Processing die assembly of vehicle door inner plate

A technology for processing molds and assemblies, which is applied to the field of processing mold assemblies for vehicle door inner panels, and can solve the problems of edge sidewall cracking, complex edge modeling of vehicle door inner panels, and insufficient forming.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

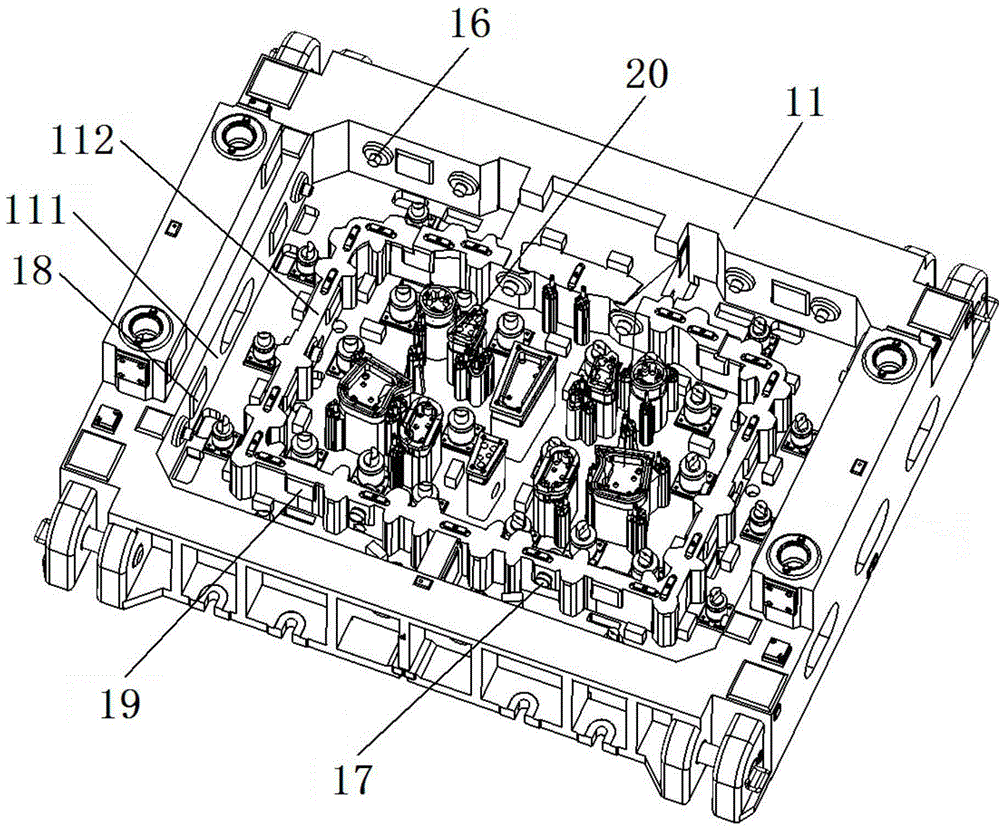

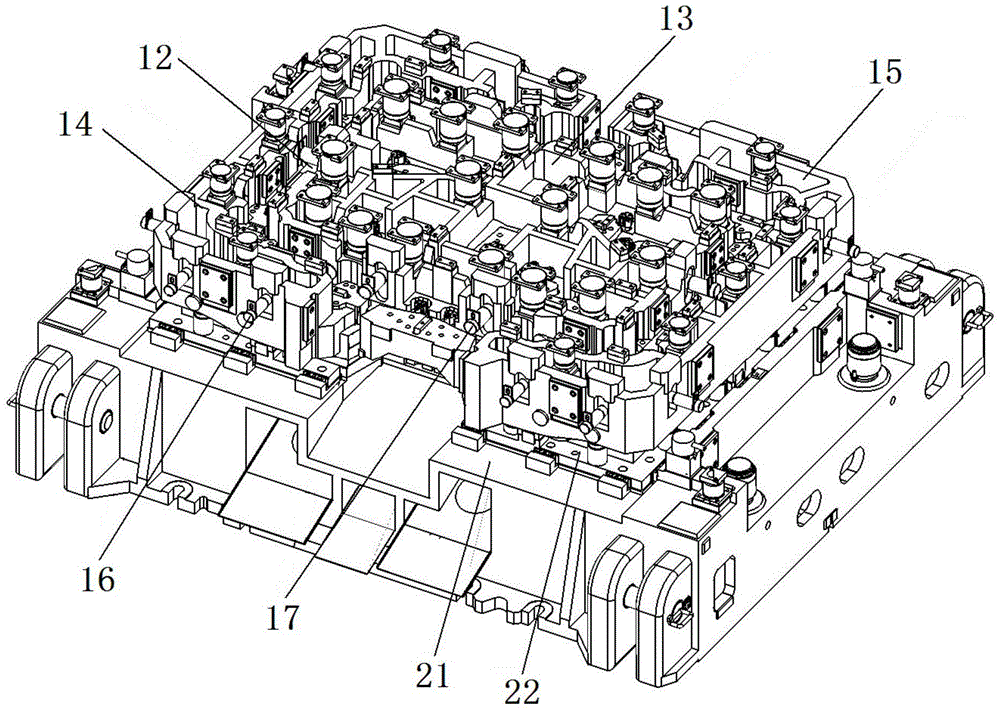

[0025] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings.

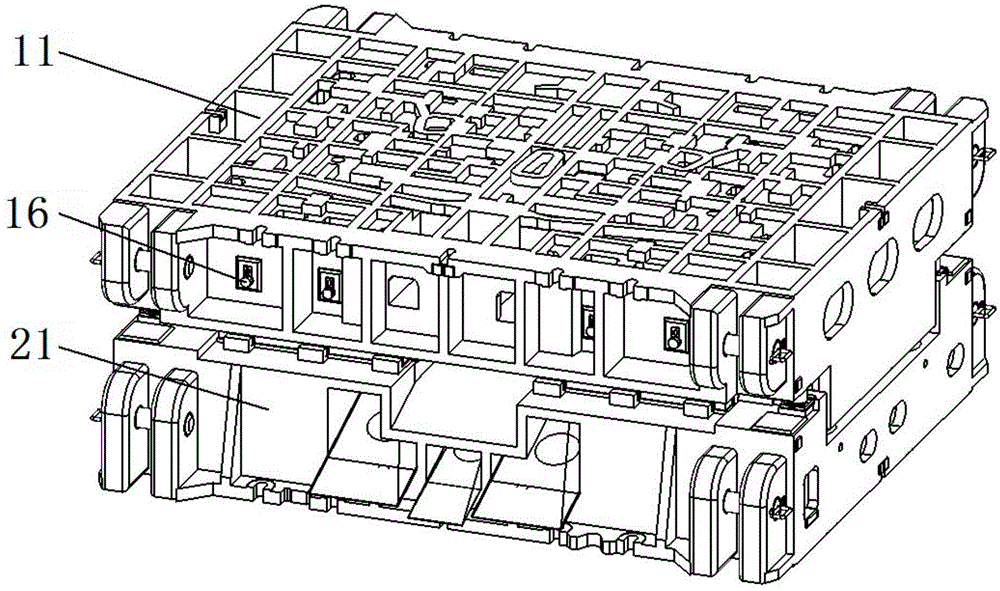

[0026] An embodiment of the present invention provides a processing die assembly for a car door inner panel, which includes a drawing die and a shaping die, the drawing die is used for drawing a blank, and the shaping die is used for shaping the drawn sheet material , and finally form the desired inner panel of the door.

[0027] The drawing die includes a drawing die and a drawing punch. The drawing operation of the sheet can be realized after the drawing die and the drawing punch interact with each other. The drawing die corresponds to the circumference of the inner panel of the car door There is a drawing plane at the position, and the general shape of the drawing plane is a plane, and there may be a small degree of curvature locally.

[0028...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com