minimum production cost E of machined tires min , the E min It consists of two parts, including workpiece delay penalty cost and machine energy consumption cost. The objective function is shown in formula (1.1):

[0077] E min = Σ i = 1 n β i · ...

Embodiment 2

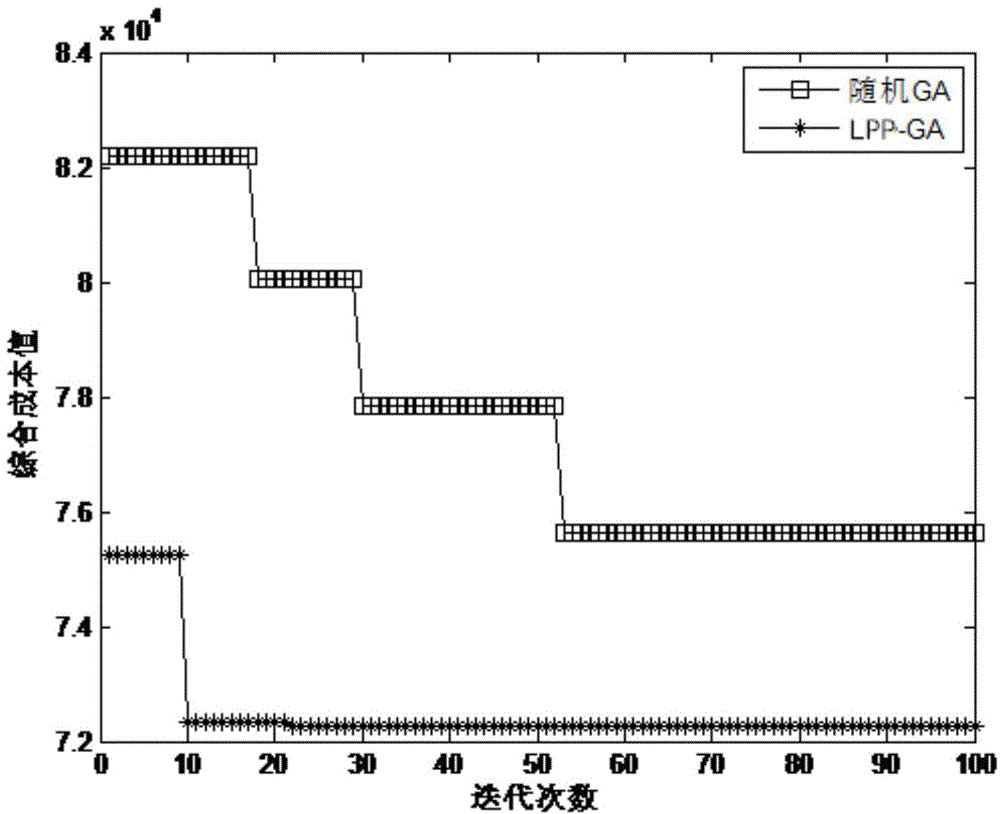

[0136] In order to verify the effectiveness of a hybrid genetic algorithm-based energy optimization scheduling method for tire vulcanization workshops proposed by the present invention, the present embodiment uses Matlab7.1 simulation software, and the CPU is Intel Core22.16GHz, and the memory is 2G on a computer. Simulation test.

[0137] The main factors that affect the performance of the algorithm are: the arrival time of the workpiece, the number of workpieces n, the coefficient of the delivery time of the workpiece, the ratio of unit energy consumption (the ratio of the machine warm-up energy consumption per unit time to the machine waiting energy consumption per unit time) and the number of machines, among which Assuming a normal distribution of workpiece arrival times: Poisson distribution: λ i = Σ j = 1 ...

Embodiment 3

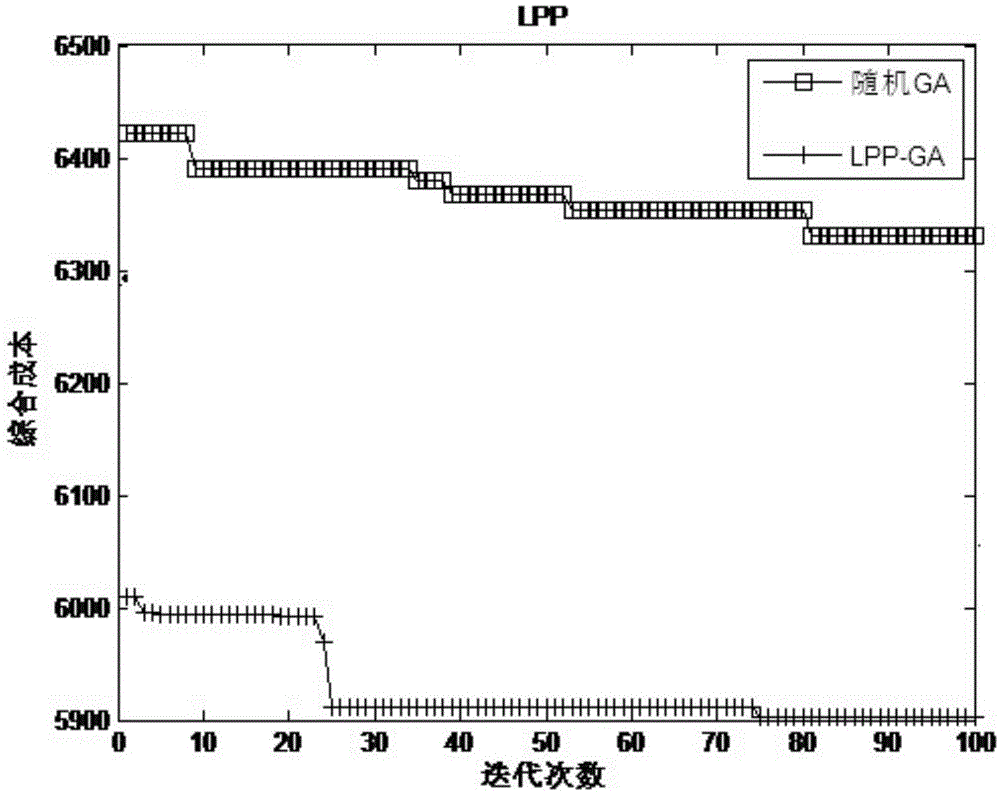

[0140] Further, in order to verify the effectiveness and practicability of the technical solution of the present invention, the technical solution proposed by the present invention is used in a rubber tire enterprise. There are currently 100 workpieces to be processed, and the production plan for 100 workpieces to be processed is arranged (see Table 1 for data). There are 12 vulcanizing machines in total. Table 2 shows the energy consumption cost rate of each machine in three states, and Table 3 Indicates the processing time of each workpiece on the machine, arrival time, delivery date and late penalty rate; Table 4 is the workpiece processing sequence table based on the LPP-GA algorithm; Table 5 is the LPP-GA genetic algorithm and random-GA (Ordinary Genetic Algorithm) Results Comparison Table.

[0141] Table 1 Production plan for workpieces to be processed

[0142]

[0143]

[0144]

[0145]

[0146] Table 2 Energy consumption cost rates in three operating state...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com