Full automatic rubber plug detecting machine

A rubber stopper detection machine, fully automatic technology, applied in the direction of sorting, etc., to achieve the effect of convenient photoelectric detection, orderly discharge, and convenient maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings.

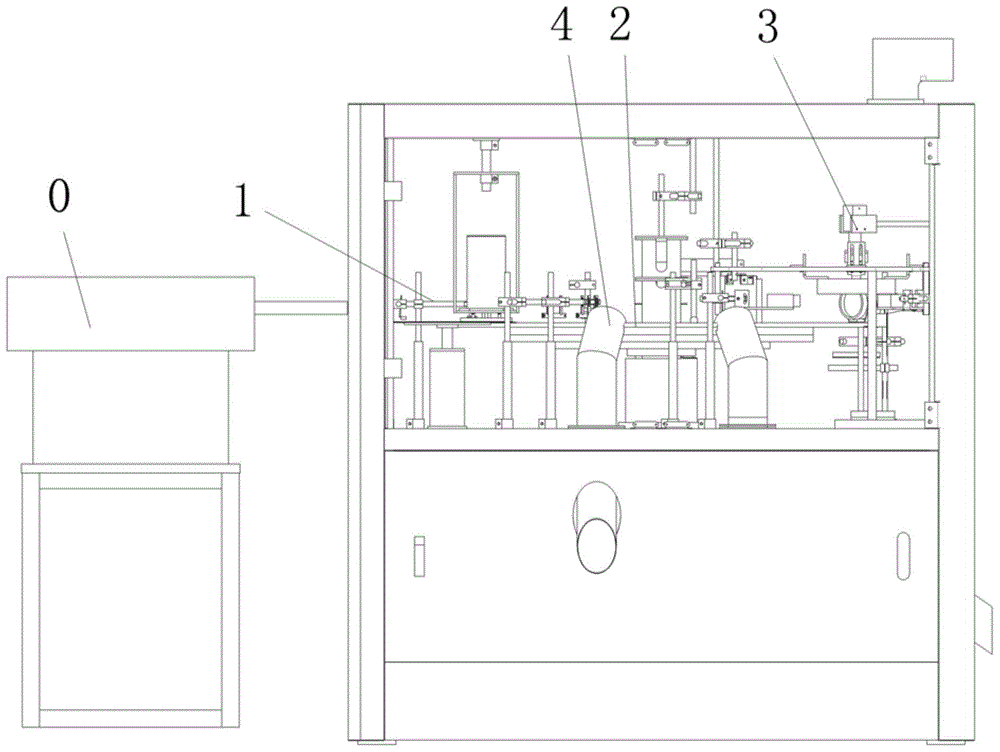

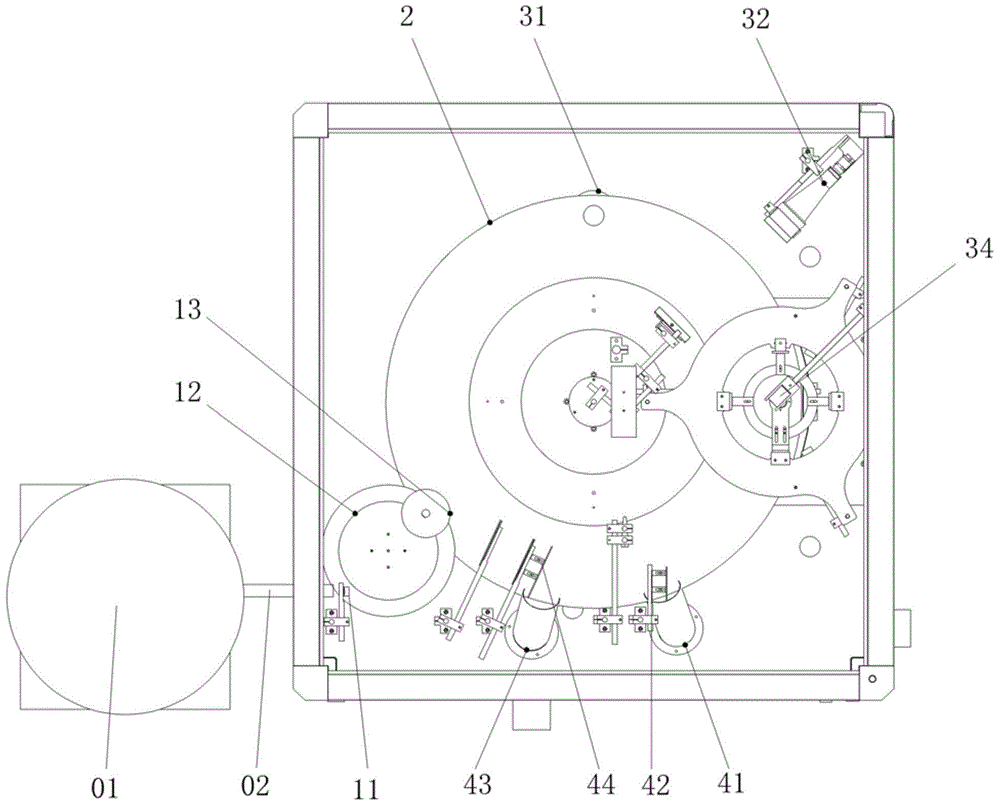

[0053] Such as Figure 1-2 As shown, a fully automatic rubber stopper inspection machine of the present invention includes a feeding mechanism 0 , a feeding arrangement mechanism 1 , a detection turntable 2 , a visual inspection device 3 and a sorting mechanism 4 .

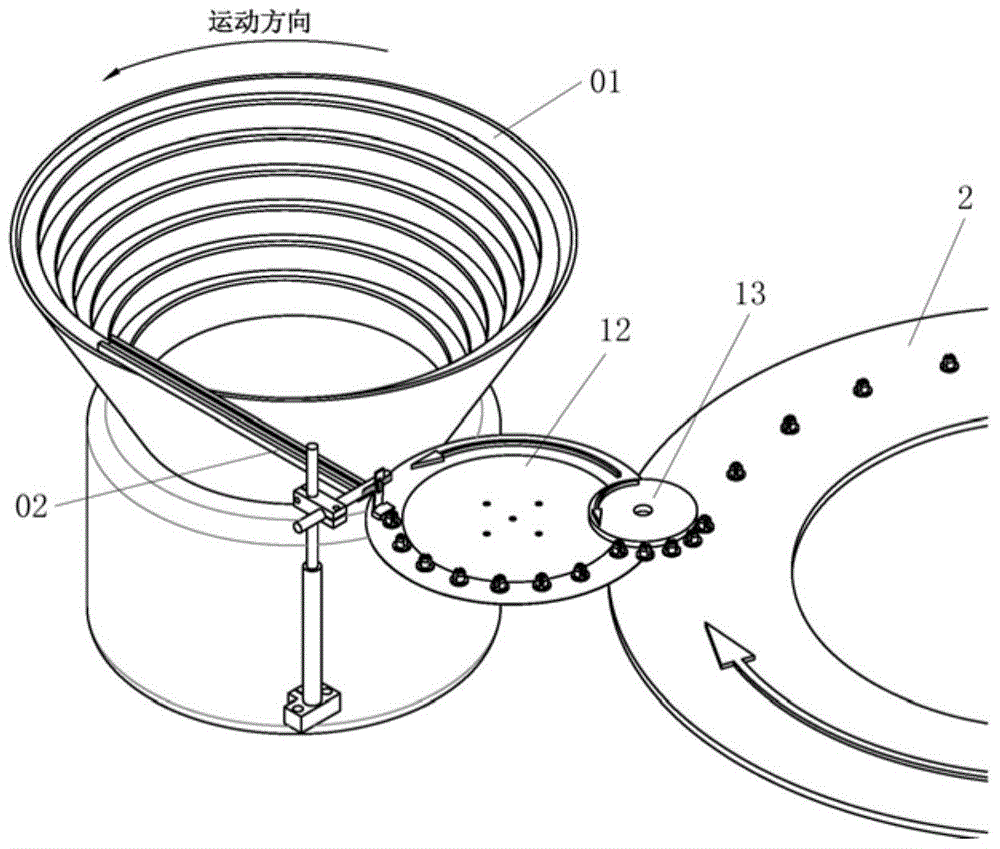

[0054] Such as image 3 As shown, the feeding mechanism 0 includes a feeding mechanism guide rail 02 and a vibrating plate 01. The vibrating plate 01 has a vibration generating device and a spiral track, and its upper part is in the shape of a bell mouth opening upward. In the inner cavity of the vibrating bell mouth, there is a spiral involute guide track at a certain angle with the inner wall. The angular width, height and helical angle of the track are set according to the type and shape of the rubber plug to be tested. For example, the cross-section of the track can match t...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap